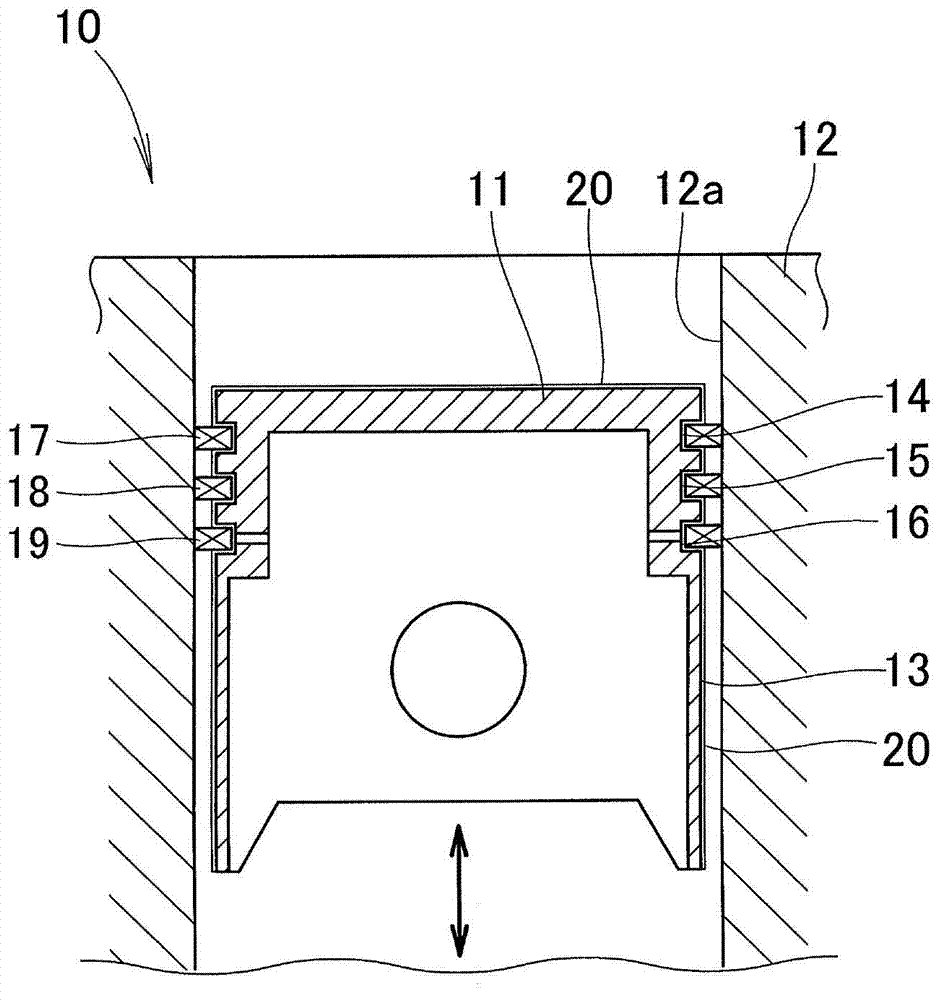

An internal combustion engine

A technology for internal combustion engines and pistons, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as high prices, achieve good sliding performance, low frictional resistance, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

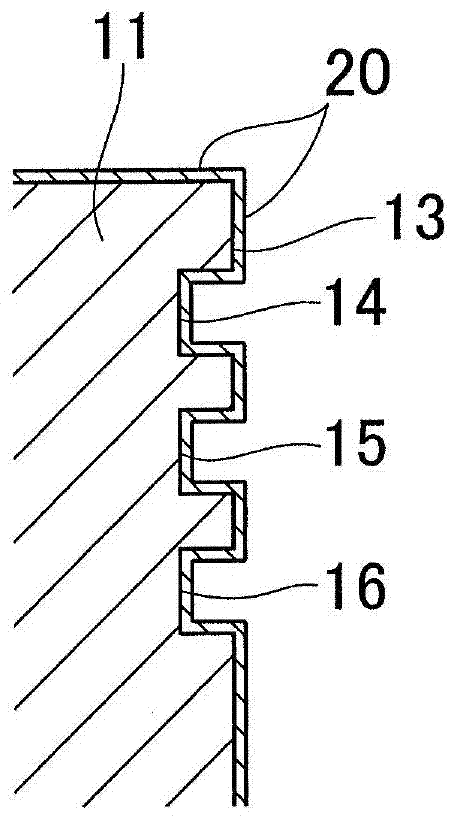

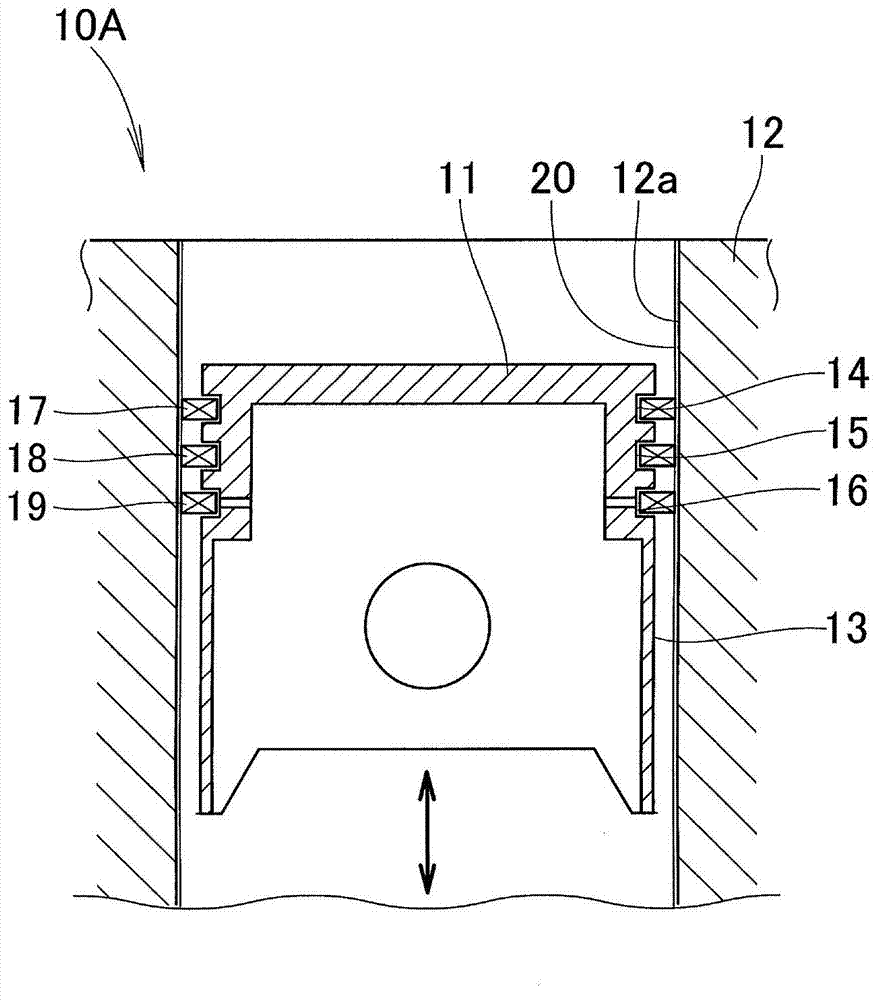

Method used

Image

Examples

experiment example 1

[0052] The electroless nickel plating solution used the Ni-P plating solution (trademark is SEK-795) produced by Japan KANIGEN Co., Ltd. Thereafter, cobalt sulfate as a source of cobalt and sodium tungstate as a source of tungsten were added to this electroless nickel plating solution to produce a Ni-P-Co-W plating solution. Thereafter, a Ni-P-Co-W thin film was formed on a predetermined aluminum substrate using the Ni-P-Co-W plating solution to prepare a plurality of samples. However, in Experimental Example 1, the silicon-containing aluminum plate (AC8A) was substituted as the aluminum substrate.

[0053] The contents of the above-mentioned various samples are shown in Table 1 below. That is, as shown in Table 1, the content of each component in a plurality of samples was changed. A plurality of samples are Comparative Examples 1-2 and Examples 1-15.

[0054] 【Table 1】

[0055]

[0056] As shown in Table 1 above, the contents of the plurality of samples are as follows...

Embodiment 1

[0059] Example 1 is a thin film of "Ni-2.0% by weight P-0.01% by weight of W" (no Co component).

Embodiment 2

[0060] Example 2 is a thin film of "Ni-weight percentage 2.0%P-weight percentage 0.5%Co-weight percentage 0.01%W".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average wear | aaaaa | aaaaa |

| Average wear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com