Patents

Literature

42 results about "Teeth counted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

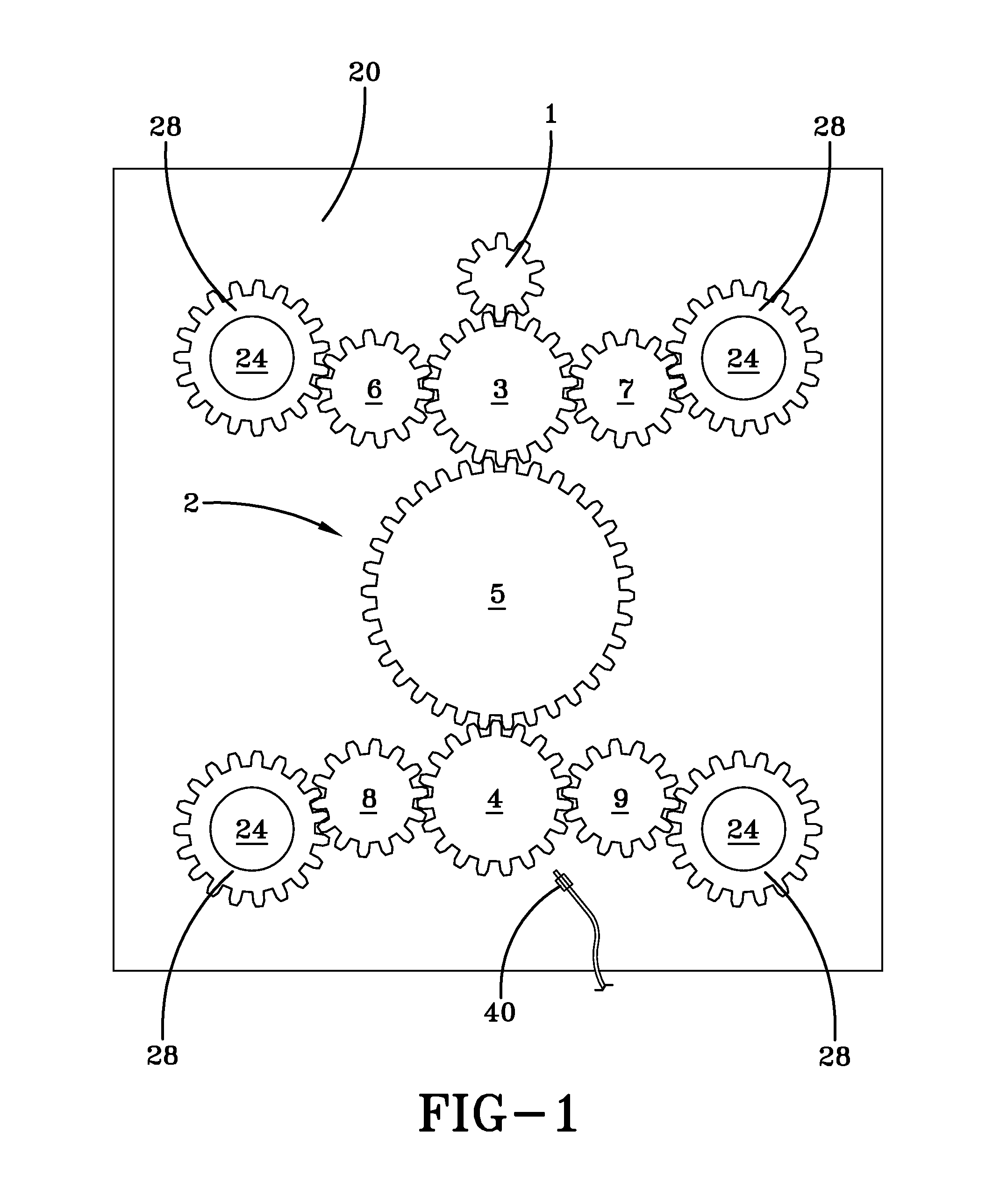

Gear apparatus

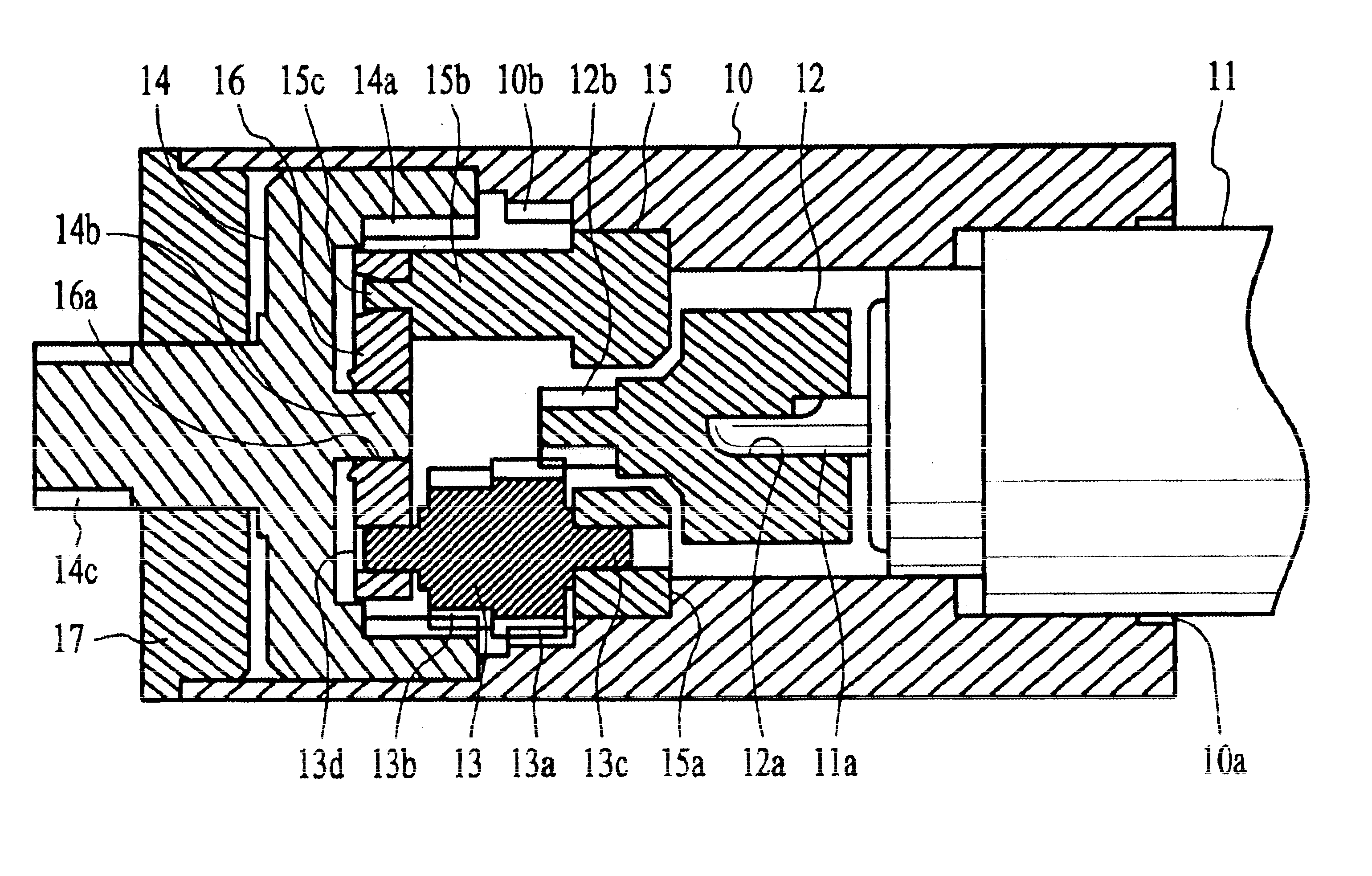

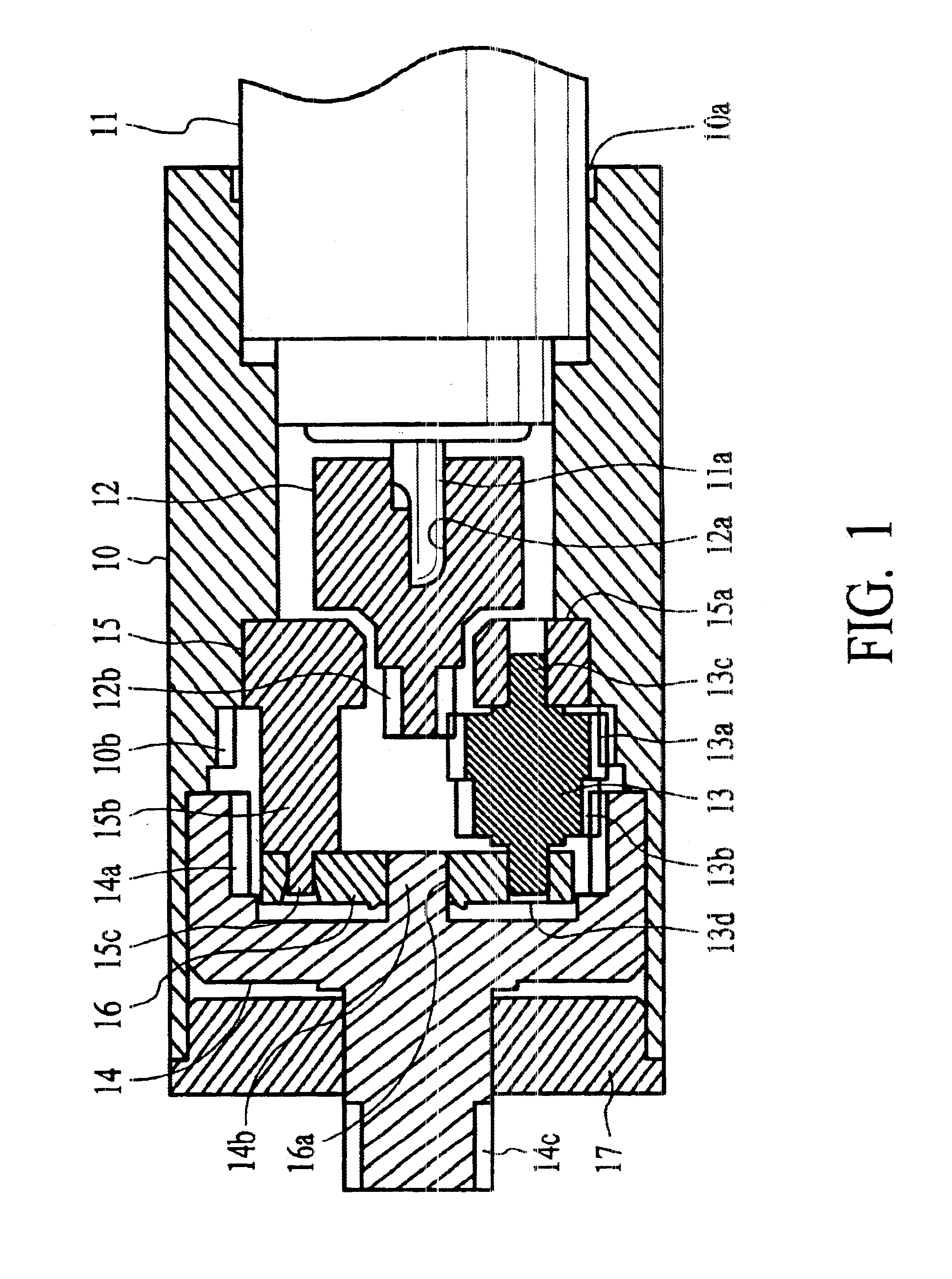

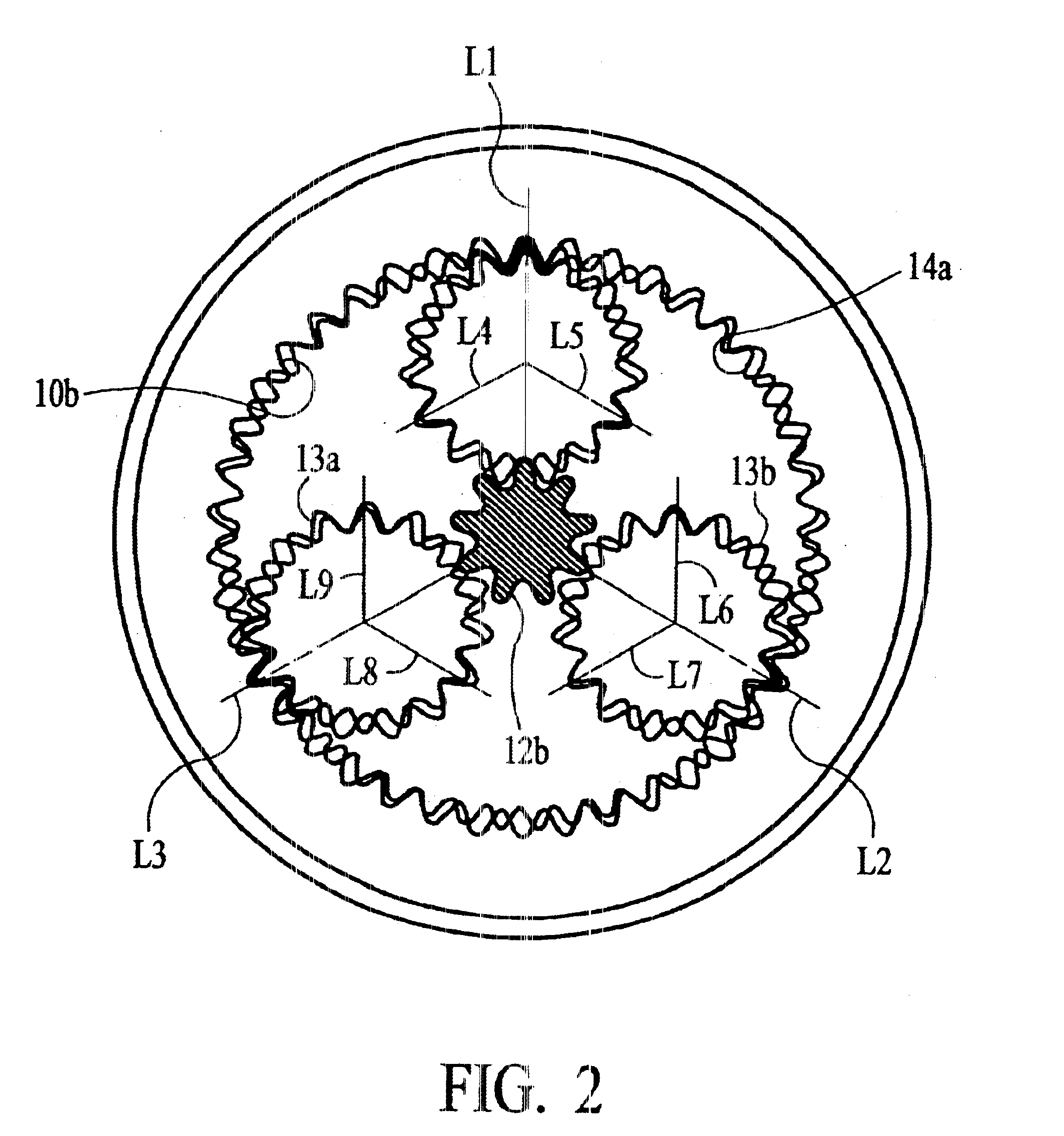

InactiveUS6632154B2Well-balanced conditionIncreased durabilityToothed gearingsTransmission elementsReduction ratioTeeth counted

Owner:SEIKO EPSON CORP

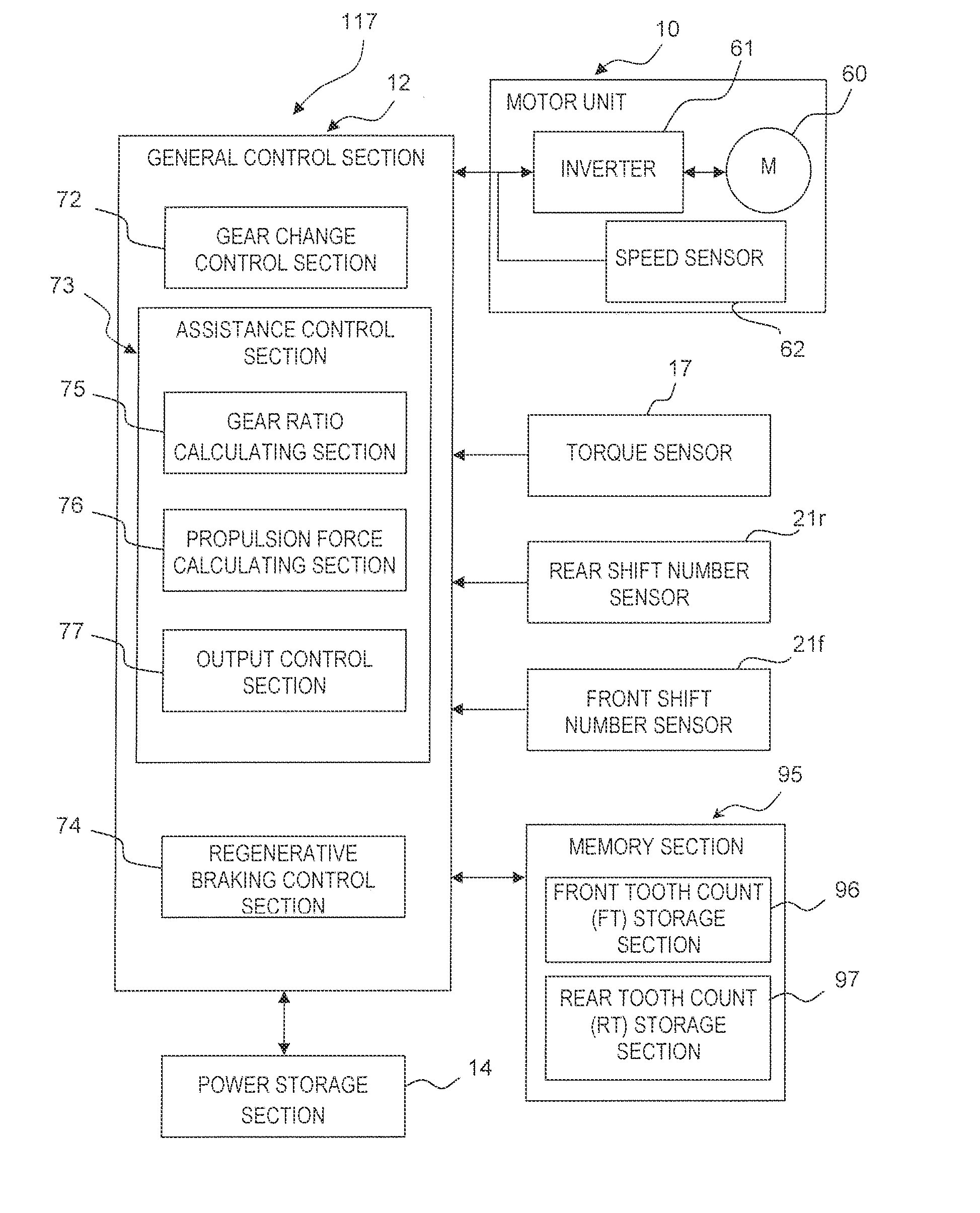

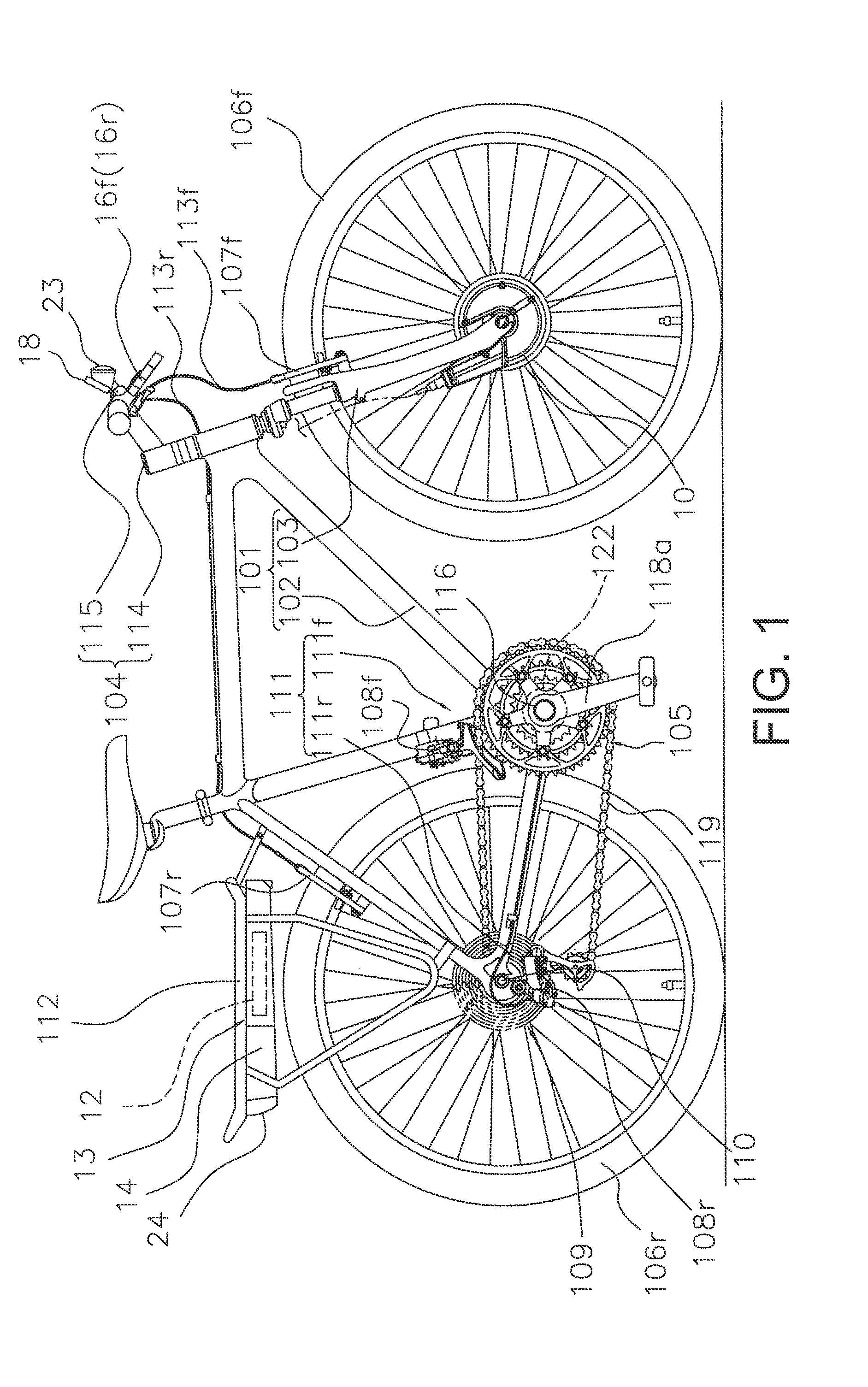

Bicycle motor-assist control system

ActiveUS8660728B2Accurate calculationAssist ratioChain/belt transmissionDigital data processing detailsControl systemMotor control

Owner:SHIMANO INC

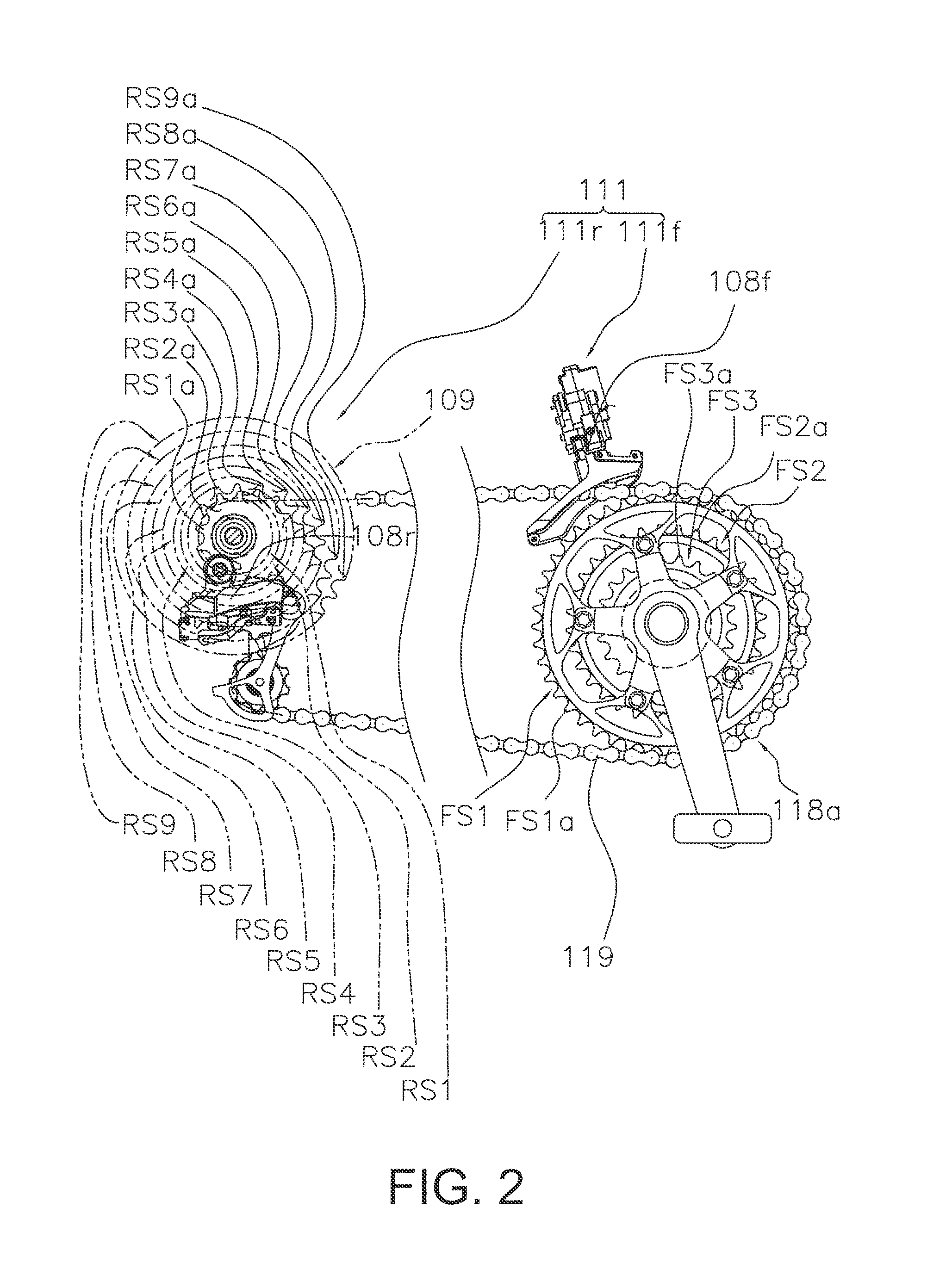

Gear apparatus

InactiveUS20030036455A1Increased durabilityImprove balanceToothed gearingsTransmission elementsGear wheelReduction ratio

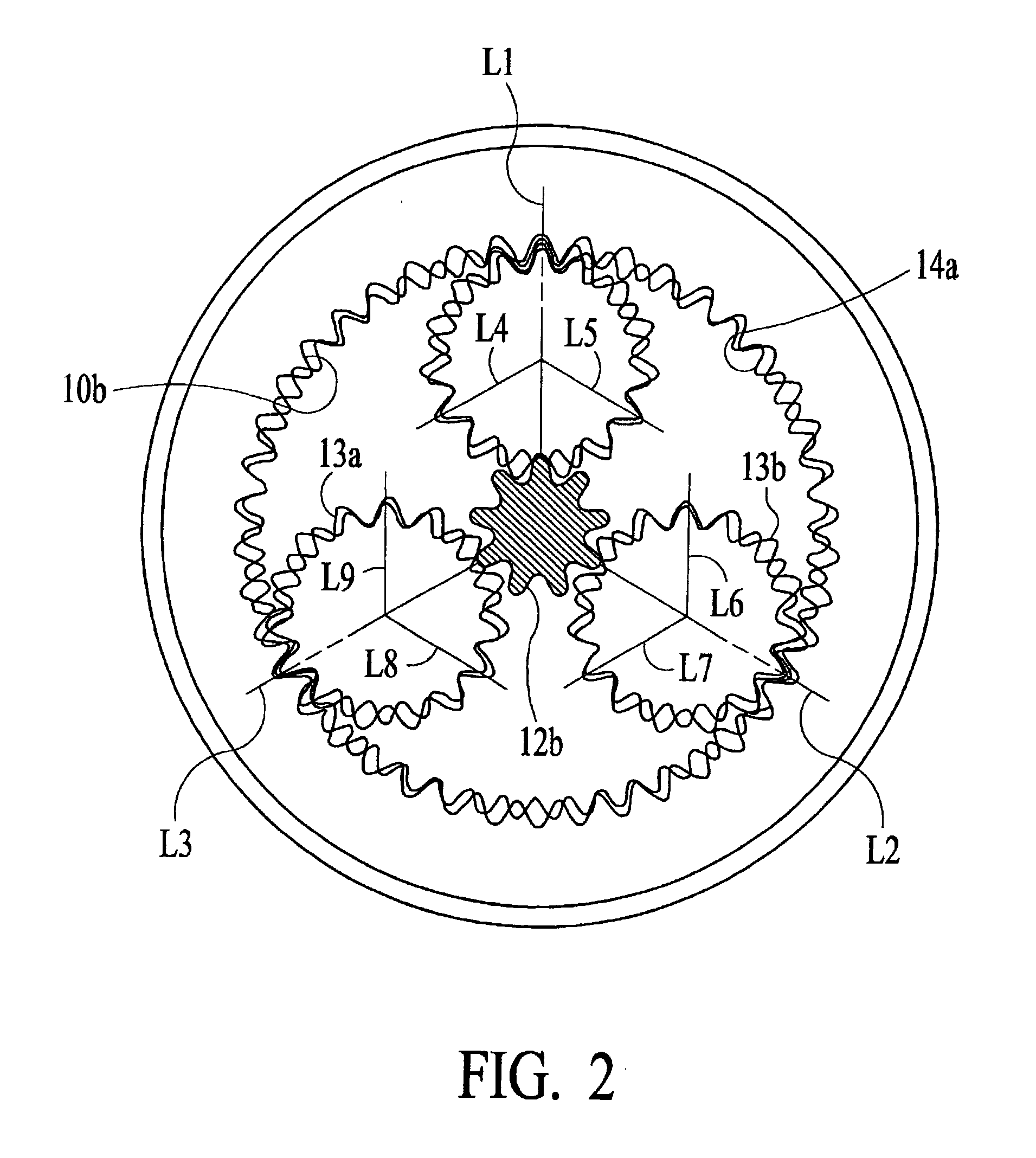

Having a sun gear with a tooth count e, n (where n is a natural number of 2 or more) planetary gears having a first gear part with a tooth count z.sub.1 meshing with the sun gear and a second gear part with a tooth count z.sub.2, a fixed internal tooth gear with a tooth count I.sub.1 meshing with the first gear part of the planetary gear, and a movable internal tooth gear with a tooth count I.sub.2 meshing with the second gear part of the planetary gear, tooth counts e, z.sub.1, z.sub.2, I.sub.1 and I.sub.2 are all a multiple of n. Even if the gear form of each gear has a small module, a planetary gear train mechanism can be configured without causing operating or assembly problems, and it is possible to provide a gear train that can be miniaturized more than conventionally and still have a sufficient gear reduction ratio.

Owner:SEIKO EPSON CORP

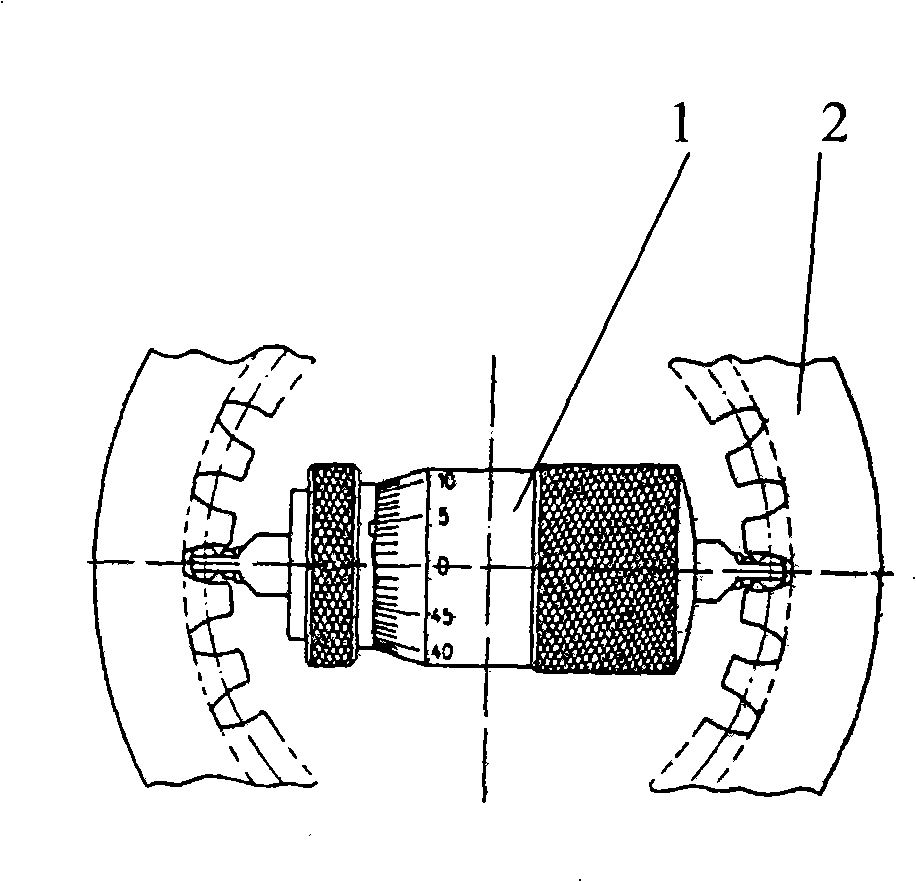

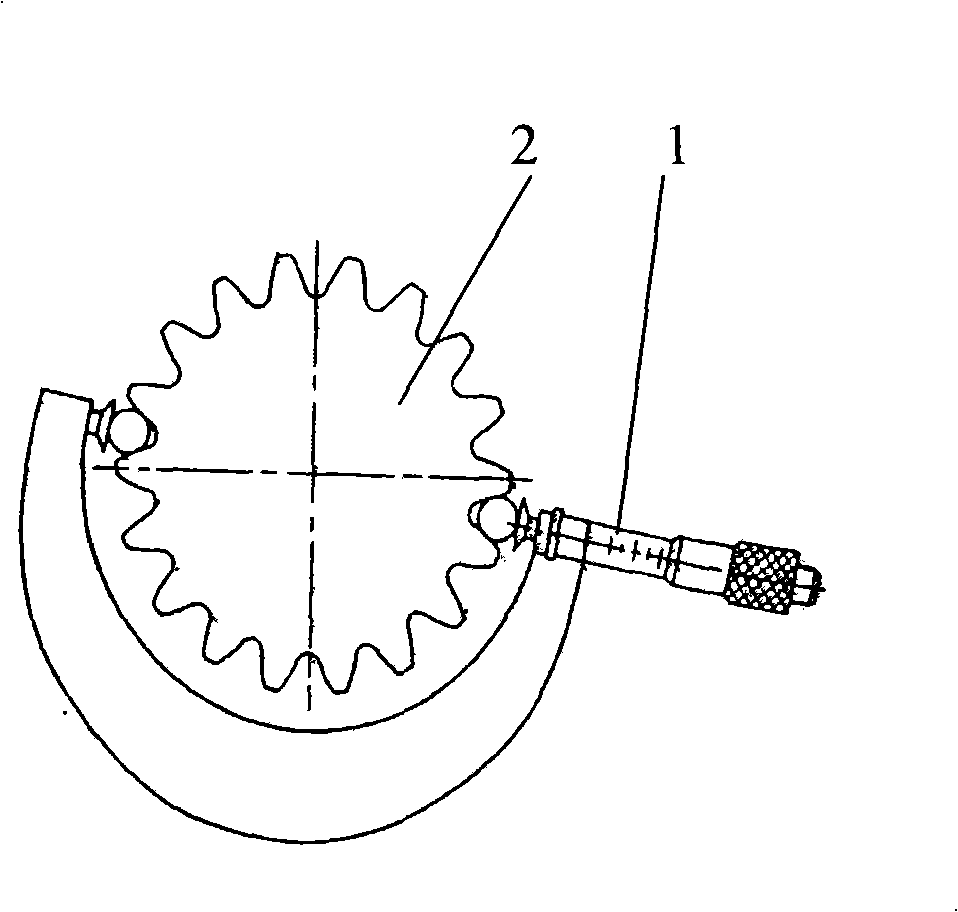

Gear cylinder or ball measurement method and system

InactiveCN101339009AAccurate spanAutomatic calculation of cross-pin distanceUsing optical meansTooth numberTeeth count

The invention provides a gear column or sphere measuring method and a system thereof. The method and the system are used for measuring an involute spur gear. The system initiates software achieving the method which comprises an image system and a data processing system. The data processing system comprises a CPU, an input device connected with the CPU by means of signal, a memory, a monitor, an output interface. The image system is connected with the CPU by means of signal. The method includes the following steps: the image system is used for inputting the outline of the gear to the coordinate system of the data processing system; two adjacent tooth top corresponding points, one tooth root point between the two points and another tooth top point are selected; the coordinates of the selected points are acquired; the coordinates of the center, the spanned tooth count and other gear parameters of the gear are computed; the outline of the gear is fitted; a base circle is drawn; the origin of a survey coordinate system coincides with the center of the gear; a spanned pin measurement sphere is supposed for measuring spanned pin distance; gear teeth are selected, and the measurement result is output. The method and the system provided by the invention significantly improve the accuracy of measurement of gears and measurement efficiency, which are used simply and conveniently.

Owner:深圳智泰精密仪器有限公司

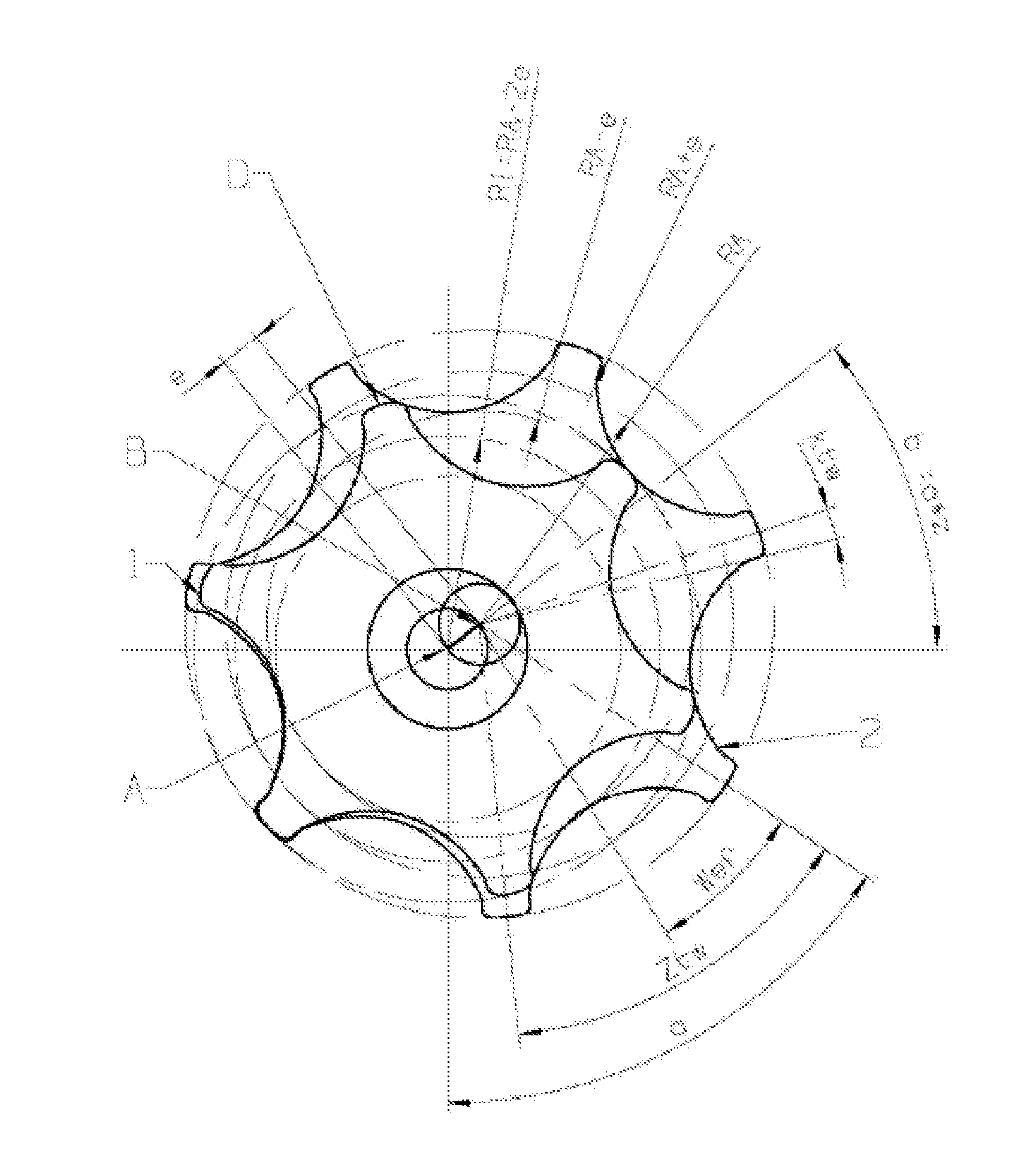

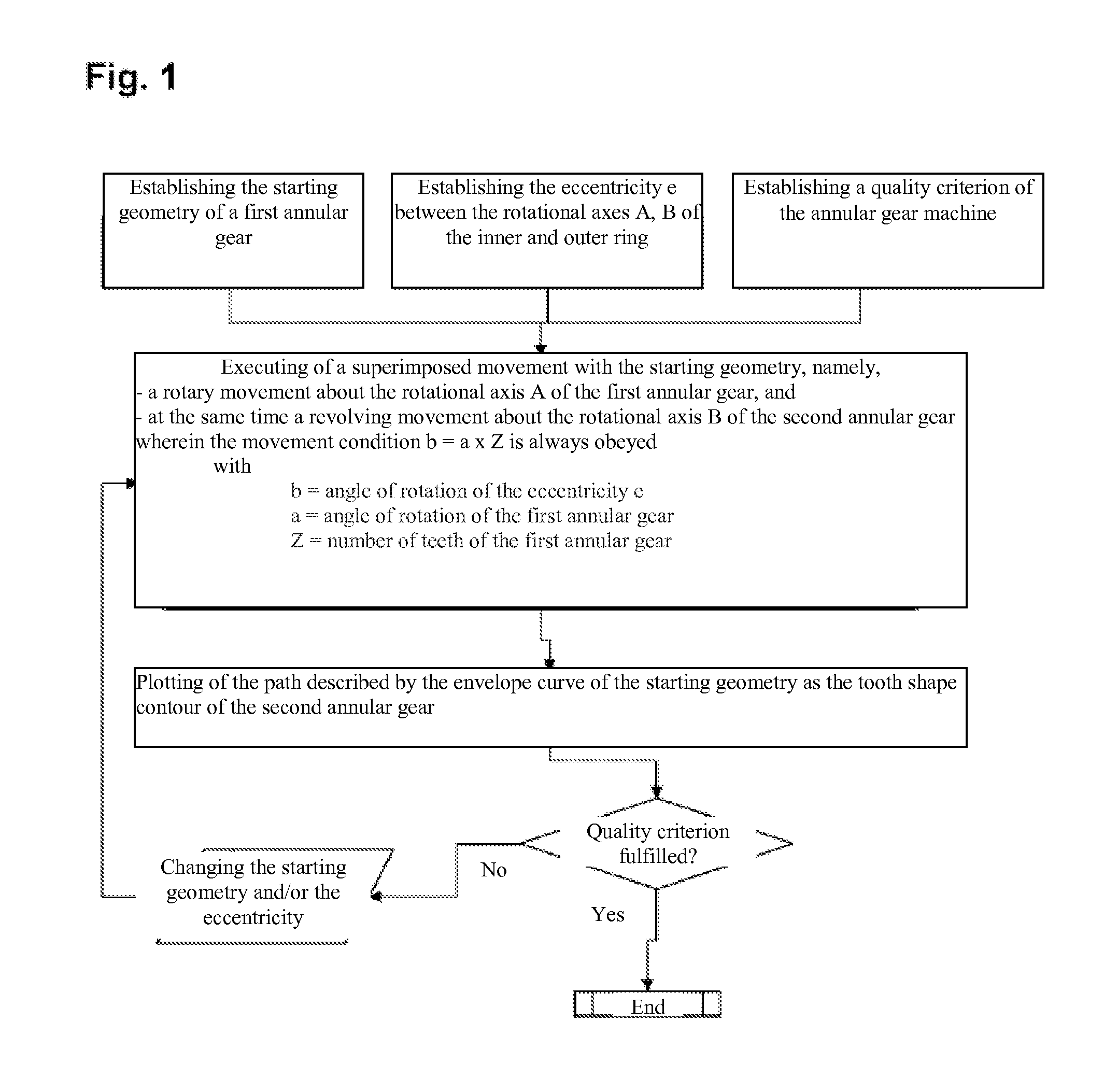

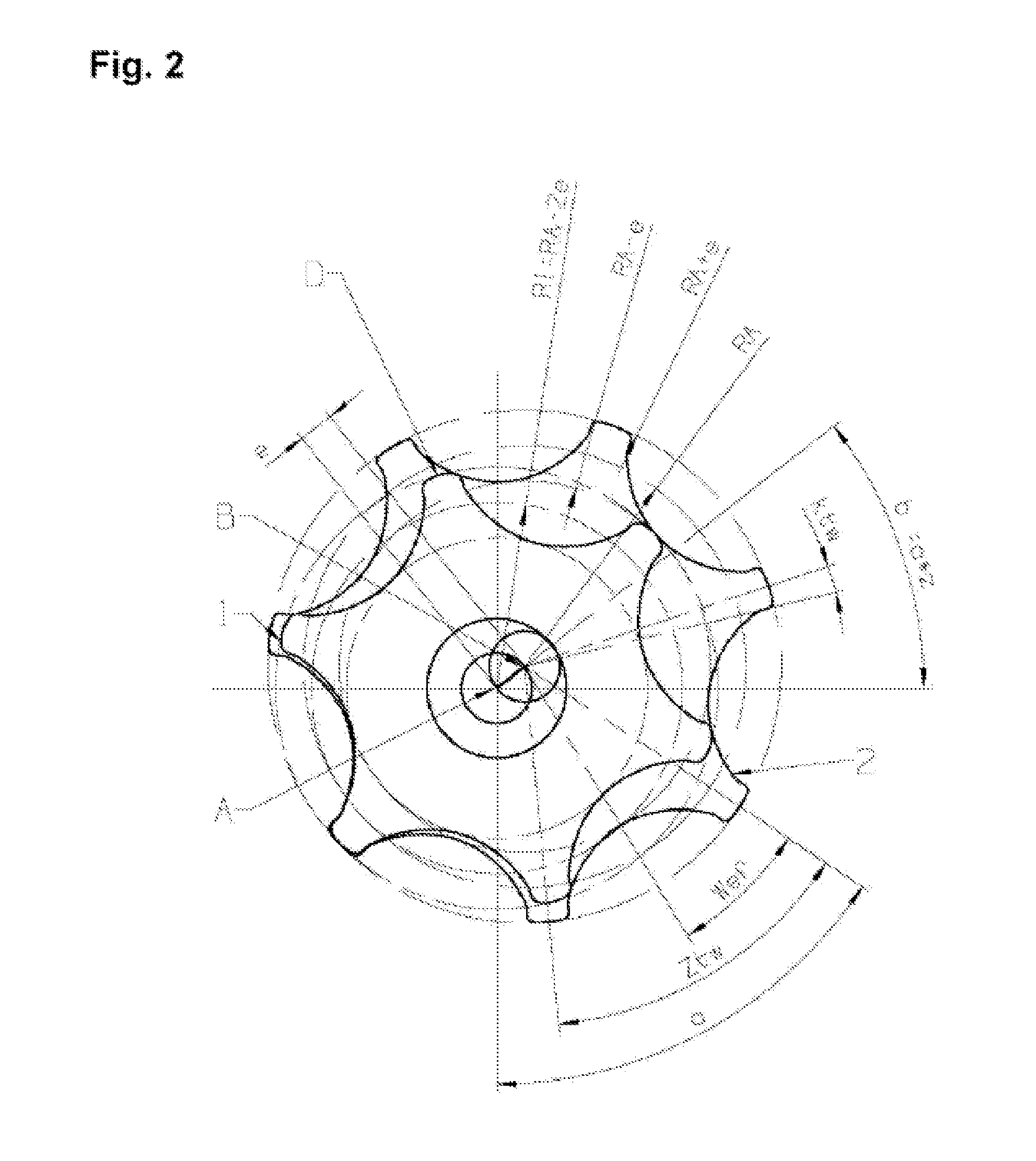

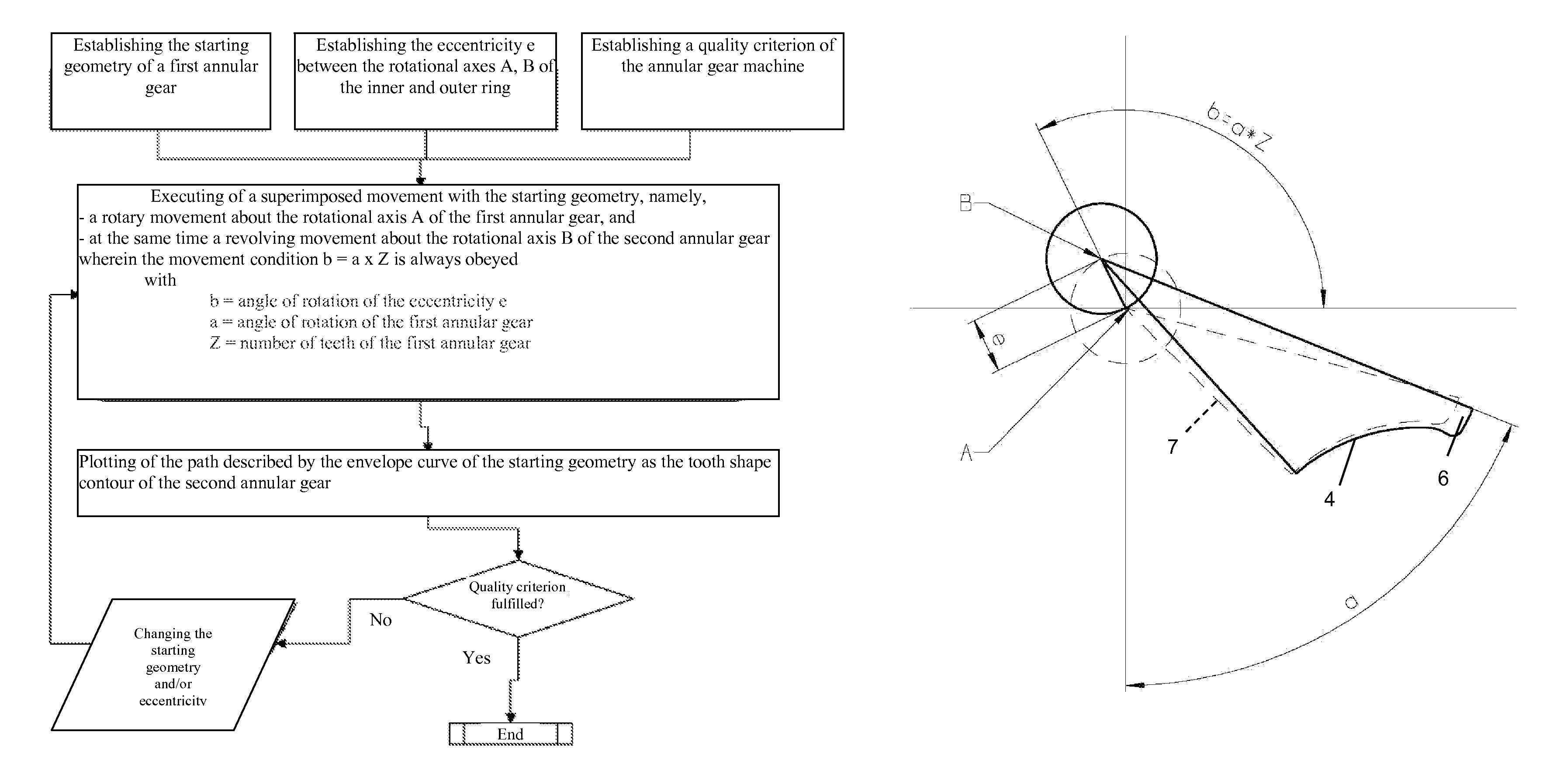

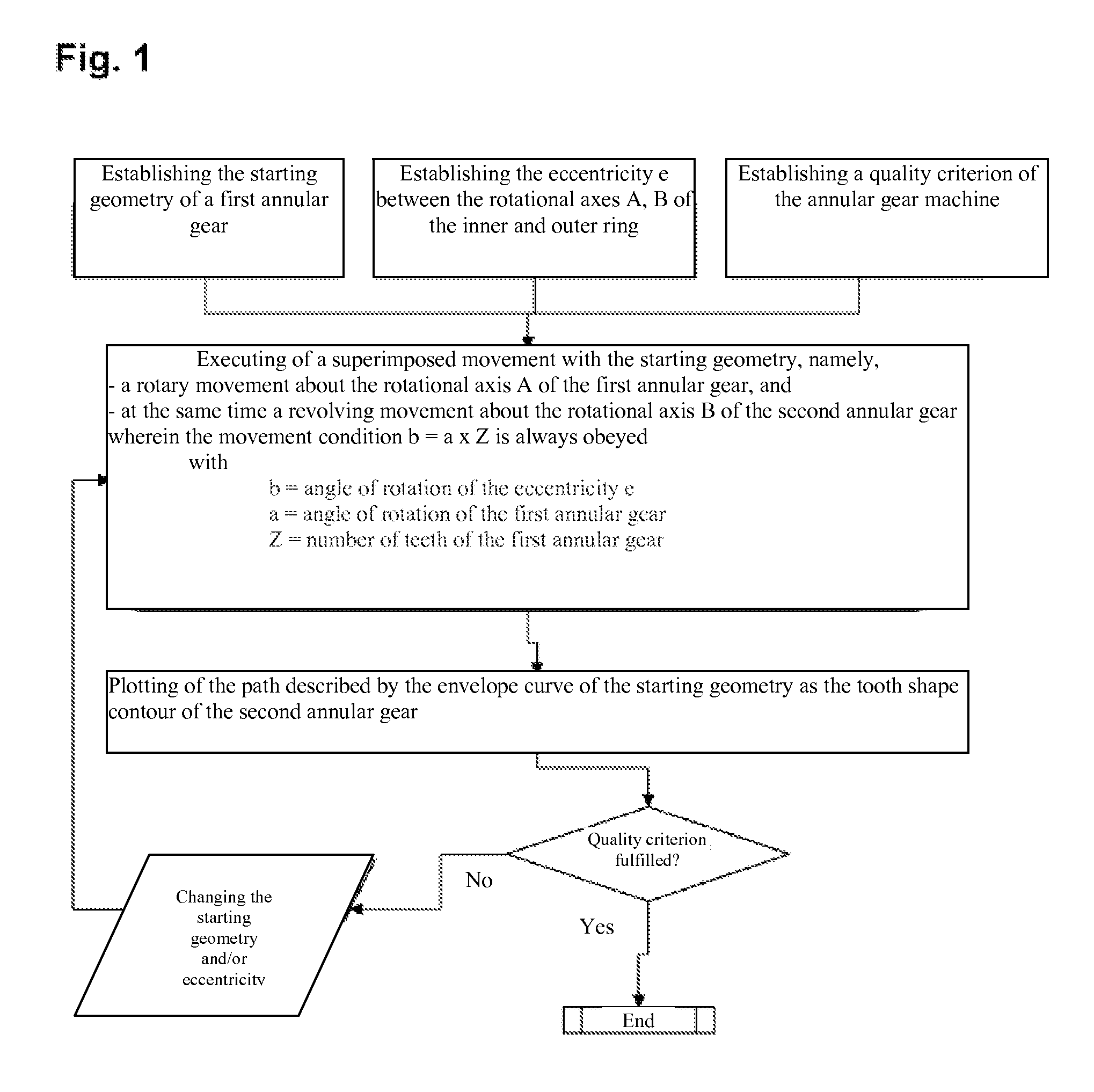

Method for producing the tooth shape of the inner and outer ring of an annular gear machine and toothed ring produced by means of said method

ActiveUS20130330222A1Improve efficiencyImprove delivery capabilitiesEngine of arcuate-engagement typeOscillating piston enginesRotational axisEngineering

In producing tooth shapes of two toothed rings of an annular gear machine, a starting geometry of a first toothed ring, at least one quality criterion of the annular gear machine, and a desired eccentricity between rotational axes of the two toothed rings are defined. A motion is performed with the starting geometry that performs a rotational motion about its rotational axis and a revolving motion about the rotational axis of the second toothed ring. The rotational and revolving motions are coupled so the rotational angle of the eccentricity equals the product of the rotational angle and tooth count of the first toothed ring. A tooth shape contour of the second toothed ring is generated by recording the path described by the envelope of the starting geometry. If the defined quality criterion is not met, the previously used starting geometry and / or the defined eccentricity is changed and steps are repeated.

Owner:NIDEC GPM GMBH

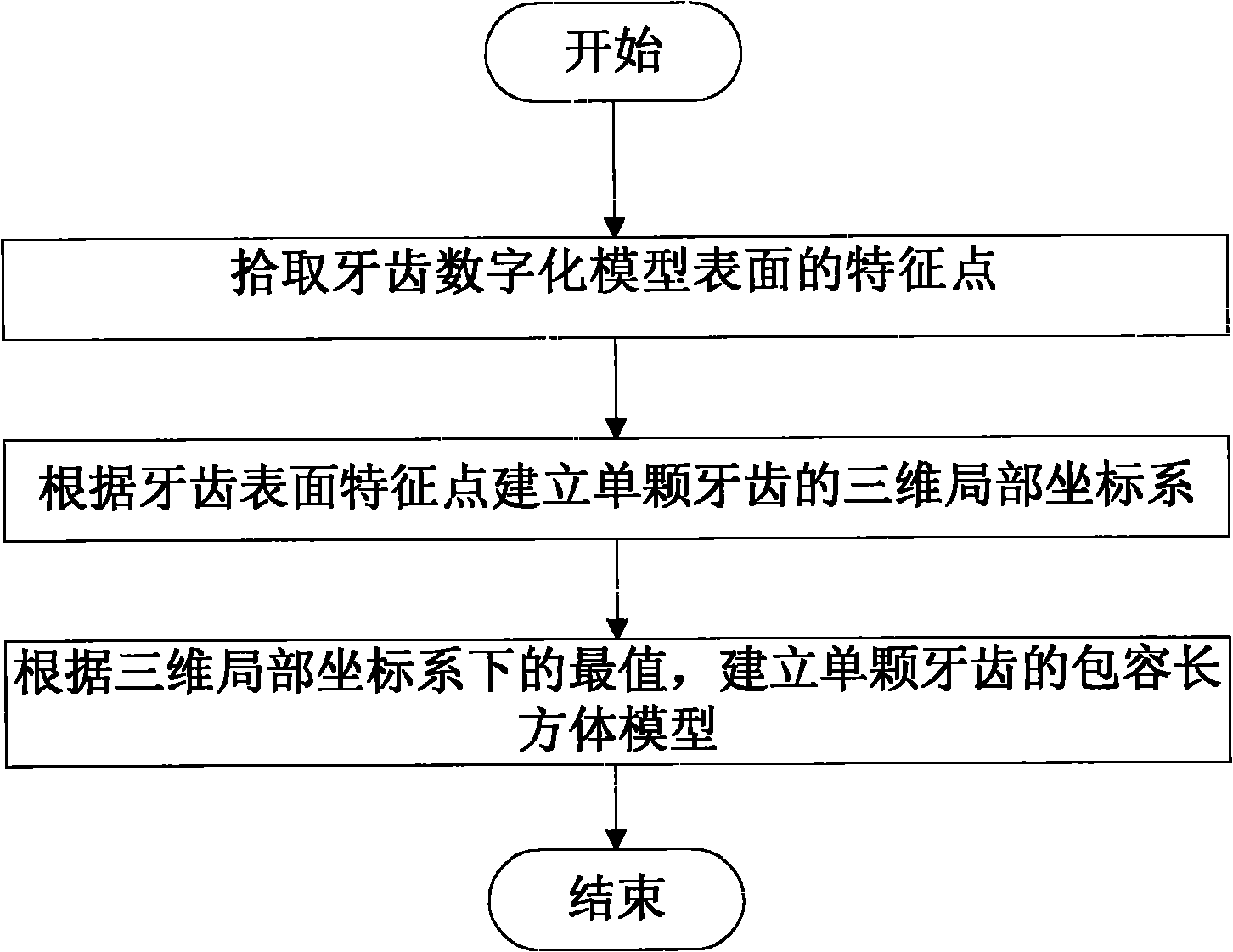

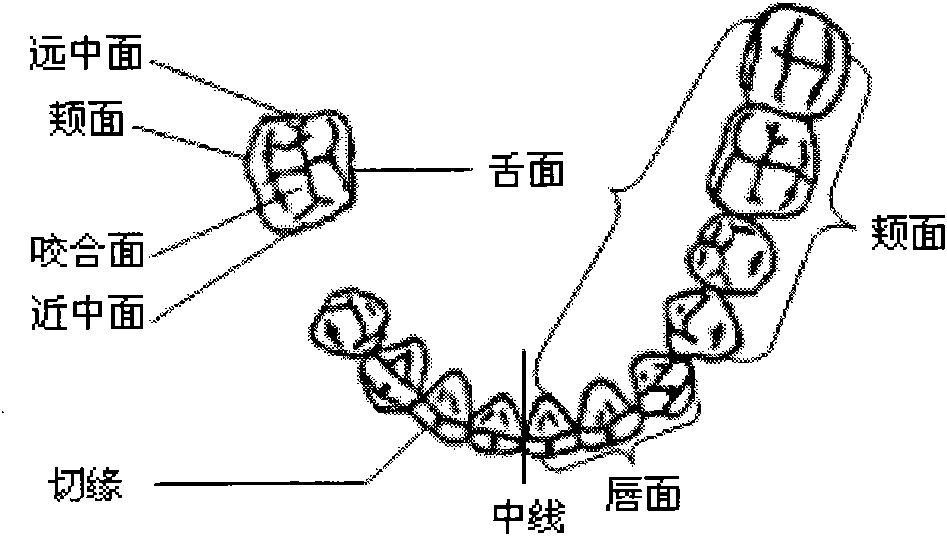

Method for determining container of single tooth

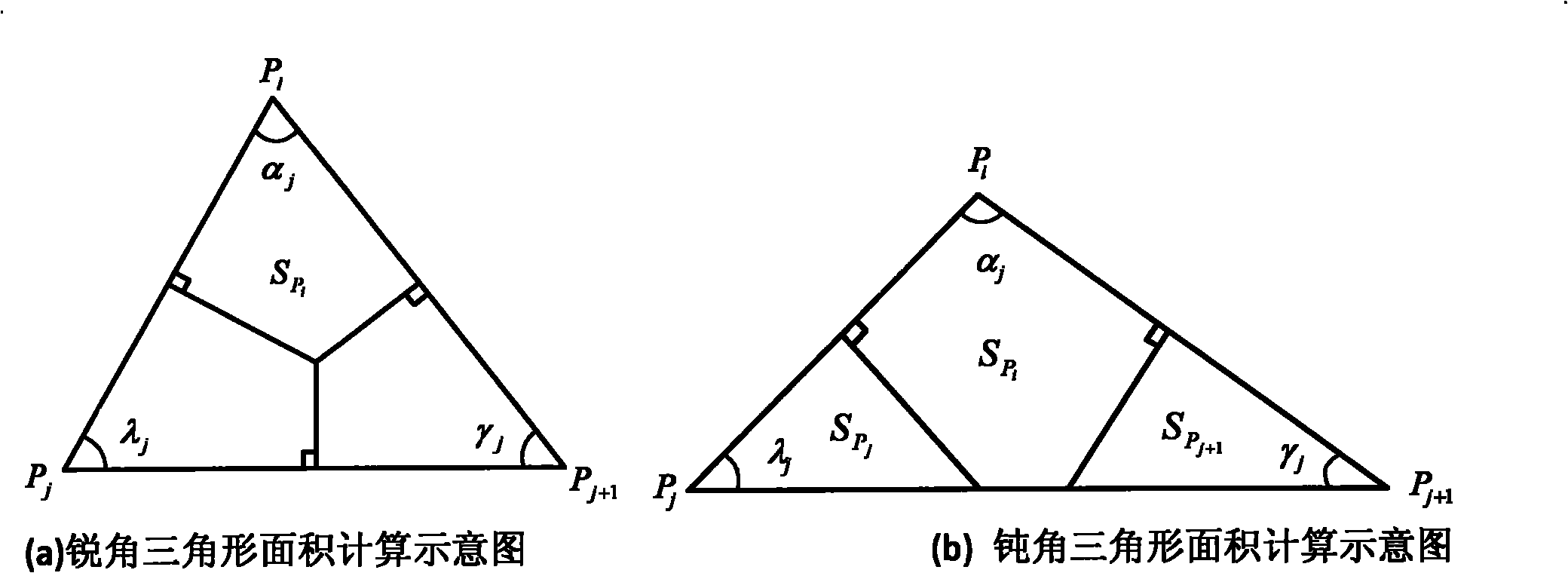

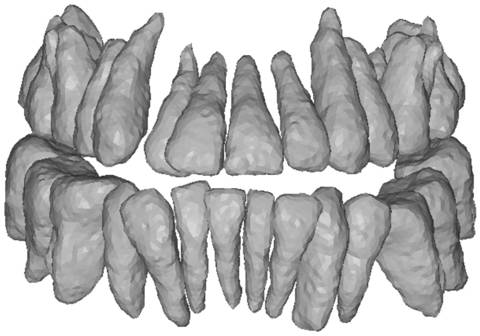

InactiveCN101944156AInnovative designReasonable designDentistrySpecial data processing applicationsIncisor toothTriangular facet

The invention discloses a method for determining a container model of a single tooth, in particular to a method for determining a container model based on tooth surface characteristics and a local three-dimensional right angle coordinate system, which mainly comprises the following steps: based on a segmentation tooth digital model, reflecting the curve degree at the peak by utilizing complex collection of a triangular facet and a discrete Gaussian curvature, collecting surface feature points of a single tooth; based on the surface feature points of the single tooth, establishing corresponding local three-dimensional right angle coordinates for incisor teeth, cuspid teeth, premolar teeth, and odontoprisis; and respectively establishing the container models of the incisor teeth, the premolar teeth, the odontoprisis and the cuspid teeth by using extreme values of the single tooth model under the three-dimensional right angle coordinate system. The invention has the advantages of novel and reasonable design, convenient implementation, high operating speed, high data processing accuracy and good implementation effect, can extract characteristic points of teeth and facilitate the operation on teeth, and can be used in the tooth correcting system.

Owner:XIAN UNIV OF SCI & TECH

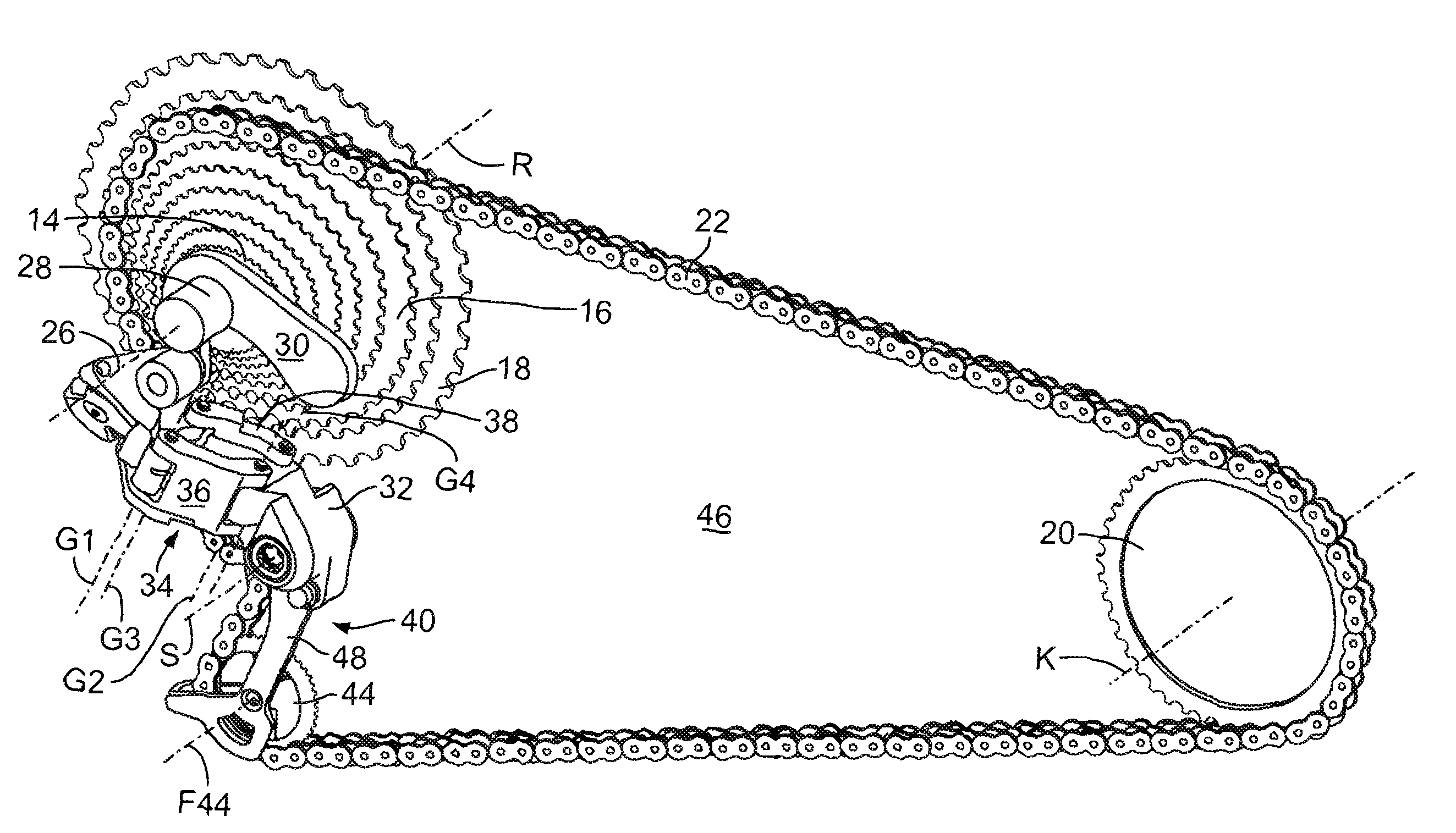

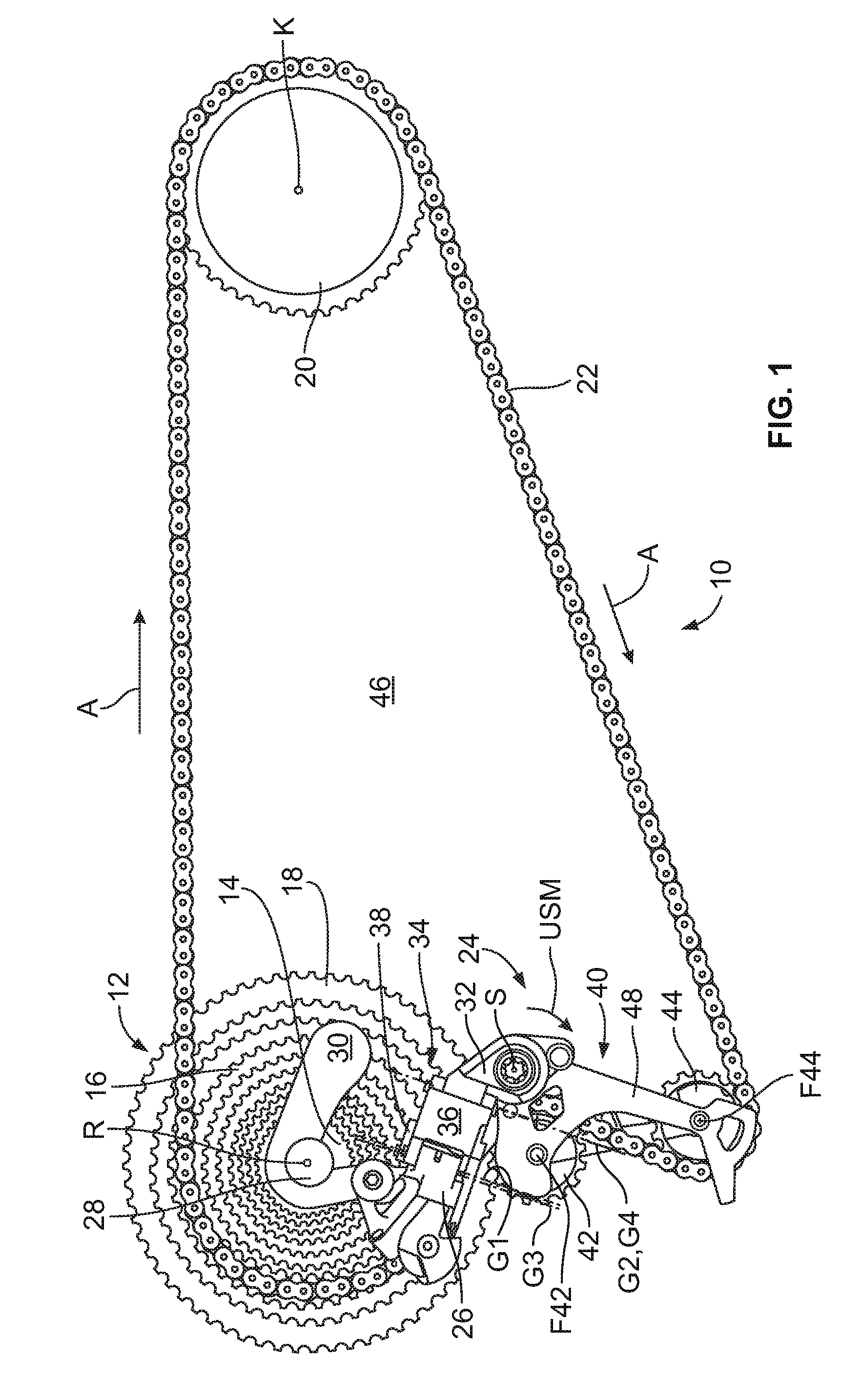

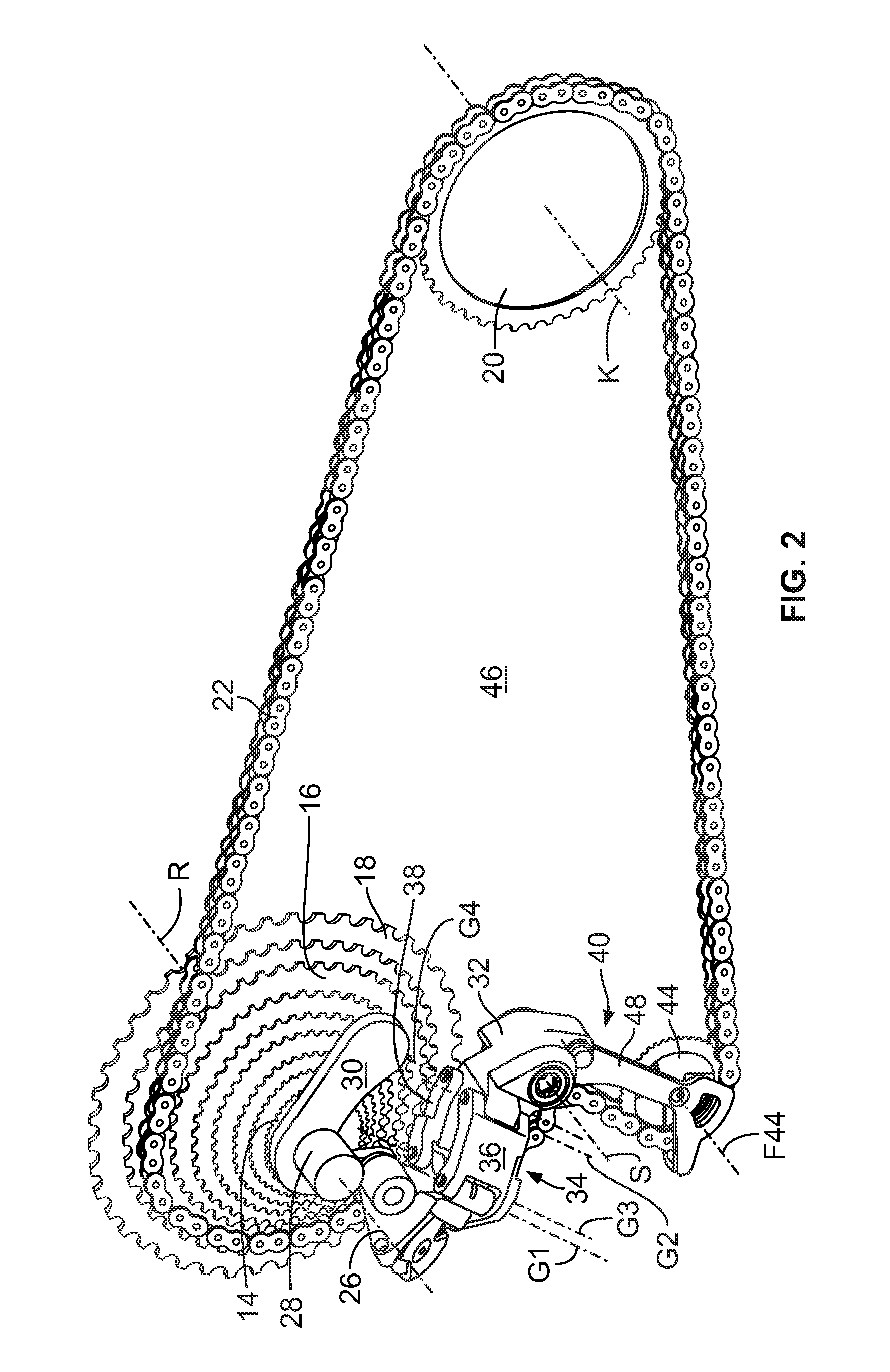

Drive arrangement for a bicycle, having a greater difference in the number of teeth between the largest and the smallest rear chain sprocket

A drive arrangement for a bicycle including a chainring having a chainring axis, a plurality of different rear sprockets, the plurality of rear sprockets sharing a sprocket axis, a drive chain that runs around the rear sprockets and the chainring and in meshing engagement with a selected active sprocket of the plurality of rear sprockets and the chainring, and a rear derailleur. The rear derailleur is configured to shift the chain over a plurality of sprockets having a difference in tooth count of over 25 teeth ranging from a smallest to a largest sprocket.

Owner:SRAM

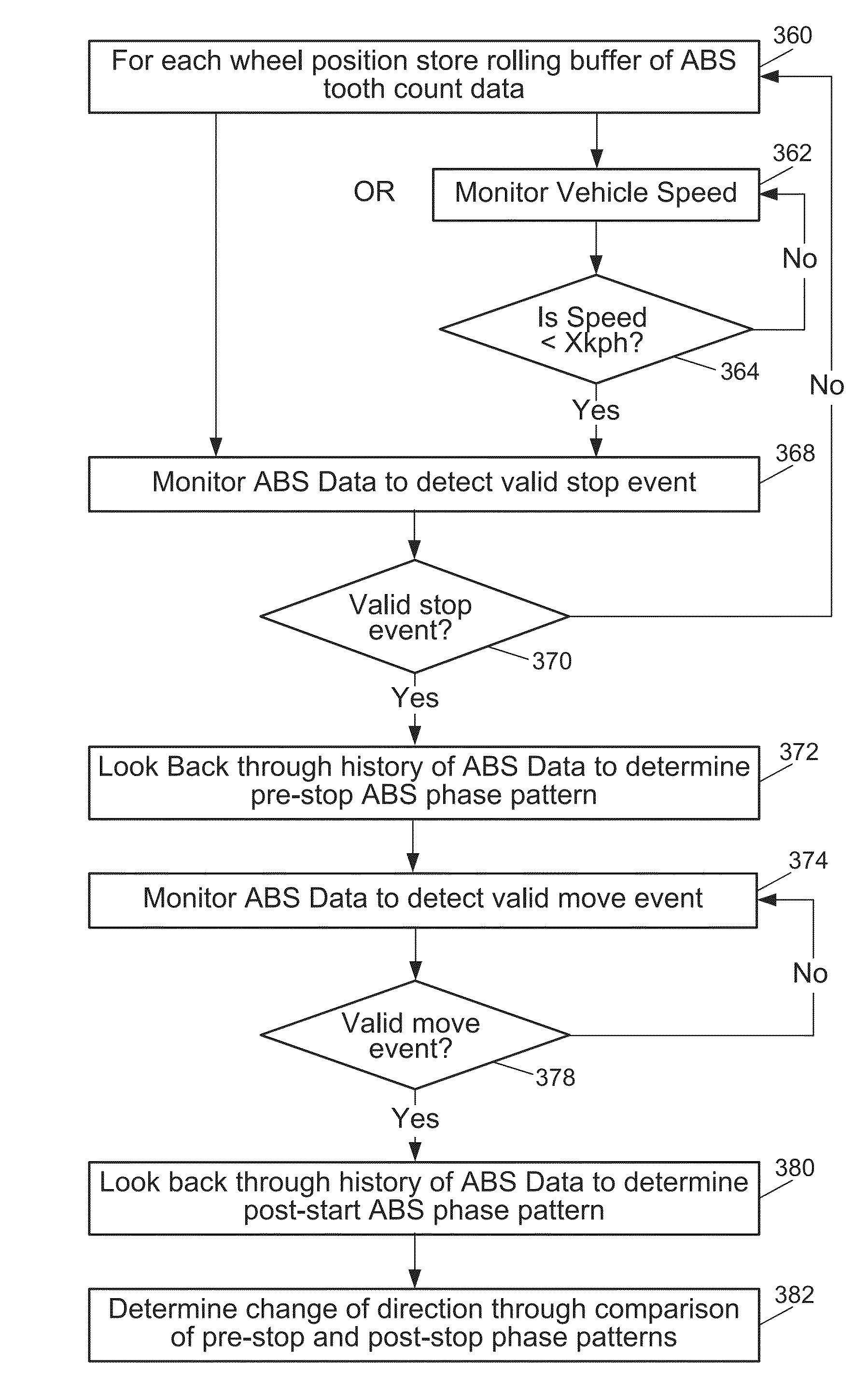

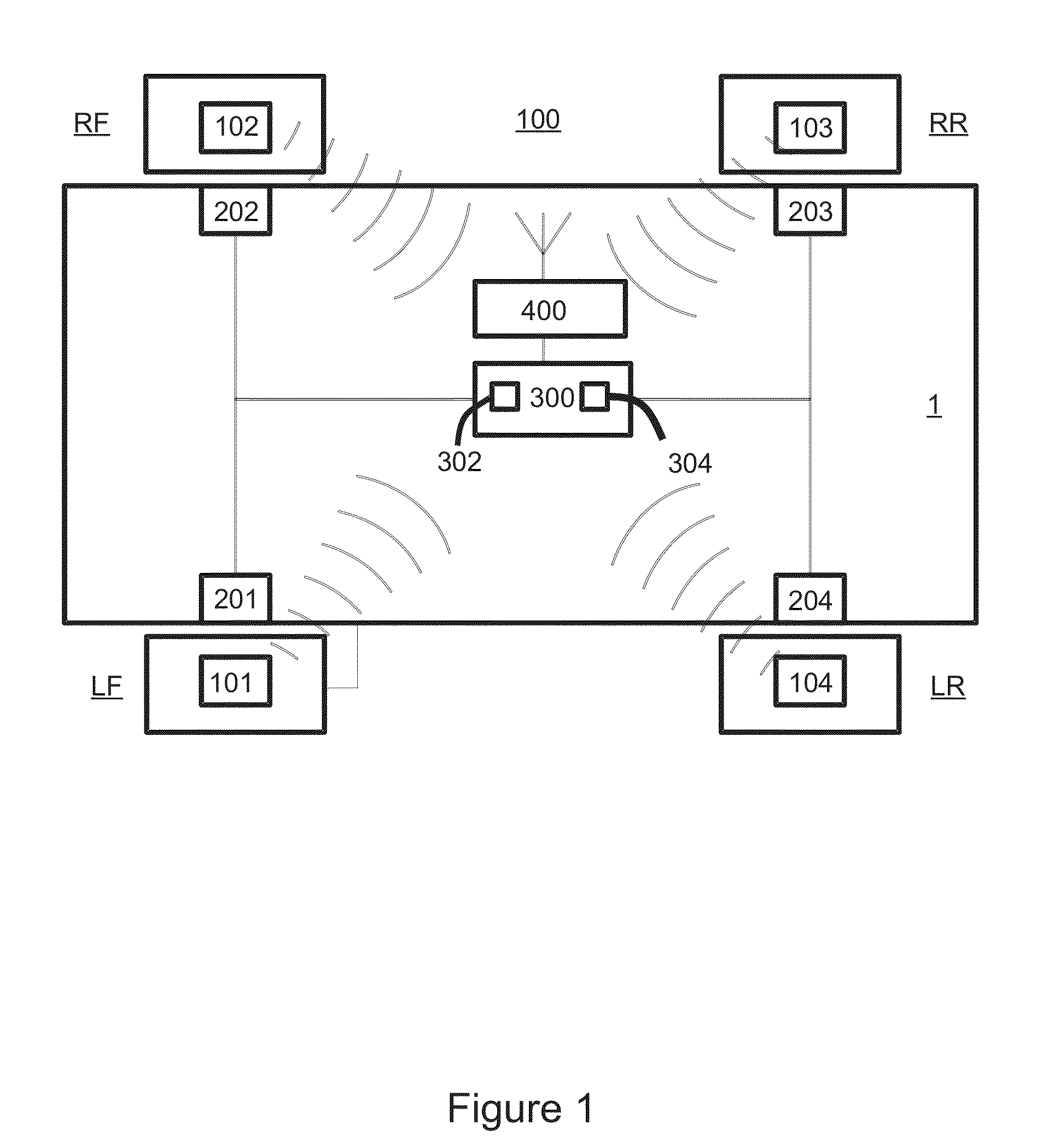

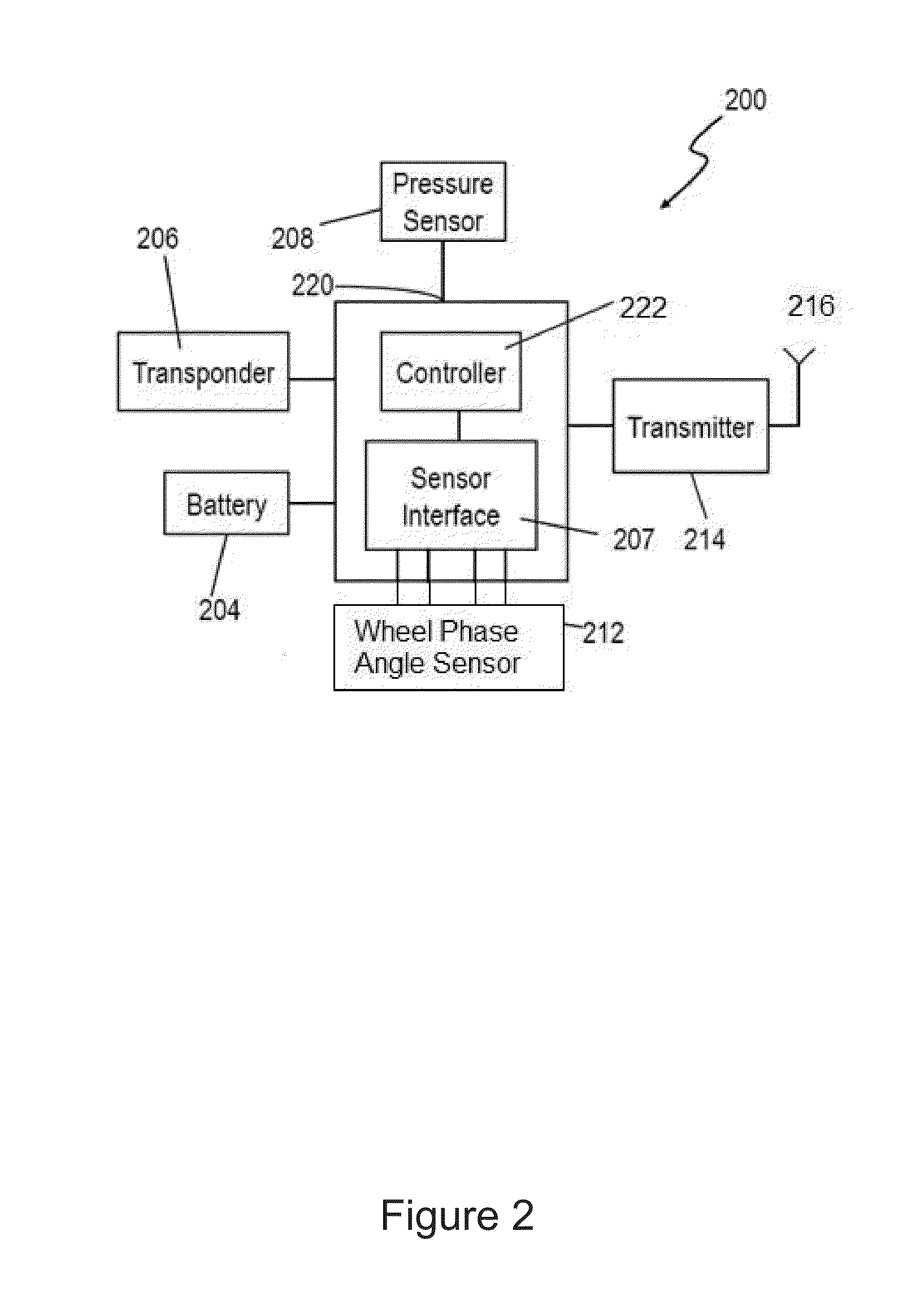

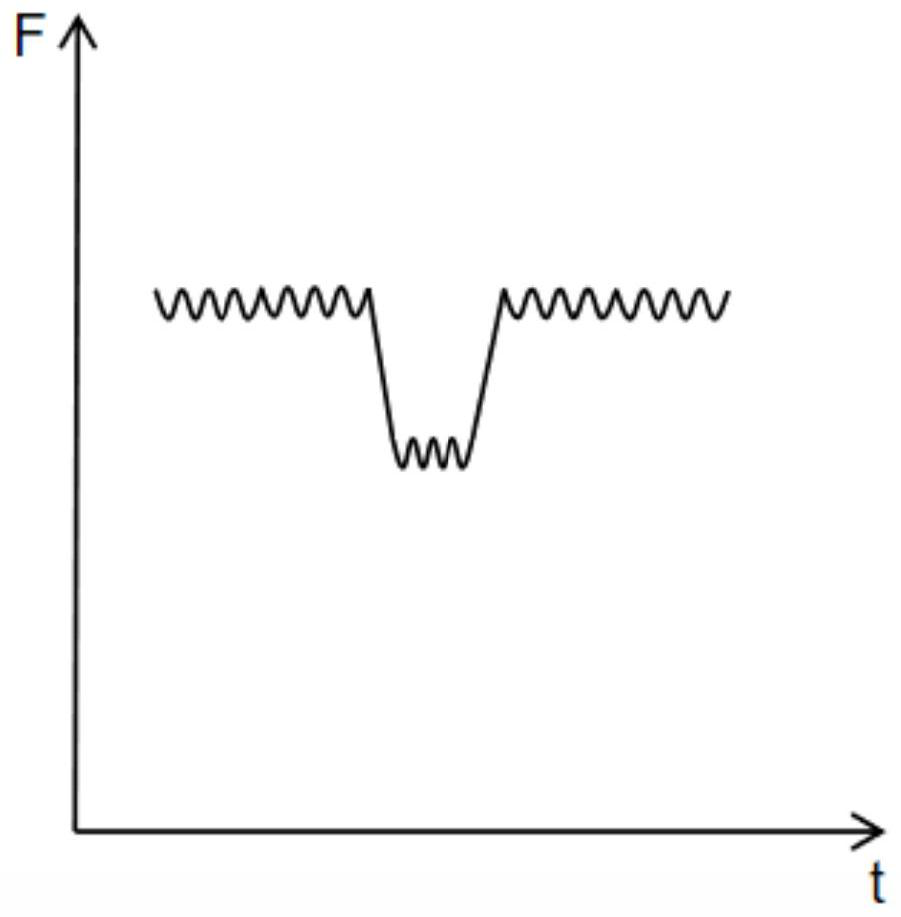

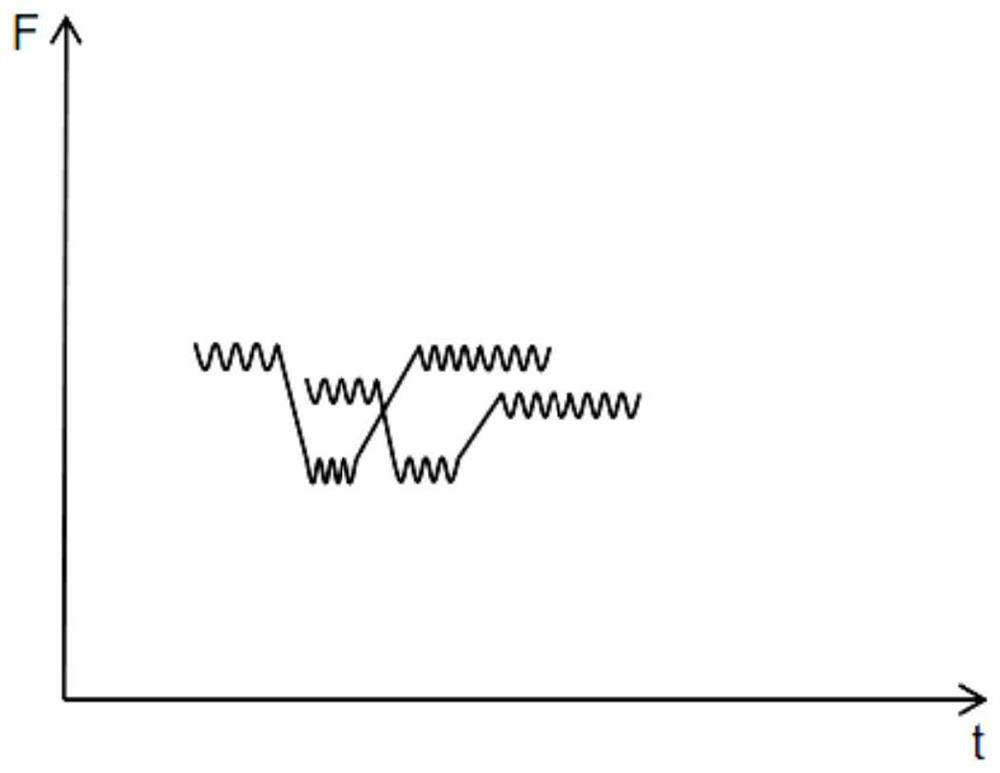

System and method for performing auto-location of a tire pressure monitoring sensor arranged with a vehicle wheel using confidence interval analysis and change of wheel direction

ActiveUS9278590B2Accurate locationIndication/recording movementTyre measurementsConfidence intervalMeasurement point

A method for determining change of direction of a vehicle includes steps of maintaining a rolling window of ABS data indicative of ABS tooth count and capturing a relevant rolling window of ABS data at the predetermined one-measurement point; storing the rolling window of the ABS data indicative of ABS tooth in a buffer; monitoring the ABS data and detecting a valid stop event which causes the rate of change of ABS tooth count to substantially decrement to zero; and monitoring the ABS data and detecting a valid move event which causes the rate of change of ABS tooth count to substantially increment from zero. The method also includes steps of determining a pre-stop phase relationship between at least two wheels based on the ABS tooth count stored in the buffer immediately prior to the valid stop event; determining a post-start phase relationship between at least two wheels based on the ABS tooth count stored in the buffer immediately subsequent to the valid move event; and correlating the pre-stop phase relationship and the post-start phase relationship to determine change of direction and confidence level.

Owner:SCHRADER ELECTRONICS LTD

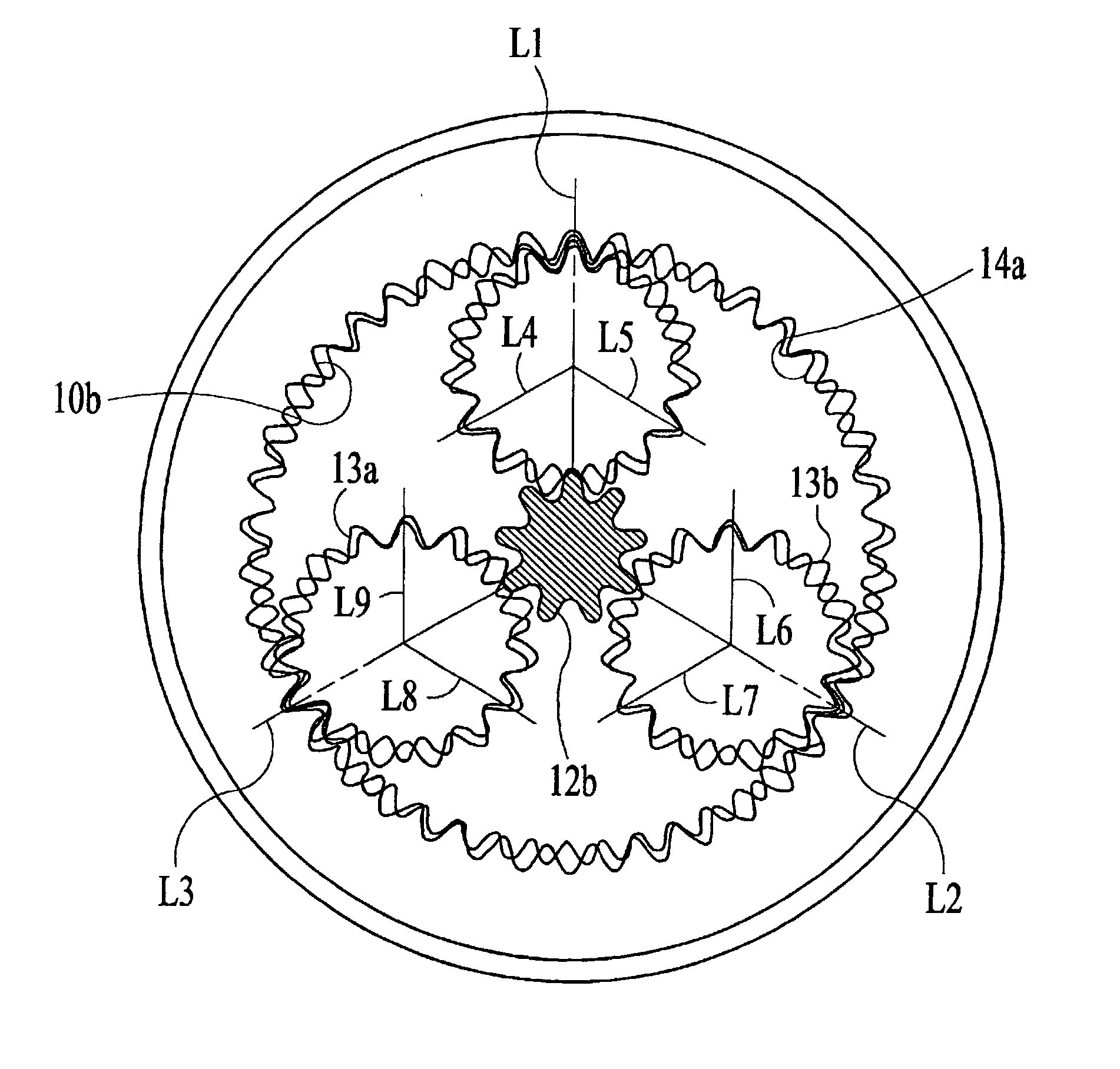

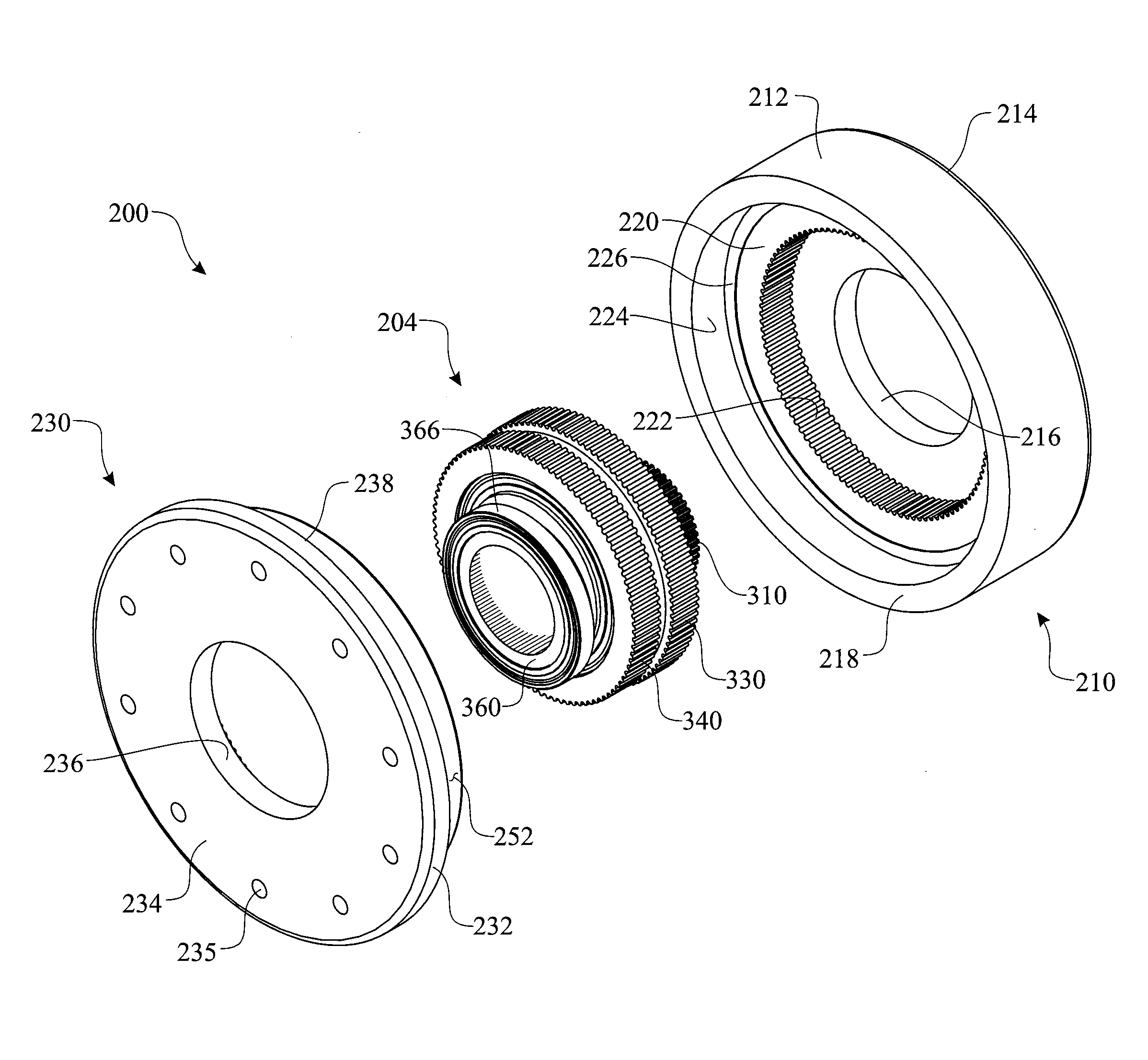

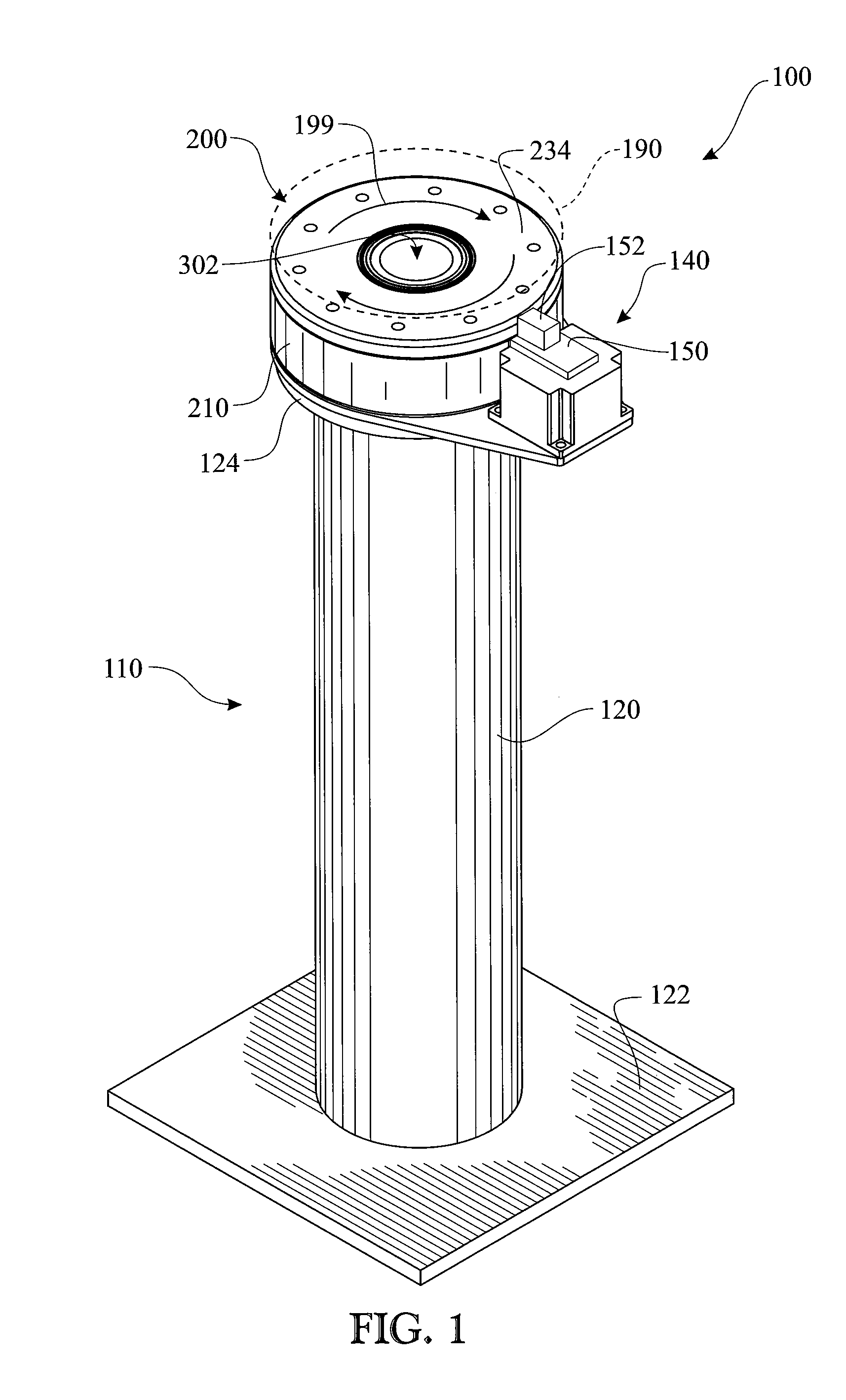

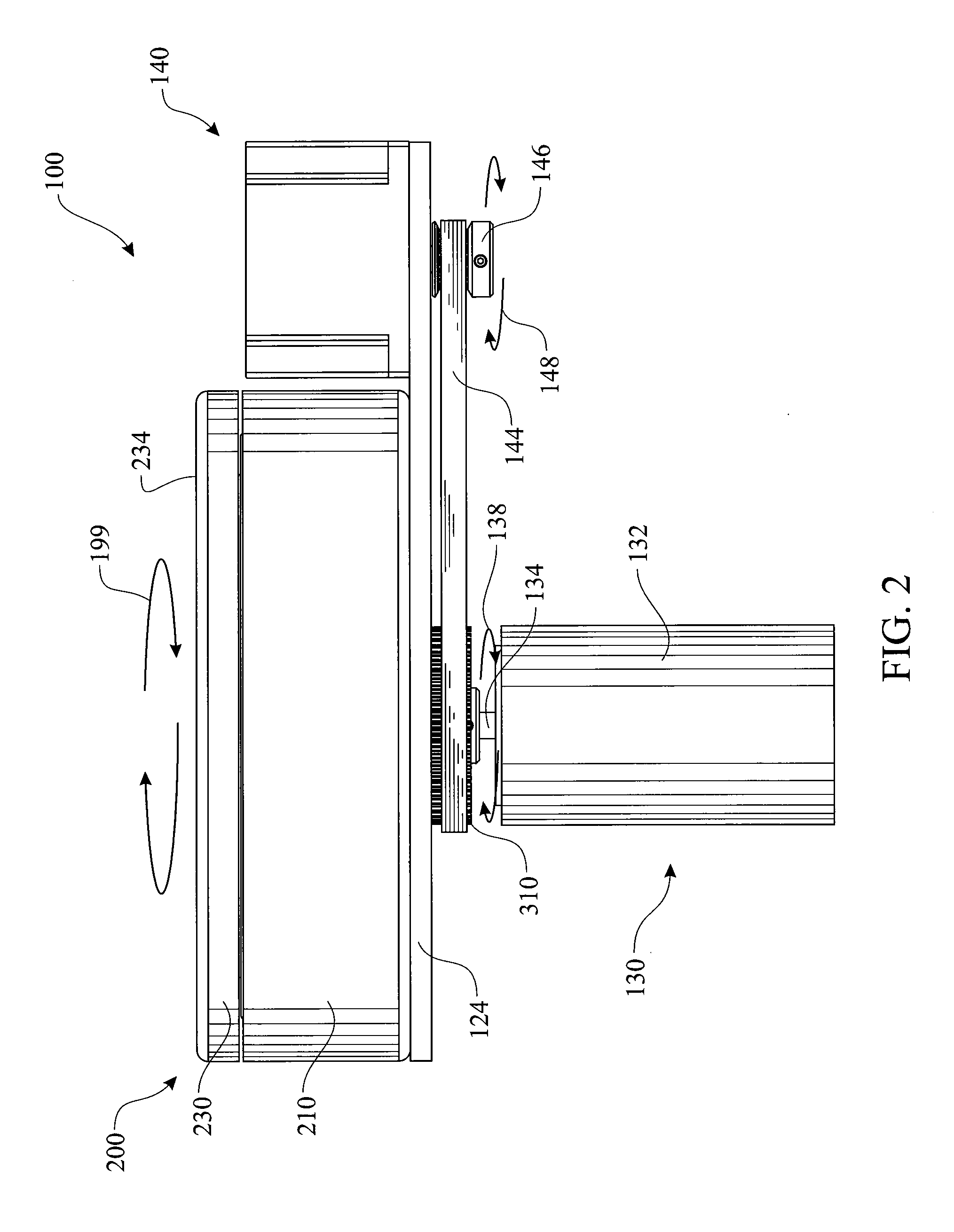

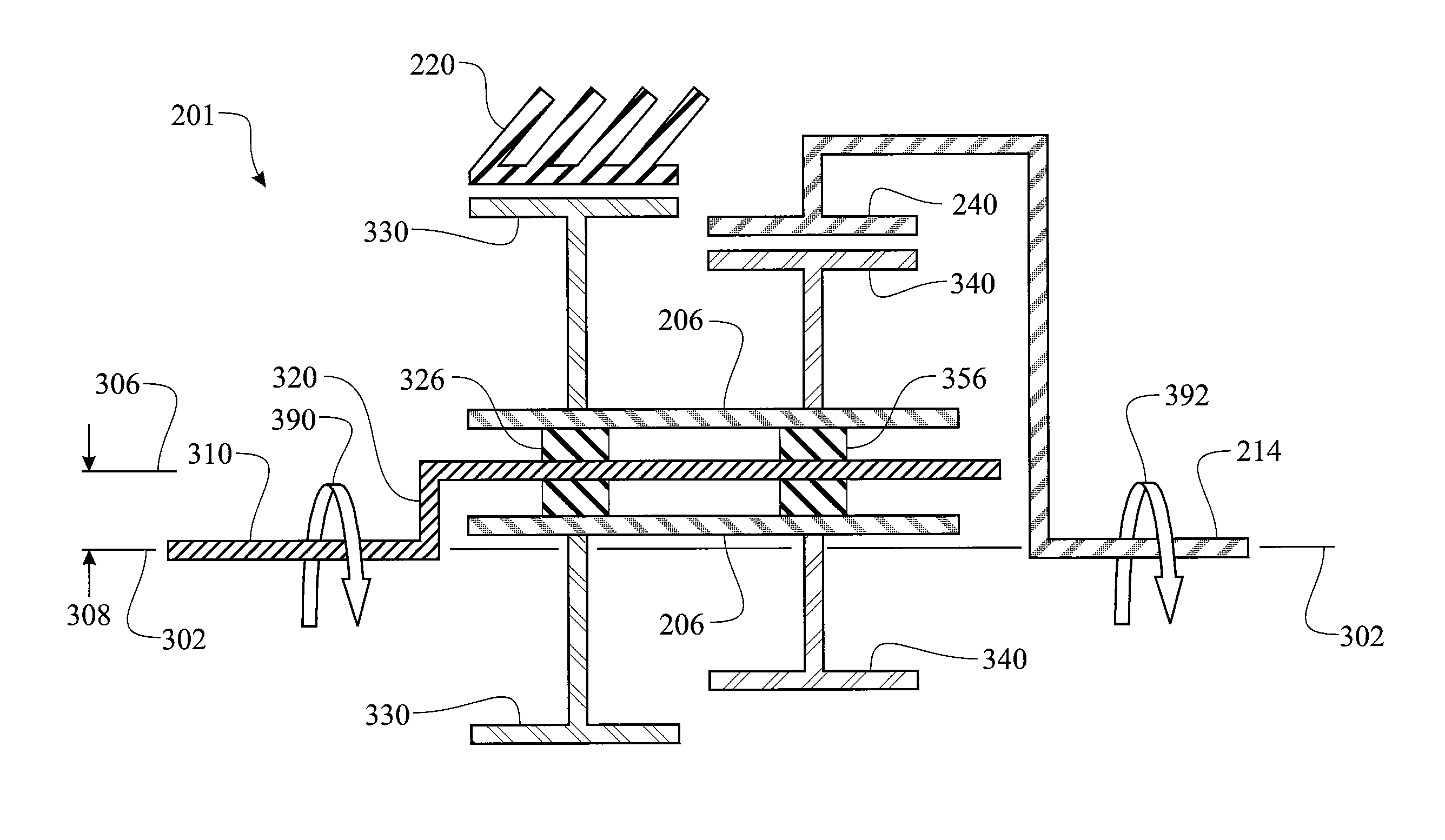

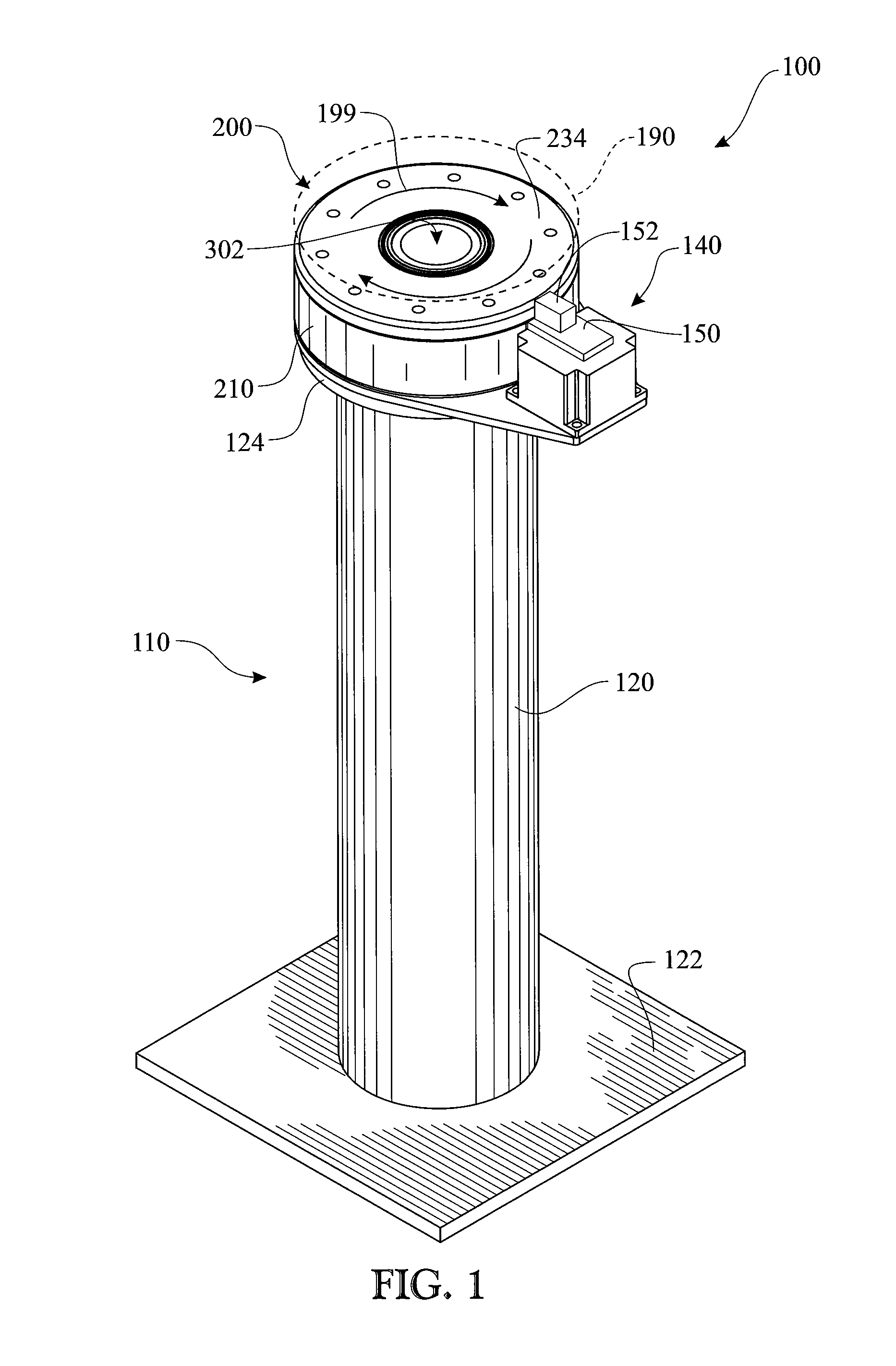

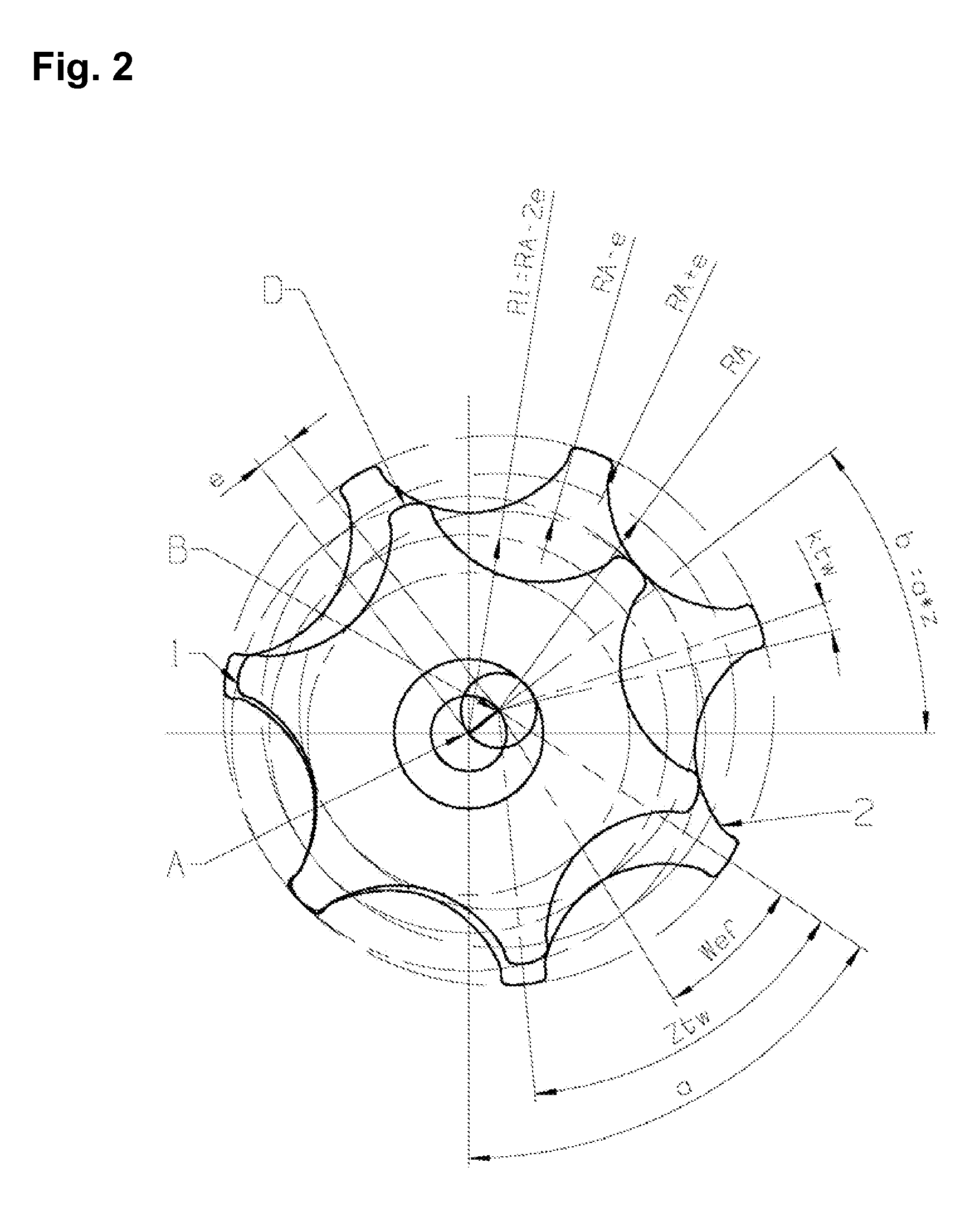

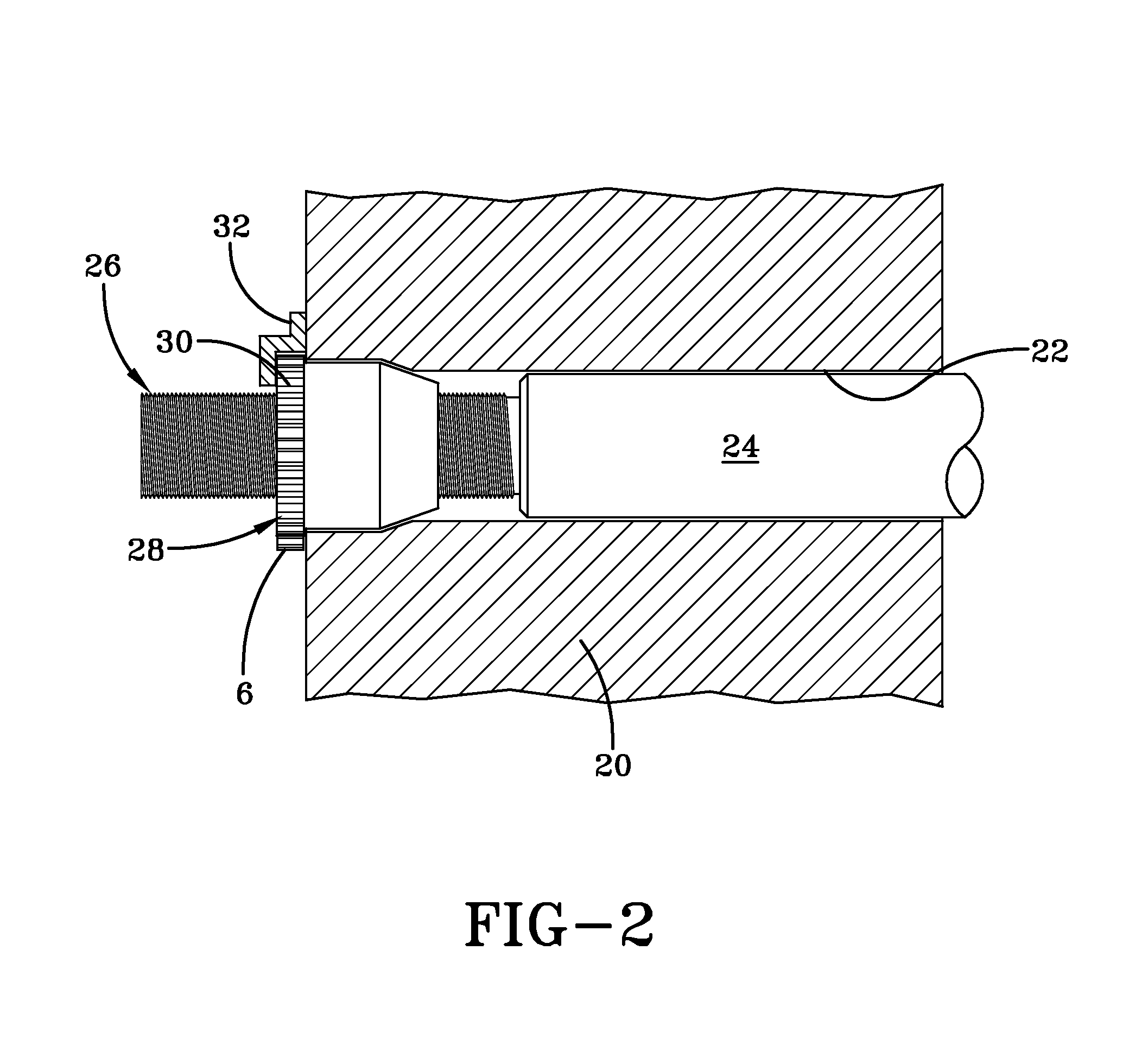

Coaxially arranged reduction gear assembly

ActiveUS20140171251A1High rotation accuracyReduced Power RequirementsToothed gearingsRotational axisTeeth count

A reduction gear assembly integrates a stationary section having a stationary internal gear configuration, an output section having an output internal gear configuration, an input shaft and planetary carrier comprising an input shaft having a shaft rotational axis and a planetary gear cam having a planetary gear rotational axis, wherein the shaft axis and cam axis are offset. A planetary gear comprising a planet wheel first stage and a planet wheel second stage is rotationally assembled to the planetary gear cam. The first stage planet wheel engages with the stationary gear. The second stage planet wheel engages with the output gear. Rotation of the input shaft rotates the planetary gear about a circular path. Engagement between the first stage and the stationary gear rotates the planetary gear. Second stage teeth engage with the output gear. Difference in first stage and second stage teeth counts causes rotation of the output section.

Owner:AB SKF

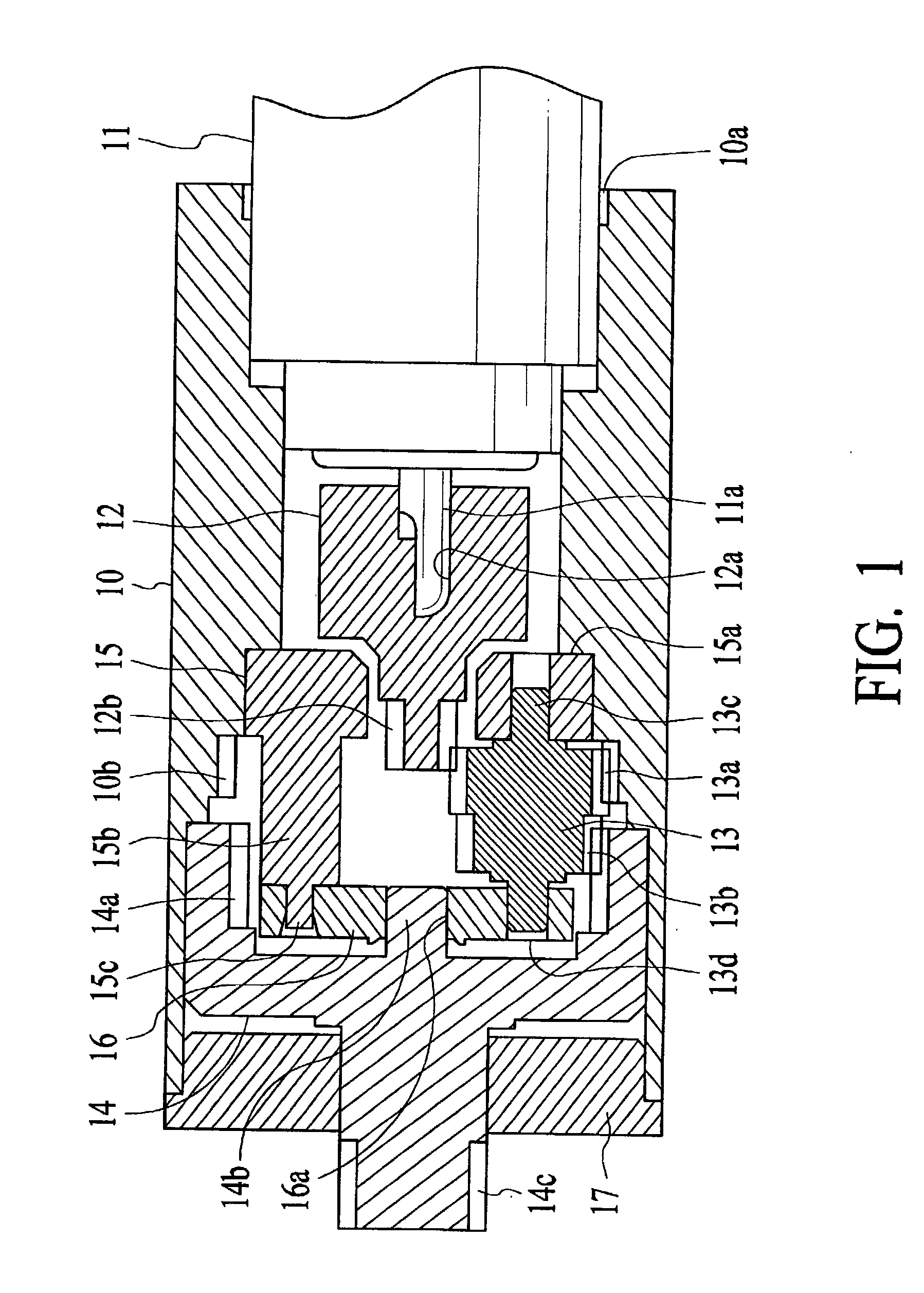

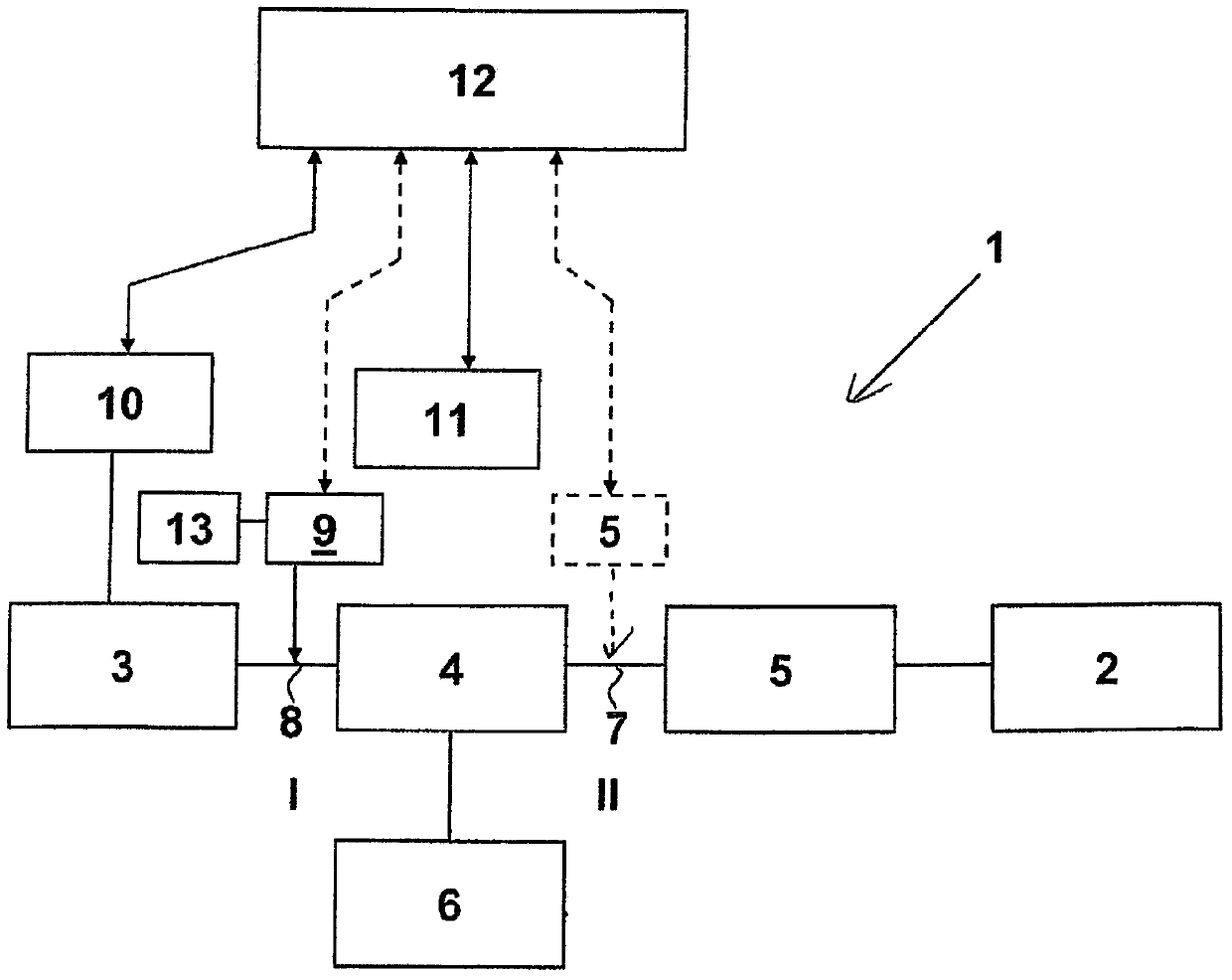

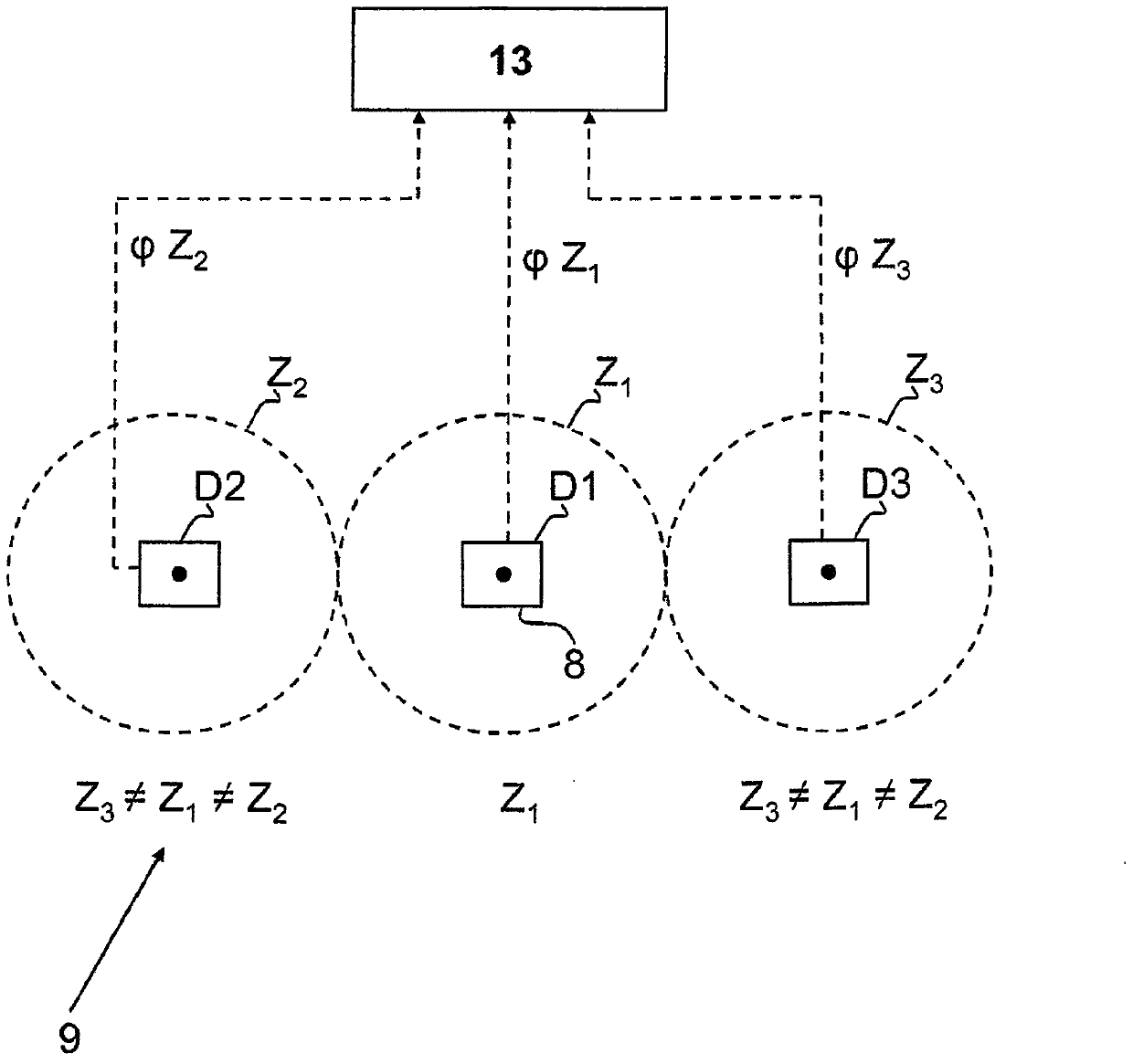

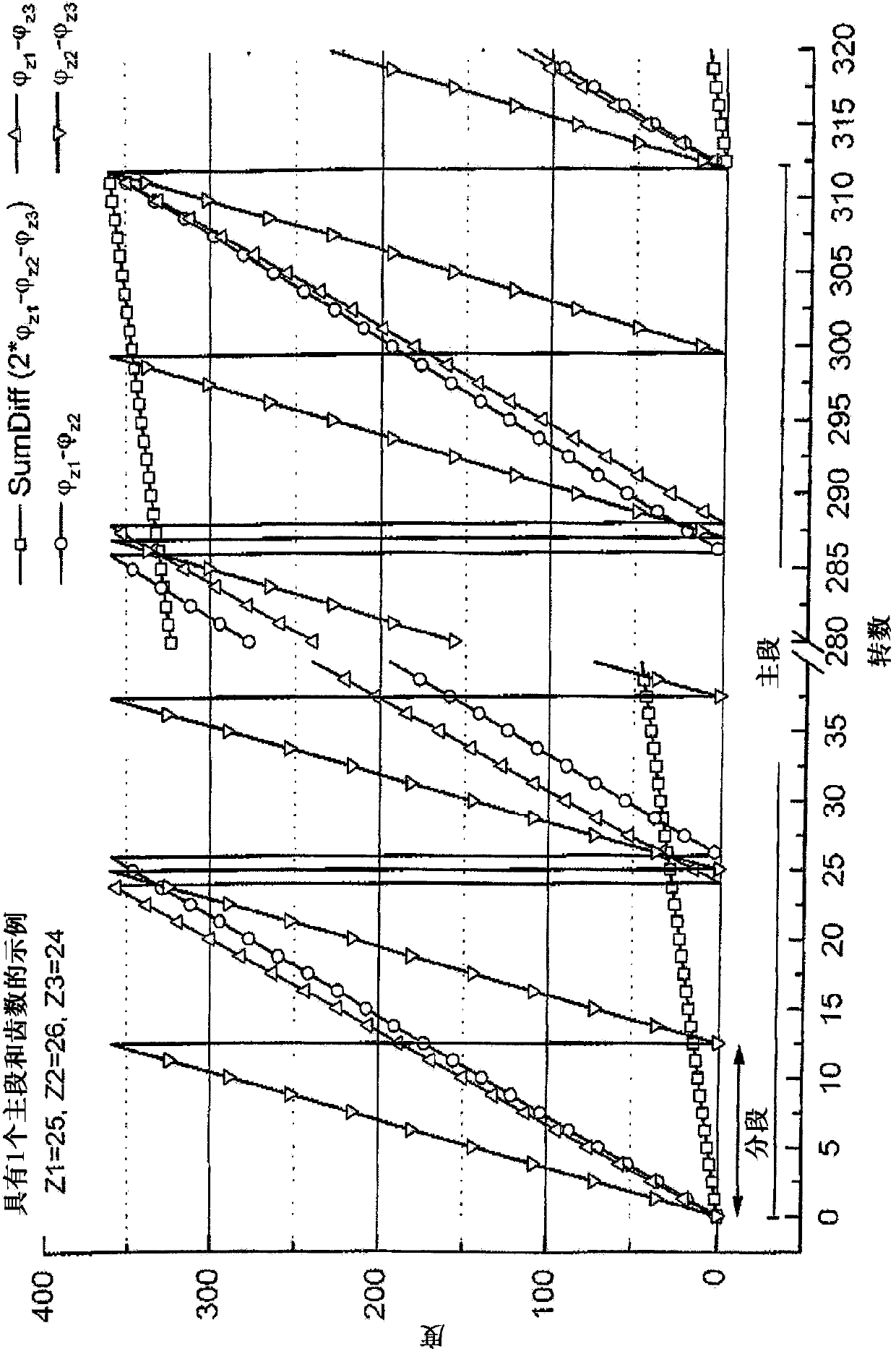

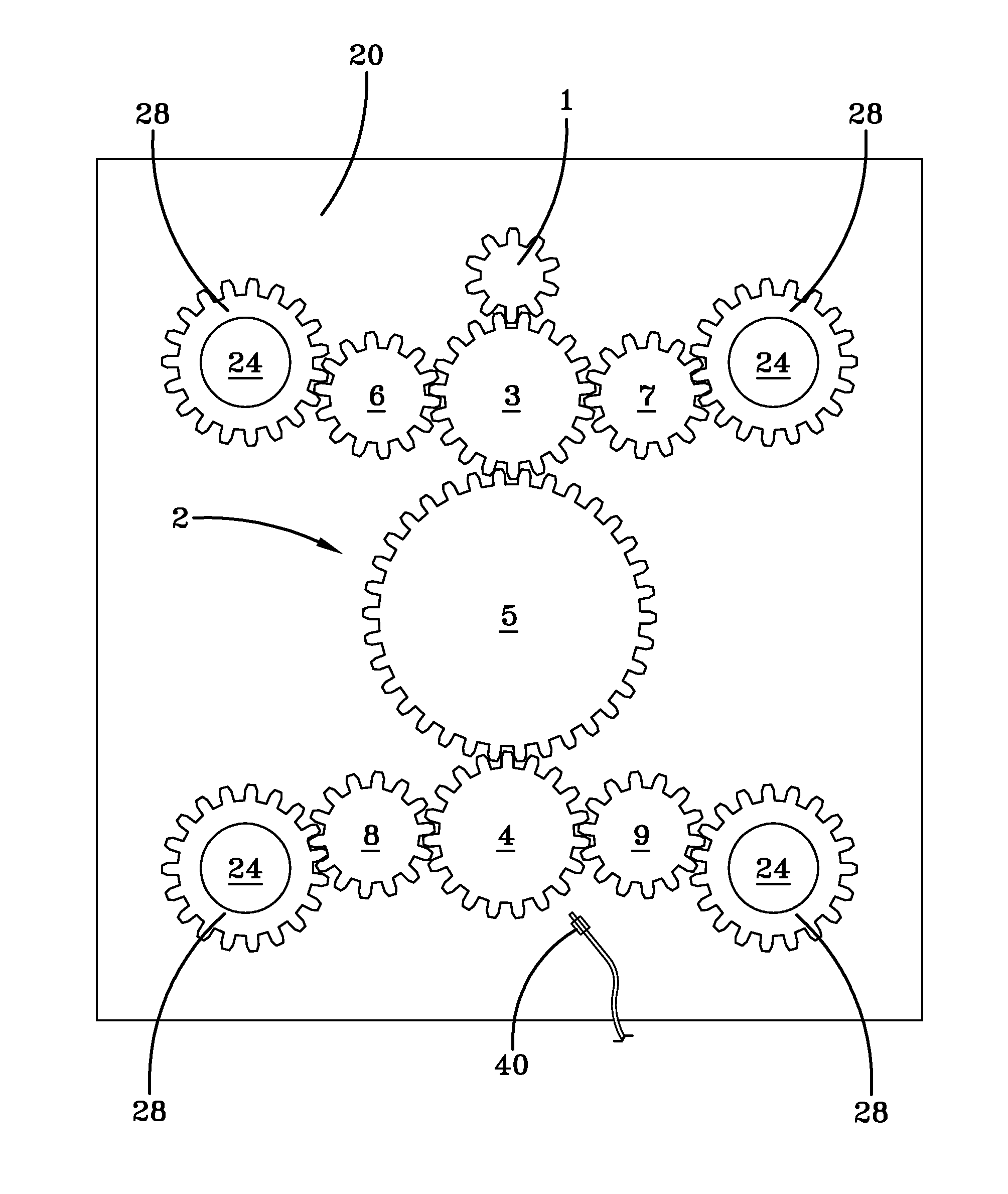

Measurement device for detecting the absolute angle of rotation of a rotating measurement object

ActiveCN103459984AReduce in quantityQuick Functional TestConverting sensor output electrically/magneticallyConverting sensor output mechanicallyMeasurement deviceAbsolute rotation

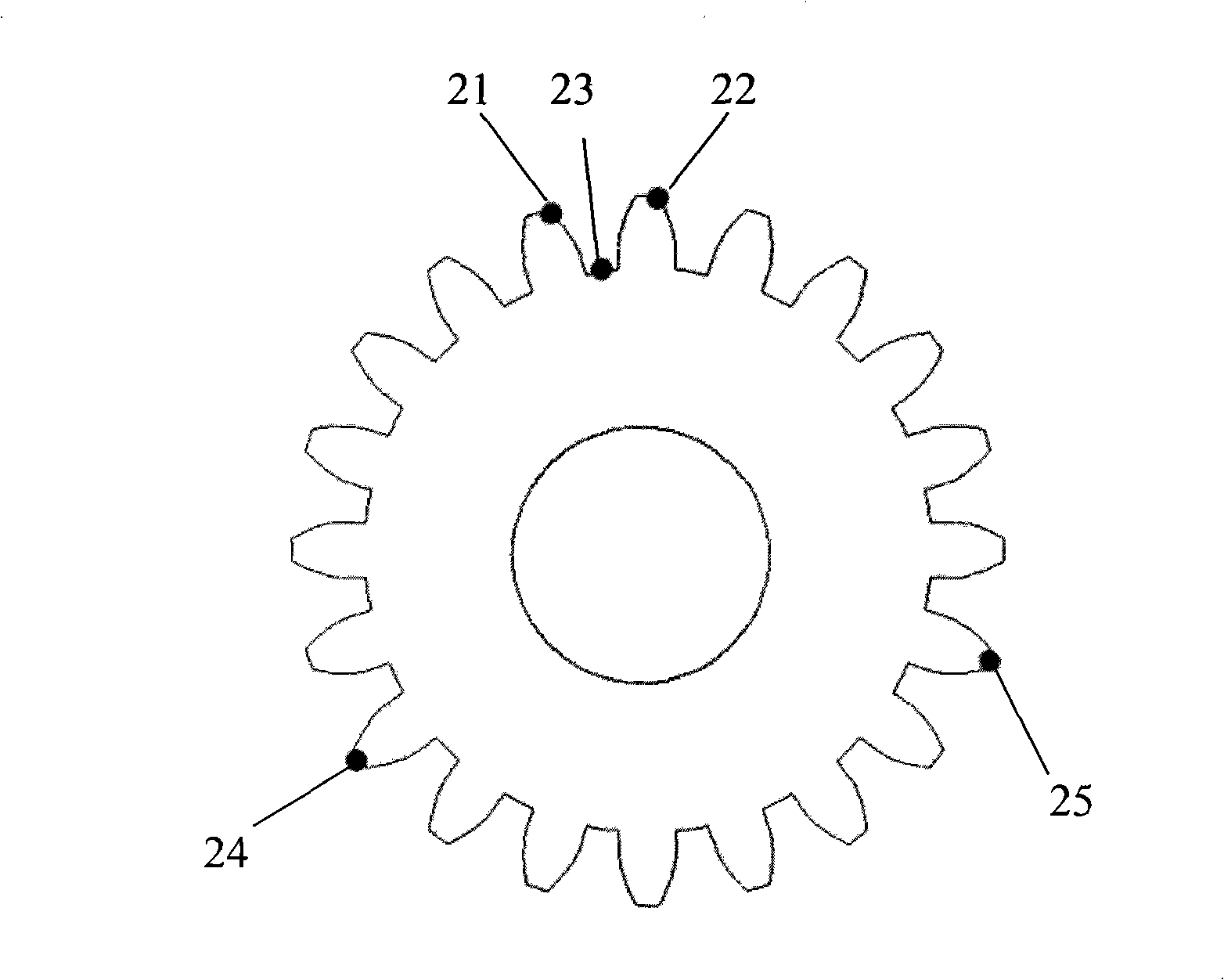

The invention relates to a measurement device (9) for detecting the absolute angle of rotation (f) of a rotating measurement object, wherein a first gear wheel (Z1) is allocated to the shaft (8) of the measurement object, wherein the first gear wheel (Z1) is engaged directly or indirectly with at least one second gear wheel (Z2) and a third gear wheel (Z3) and wherein the tooth counts (z1, z2, z3) of the individual gear wheels (Z1, Z2, Z3) are different from each other, wherein a rotation angle encoder (D1, D2, D3) is allocated to each gear wheel (Z1, Z2, Z3) which detects the angles of rotation (fz1, fz2, fz3) of the allocated gear wheels (Z1, Z2, Z3), wherein there is a computing unit which determines at least the difference (fz1 - fz2) in the angle of rotation of the second gear wheel (Z2) to the first gear wheel (Z1) and the difference (fz1 - fz2); in the angle of rotation of the third gear wheel (Z3) to the first gear wheel (Z1) and, based on a sum (SumDiff = (fz1 - fz2) + (fz1 - fz3)) of the differences (fz1 - fz2, fz1 - fz3) of the determined angles of rotation (fz1, fz2, fz3) of the gear wheels (Z1, Z2, Z3), determines the number of whole-number revolutions and the remaining angle of rotation (fz1) of the shaft of the measurement object.

Owner:AUMA RIESTER GMBH & CO KG

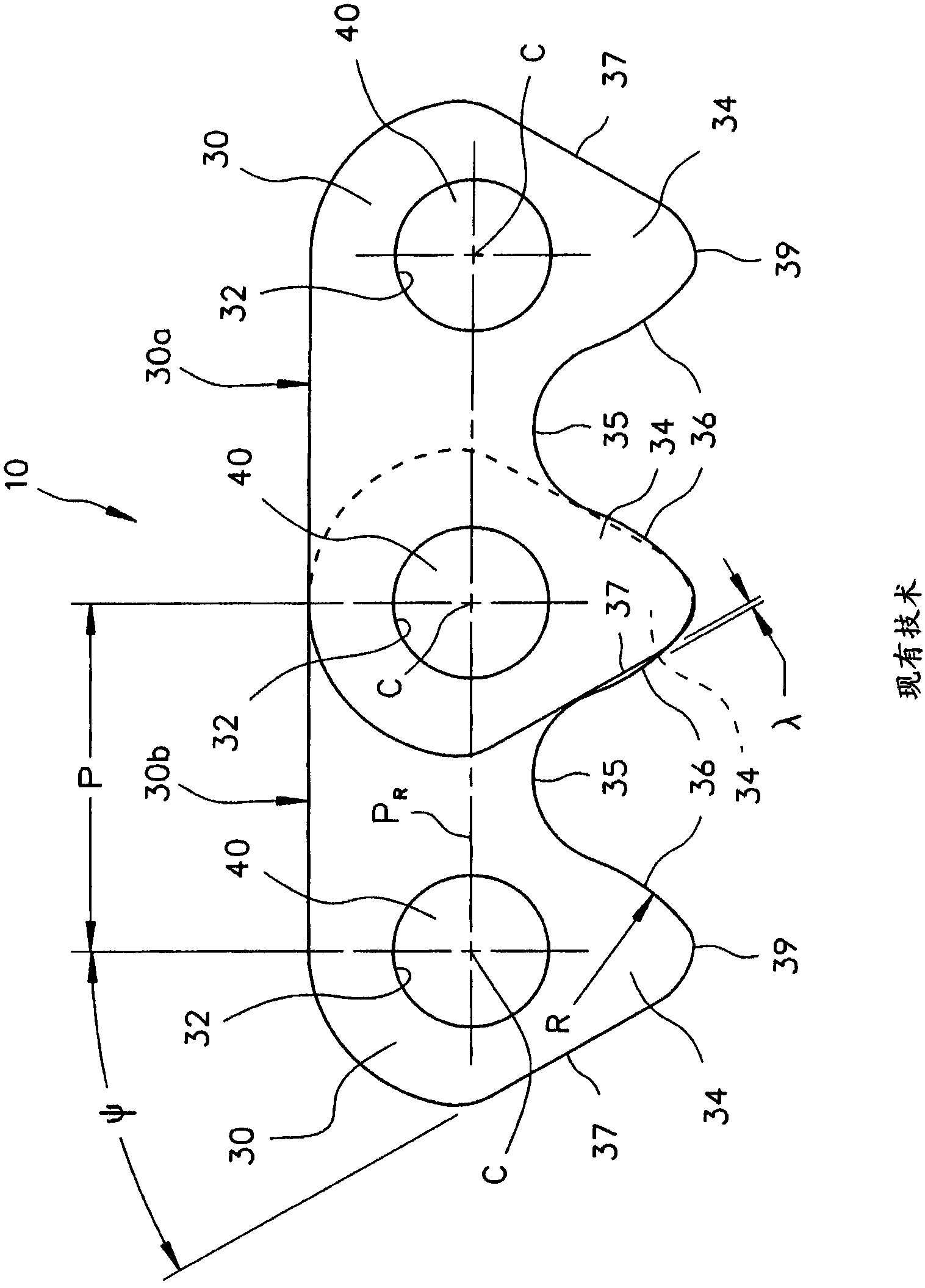

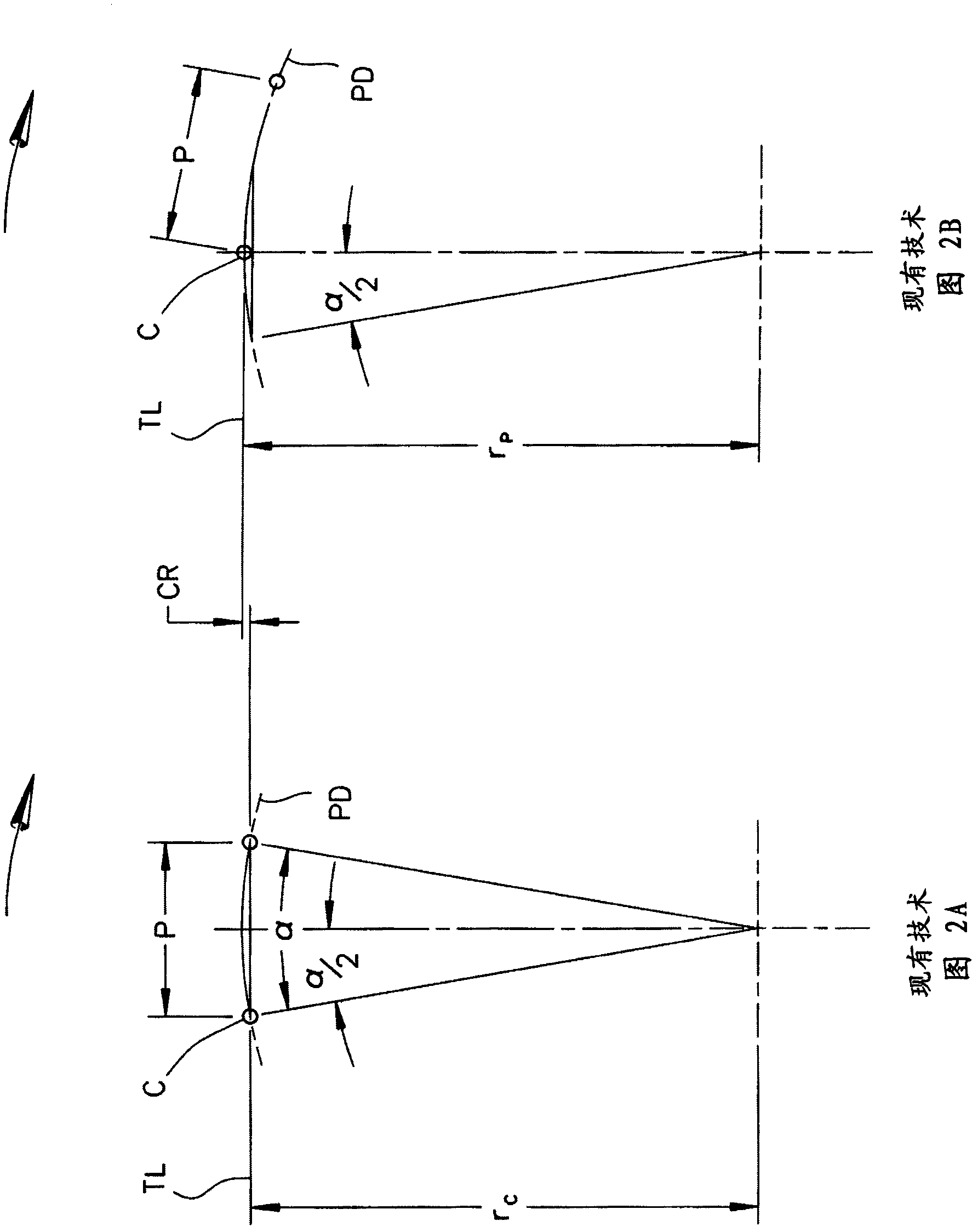

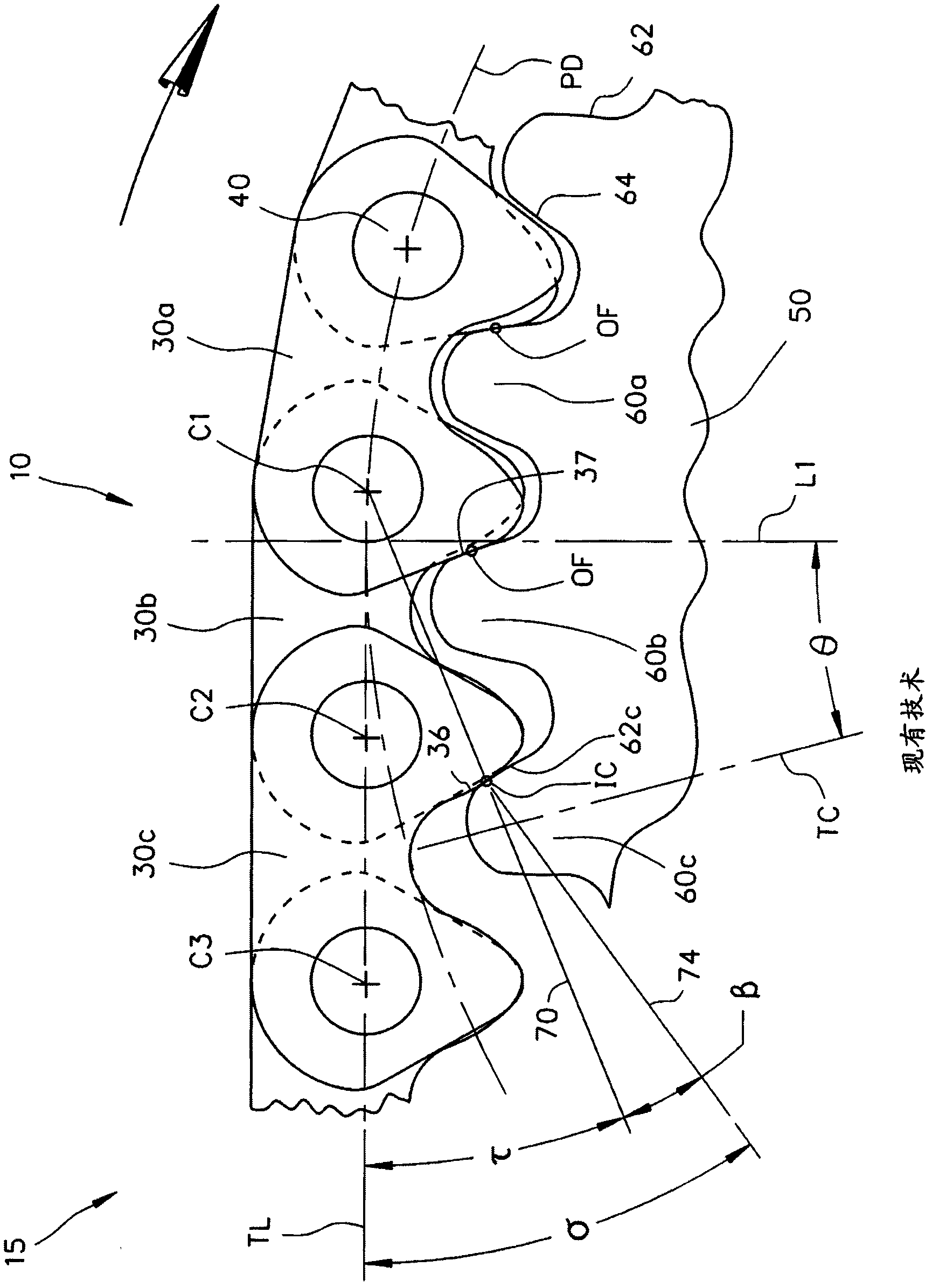

Inverted tooth chain and sprocket drive system with reduced meshing impact

An inverted tooth chain and sprocket drive system in which the initial contact distance ICD, the meshing impact angle Sigma (s), the link plate entrance angle Beta (ss), and other aspects of the meshing geometry are controlled and optimized to reduce noise and vibration by using a particular chain link plate form and, in preferred cases, by modifying the sprocket tooth pressure angle. The system can include first and second sprockets for which the pressure angle can be controlled to ensure that the desired values for the initial contact distance ICD, the meshing impact angle Sigma (s), and the link plate entrance angle Beta (ss) are equal for both sprockets even though the sprockets have different tooth counts. For a chain pitch P in the range of 6.35mm to 7.7mm, the initial contact distance IC0 is controlled such that 0.49P = IC0 = 0.53P, the meshing impact angle Sigma (s) is controlled such that s < 34 DEG , and the link plate entrance angle Beta (ss) is controlled such that ss = 9 DEG . For certain chain and sprocket configurations, s < 31 DEG and ss < 7 DEG .

Owner:CLOYES GEAR & PRODS INC

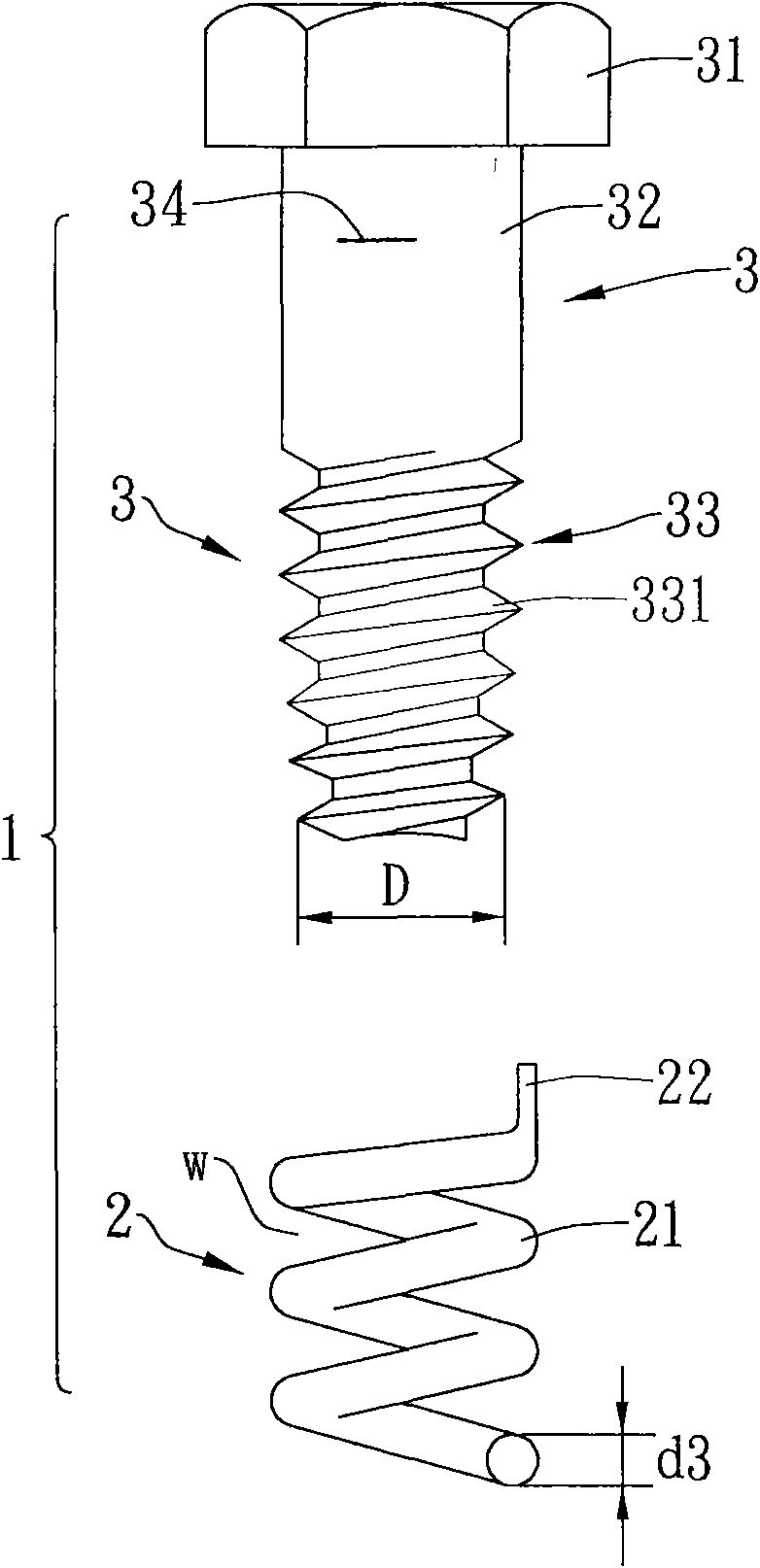

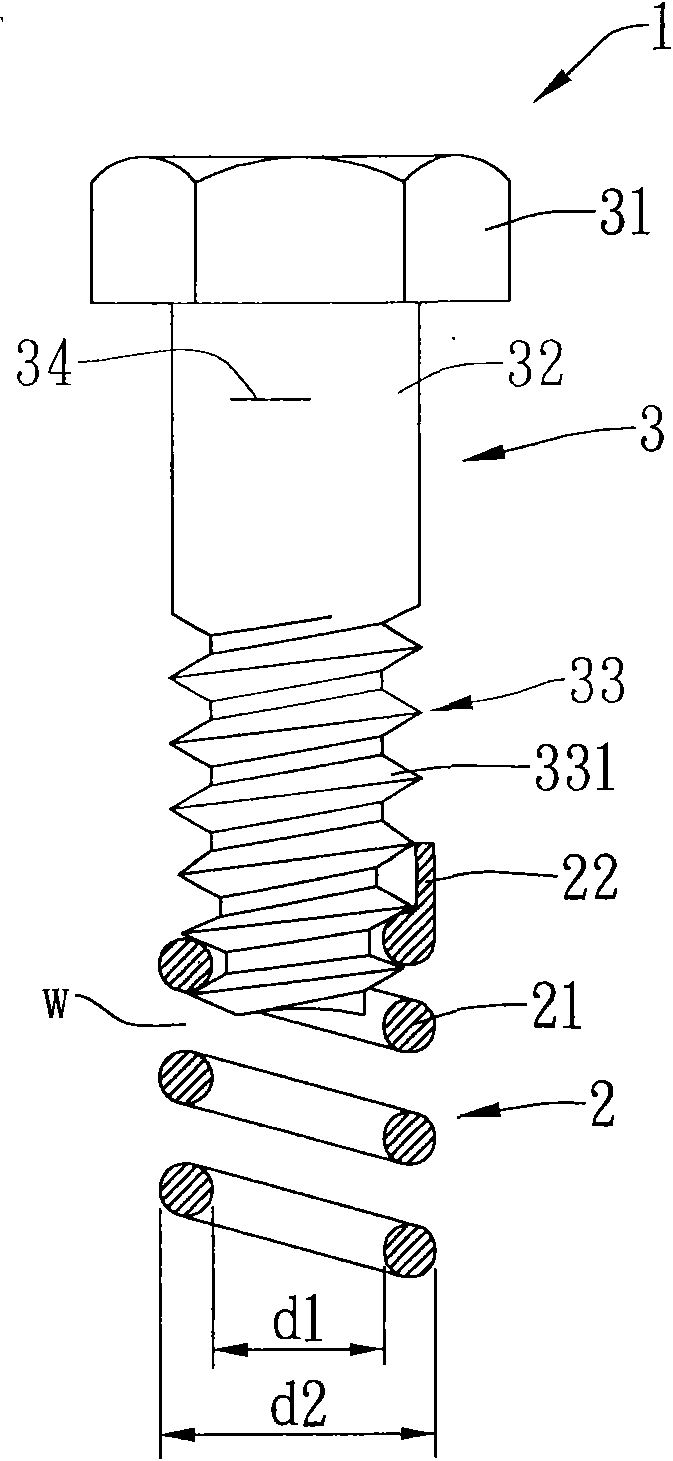

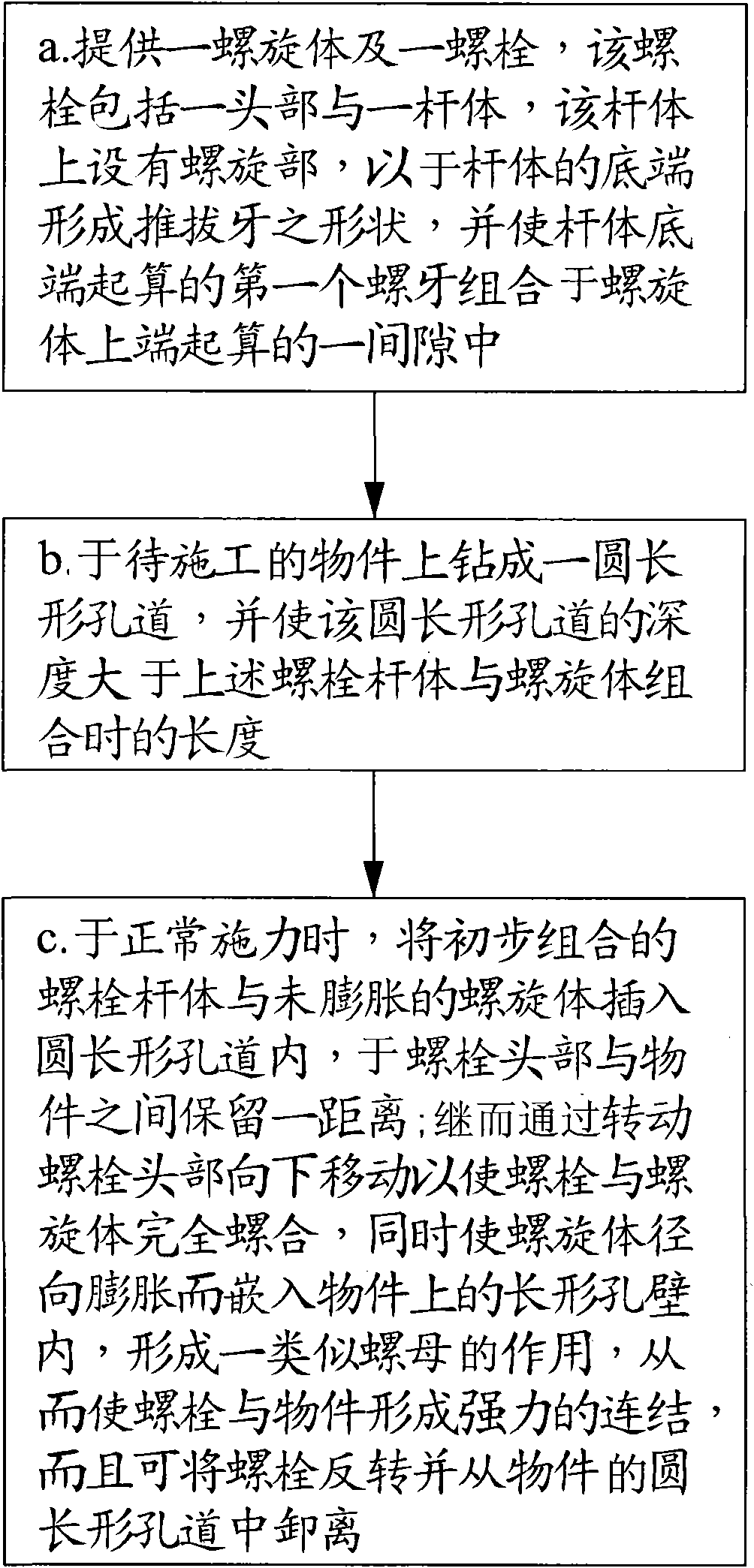

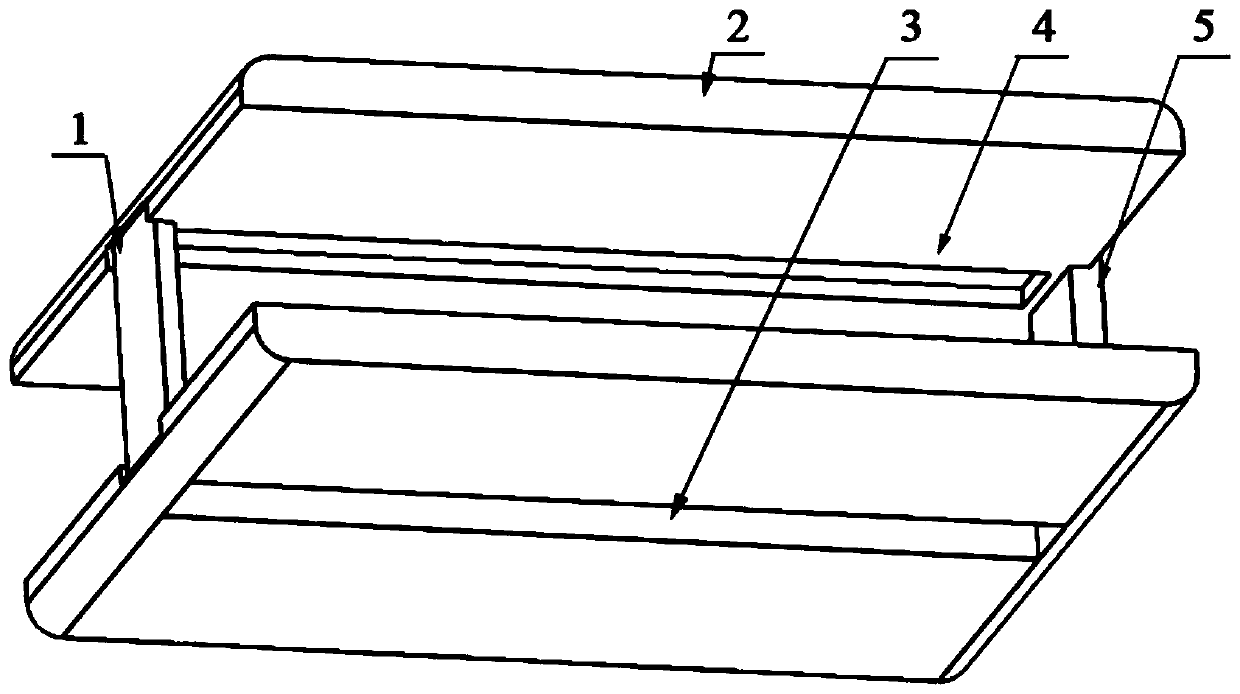

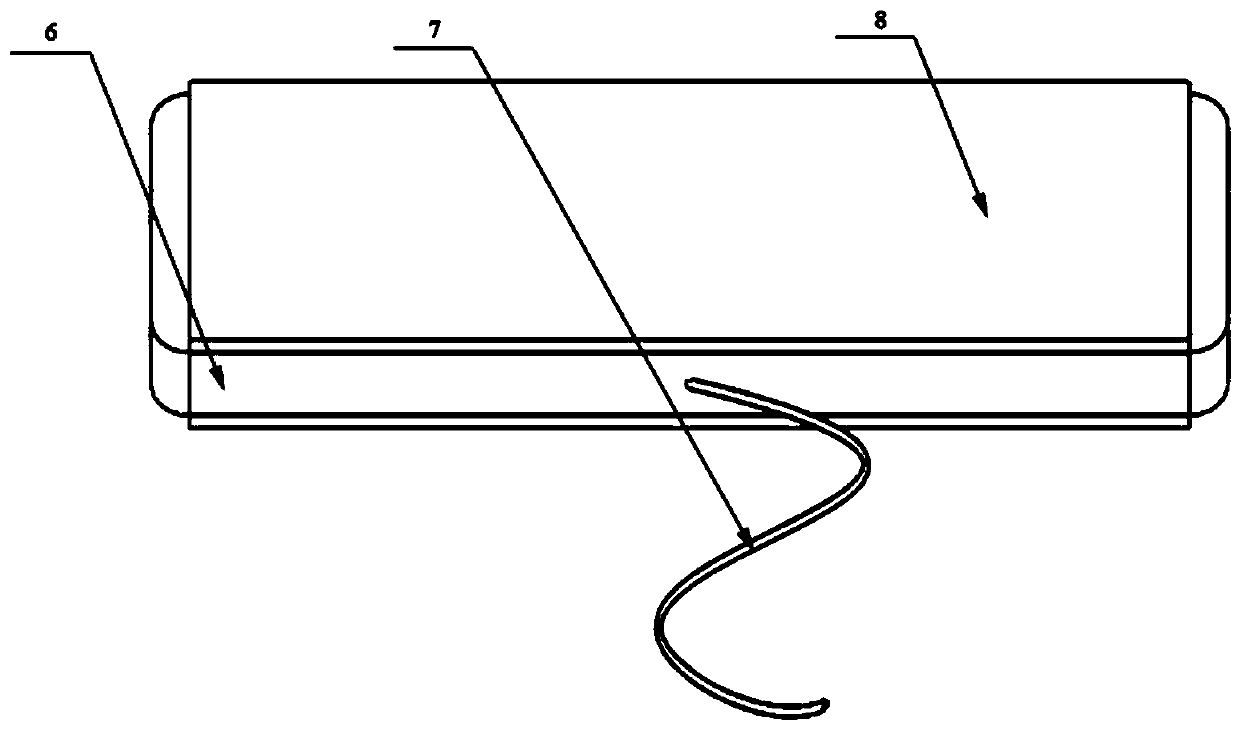

Improvement device for reusable expansion screw and mounting method thereof

The invention discloses an improvement device for a reusable expansion screw. The improvement device comprises a spiral body and a bolt, wherein the spiral body is formed by spirally coiling a strip wire body; the bolt comprises a head and a rod body; and the rod body is provided with a spiral part for forming a plurality of equal-pitch spiral teeth, the spiral teeth form a shape of taper thread at the bottom end of the rod body, and the maximum outside diameter of the first spiral tooth counted from the bottom end of the rod body is greater than the inside diameter of the spiral body. Therefore, in mounting steps, when the first spiral tooth is combined in a clearance of the spiral body, and after the rod body of the bolt and the spiral body are inserted into an object to be constructed at the same time by an operator to form a circular long pore canal with enough depth, the first spiral tooth with enough depth can be gradually screwed with the spiral body by means of rotating the head of the bolt no mater in a normal or abnormal use state so that the spiral body moves and expands relative to the bolt and then the bolt and the object form strong connection.

Owner:李宽弘 +1

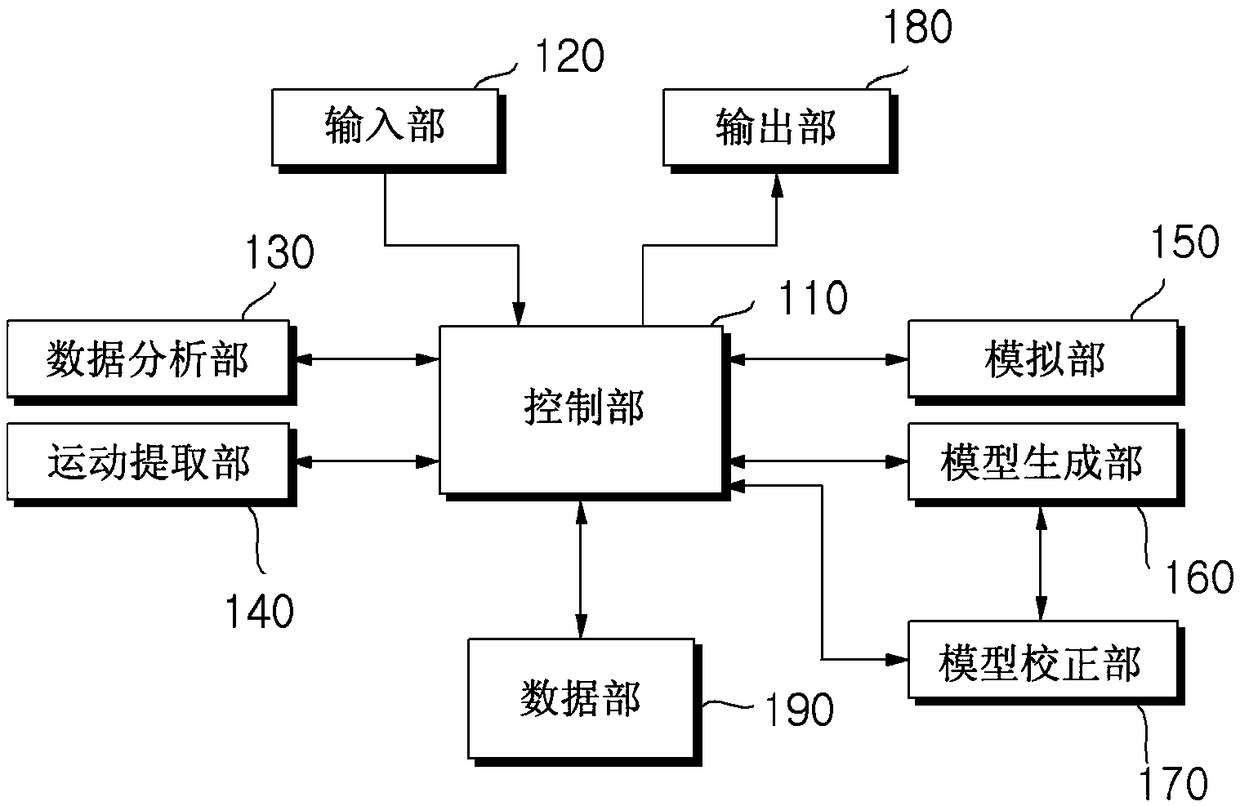

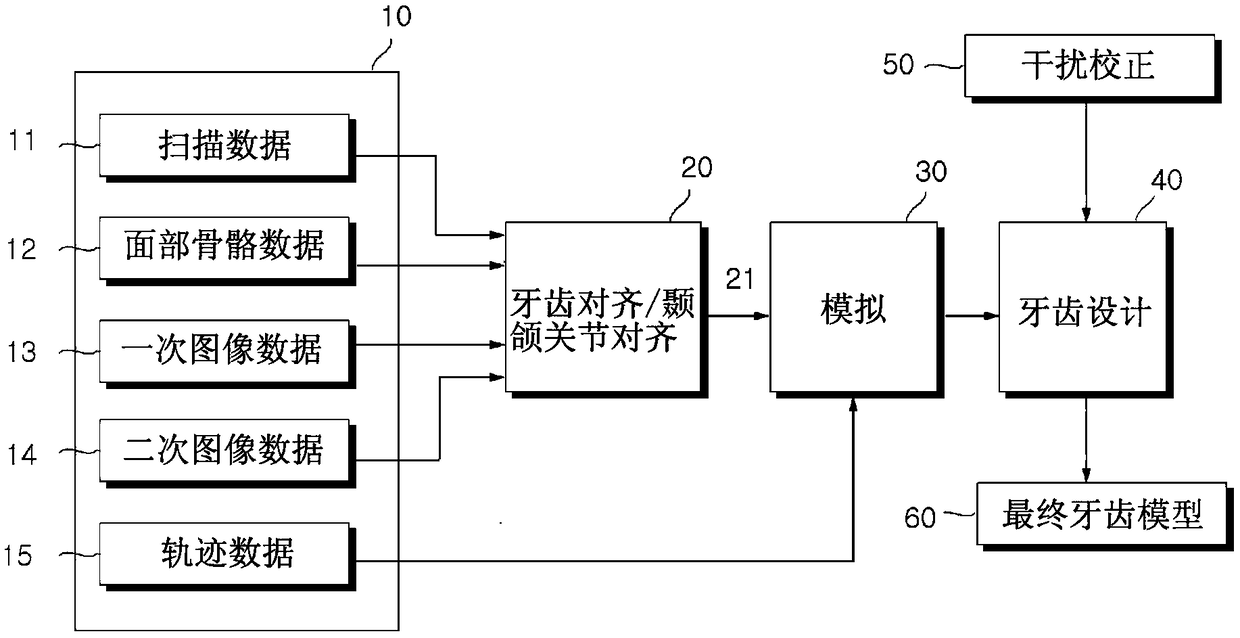

Dental three-dimensional data processing device and method thereof

ActiveCN109069097AAccurate and Sophisticated DiagnosisGood treatment effectMedical simulationImage enhancementTreatment effectCountermeasure

Owner:MEDIT CORP

Tooth biting force measuring device based on flexible materials

ActiveCN110652309AImprove applicabilityReliable measurementMuscle exercising devicesMuscular strength measurementBite force quotientTooth number

The invention discloses a tooth biting force measuring device based on flexible materials. The tooth biting force measuring device based on flexible materials comprises a flexible tooth sleeve of which openings at two ends are in the shape of an H, wherein the chewing surfaces of upper teeth and lower teeth can be separately embedded into the two openings of the tooth sleeve; a diaphragm is arranged between the two openings; grooves for accommodating the sharp ends of the teeth are formed in the positions which are in contact with the chewing surfaces of the upper teeth and the lower teeth, ofthe two side surfaces of the diaphragm; a micro pressure sensor which can sense the biting force of the upper teeth and the lower teeth is arranged in the diaphragm; and a pressure signal receiving and processing system is in communication connection to the micro pressure sensor. The tooth biting force measuring device based on flexible materials disclosed by the invention can be freely assembledin accordance with different crowds, different tooth types and measured tooth number, and has high applicability; during biting force measuring, the feeling of a human body can be similar to the realfeeling of chewing foods, so that the measuring is realer and more reliable; and the tooth biting force measuring device based on flexible materials is convenient to maintain, low in cost and can berepeatedly used.

Owner:SOUTHEAST UNIV

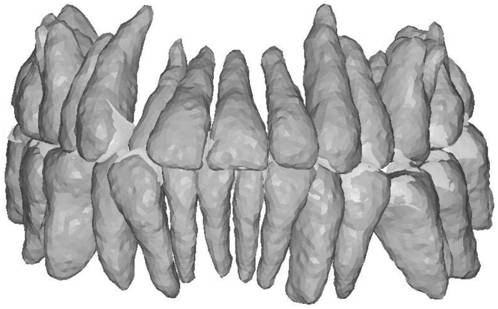

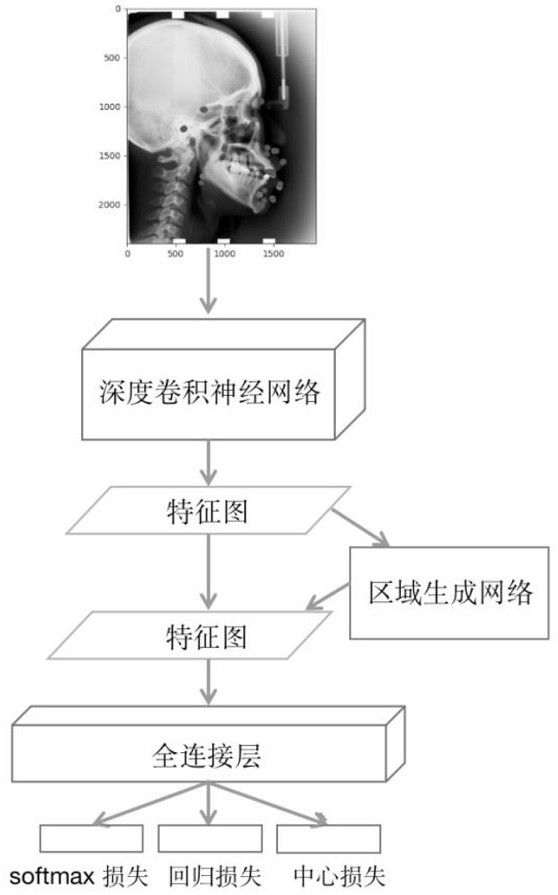

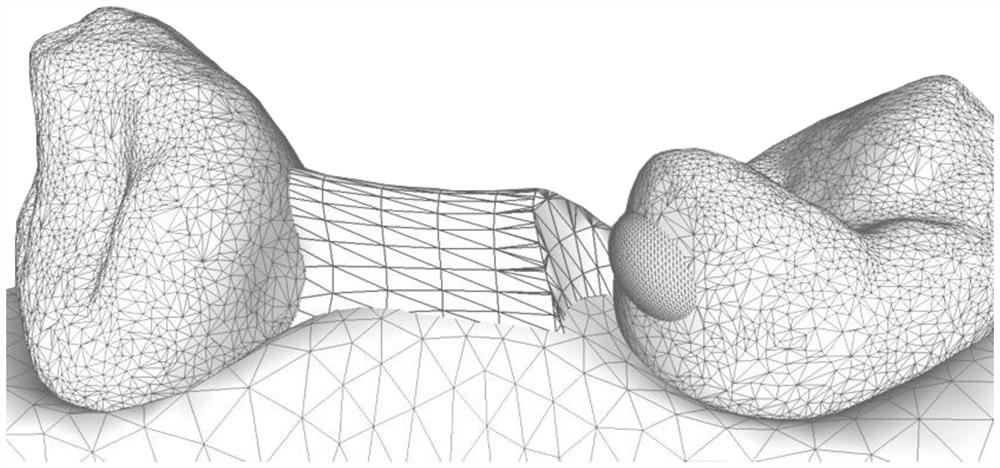

Method for automatically fusing oral scanning tooth data and CBCT data and application thereof

PendingCN114549540ASolve the shortcomings of low precisionHigh precisionImage enhancementImage analysisUpper teethTeeth counted

The invention relates to a method for automatically fusing oral scanning tooth data and CBCT data. The method comprises the following steps: S1, loading oral scanning grid data; s2, dividing the mouth scanning grid data; s3, loading the CBCT data; s4, CBCT data AI segmentation is carried out; s5, carrying out gridding generation on a CBCT data segmentation result; s6, registration of oral scanning dental crown data and CBCT gridding data is carried out; s7, coordinate position information of the registered CBCT upper teeth and the registered CBCT lower teeth is calculated, and new CBCT upper tooth and lower tooth grid data are generated; s8, matching the upper tooth crown with an association point set; s9, matching a lower tooth crown with an association point set; s10, carrying out CBCT grid data deformation; and S11, reconstruction optimization of the CBCT grid data is carried out. According to the automatic fusion method based on the oral scanning tooth data and the CBCT data, the advantages of high dental crown precision of the oral scanning data and complete tooth root form of the CBCT data can be integrated, the appearance form after the oral scanning dental crown and the CBCT teeth are integrally fused is obtained, clinical doctors can be well guided to carry out work, and the tooth treatment precision is improved.

Owner:BONDENT TECH

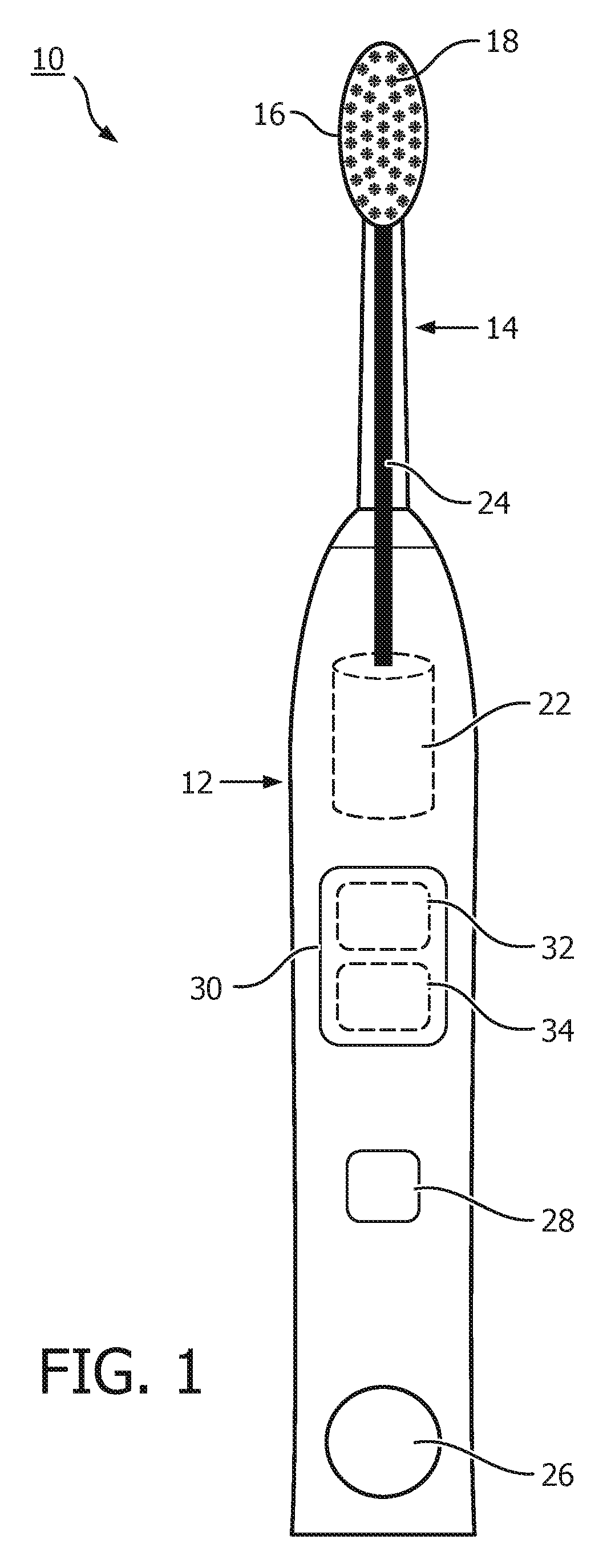

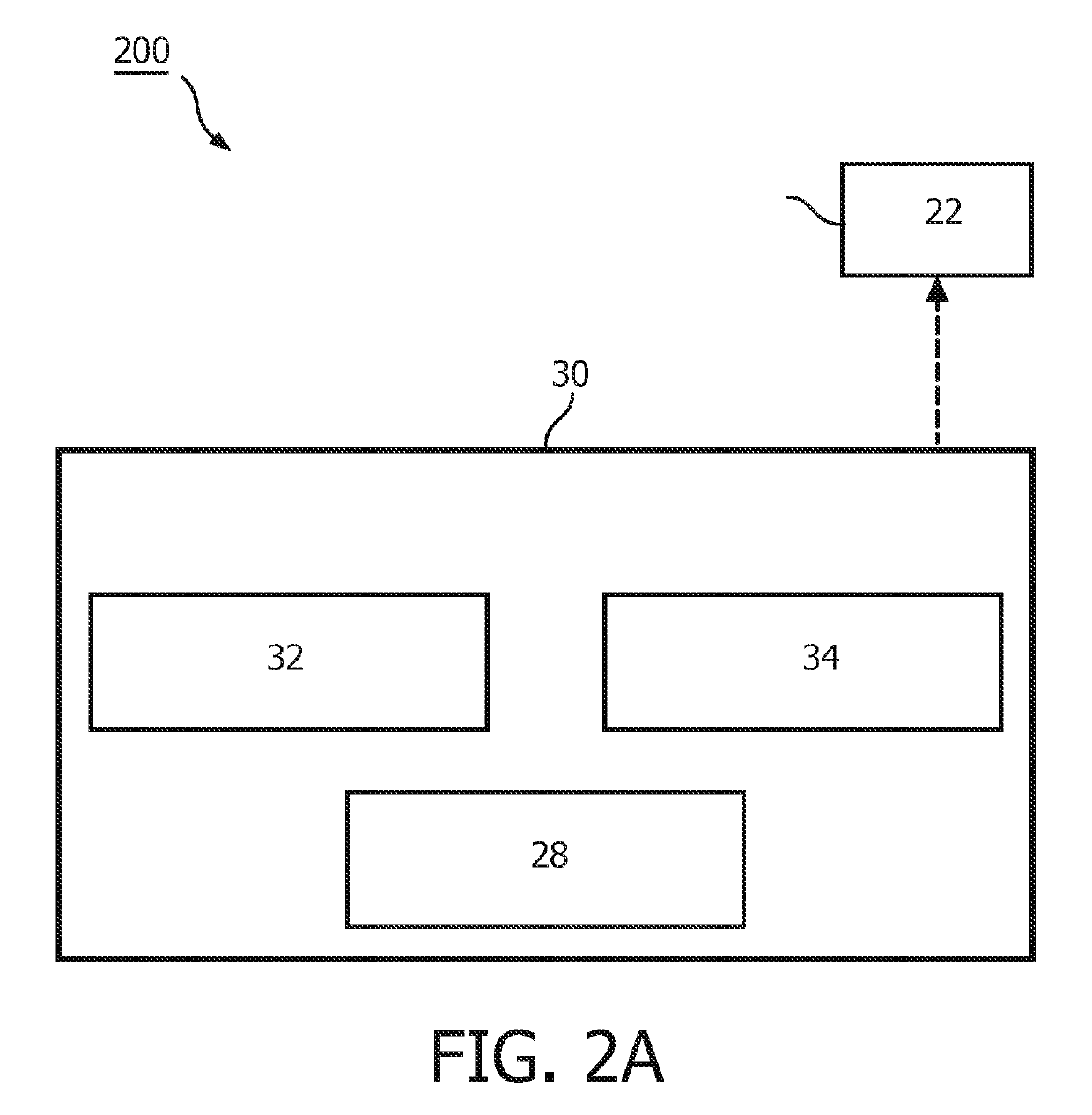

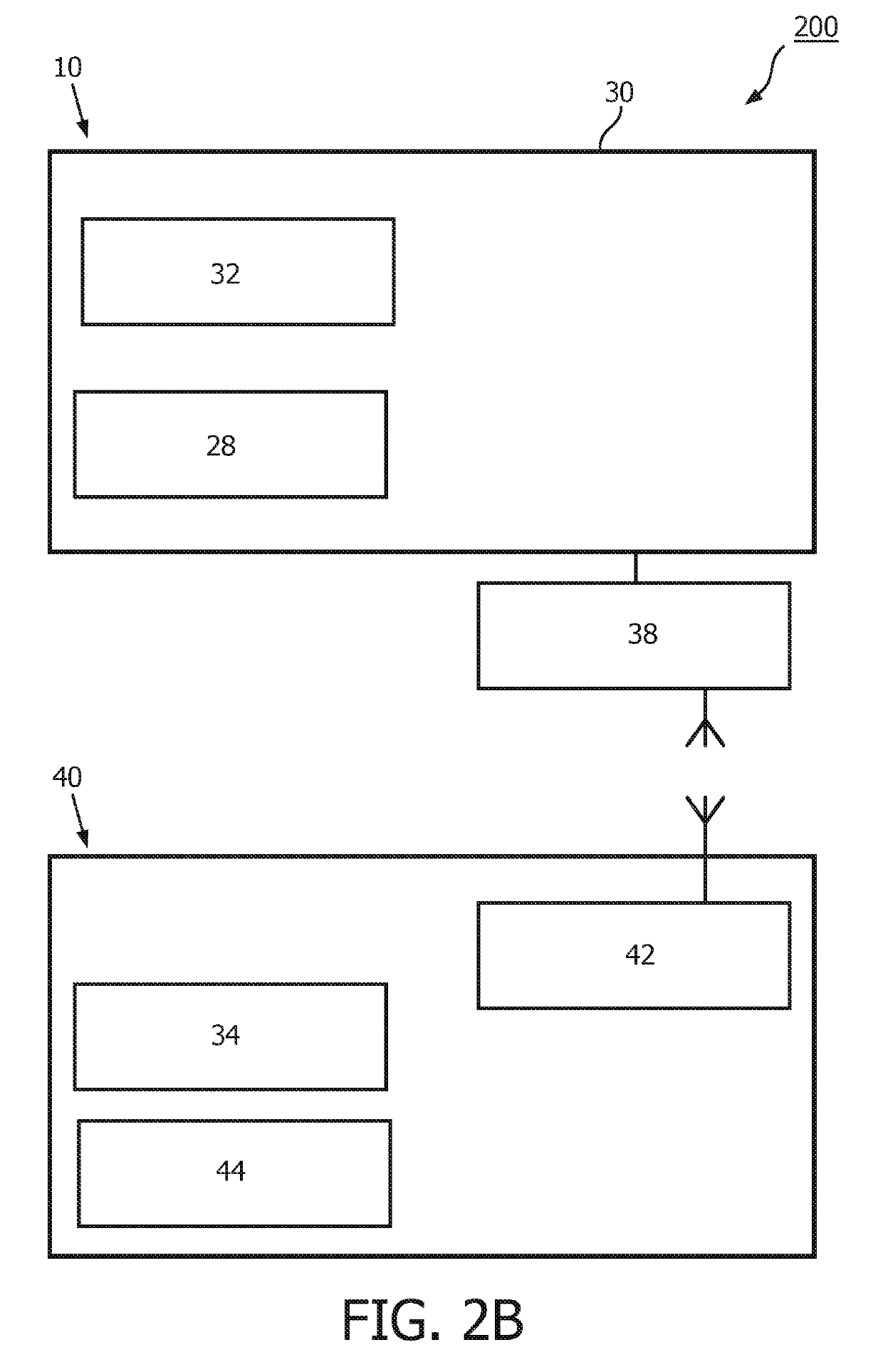

Methods and systems for oral cleaning device localization

Owner:KONINKLJIJKE PHILIPS NV

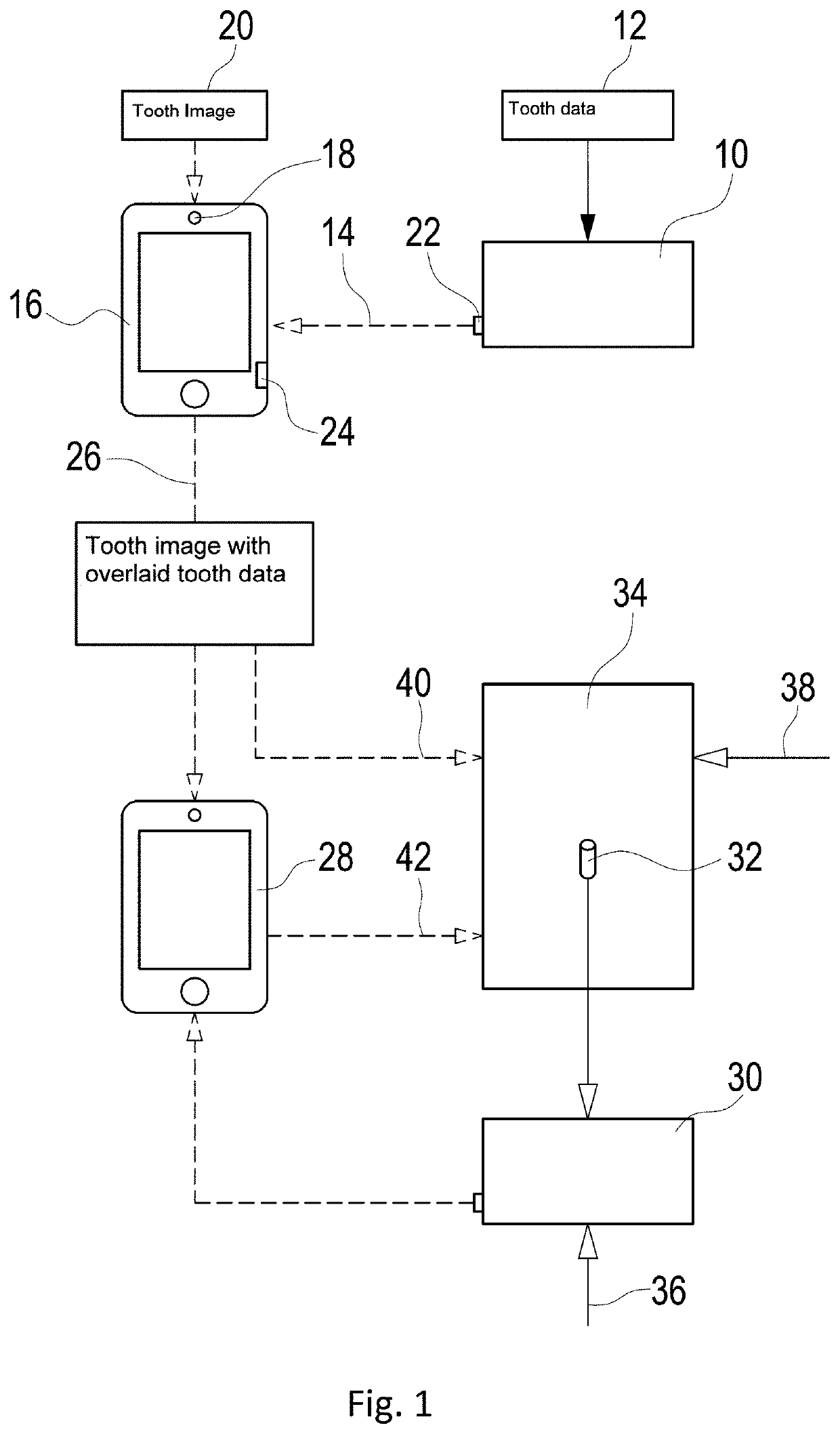

Support system for the manufacture of dental restorations, as well as dental restoration system

PendingUS20210007833A1Simple and reliable allocationEasy to operateImpression capsArtificial teethSupporting systemDisplay device

A support system for the manufacture of dental restorations comprises a measuring device which acquires the restoration tooth data of a dental restoration. The restoration tooth data acquired are transmitted to a data processing device connected with a measuring device. The data processing device comprises an analysis module that compares the restoration tooth data with previously determined target tooth data, i.e. patient tooth data. A display device that displays the comparison result is integrated in the data processing device.

Owner:VITA ZAHNFABRIK H RAUTER GMBH & CO KG

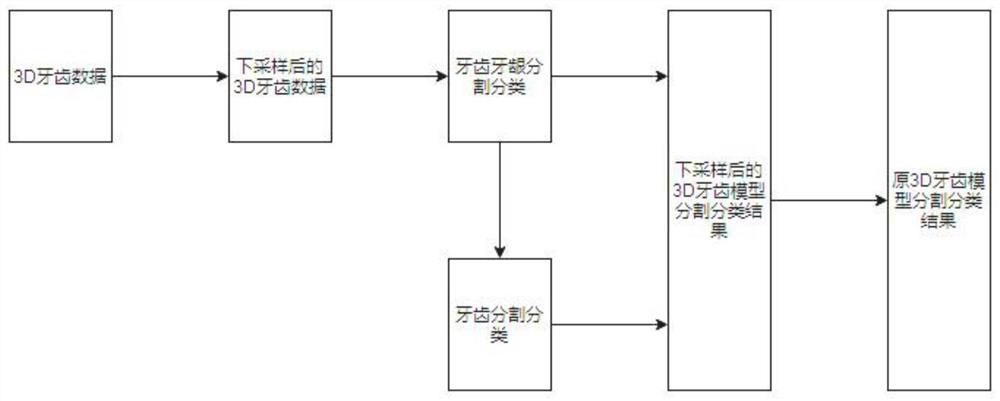

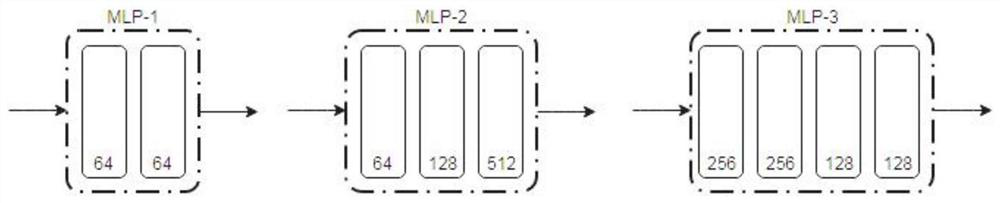

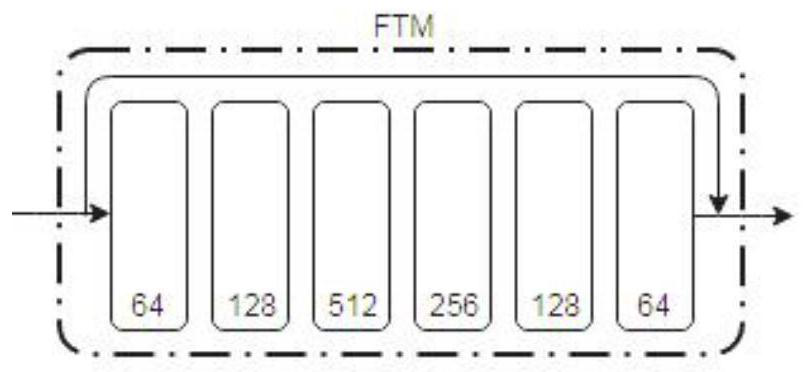

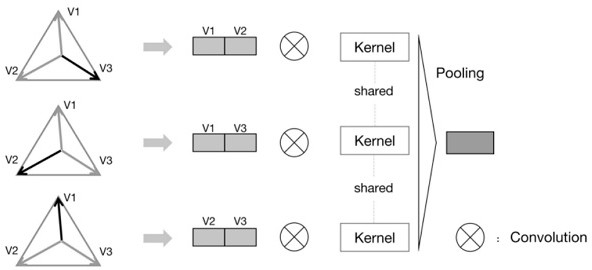

3D tooth segmentation and classification method based on deep learning

PendingCN113628222AAchieve the purpose of separating the target teethTo achieve the purpose of precise markingImage enhancementImage analysisClassification methodsData acquisition

The invention discloses a 3D tooth segmentation and classification method based on deep learning. A model framework used in the method is divided into four stages: stage 1: performing sample data acquisition and manufacturing; stage 2, building and training a deep network model based on two-segmentation between teeth and gingiva; stage 3, building and training a deep network model based on sixteen types of segmentation between teeth; and step 4, integrating results of the step 2 and the step 3. The invention is based on a deep convolutional network, and includes performing tooth and gingiva segmentation through a binary classification task, so that the purpose of separating target teeth is achieved; performing sixteen types of tooth interior segmentation tasks on the teeth; due to the difference of the number of patches between single teeth, performing deep learning model training by using different loss weights; performing post-processing by combining tooth and gingiva results and applying a graph cut algorithm; and finally, upsampling original 3D tooth data by using a support vector machine algorithm so as to achieve the purpose of accurately marking actual 3D teeth.

Owner:杭州隐捷适生物科技有限公司

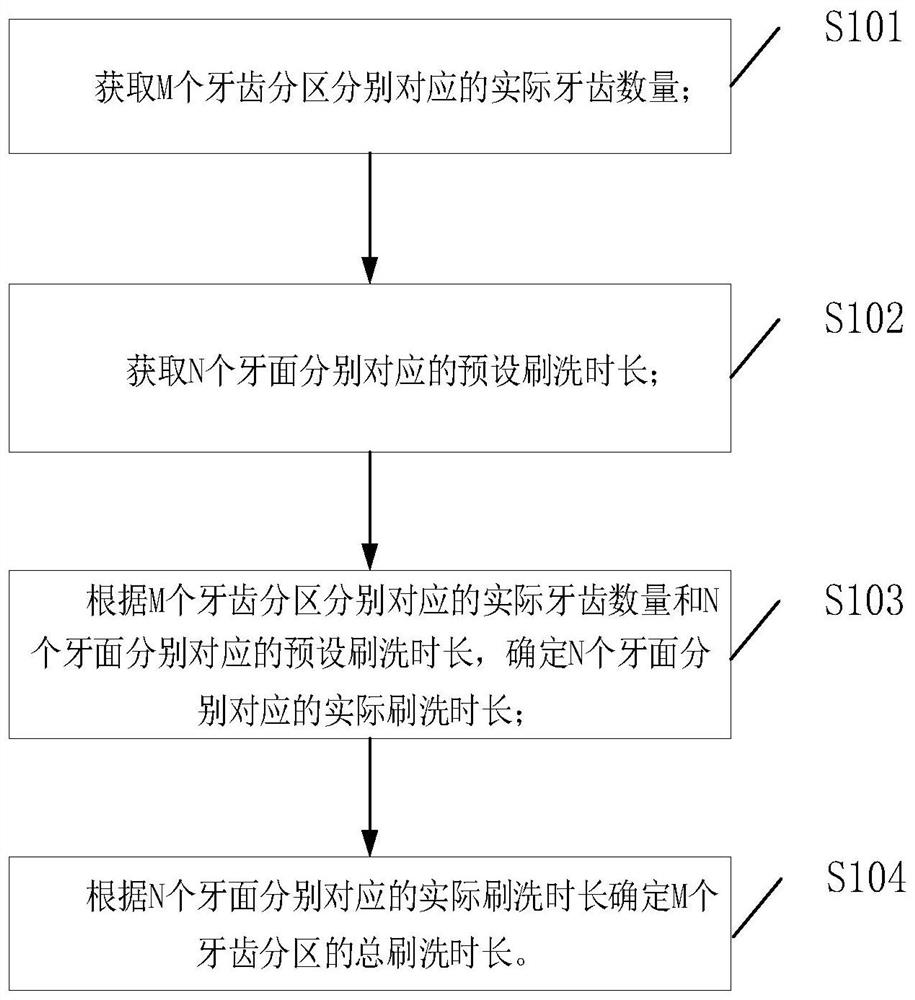

Data processing method and device for adjusting brushing duration

InactiveCN112541277AFlexible adjustmentSolve the problem that the brushing time cannot be effectively controlled according to the number of teethDesign optimisation/simulationSpecial data processing applicationsTeeth countedTooth number

The invention provides a data processing method for adjusting brushing duration, which is used for realizing intelligent dynamic adjustment of brushing duration of tooth partitions, and is characterized in that each tooth partition comprises M tooth partitions, each tooth partition comprises at least one tooth surface, the M tooth partitions comprise N tooth surfaces in total, and M and N are integers. The method comprises the following steps: acquiring actual tooth numbers respectively corresponding to M tooth partitions, acquiring preset brushing durations respectively corresponding to the Ntooth surfaces, according to the actual tooth number corresponding to the M tooth partitions and the preset brushing duration corresponding to the N tooth surfaces, determining the actual brushing duration corresponding to the N tooth surfaces, and determining the total brushing duration of the M tooth partitions according to the actual brushing durations corresponding to the N tooth surfaces respectively. On the basis of the number of teeth, flexible adjustment of the tooth brushing time is achieved, and damage to the teeth due to the fact that the tooth brushing time is too long under the condition that the oral cavity lacks teeth is avoided.

Owner:SHENZHEN LEBOND TECH CO LTD

Coaxially arranged reduction gear assembly

ActiveUS8827855B2High rotation accuracyReduced Power RequirementsToothed gearingsRotational axisTeeth count

A reduction gear assembly integrates a stationary section having a stationary internal gear configuration, an output section having an output internal gear configuration, an input shaft and planetary carrier comprising an input shaft having a shaft rotational axis and a planetary gear cam having a planetary gear rotational axis, wherein the shaft axis and cam axis are offset. A planetary gear comprising a planet wheel first stage and a planet wheel second stage is rotationally assembled to the planetary gear cam. The first stage planet wheel engages with the stationary gear. The second stage planet wheel engages with the output gear. Rotation of the input shaft rotates the planetary gear about a circular path. Engagement between the first stage and the stationary gear rotates the planetary gear. Second stage teeth engage with the output gear. Difference in first stage and second stage teeth counts causes rotation of the output section.

Owner:AB SKF

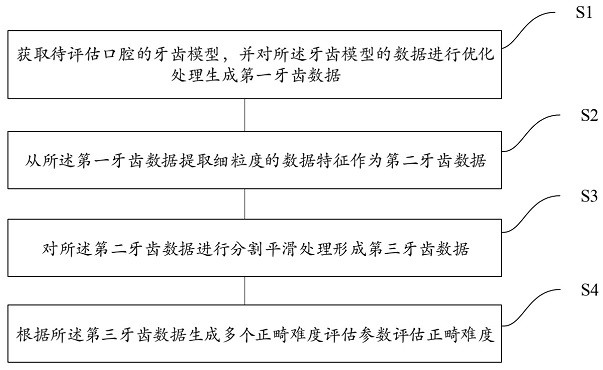

An automatic orthodontic difficulty coefficient evaluation method

ActiveCN114463328BImprove accuracyFacilitate large-scale promotion and applicationImage enhancementImage analysisTeeth countedBiomedical engineering

The invention discloses an automatic orthodontic difficulty coefficient evaluation method, comprising: obtaining a tooth model of the oral cavity to be evaluated, and optimizing the data of the tooth model to generate first tooth data; extracting details from the first tooth data The data features of the granularity are used as the second tooth data; the second tooth data is segmented and smoothed to form the third tooth data; a plurality of orthodontic difficulty evaluation parameters are generated according to the third tooth data to evaluate the orthodontic difficulty. The automatic orthodontic difficulty coefficient evaluation method of the present invention fully digitally and automatically processes the orthodontic difficulty coefficient evaluation, effectively improves the accuracy of the orthodontic difficulty evaluation, does not rely on the experience judgment of doctors, and is conducive to large-scale popularization and application.

Owner:SICHUAN UNIV

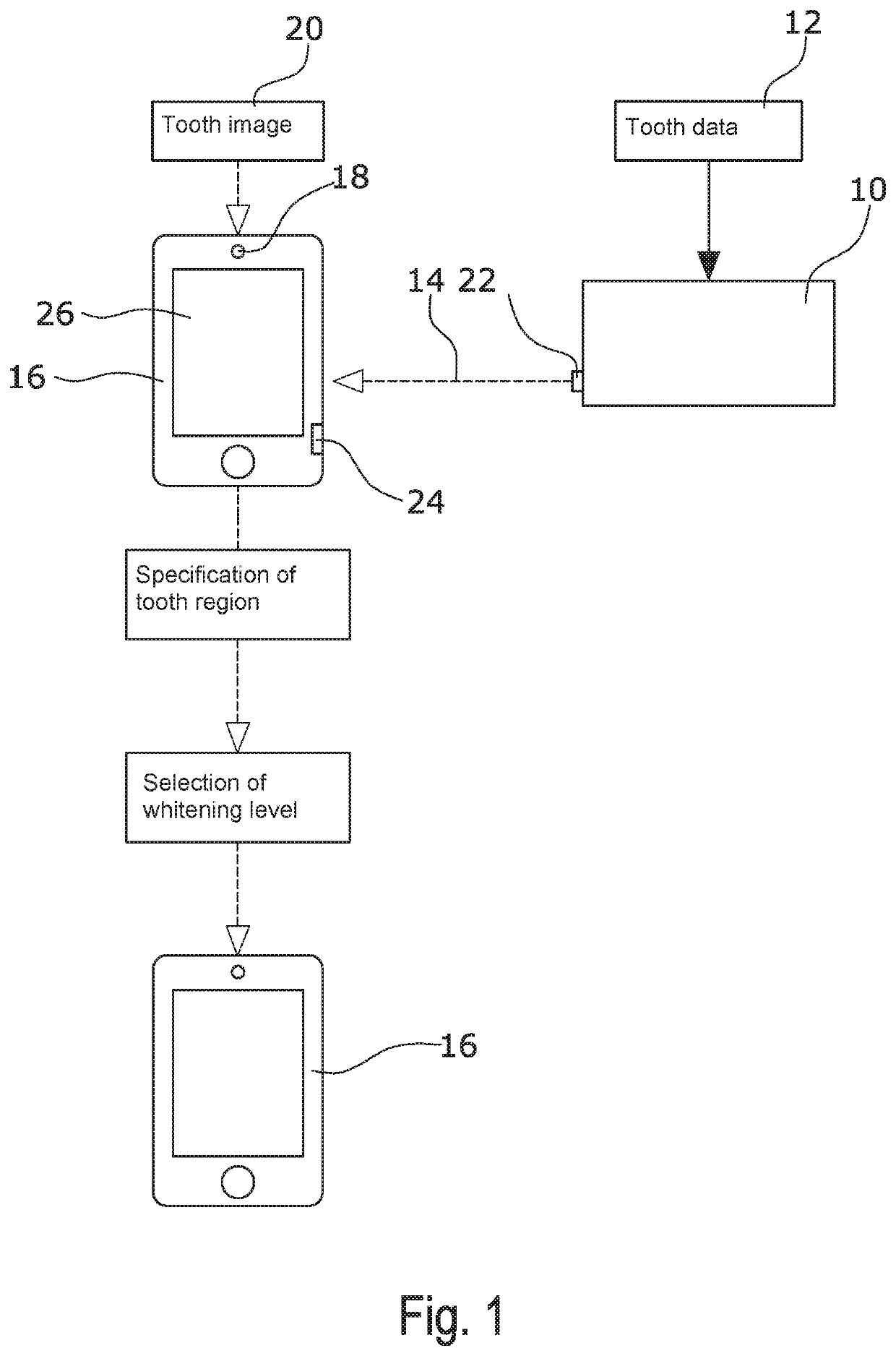

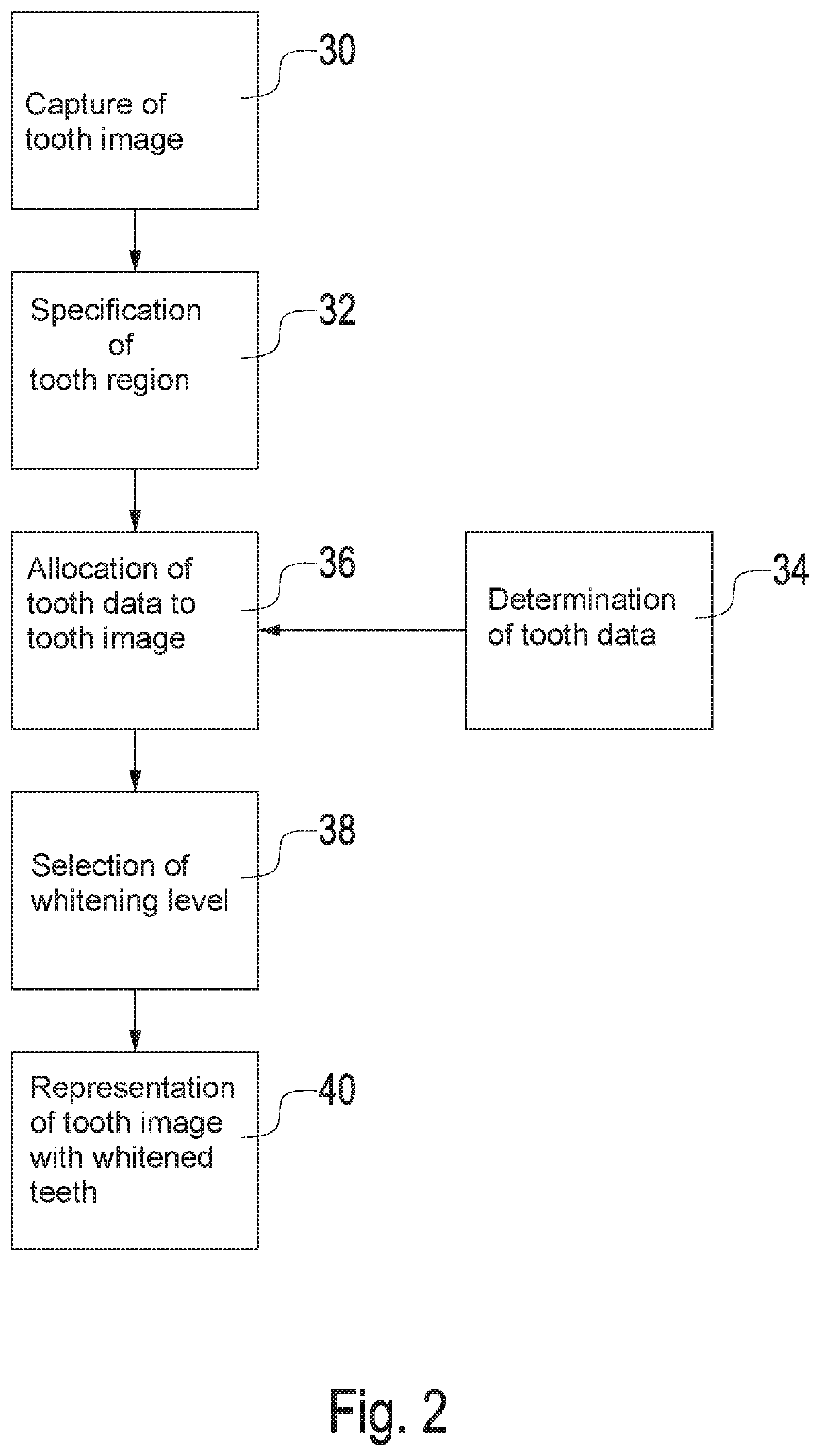

Assistance system for dental treatment, in particular by changing a tooth color

An assistance system for dental treatment, particularly for changing tooth color, is provided herein, including a measuring device for determining tooth data. The data captured is transmitted from the measuring device to a data processing means. The data processing means includes a camera for capturing a tooth mage. Using a selection means, a color change level for the tooth image or the teeth is specified and, thereafter, the tooth image is adapted based on the selected color change level using an adaptation means. Thus, it is possible to show the patient an image of a color change of his teeth caused by the dental treatment in relation to the appearance of his face, so the patient can judge a color change in relation to his or her face.

Owner:VITA ZAHNFABRIK H RAUTER GMBH & CO KG

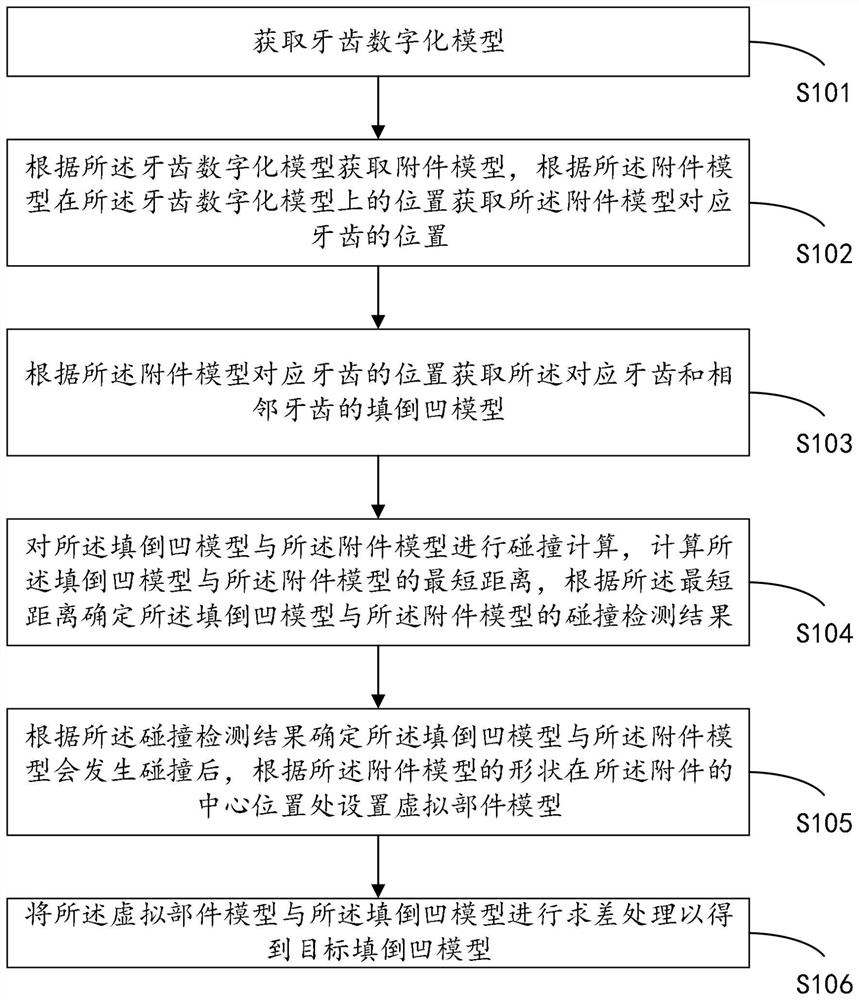

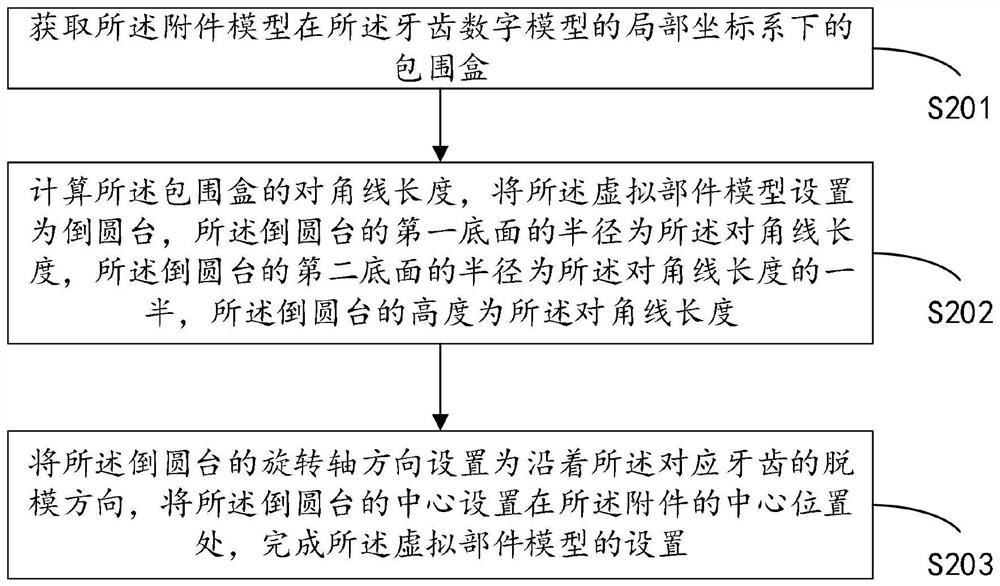

Accessory avoiding method and device for filling undercut of tooth digital model, medium and equipment

The invention provides an accessory avoiding method and device for filling an undercut of a tooth digital model, a medium and equipment. The method comprises the following steps: acquiring the tooth digital model; acquiring an accessory model and an undercut filling model of adjacent teeth according to the digital tooth model; performing collision calculation on the undercut filling model and the accessory model, calculating the shortest distance between the undercut filling model and the accessory model, and determining a collision detection result of the undercut filling model and the accessory model according to the shortest distance; after it is determined that the undercut filling model and the accessory model will collide according to the collision detection result, a virtual part model is arranged at the center position of the accessory according to the shape of the accessory model; and carrying out differencing processing on the virtual part model and the undercut filling model to obtain a target undercut filling model. According to the method, accessories can be automatically avoided in the process of generating the undercut filling grid, and the cost of manual repair is reduced.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

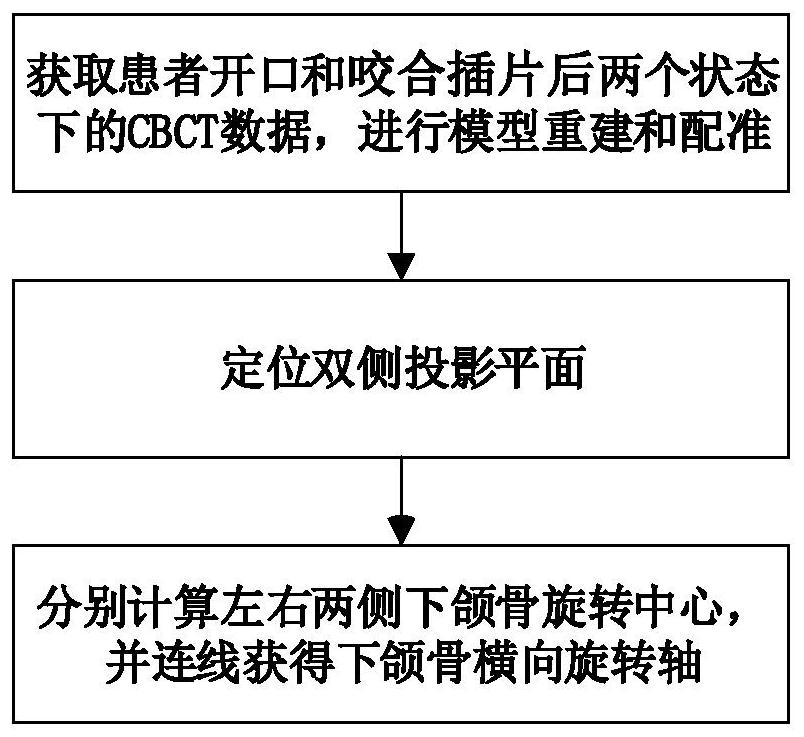

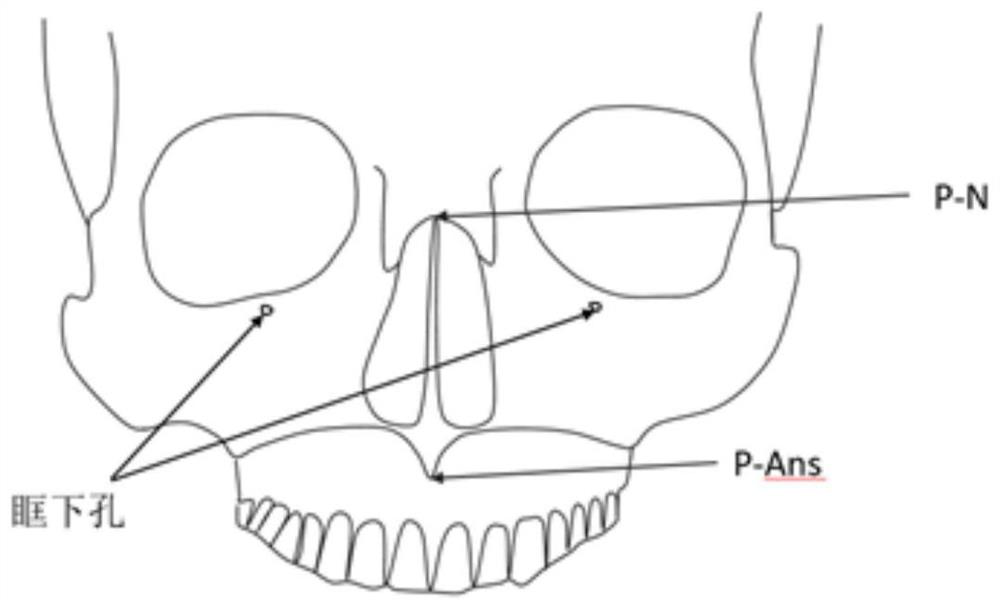

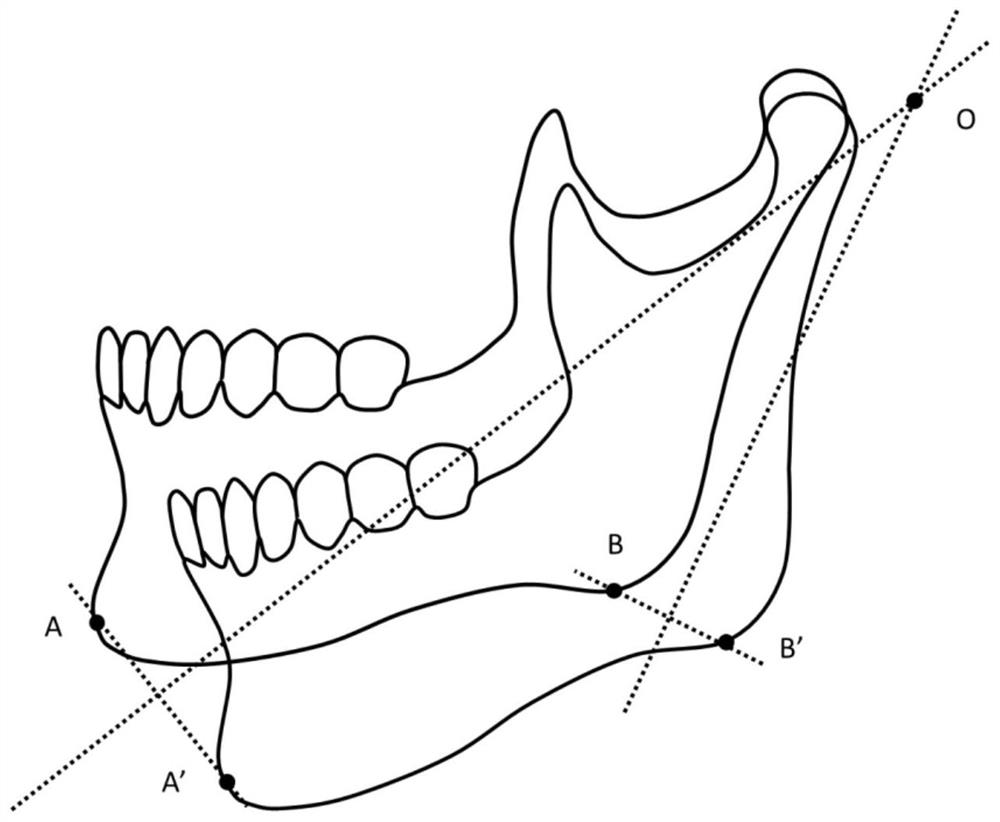

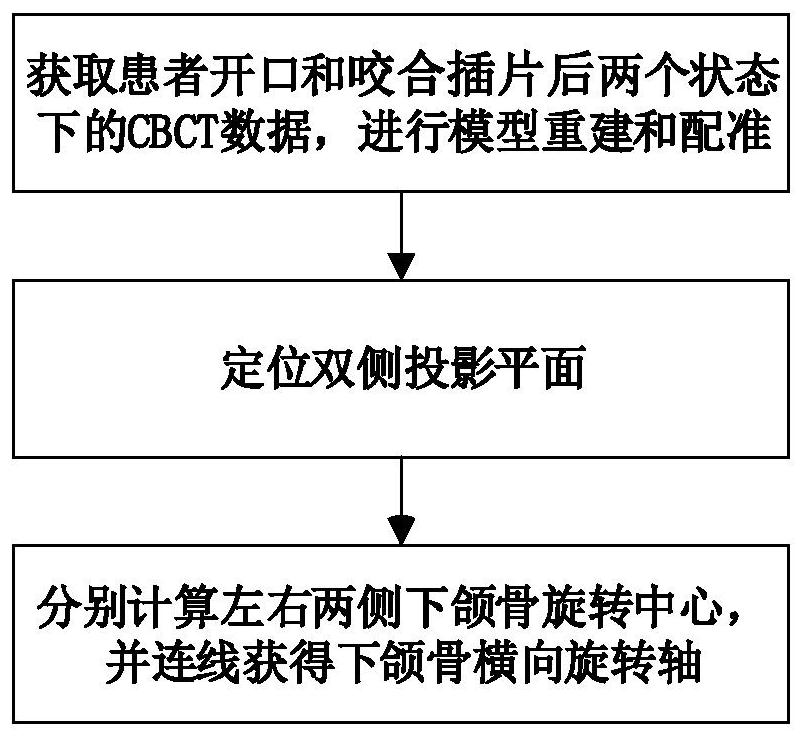

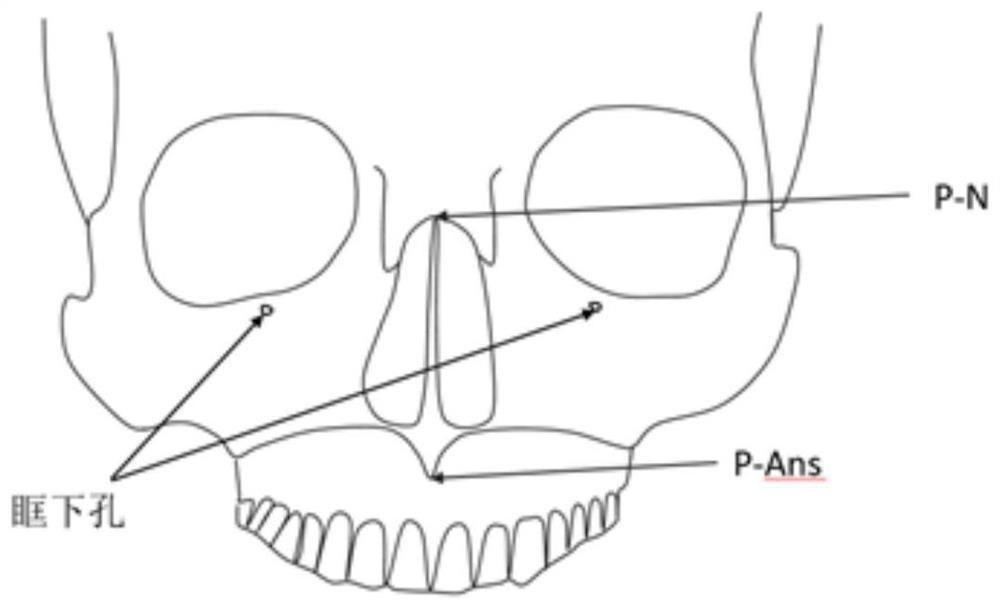

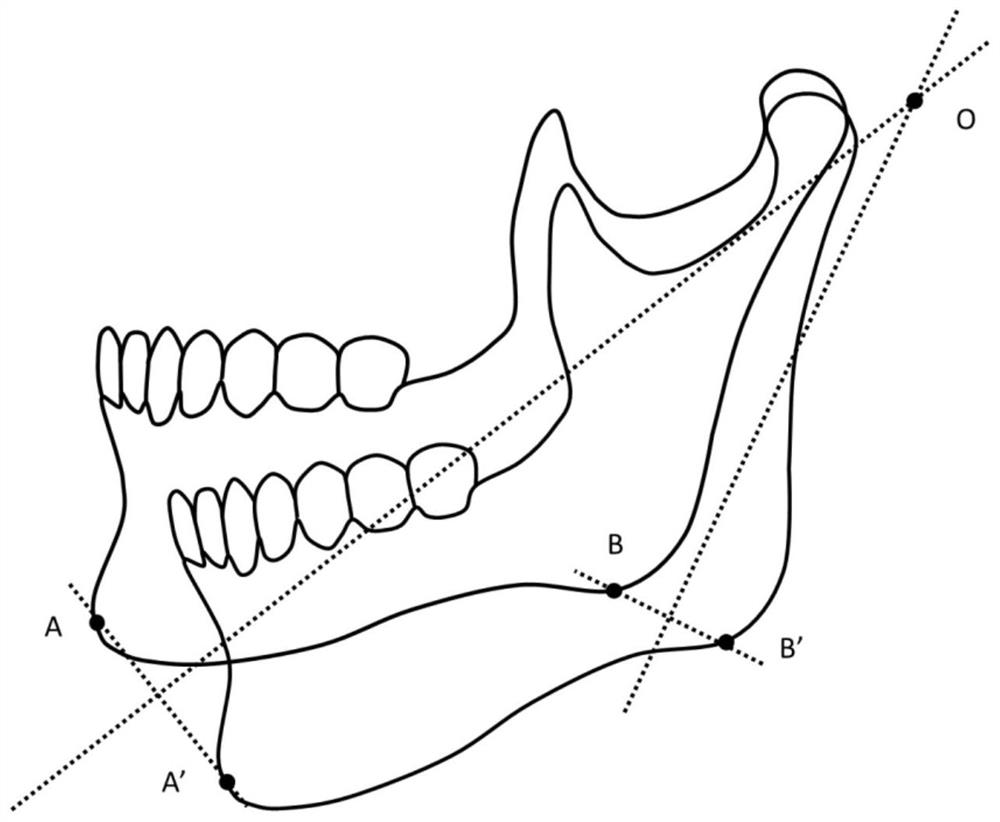

Transverse rotation axis positioning and extracting method for lower jawbone CBCT data

The invention discloses a transverse rotation axis positioning and extracting method for lower jawbone CBCT data. The method comprises the steps that CBCT data of a patient in a closed state and CBCTdata of the patient in a state after occlusion and insertion are collected, and CBCT data of the patient in an open state and CBCT data of the patient in a closed state are obtained; registration operation is conducted on the closed CBCT data of the patient in the closed state and the open CBCT data of the patient in the state after occlusion and insertion; projection planes on the two sides are positioned; and the rotation centers of movement of the left jawbone and the right jawbone are obtained through processing, and a transverse rotation axis of the lower jawbone is obtained through connection. According to the method, the more accurate transverse rotation axis of the lower jawbone is obtained, a more real data result closer to teeth of the patient is obtained, and meanwhile the convenience and precision of tooth data positioning are improved.

Owner:施洁珺

Method for producing the tooth shape of the inner and outer ring of an annular gear machine and toothed ring produced by means of said method

ActiveUS9273687B2Sure easyEngine of arcuate-engagement typeOscillating piston enginesRotational axisTeeth count

Owner:NIDEC GPM GMBH

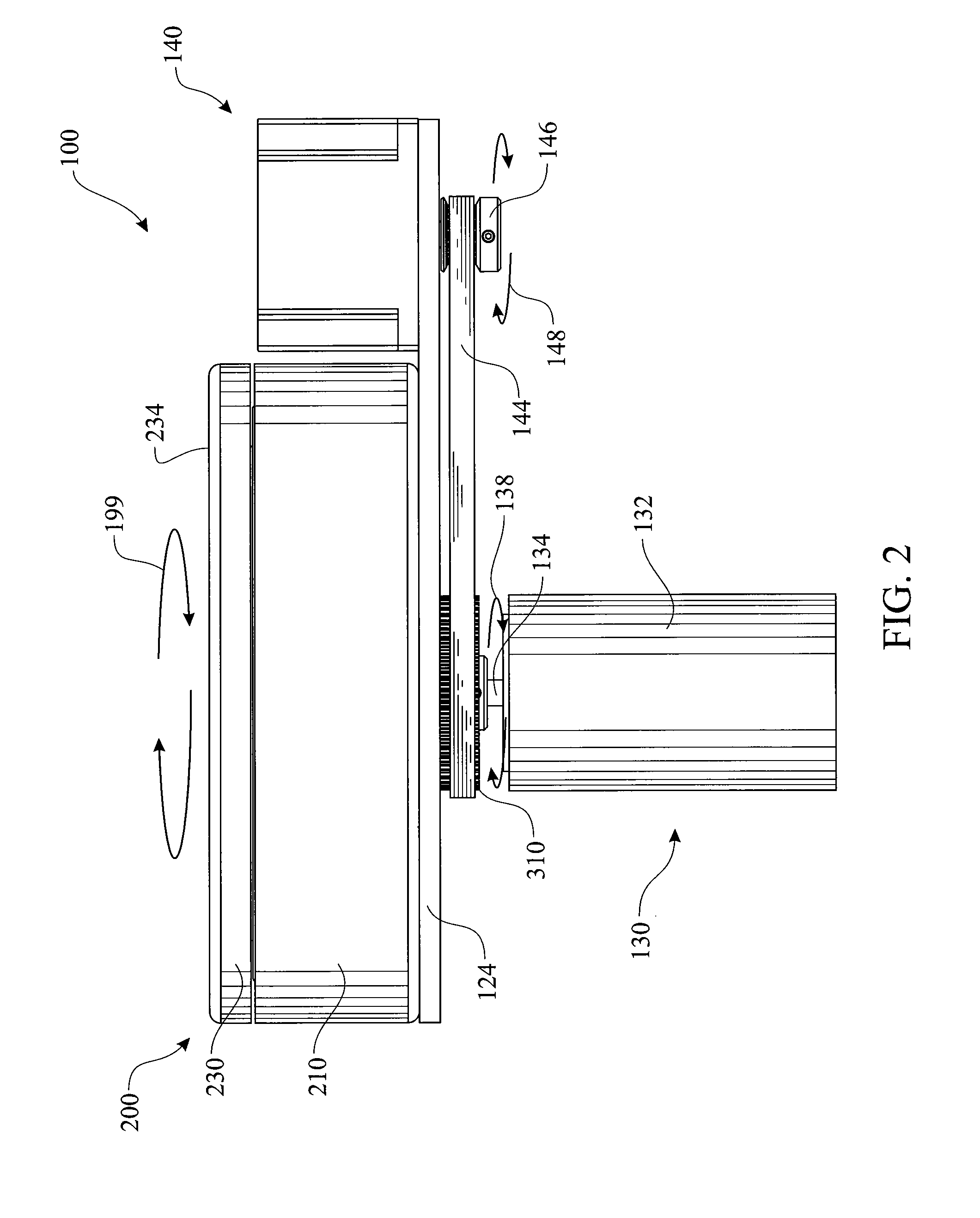

System and method to account for thermal die expansion

InactiveUS8580168B1Easy and cost-effective retrofittingEliminate needAuxillary shaping apparatusLinear motionGear wheel

A system and method for effecting die height adjustments of a casting machine, such as to account for thermal die expansion. The system and method finds use on a die casting machine having a driven gear train for causing linear movement of a movable platen thereof. Based on known characteristics of the gears of the gear train and of threaded tie bar nuts upon which the gear train operates, a given rotation of a gear train gear can be converted into a linear movement of the movable platen. A sensor is used to count the teeth of a rotating gear train gear and a controller is provided to correlate the tooth count with a corresponding linear travel distance of the movable platen.

Owner:HONDA MOTOR CO LTD

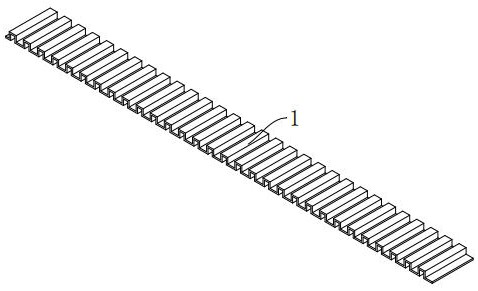

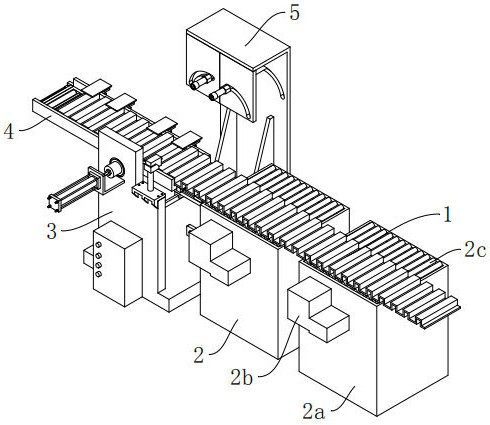

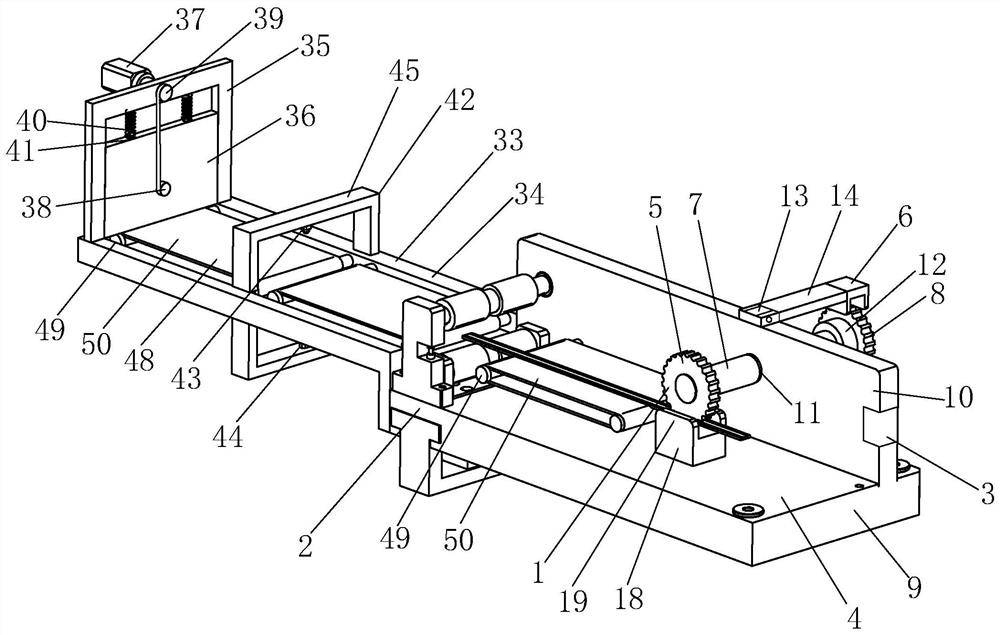

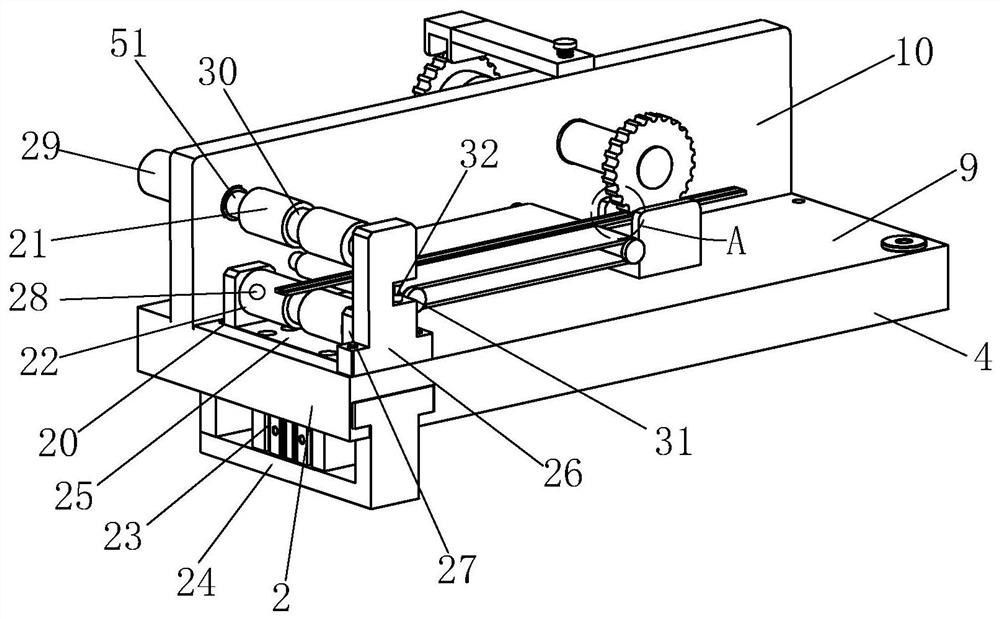

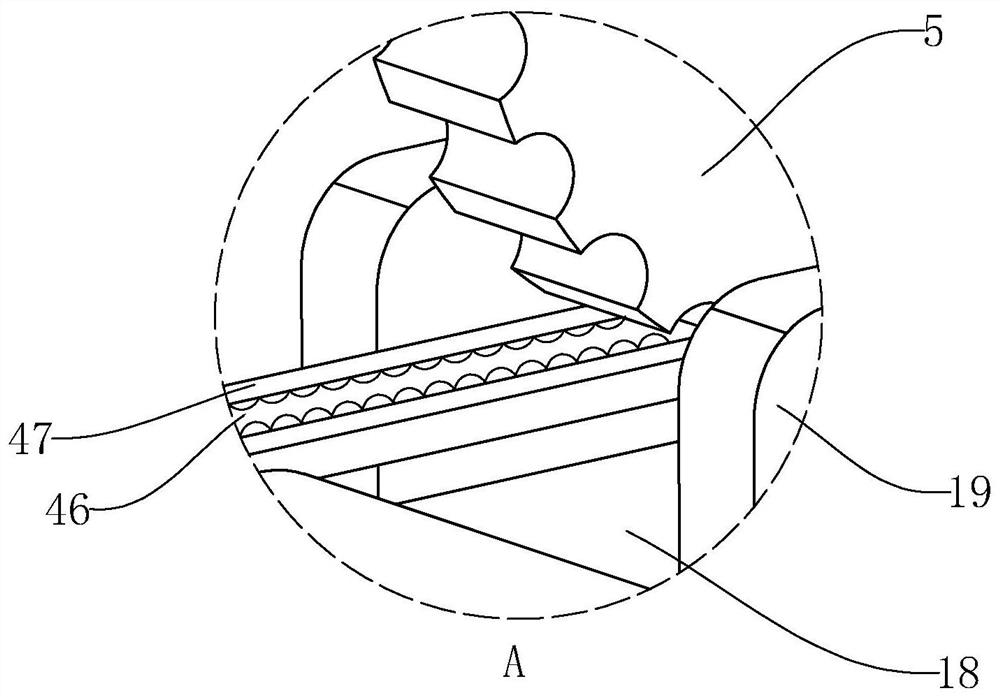

Intelligent tooth counting equipment for processing sawtooth heat dissipation fins

InactiveCN112122397AEasy way to count teethEasy to implementHeat exchange apparatusMetal working apparatusOral problemsTeeth counted

The invention relates to the field of heat dissipation fin processing, in particular to intelligent tooth counting equipment for processing sawtooth heat dissipation fins. The intelligent tooth counting equipment comprises a tooth counting tray, a tray position adjusting mechanism, a tooth counting position adjusting mechanism and a tooth counting mechanism, wherein the tooth counting tray is usedfor storing the fins to be subjected to tooth counting, and is adaptively adjusted according to different sizes of the fins placed on the tooth counting tray; the tray position adjusting mechanism isarranged on the lateral of the tooth counting tray and used for driving the tooth counting tray to do linear motion and adjusting the position of the tooth counting tray; the tooth counting positionadjusting mechanism is arranged at the top of the tooth counting tray and located on the opposite side of the tray position adjusting mechanism and is used for counting teeth of the fins placed on thetooth counting tray; and the tooth counting mechanism is arranged on the lateral of the tooth counting position adjusting mechanism and used for driving the tooth counting position adjusting mechanism to move. According to the intelligent tooth counting equipment, a tooth counting method is simple, easy to implement and accurate in tooth counting, the problem of inaccurate tooth counting of an existing tooth counting method is solved, a good effect is obtained, and the intelligent tooth counting equipment has practical value in industrial batch production of the sawtooth heat dissipation fins.

Owner:陶仁元

Tooth model matching method

ActiveCN106510867BSolve the problem of quantitative evaluation of orthodontic effectSolve quality inspection problemsOthrodonticsOral problemsEngineering

The invention discloses a method for matching teeth with a model. The method comprises the following steps: introducing a virtual expected digital tooth model; obtaining a tooth data and generating a virtual digital tooth model; preliminarily matching and placing the digital tooth model together with the expected digital tooth model into a same coordinate system; adopting a three-dimensional matching algorithm for accurately matching the digital tooth model with the expected digital tooth model; obtaining a deviation value after the digital tooth model is matched with the expected digital tooth model. The invention provides a condition for quantitatively adjusting an orthodontic scheme on the basis of an orthodontic effect; the quality control problem is solved; a quantitative effect evaluation scheme is also supplied for the traditional orthodontics.

Owner:上海牙典医疗器械有限公司

Mutually-spliced zipper inspection device

PendingCN113686249AAvoid competing quality problemsThere can be no quality problems with each otherUsing optical meansSortingAlgorithmTeeth counted

The invention discloses a mutually-spliced zipper inspection device which comprises a processor and a zipper length detection module used for detecting the moving distance of a detected zipper; and a tooth number detection module, used for detecting and outputting the number of zipper teeth of the detected zipper. A data receiving module, a calculation module and a data output module are arranged in the processor; the data receiving module is connected with the zipper length detection module and the tooth number detection module and is used for receiving the moving distance L of the detected zipper and the tooth number n of the zipper in the section detected by the tooth number detection module in real time; the calculation module calculates the ratio m of L to n according to the moving distance L of the detected zipper and the number n of zipper teeth in the section of zipper, and judges whether m meets the standard or not; the data output module outputs a judgment result or outputs a warning signal when m does not meet the standard; the device can detect whether the tooth number per unit length of the mutually-spliced zipper meets the standard or not, guarantees the zipper quality, is convenient to detect, and improves the detection efficiency.

Owner:WENZHOU HEHE ZIPPER

A method for extracting lateral rotation axis location of mandibular cbct data

ActiveCN112494163BPrecision Lateral Rotation AxisReal data resultsOthrodonticsJaw boneCentre of rotation

Owner:施洁珺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com