Bearing arrangement with a back-up bearing, in particular for mounting the rapidly rotating shaft of a compressor

A technology for bearing devices and supporting shafts, which is applied in the direction of rotating bearings, shafts and bearings, rolling contact bearings, etc., and can solve problems such as damage to spare bearing forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

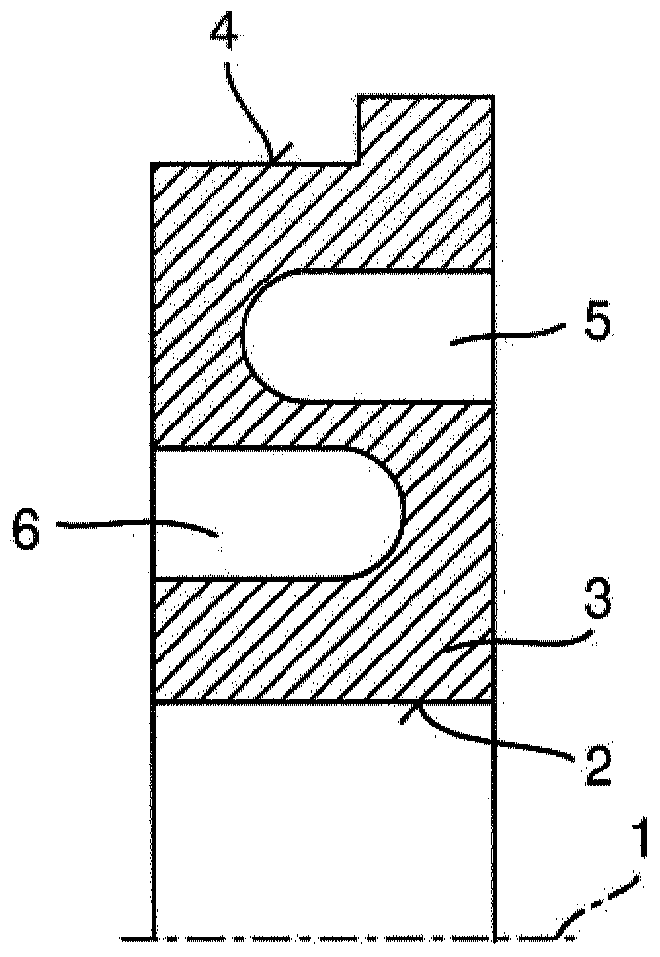

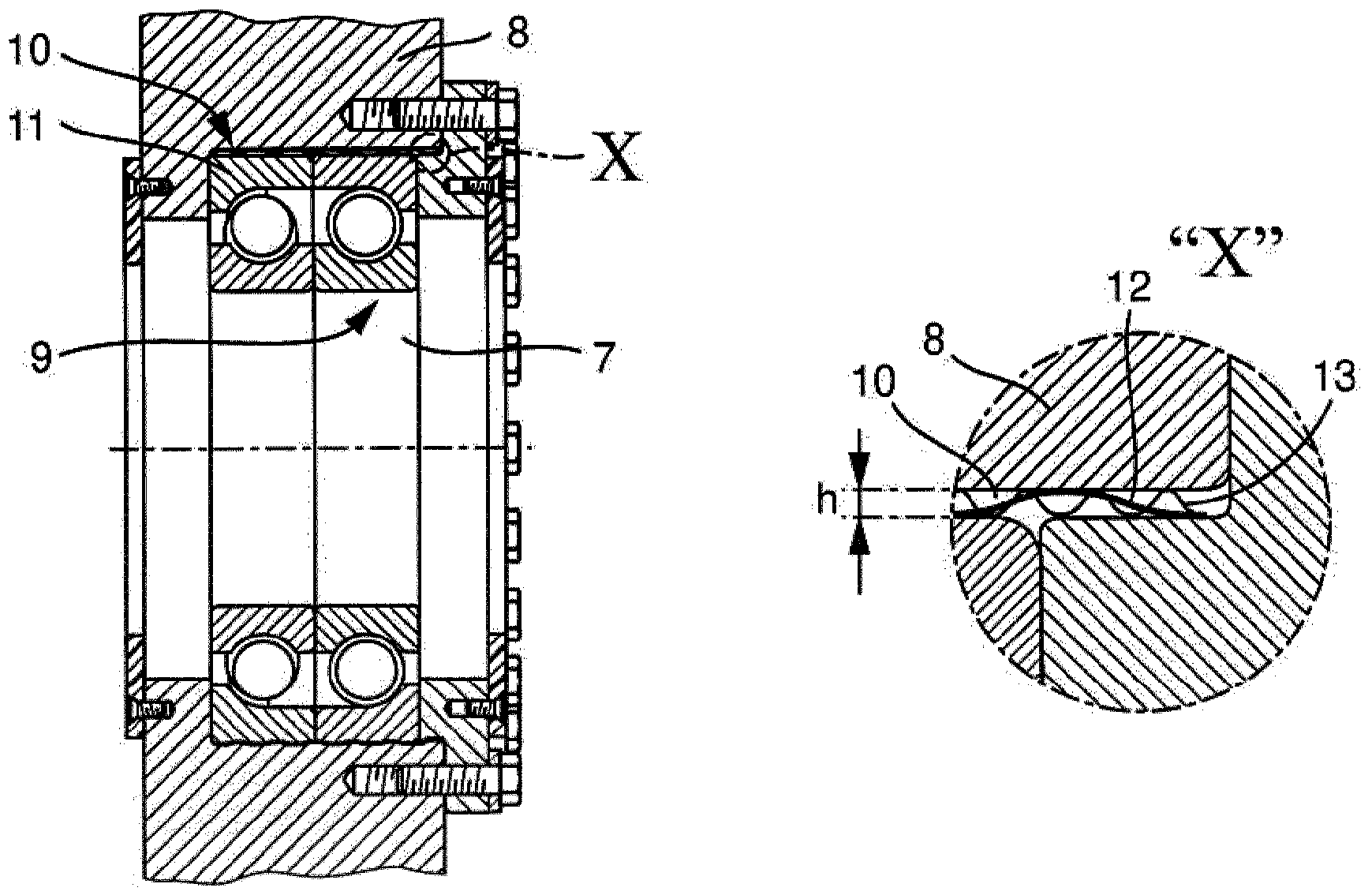

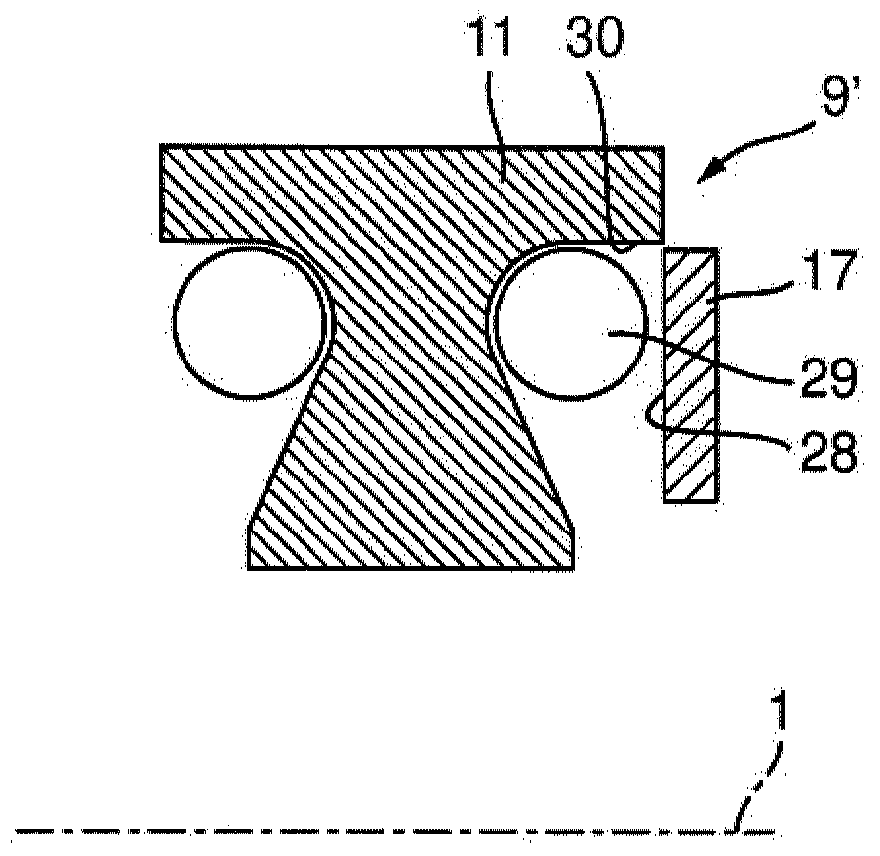

[0029] figure 1 A bearing arrangement is shown in which the shaft is mounted rotatably about the axis of rotation 1 by means of a magnetic bearing. The bearing arrangement includes at least one backup bearing, which is designed as a rolling bearing, in particular a double row angular contact ball bearing, and can absorb forces both in the axial direction and in the radial direction. The outer ring of the rolling bearing is arranged on the inner surface 2 of the bearing receptacle 3 pointing toward the axis of rotation 1 . The outer surface 4 of the bearing receptacle 3 is arranged on the stationary housing. As long as the shaft is mounted in a magnetic bearing, the inner ring of the rolling bearing is spaced from the peripheral side of the shaft by a backup bearing gap.

[0030] The bearing arrangement is part of the bearing of the shaft of the compressor, which rotates at a rotational speed of approximately 6000 revolutions per minute and is of solid design. If the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com