Drive arrangement for a bicycle, having a greater difference in the number of teeth between the largest and the smallest rear chain sprocket

a technology for rear chain sprockets and drives, which is applied in the direction of mechanical equipment, transportation and packaging, and gearing, etc., and can solve problems such as particularly problemati

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

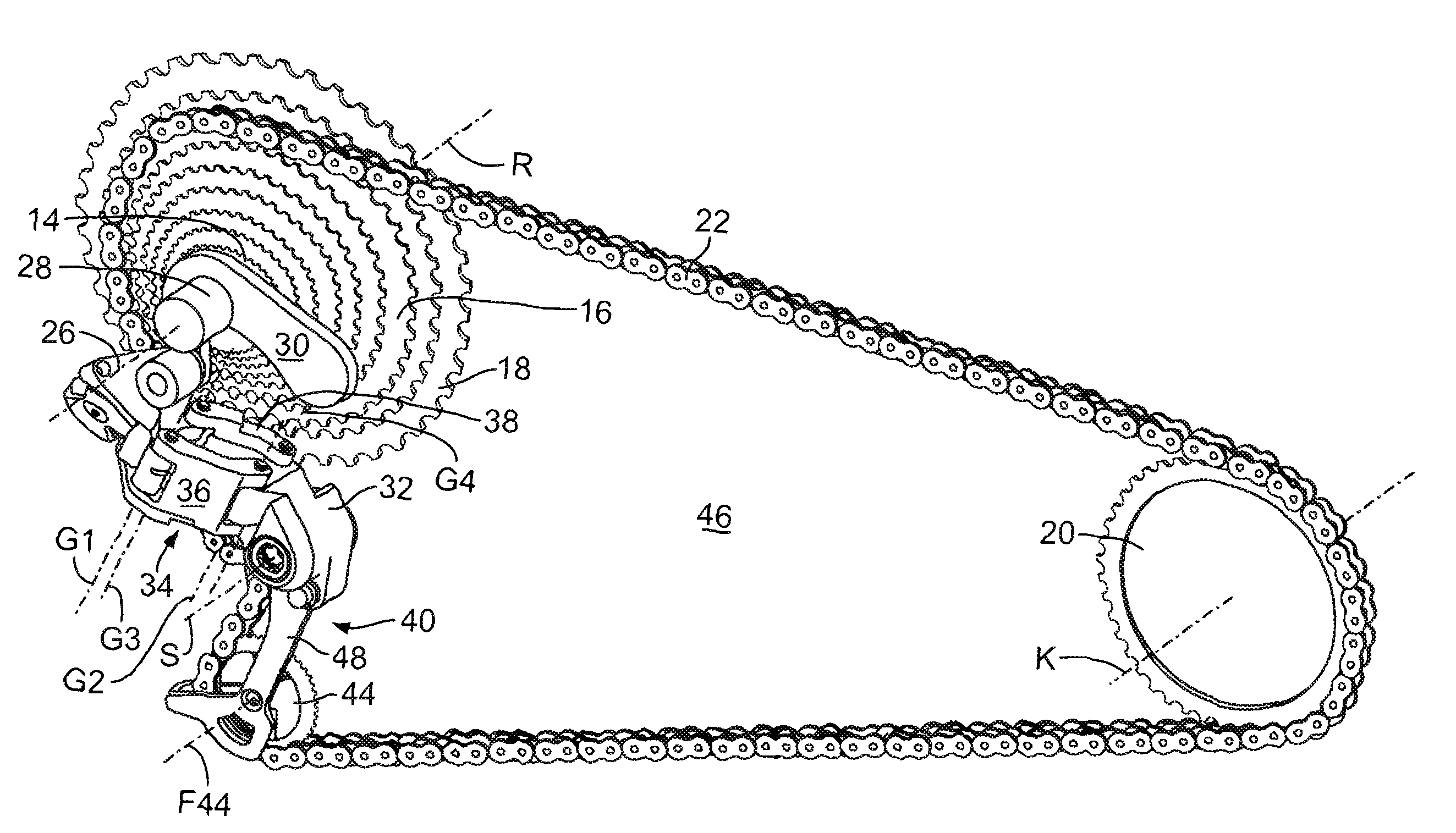

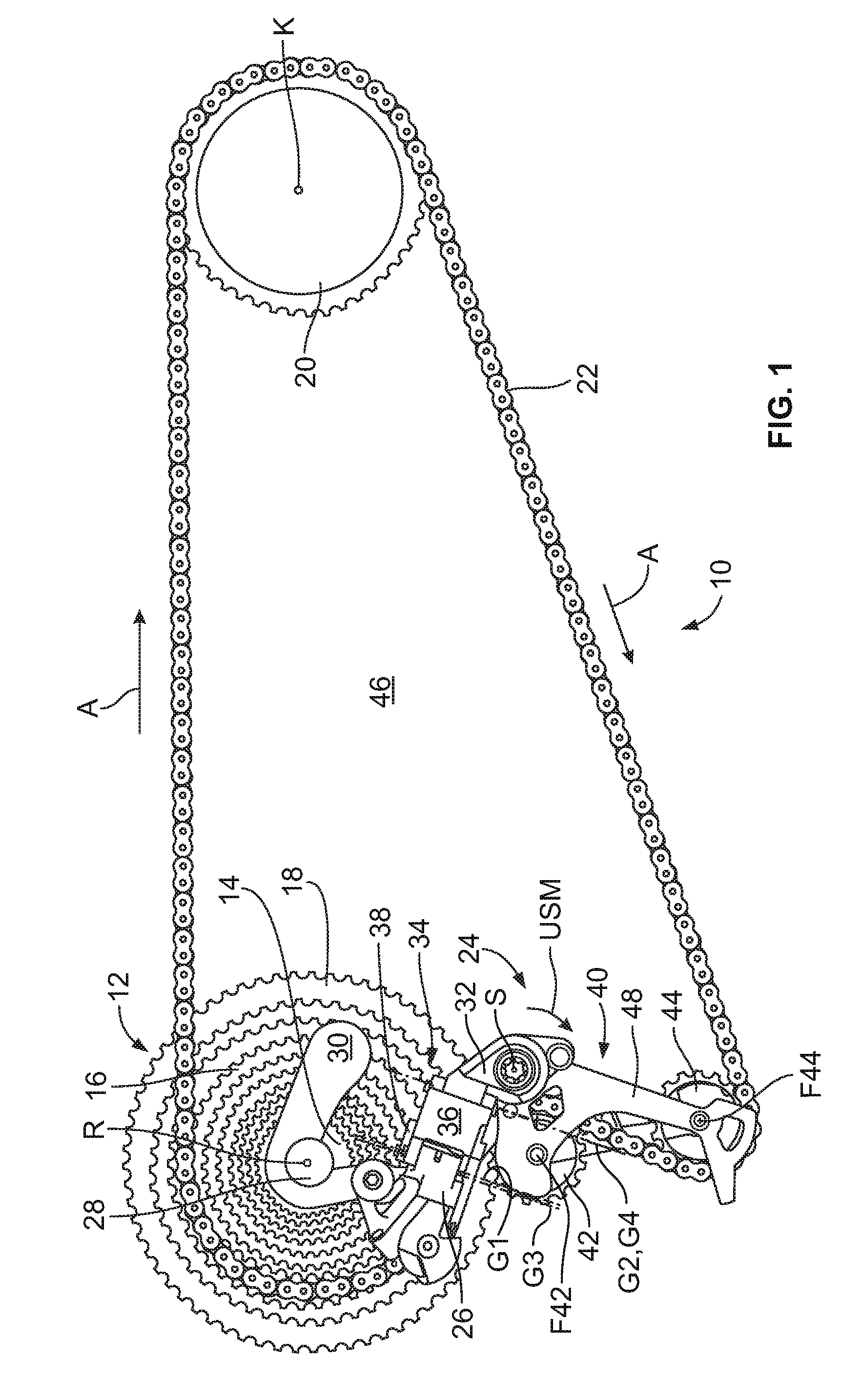

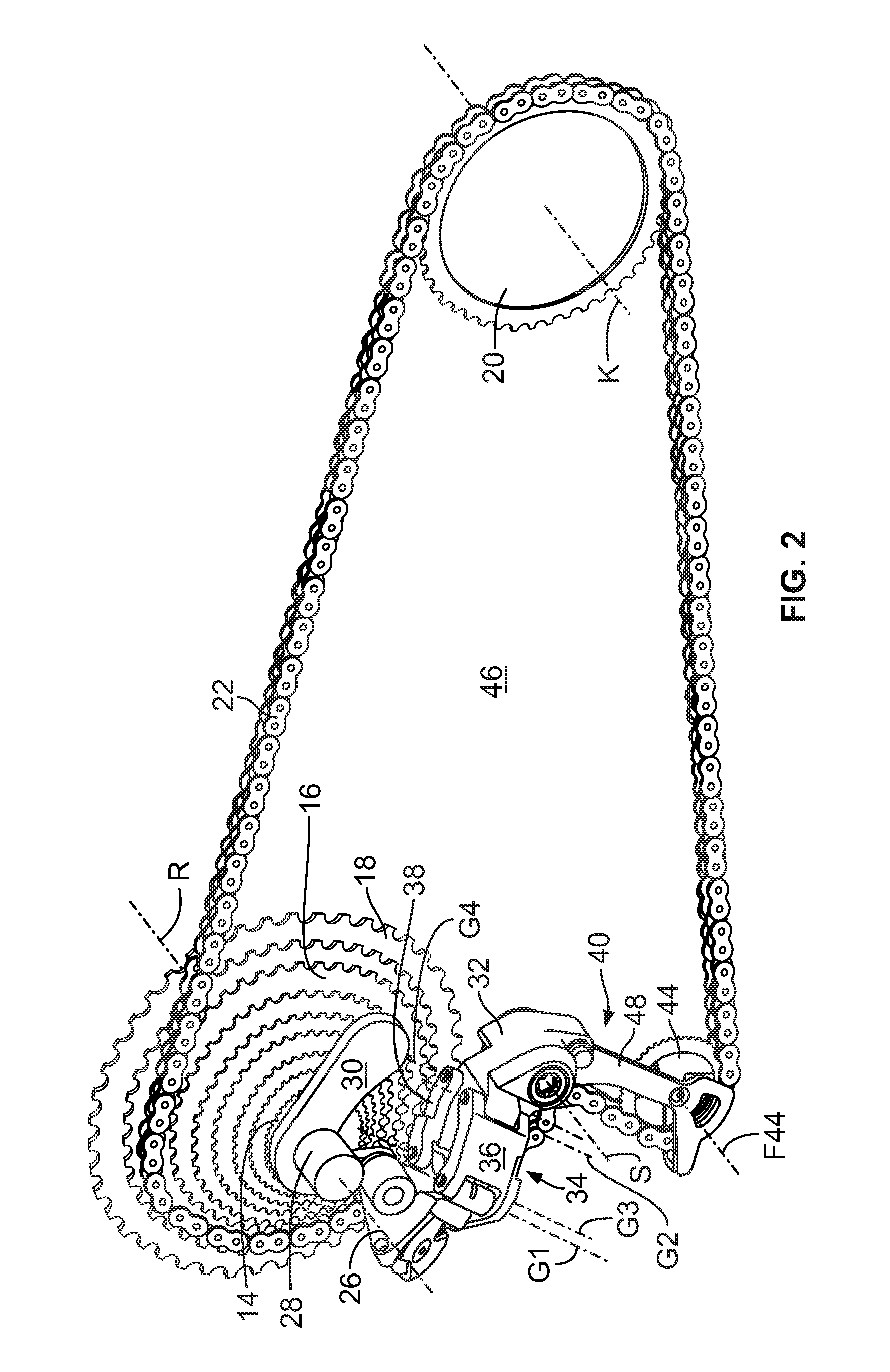

[0043]In the following, reference will be made to FIGS. 1 to 7 jointly, for an explanation of the present invention. If individual figures are particularly suitable for a representation of the technical characteristics being described, at specific locations of the description, this will be separately emphasized.

[0044]In the figures, an embodiment of a drive arrangement of the present application, according to the invention, is referred to in general as 10.

[0045]The drive arrangement 10 comprises an arrangement 12 of sprockets that are coaxial with reference to a sprocket axis R. Sprocket axis R is orthogonal to the plane of the drawing of FIG. 1. Only the sprocket having the smallest diameter is identified with the reference symbol 14, the sprocket selected to be active in FIG. 1 is identified with the reference symbol 16, and the sprocket having the largest diameter is identified with the reference symbol 18. In the example shown in the figures, the arrangement 12 of the coaxial re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com