C30 grade steel slag powder self-consolidating concrete, preparation method and prefabricated component thereof

A technology of self-compacting concrete and steel slag powder, which is applied to the preparation of C30 grade steel slag powder self-compacting concrete and the field of C30 grade steel slag powder self-compacting concrete, can solve the problems of reduced metal components, difficulty in recycling, and no good utilization of waste steel slag. , to achieve good compaction, excellent homogeneity, and the effect of meeting the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The present invention also relates to a preparation method of C30 grade self-compacting concrete, comprising the following steps:

[0080] (1) Sorting, crushing and screening the waste concrete in the construction waste, sieving out the particles smaller than 9.50mm and larger than 20mm, and processing the aggregate particle size in the range of 10mm to 20mm to make recycled coarse aggregate ;

[0081] (2) In order to prevent sticking to the pot, weigh an appropriate amount of each material, mix concrete, wait until the inner wall of the mixer is glued with cement mortar, take out the concrete, and weigh material A, recycled coarse aggregate, natural coarse aggregate, water, powder Coal ash and admixture are fed in the order of recycled coarse aggregate, natural coarse aggregate, A material, fly ash and admixture, then start the mixer and dry mix for 1-10 minutes;

[0082] (3) Add the weighed water and additional water, and continue to stir for 1-10 minutes.

[0083] ...

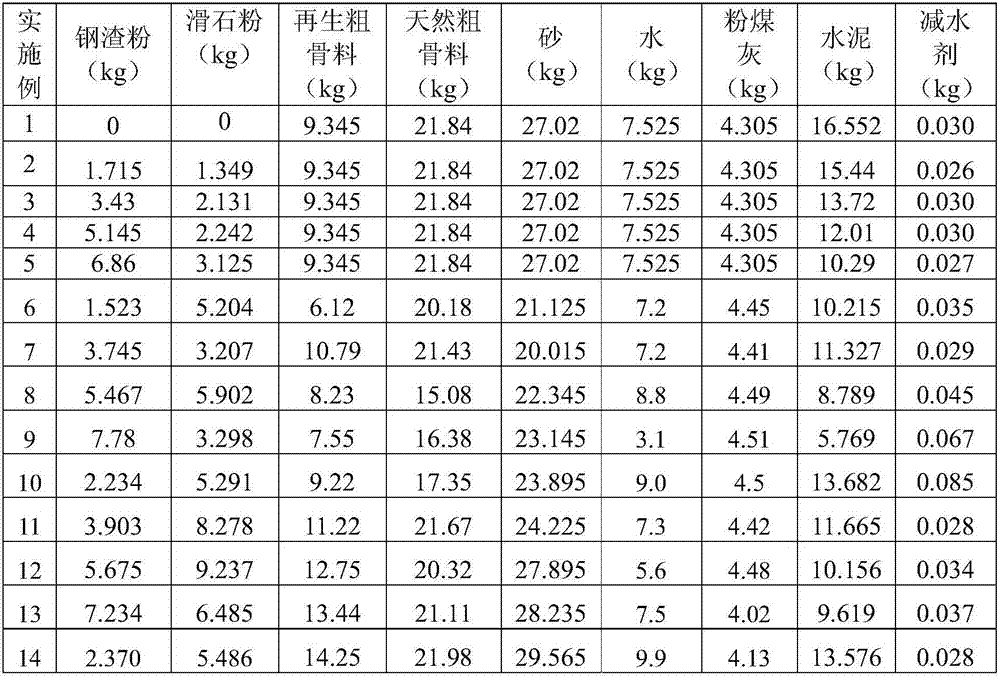

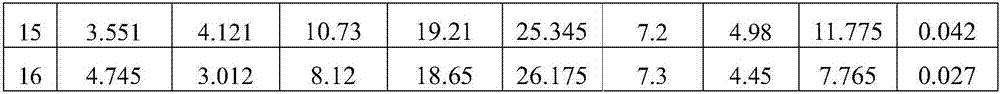

Embodiment 1~16

[0094] (1) Prepare raw materials:

[0095] Cement: P O42.5 ordinary Portland cement, apparent density is 3.10g / cm 3 .

[0096] Fly ash: Class I fly ash, apparent density 2.04g / cm 3 .

[0097] Sand: medium sand with a fineness modulus of 2.36 and an apparent density of 2.65g / cm3 , bulk density is 1.45g / cm 3 , the moisture content is 0.4%.

[0098] Natural coarse aggregate: crushed stone with a continuous particle size of 5-20mm, and an apparent density of 2.75g / cm 3 , bulk density is 1.35g / cm 3 , The water absorption rate is 0.45%.

[0099] Regenerated coarse aggregate: After sorting, crushing and screening waste concrete in construction waste, and sieving out particles smaller than 9.50mm and larger than 20mm, the aggregate particle size is processed into recycled coarse aggregate with a particle size of 10mm to 20mm Aggregate, the apparent density is 2.35g / cm 3 , bulk density is 1.23g / cm 3 , The water absorption rate is 4.76%.

[0100] Steel slag powder: The waste s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com