Dental processing technology and processing device thereof

A processing device and processing technology, applied in dentistry, medical science, filling teeth, etc., can solve the problem of slow work efficiency of staff, reduce the possibility of damaging the porcelain veneer, save work time, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

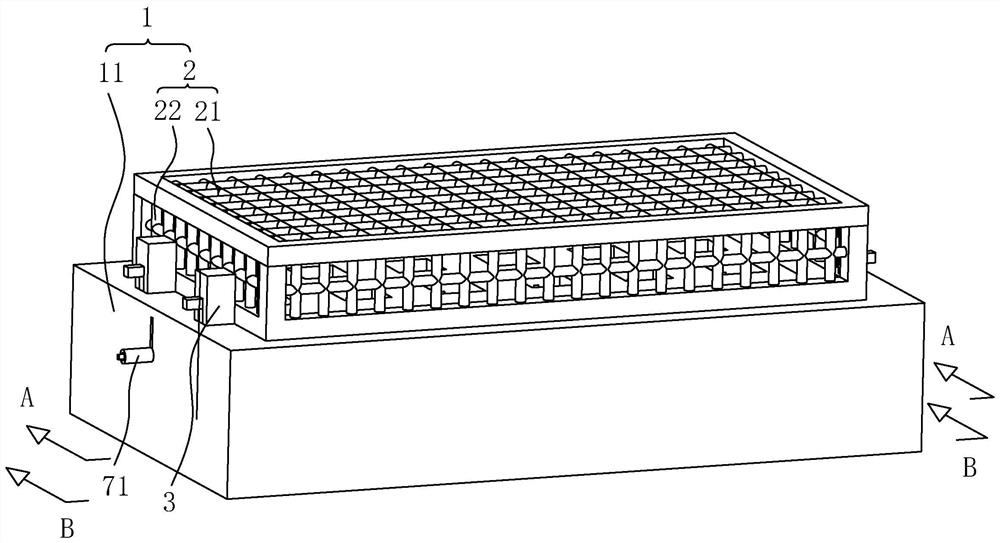

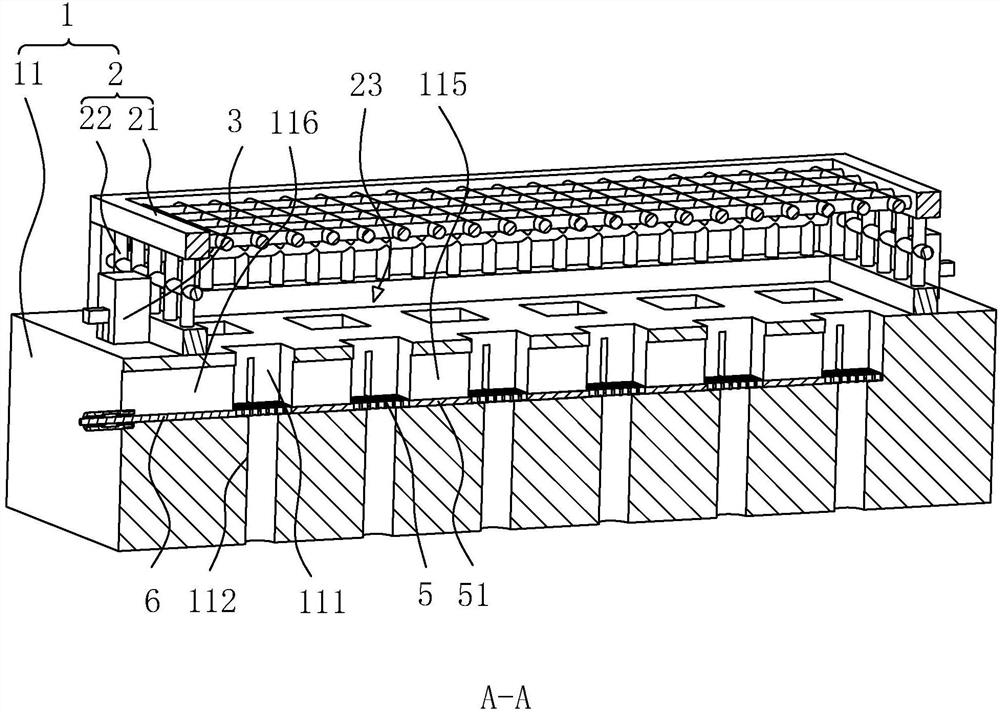

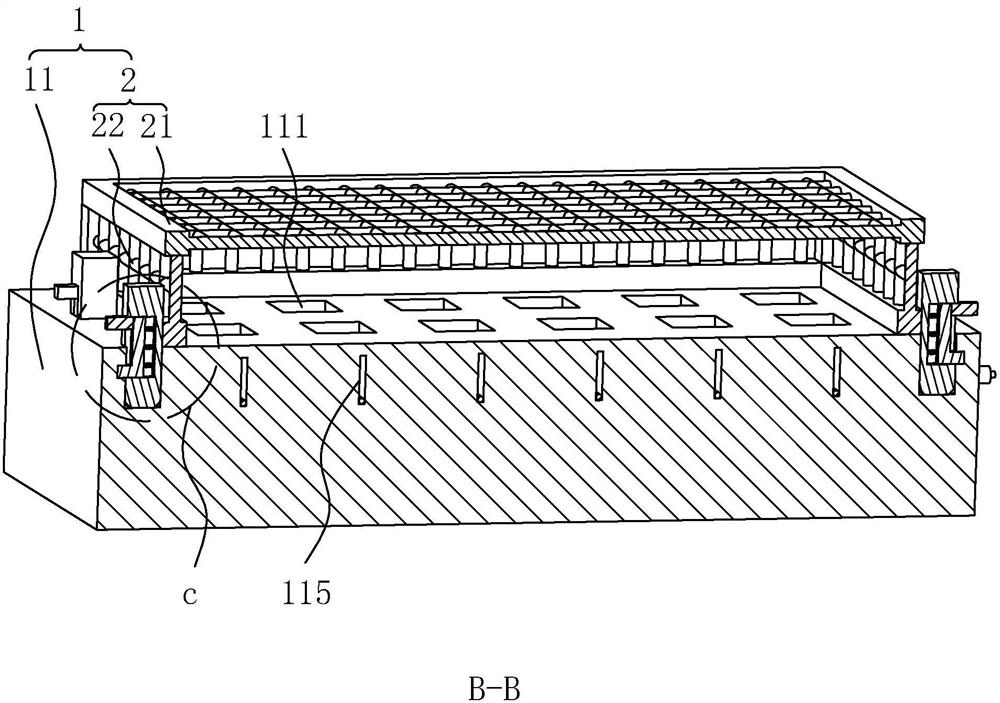

[0050] The following is attached Figure 1-5 The application is described in further detail.

[0051] The embodiment of the application discloses a dental processing technology and a processing device thereof. Dental processing technology includes the following steps:

[0052] Clean the silicone tray and cast the super-hard plaster model.

[0053]Make inspection silicone guide plates on the teeth that need to be made and adjacent teeth, so that the prepared porcelain veneer can be inspected through the inspection silicone guide plate, thus ensuring the fit between the porcelain veneer and the user's teeth, and improving the quality of the user's teeth. comfort.

[0054] Divide the plaster model to make a removable and wearable independent model, make a retainable groove on the mesial and distal sides of the root of the removable model, and make a T-shape at the root tip to be the retention type.

[0055] Removable root coating gap agent.

[0056] Replicate the removable d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com