Super-retarding polycarboxylic acid type water-reducer as well as preparation method and application thereof

A technology of retarding polycarboxylate and superplasticizer, which is applied in the preparation of superplasticizers, ultra-retarding polycarboxylate superplasticizers, and self-compacting steel pipe concrete, which can solve the problem of concrete compaction in steel pipes Low pressure, low construction efficiency, excessive pump pressure, etc., to avoid abnormal setting time, complete reaction, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

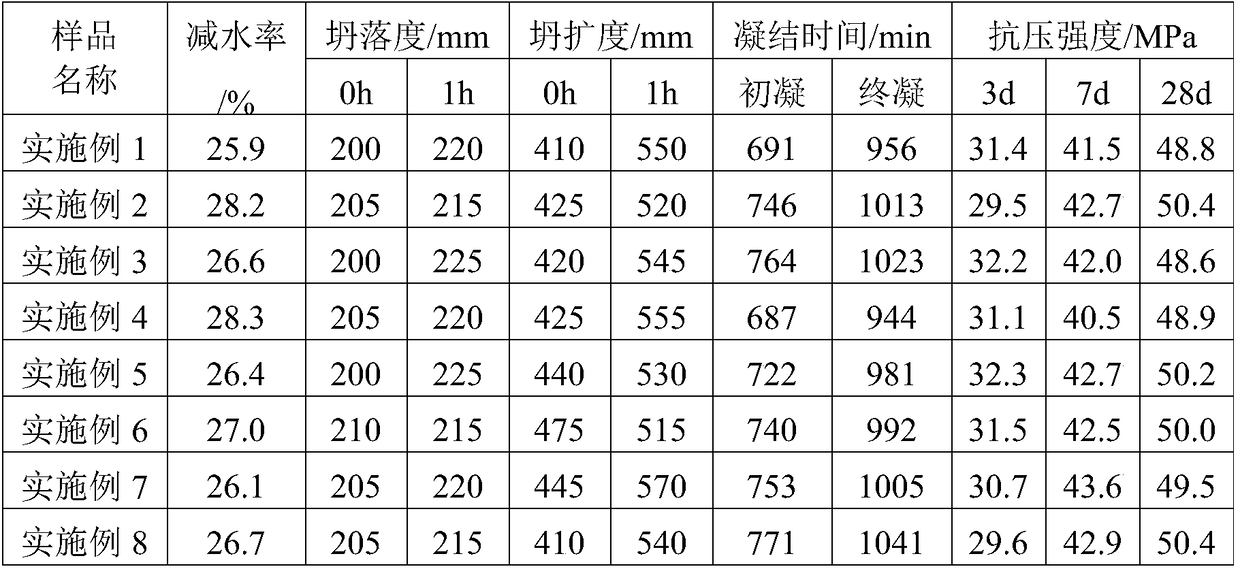

Embodiment 1

[0038] (1) Preparation of graft copolymer: Add 3.2 parts of 2-hydroxyethyltrimethylammonium chloride and 5.7 parts of maleic anhydride in a four-necked flask equipped with stirrer, thermometer, reflux condenser and water separator, heat Dissolve at 90°C-100°C; add 0.11 parts of p-toluenesulfonic acid and raise the temperature to 130°C-140°C, and keep it warm for 4h-6h;

[0039] (2) Preparation of super-retarded polycarboxylate water reducer: 24.0 parts of acrylic acid, 38.6 parts of hydroxyethyl acrylate, 7.7 parts of glycerin, 1.43 parts of ferrous sulfate and 9.60 parts of sodium hypophosphite were added to 250 parts of water , to prepare a mixed solution; add 9.0 parts of the prepared graft copolymer, 399.8 parts of hydroxybutyl vinyl polyoxyethylene ether, 234.1 parts of water and 2.40 parts of hydrogen peroxide in a four-necked bottle equipped with a stirrer and a thermometer ;Heat the four-necked bottle to 40°C~45°C, add the mixed solution dropwise within 3h~4h, and cont...

Embodiment 2

[0041] (1) Preparation of graft copolymer: Add 3.1 parts of 2-hydroxyethyltrimethylammonium chloride and 5.5 parts of maleic anhydride in a four-necked flask equipped with stirrer, thermometer, reflux condenser and water separator, heat Dissolve at 90°C to 100°C; add 0.09 parts of p-toluenesulfonic acid and raise the temperature to 130°C to 140°C, and keep it warm for 4h to 6h;

[0042] (2) Preparation of super-retarded polycarboxylate water reducer: add 27.6 parts of methacrylic acid, 41.7 parts of hydroxypropyl acrylate, 4.8 parts of isopropanol, 1.40 parts of Mohr's salt and 10.32 parts of sodium hypophosphite into 250 8.7 parts of prepared graft copolymer, 385.2 parts of hydroxybutyl vinyl polyoxyethylene ether, 250 parts of water and 2.34 parts of over Hydrogen oxidation; heat the four-necked bottle to 40°C-45°C, add the mixed solution dropwise within 3h-4h, and continue to keep warm for 1h-2h after the dropwise addition is completed; after the reaction is completed, the ...

Embodiment 3

[0044] (1) Preparation of graft copolymer: Add 3.1 parts of 2-hydroxyethyltrimethylammonium chloride and 5.5 parts of maleic anhydride in a four-necked flask equipped with stirrer, thermometer, reflux condenser and water separator, heat Dissolve at 90°C to 100°C; add 0.08 parts of sulfamic acid and raise the temperature to 120°C to 125°C, and keep it warm for 4h to 6h;

[0045] (2) Preparation of ultra-retarded polycarboxylate water reducer: 27.7 parts of methacrylic acid, 37.4 parts of hydroxyethyl acrylate, 7.4 parts of glycerin, 1.24 parts of ferrous sulfate and 10.05 parts of phosphorous acid were added to 250 parts In water, prepare a mixed solution; add 8.7 parts of the prepared graft copolymer, 387.1 parts of hydroxybutyl vinyl polyoxyethylene ether, 250 parts of water and 2.81 parts of tert-butyl base hydrogen peroxide; heat the four-necked bottle to 40°C-45°C, add the mixed solution dropwise within 3h-4h, and continue to keep warm for 1h-2h after the dropwise addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com