Measurement device for detecting the absolute angle of rotation of a rotating measurement object

A technology of rotating angle and measuring equipment, applied in the direction of measuring device, converting sensor output, using mechanical device to transfer sensing components, etc., can solve the problem that it is impossible to determine the exact angular position of the axis of the measured object, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

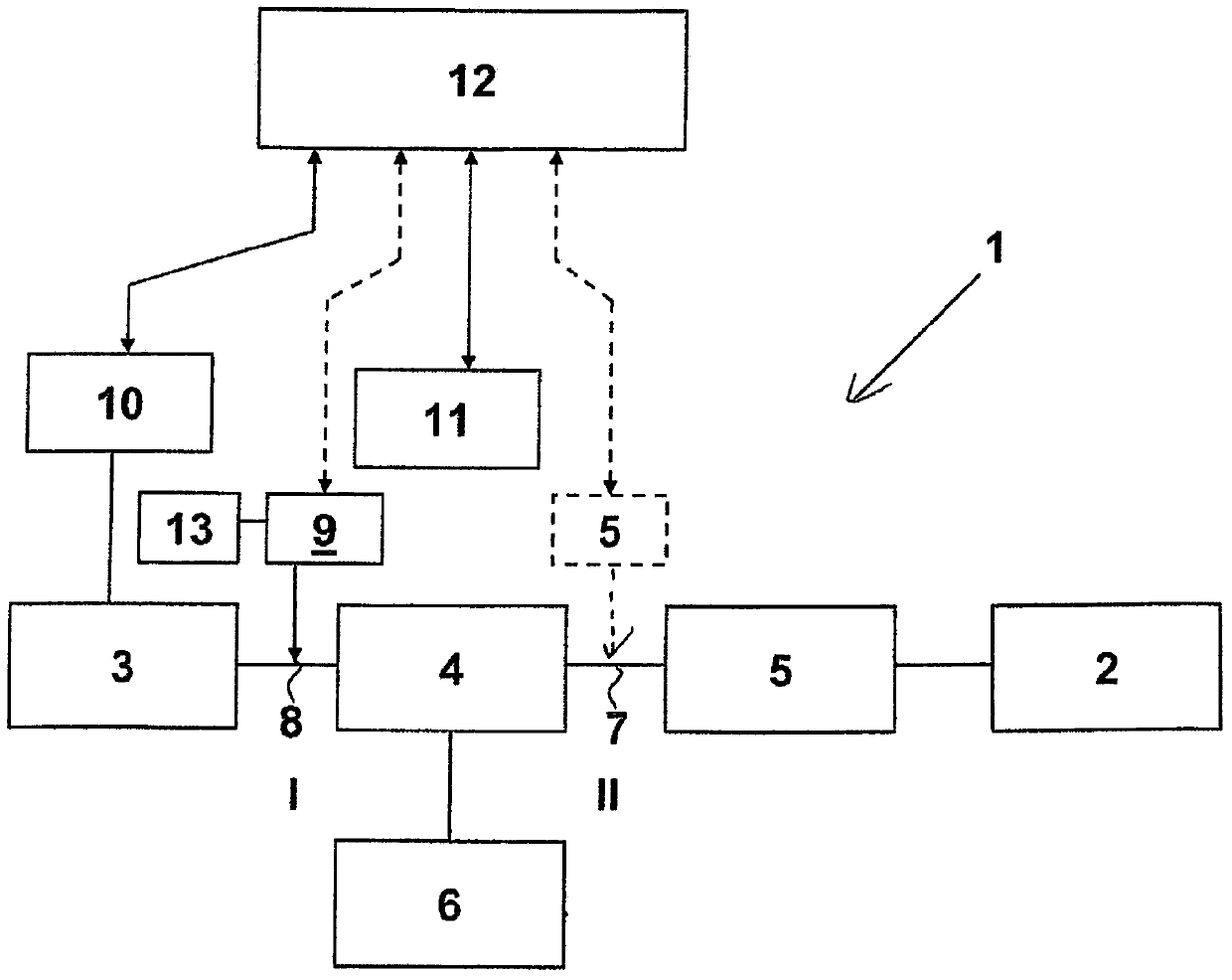

[0029] figure 1 It is a schematic diagram of the control element 1 used to actuate the flow control mechanism 2-corresponding to the actuator 1. The flow control mechanism 2 is, for example, a valve, a gate, a throttle valve or a flapper.

[0030] The control element 1, corresponding to the actuator 1, usually consists of a motor 3 with a corresponding sensor device 10, an actuator driver 4 with a corresponding sensor device 11, a reduction gear 5 and a flow control mechanism 2. The control of the actuator 1 is performed by means of the upper-level control unit 12. The control unit 12 can be integrated into the actuator driver 4, it can be embedded in the actuator driver 4, or it can be implemented as a separate component. Generally, in the processing industry that manufactures products from raw materials or starting materials by applying chemical, physical or biological processes, the actuator driver 4 used for the flow control mechanism 2 in the processing is designed in such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com