Improvement device for reusable expansion screw and mounting method thereof

An expansion screw and installation method technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of inability to screw threads, breakage of bolts, and inability to radially expand the helical body, and achieve effective screwing, efficient operation, and saving. The effect of drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

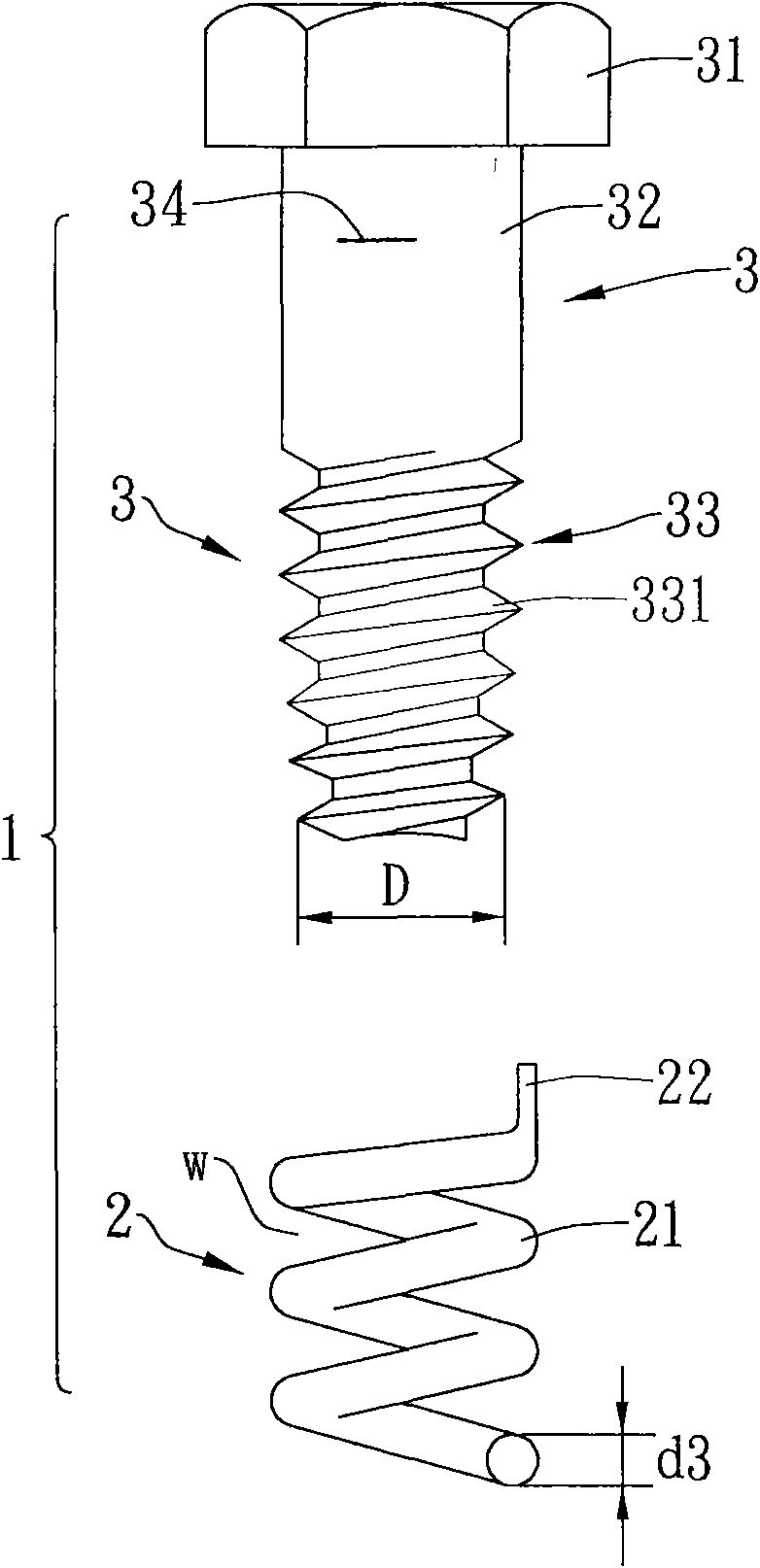

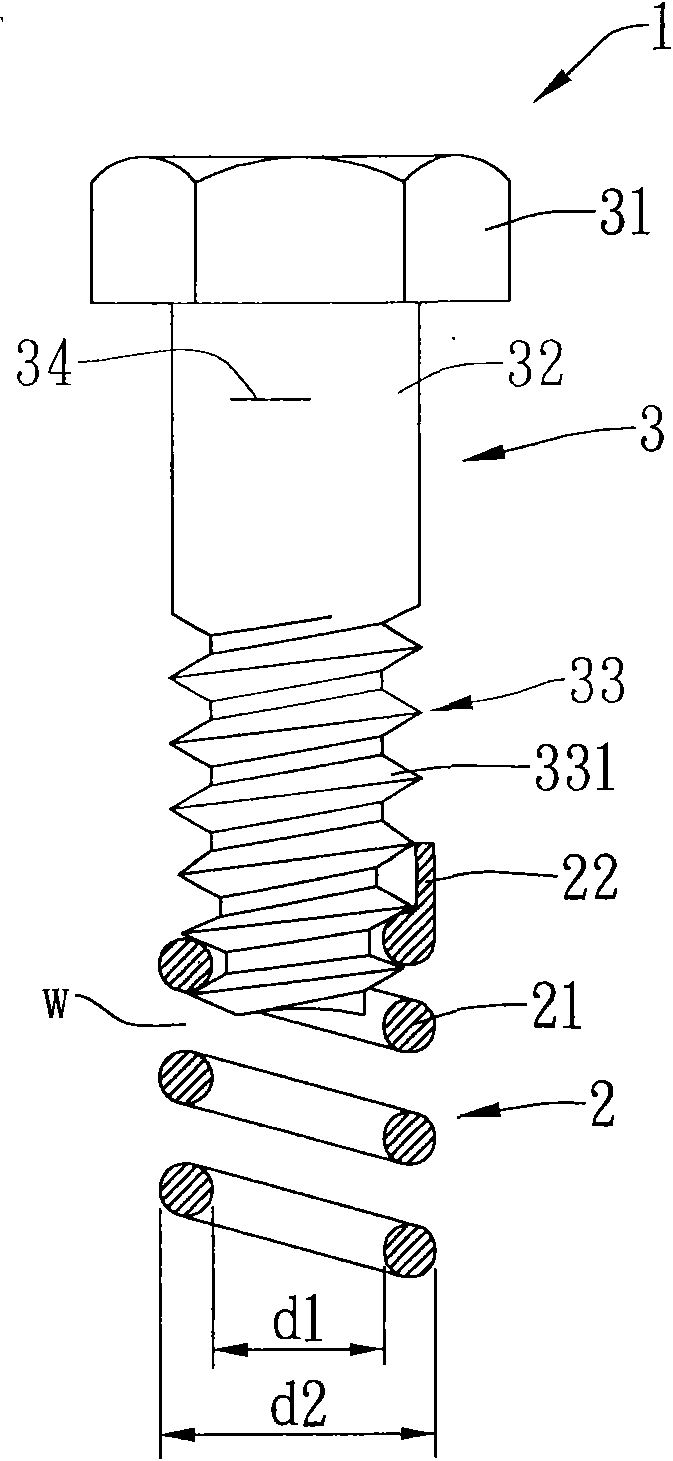

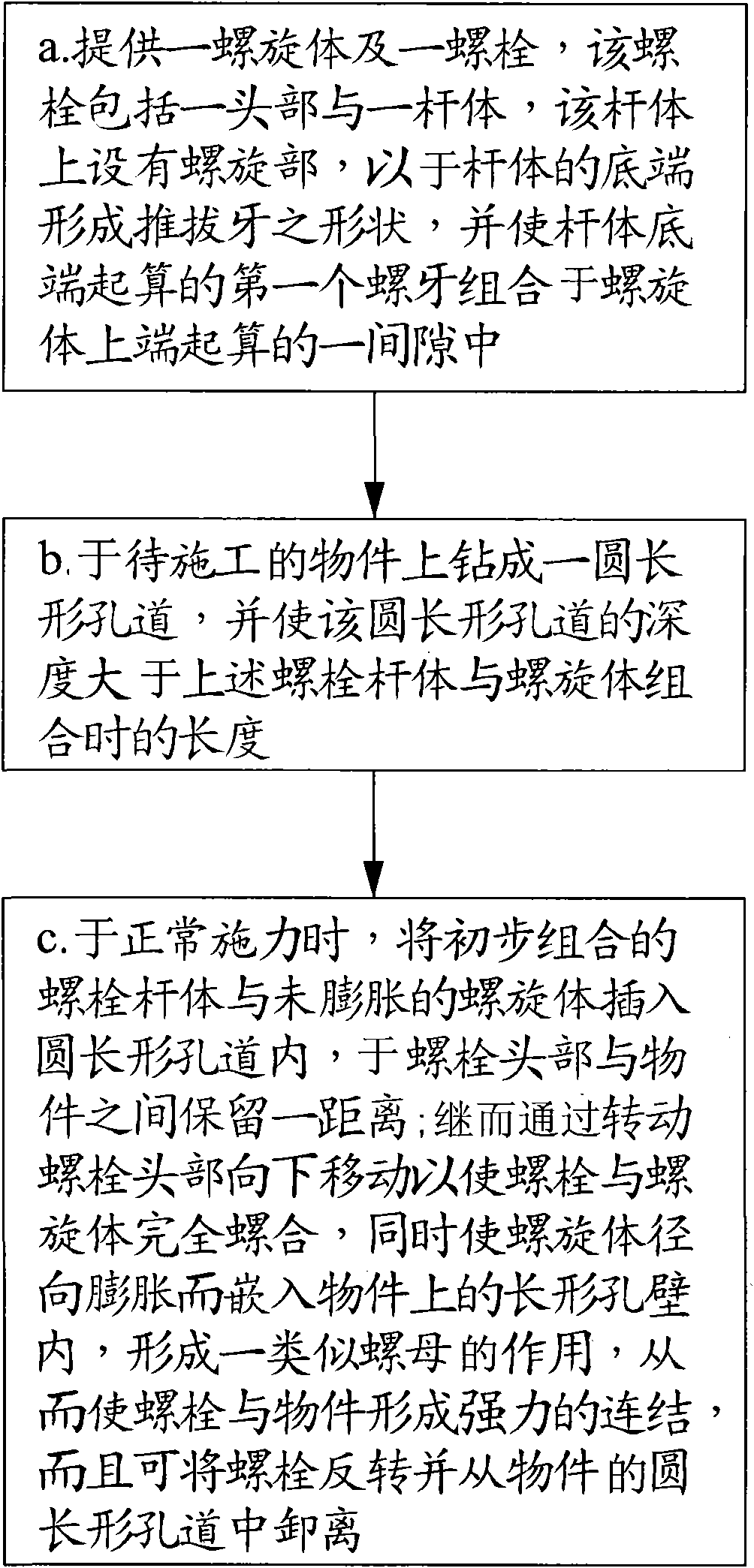

[0054] see figure 1 , figure 2 As shown, it is a preferred embodiment of the improvement device 1 of the reusable expansion screw of the present invention, which includes a spiral body 2 and a bolt 3 .

[0055] The spiral body 2 is formed by a long strip wire body 21 with a diameter spirally wound in the direction of the same mandrel. The lower end of the long strip wire body 21 is a free end, and the upper end is a flat stopper. The stopper 22, when the elongated wire body 21 is wound and formed into a long helix 2, the helix 2 forms an inner diameter d1, an outer diameter d2 and a plurality of equal distances in the direction of the parallel mandrel gap w, and the stop portion 22 extends from the upper end of the spiral body 2 toward a direction parallel to the spindle.

[0056] The bolt 3 is made of heat-treated medium-carbon steel, and the bolt 3 can also be made of alloy steel or processed to make it equal to or higher than the strength and hardness of the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com