Composition for double clutch gearbox oil, use of composition and lubricating oil comprising composition

A composition and dual-clutch technology, applied in the field of lubricating oil, can solve problems such as the inability to protect DCT, and achieve the advantages of friction durability, simple manufacturing process, and excellent low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

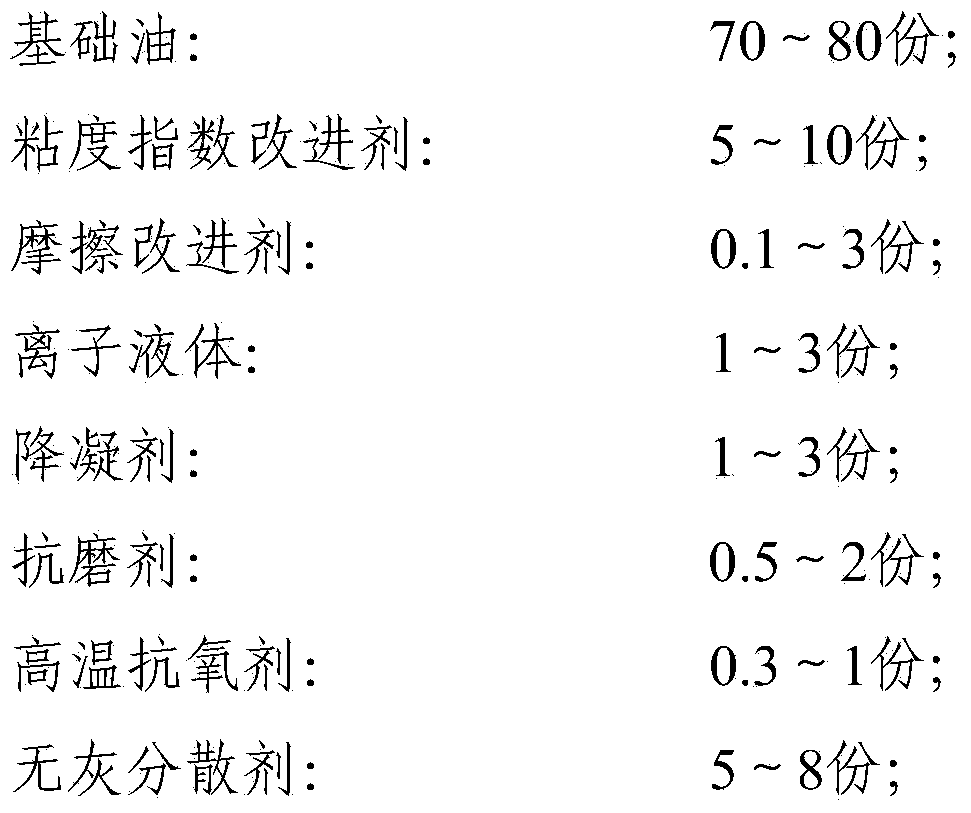

Method used

Image

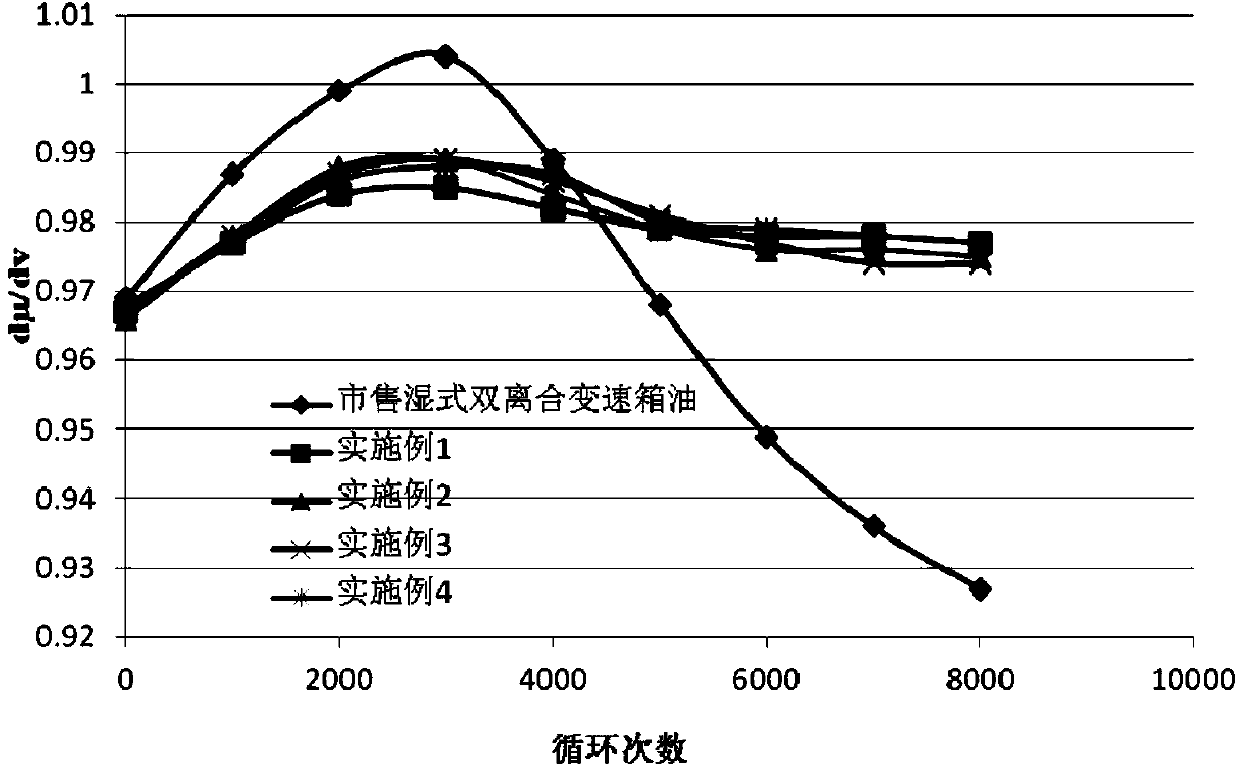

Examples

Embodiment 1

[0045] The composition (mass percentage) of the dual-clutch gearbox oil composition is as follows: base oil (by mass ratio 4cSt type III base oil: 3cSt type III base oil = 1:2.3) 77.9%, viscosity index improver (by mass ratio PMA: PIB=6.2:2.0) 8.2%, friction modifier dioctadecyl phosphite 1.2%, 3-n-octyl-1-methyl-imidazole molybdate ionic liquid 2.5%, other ingredients: pour point depressant polymer Methacrylate 2.0%, antiwear agent trialkyl dithiophosphate 1.0%, high temperature antioxidant di-n-butyl dithiocarbamate isooctyl 0.5%, ashless dispersant polyisobutenyl succinimide Amine 6.0%, metal detergent calcium alkylbenzene sulfonate 0.2%, metal deactivator thiadiazole octadecylamine formaldehyde condensate 0.5%.

Embodiment 2

[0047] The composition of the dual-clutch transmission oil composition is as follows: base oil (by mass ratio 4cSt type III base oil: 3cSt type III base oil: PAO4=1:2.2:0.5) 75.8%, viscosity index improver PMA 9.4%, friction Improver boronated glycerol monooleate 2.0%, tributyl alkyl quaternary phosphonium salt ionic liquid 3.0%, other ingredients: pour point depressant di-n-butyl dithiocarbamate isooctyl ester 1.8%, anti-wear Dithiophosphate acrylate 1.0%, high temperature antioxidant bisbutyl diphenylamine 0.5%, ashless dispersant polyisobutenyl succinimide 5.8%, metal detergent calcium alkylbenzene sulfonate 0.2%, metal passivation Thiadiazole stearylamine formaldehyde condensate 0.5%.

Embodiment 3

[0049] The composition of the dual clutch transmission oil composition is as follows: base oil 4cSt type III base oil 78.3%, viscosity index improver PMA8.0%, friction modifier glycerol dioleate 0.2%, methylimidazole tetrafluoroborate Salt ionic liquid 3.0%, other ingredients: pour point depressant polymethacrylate 2.0%, antiwear agent dithiophosphate acrylate 1.0%, high temperature antioxidant dibutyl diphenylamine 0.5%, ashless dispersant polyisobutylene base Succinimide 6.0%, metal detergent calcium alkylbenzene sulfonate 0.5%, metal deactivator thiadiazole octadecylamine formaldehyde condensate 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com