Automatic tooth grinding machine

A gear grinding machine and automatic technology, which is applied in the direction of metal sawing equipment, tool trimming of sawing machine devices, metal processing equipment, etc., can solve the problems of affecting output, low work efficiency, and increased labor costs, and achieves improved saw blade grinding. The effect of improving quality, realizing the automation of gear grinding, and improving the efficiency of gear grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

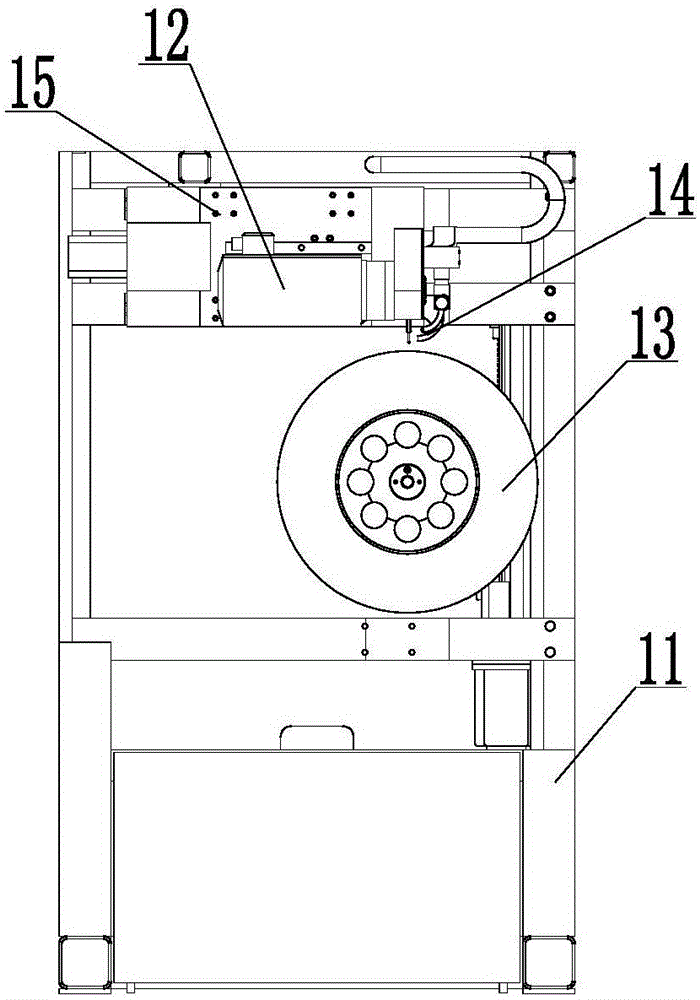

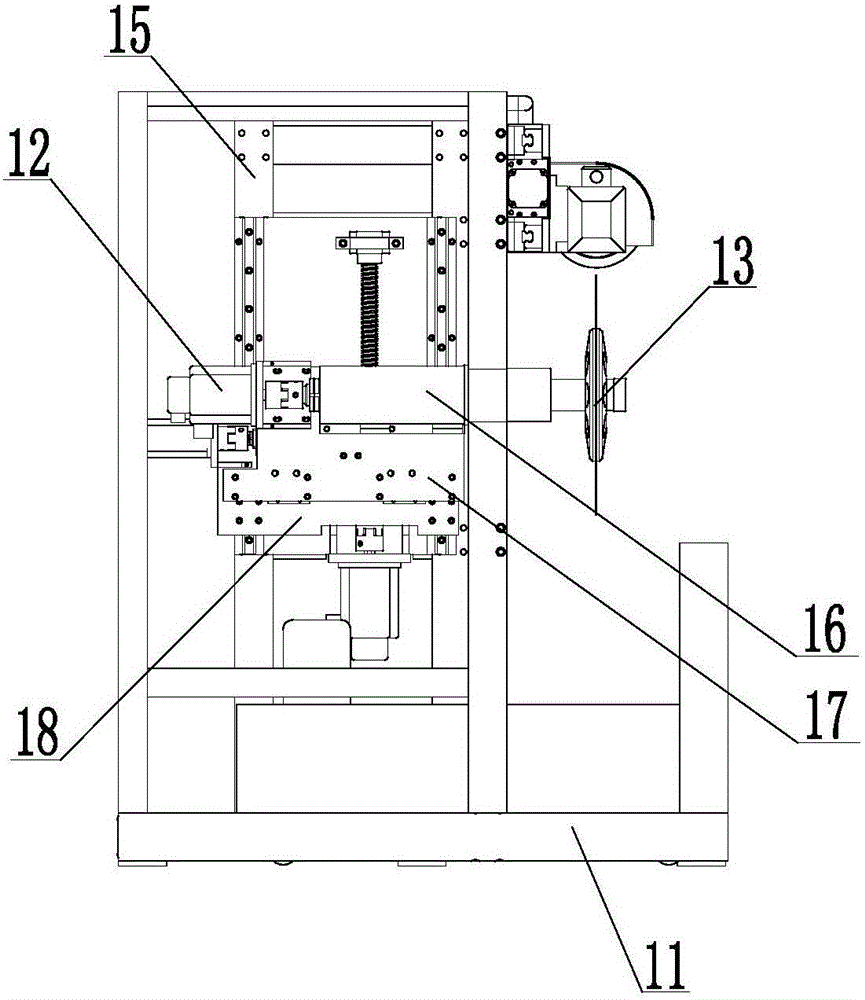

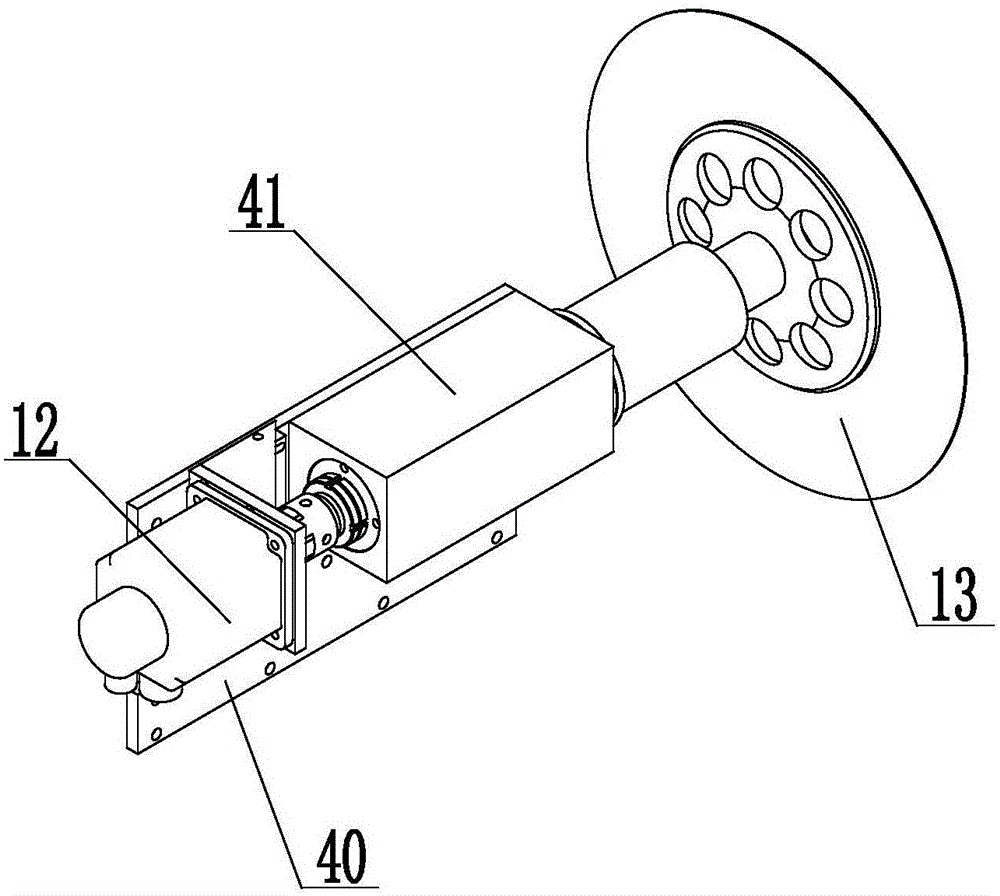

[0018] Such as Figure 1 to Figure 7 As shown, an automatic gear grinding machine includes a frame 11, the frame 11 is provided with a grinding head motor 12, the grinding head motor 12 is provided with a circular saw blade 13, and the circular saw blade 13 is connected with the grinding head motor 12 through a rotating mechanism 16 , the frame 11 is provided with the front angle adjustment left and right moving mechanism 15, the grinding head motor 12 is connected with the front angle adjustment left and right movement mechanism 15, the frame 11 is provided with the chamfering front and rear movement mechanism 17, the chamfering front and rear mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com