Unitary decorative blocks cut from concrete blanks and their production

A technology of integral structure and decorative bricks, applied in the field of building wall and floor decoration products, concrete material building wall and floor decoration bricks, can solve the problems of slow mold turnover, many production process links, long production cycle, etc. The effect of simplicity, fewer production process links, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

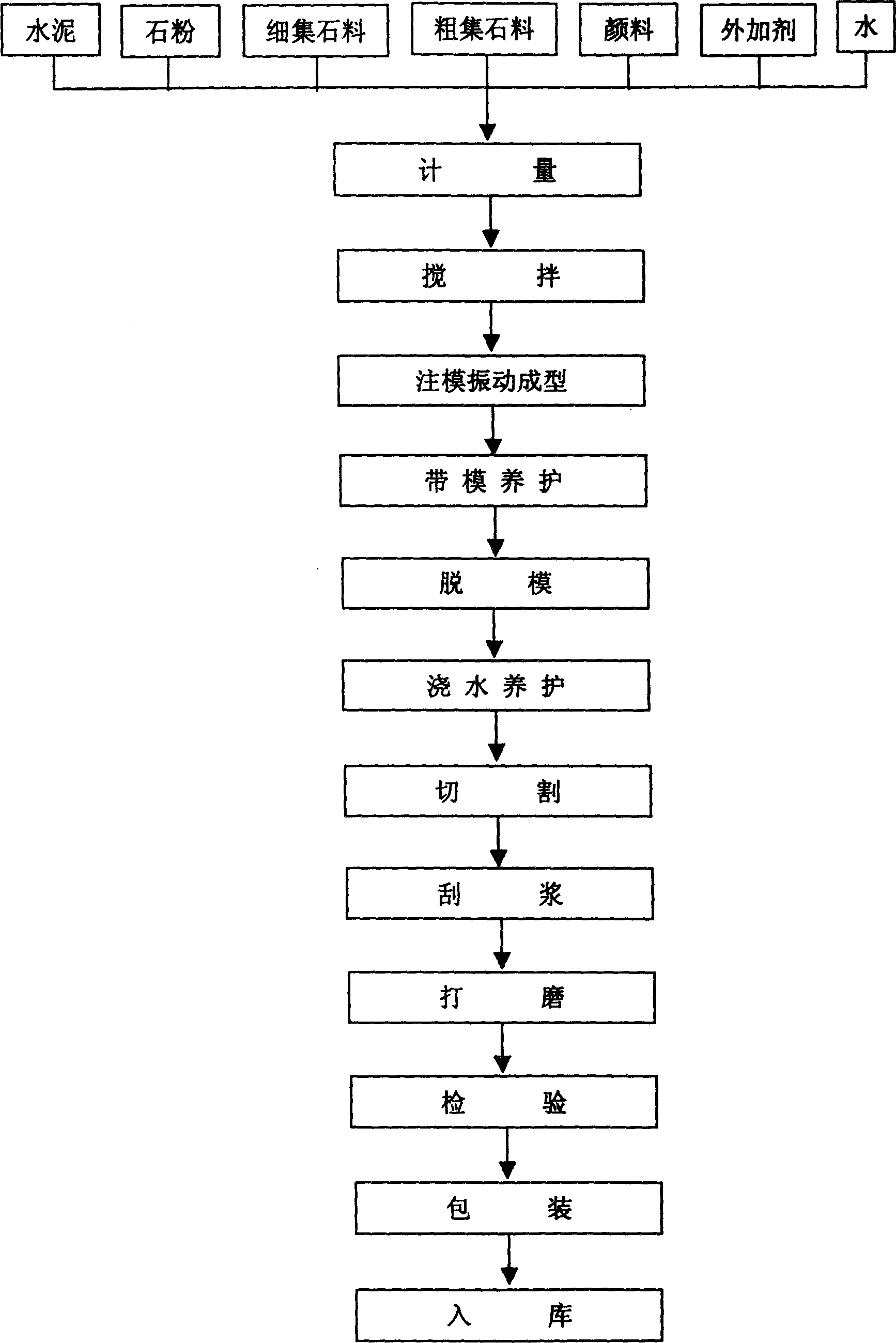

Image

Examples

Embodiment 1

[0032] The component formula of the decorative brick concrete body is: the label is 400 # 1 part of ordinary Portland cement, 0.5 part of stone powder with a mud content of less than 2%, 0.6 part of fine aggregate stone with a mud content of less than 2%, coarse aggregate stone with a particle size of less than 15cm and a mud content of less than 1% 2.0 parts, 0.02 parts of brightener (ie water reducing agent), 0.40 parts of water. The prepared component raw materials are added into the mixer, fully stirred and mixed, and poured into the steel mold that can be split into two decorative brick bodies to prepare the concrete body. Forming takes the form of vibration forming. After forming, carry out curing with the mold first, and cure until it is suitable for demoulding to remove the mold, and then carry out curing with water, and cure until the concrete body is suitable for cutting. After curing, split the concrete body into two pieces of decorative brick body, then scrape th...

Embodiment 2

[0034] The component formula of the decorative brick concrete body is: the label is 400 # 1 part of aluminum sulfate quick-hardening cement, 0.8 parts of stone powder with a mud content of less than 2%, 1.0 part of finely aggregated stone with a mud content of less than 2%, 3.0 parts of natural gravel with a mud content of less than 1% and a maximum particle size of less than 10cm 0.005 parts of high-efficiency water reducer named "FDN", 0.4 parts of iron oxide red, and 0.55 parts of water. The processing technology method of decorative brick is identical with embodiment 1.

Embodiment 3

[0036] The component formula of the decorative brick concrete body is: the label is 400 # 1 part of ordinary Portland cement, 0.6 parts of stone powder with a mud content of less than 2%, 0.8 parts of finely aggregated stone with a mud content of less than 2%, 2.0 parts of natural pebbles with a maximum particle size of less than 12cm and a mud content of less than 1% , "FDN" superplasticizer 0.01 parts, iron oxide yellow 0.5 parts, water 0.5 parts. The processing technology method of decorative brick is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com