Gear cylinder or ball measurement method and system

A measurement method and measurement system technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of poor accuracy, slow measurement speed, and expensive measurement instruments, and achieve the purpose of improving measurement efficiency, improving measurement accuracy, and eliminating artificial Effects of measurement error factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

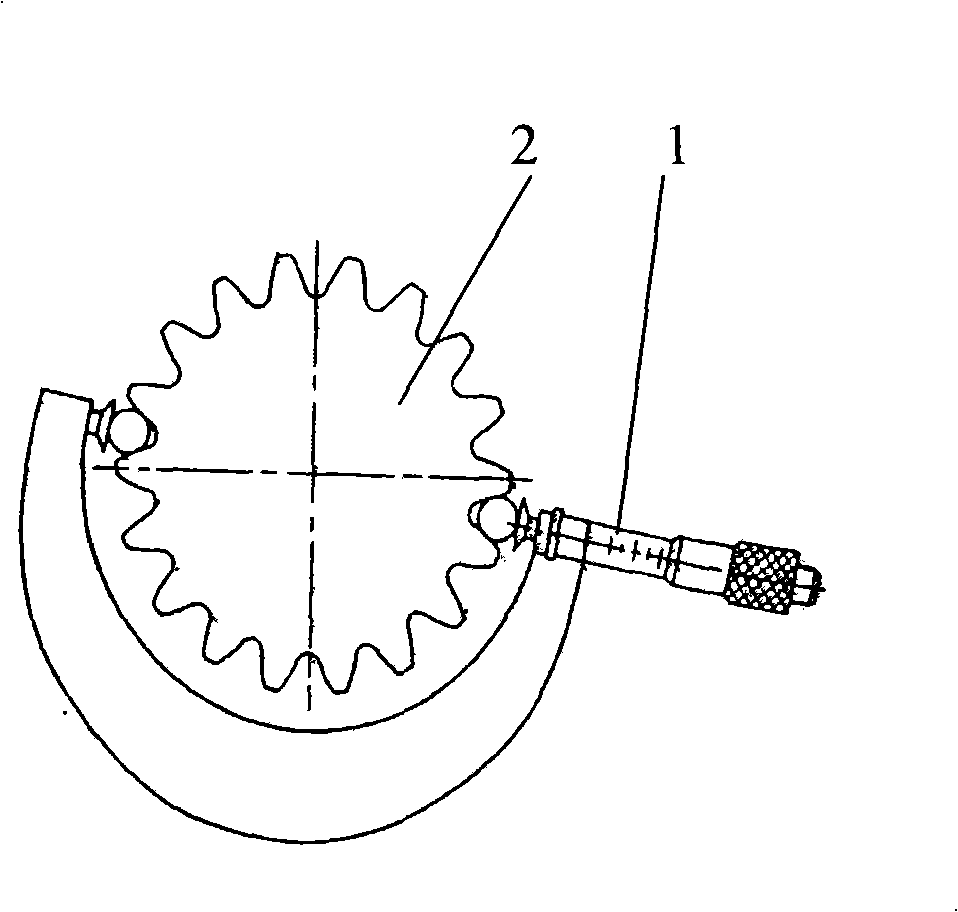

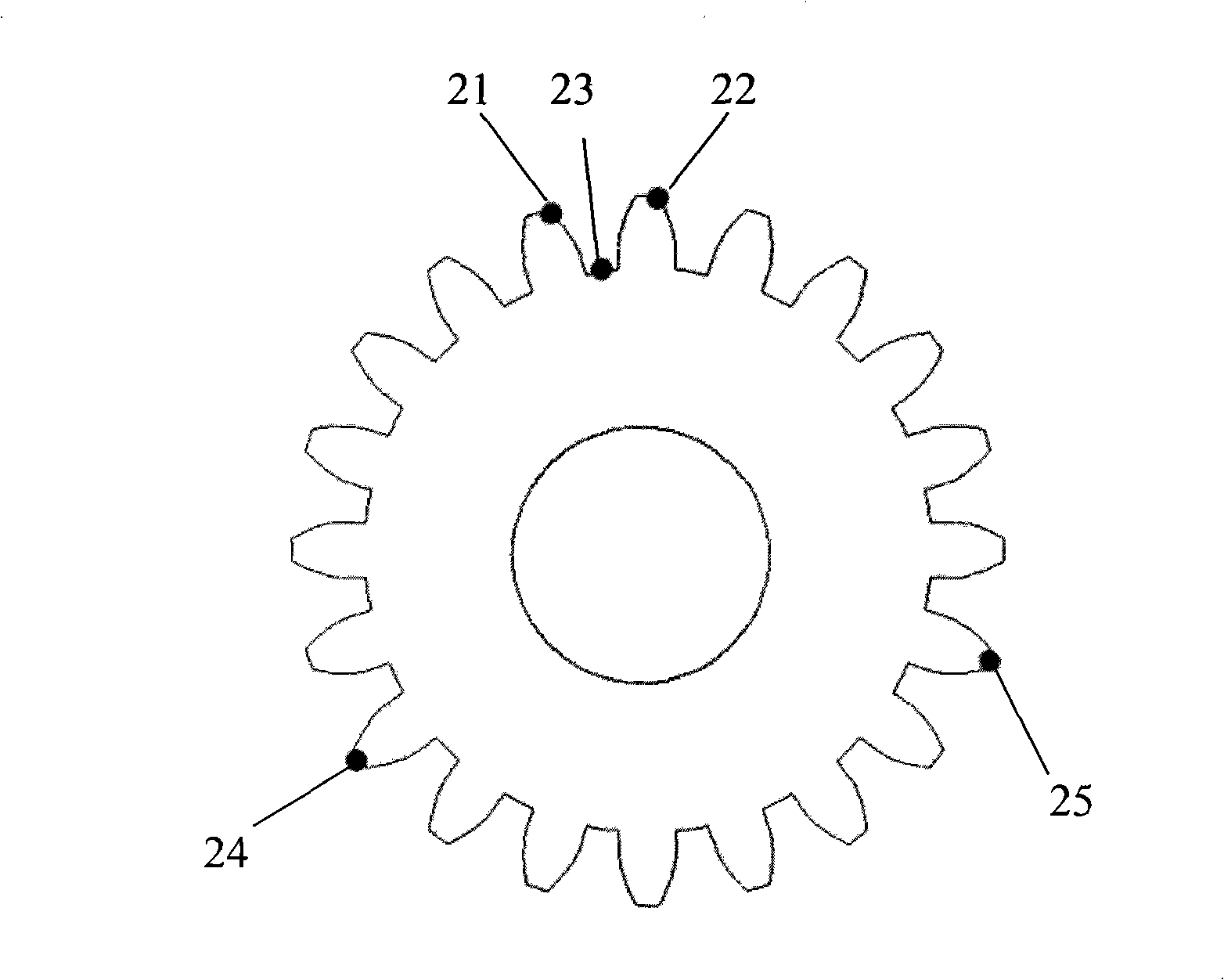

[0041] The gear cylinder or ball measuring method and system of the present invention realizes the measurement of the gear basic parameters and the gear spanning distance of the involute spur gear (including the external gear and the internal gear).

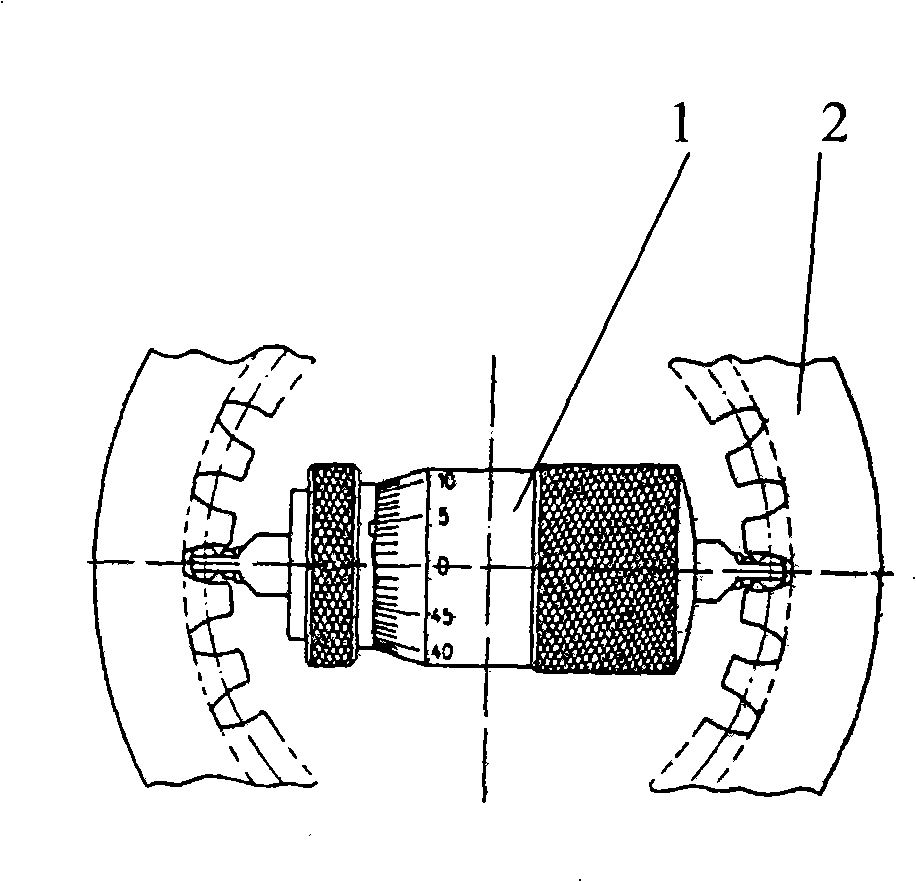

[0042] The gear cylinder or ball measurement method of the present invention is Figure 4 The gear cylinder or ball measurement system of the present invention shown is implemented. like Figure 4 As shown, the system includes an image system 4 and a data processing system 5. The data processing system 5 includes a central processing unit 51, an input device 52 electrically connected to the central processing unit 51 or connected by a wireless signal, and an input device 52 electrically connected to the central The memory 53, the monitor 54 and the output interface 55, the image system 4 is connected with the central processing unit 51 by electrical or wireless signal connection, and the software for realizing the following gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com