Steel fiber self-compacting concrete and preparation method thereof, and prefabricated member

A self-compacting concrete and steel fiber technology, applied in the field of building materials, can solve the problems of small and no increase in compressive strength, and achieve the effects of good compaction, reduced wear and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

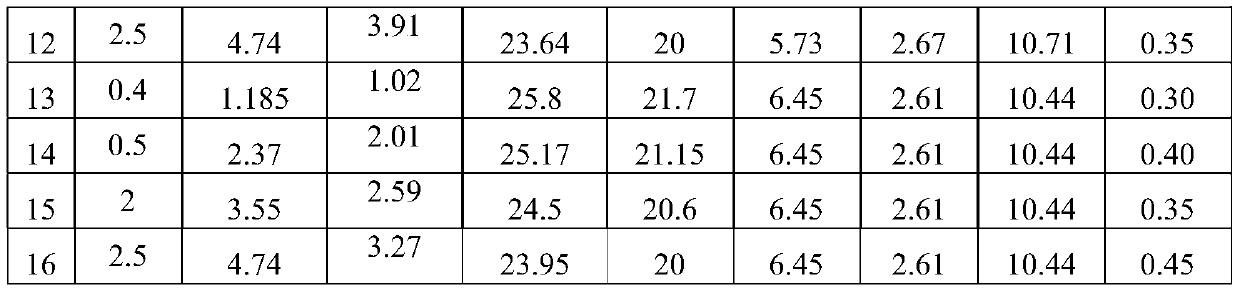

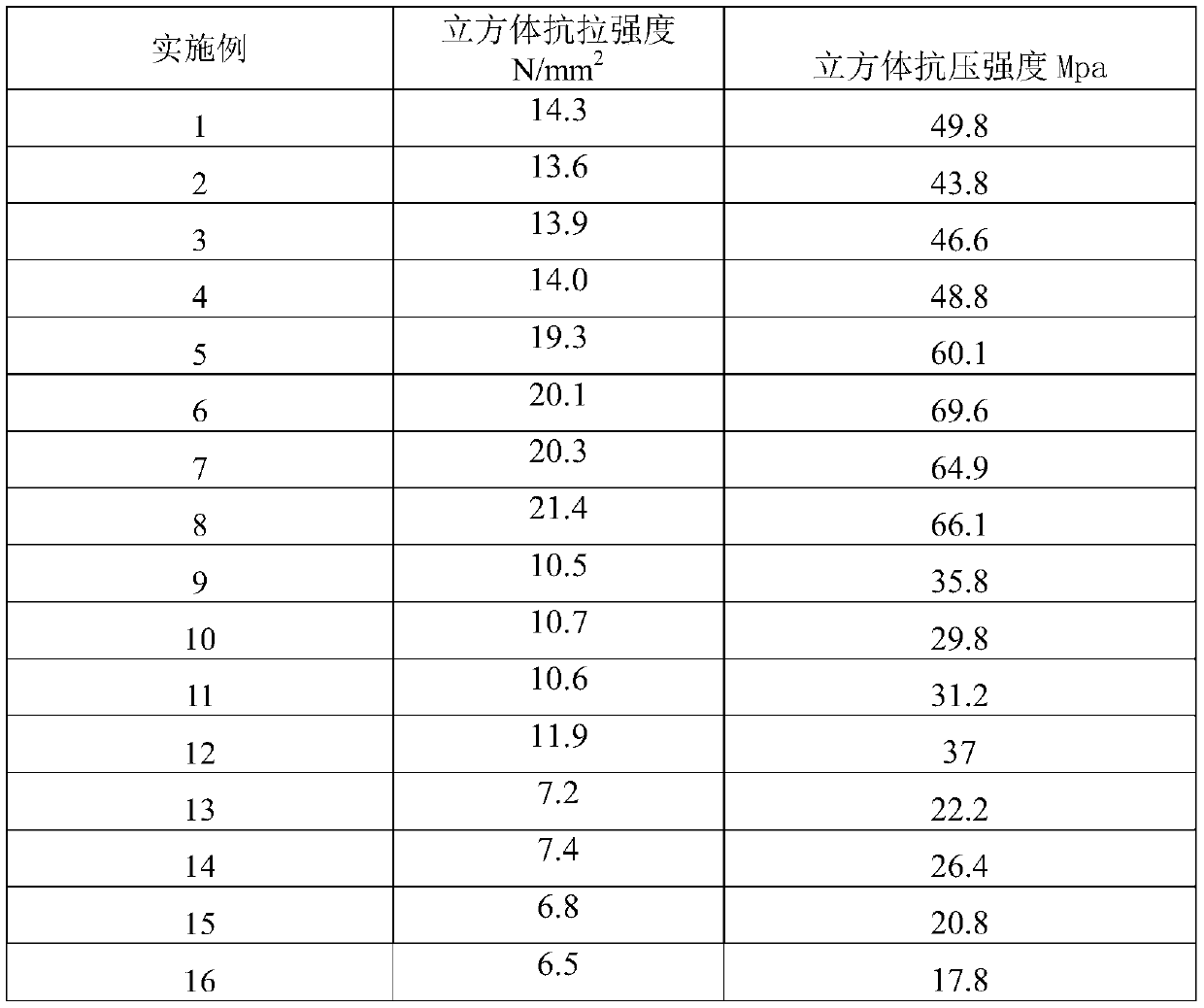

Embodiment 1~16

[0101] (1) Prepare raw materials:

[0102] Magnetic beads: iron oxide body after strong magnetic treatment, with a particle size of 2-5mm.

[0103] Cement: P O42.5 ordinary Portland cement, apparent density is 3.10g / cm 3 .

[0104] Fly ash: Class I fly ash, apparent density 2.04g / cm 3 .

[0105] Sand: medium sand with a fineness modulus of 2.36 and an apparent density of 2.65g / cm 3 , bulk density is 1.45g / cm 3 , the moisture content is 0.4%.

[0106] Natural coarse aggregate: crushed stone with a continuous particle size of 5-20mm, and an apparent density of 2.75g / cm 3 , bulk density is 1.35g / cm 3 , The water absorption rate is 0.45%.

[0107] Short steel fiber: 0.06cm in diameter, 0.6-1.8cm in length, the shape can be straight steel fiber (a), prismatic steel fiber (b), corrugated steel fiber (c), hook-shaped steel fiber ( d / e), large-headed steel fibers (f), double-pointed steel fibers (g), bundled steel fibers (h), etc., were purchased from the market.

[0108] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com