High friction brake shoe assembly

A technology of brake components and components, which is applied in the direction of brake components, brake parts, friction linings, etc., can solve the problems of accelerating friction material wear, shortening the life of brake components, etc., and achieve the effect of high friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following detailed description illustrates the invention by way of illustration and not limitation. This description clearly enables one skilled in the art to make and use the invention, describing various embodiments, matching modifications, variations, substitutions, and uses of the invention, including what is presently believed to be the best mode of carrying out the invention.

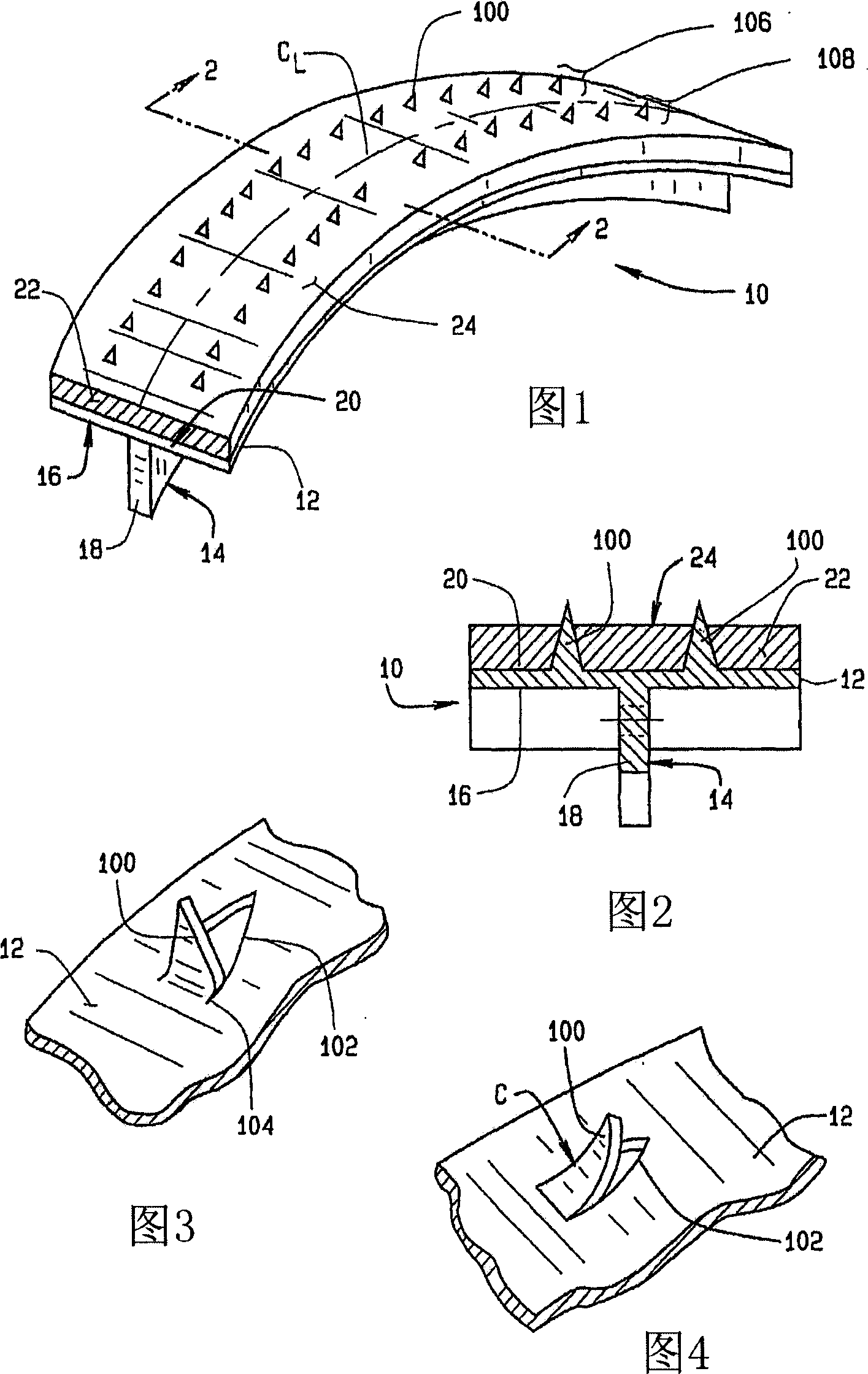

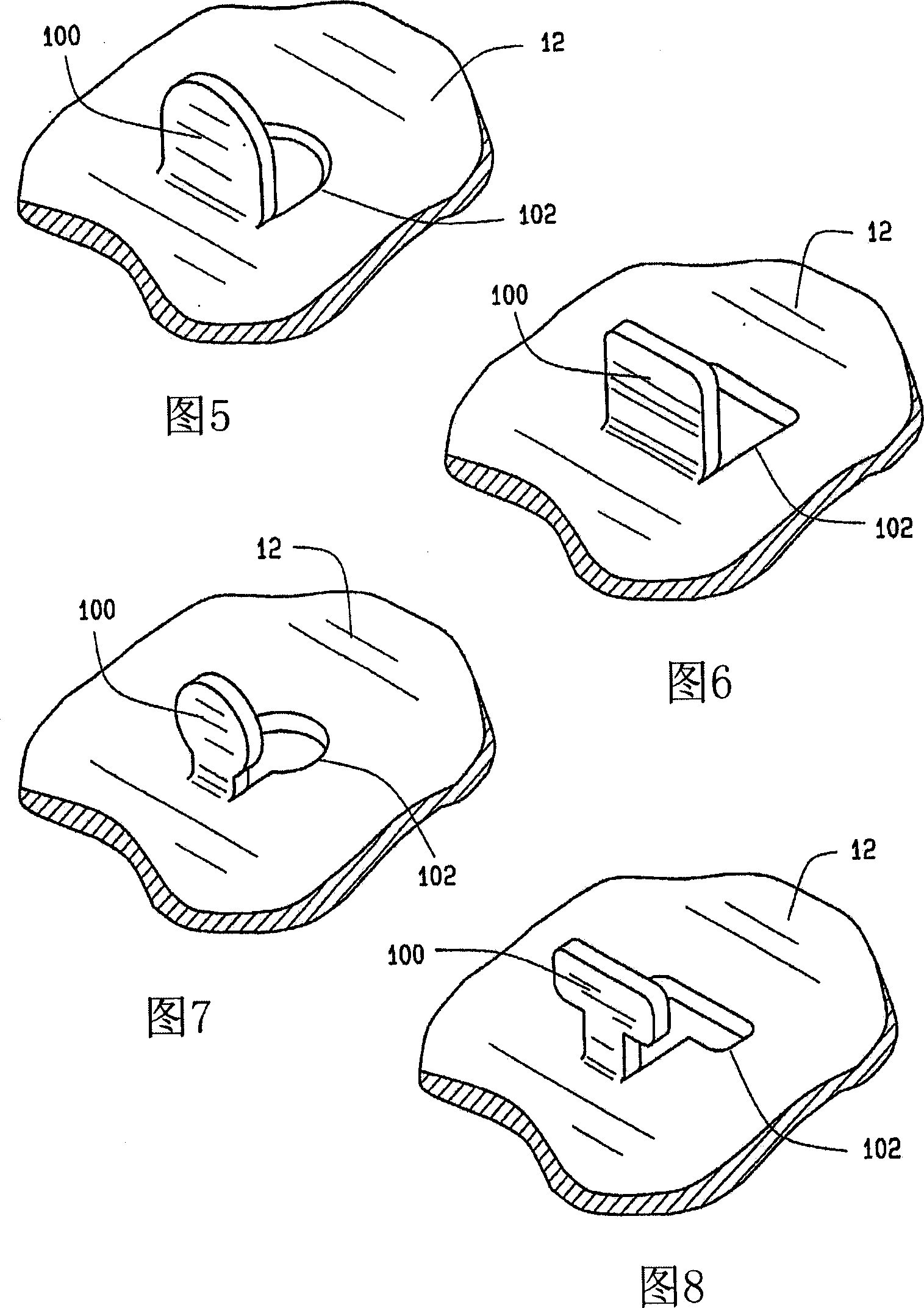

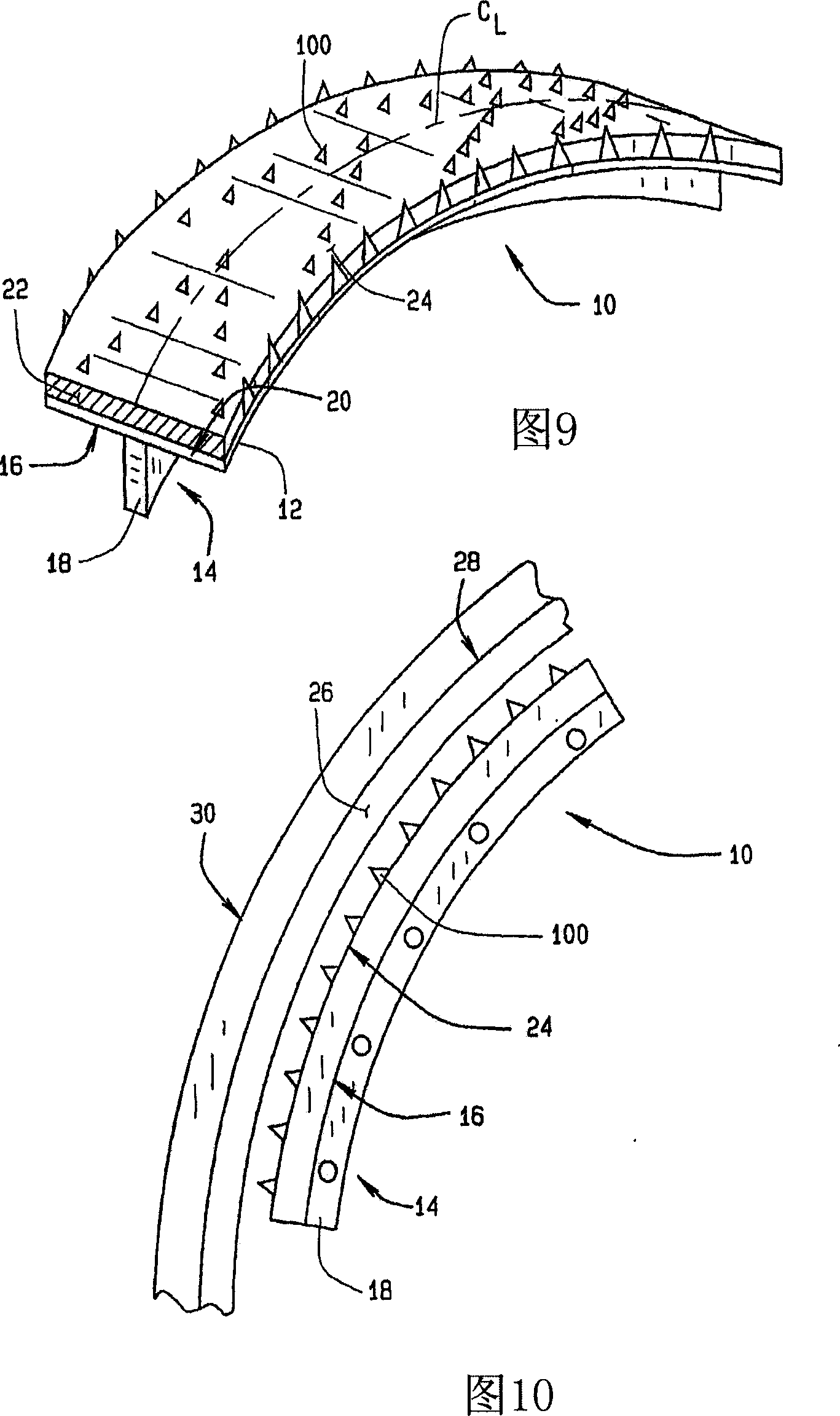

[0029] Referring to FIG. 1 , a brake shoe part of the present invention is marked with 10 . The brake shoe member 10 comprises a cylindrically curved brake shoe plate forming part of the surface of the cylinder. The brake shoe member 10 is provided with one or more connection points 14 on a lower surface 16 adapted to allow easy connection of the brake shoe member 10 to a support structure (not shown) of a motor vehicle wheel. The specific characteristics of the connection point 14 vary depending on the specific application for which the brake shoe assembly 10 is intended.

[0030] Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com