Artificial aging treatment method of high carbon steel wires

A technology of artificial aging treatment and high-carbon steel, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of increased production costs, increased material production costs, etc., and achieve the effect of stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] An artificial aging treatment method for high carbon steel wire rod, said method comprising:

[0030] (1) Stack high-carbon steel wire rods in a constant temperature furnace for heat preservation. The heat preservation temperature is controlled at 100-150°C, and the heat preservation time is controlled at 50-200min;

[0031] (2) Cooling with the furnace, the surface temperature of the high-carbon steel wire rod is 30-40°C when it comes out of the furnace, and the cooling time is controlled above 30 minutes;

[0032] (3) Naturally cool to room temperature, and the room temperature is controlled at 23±5°C.

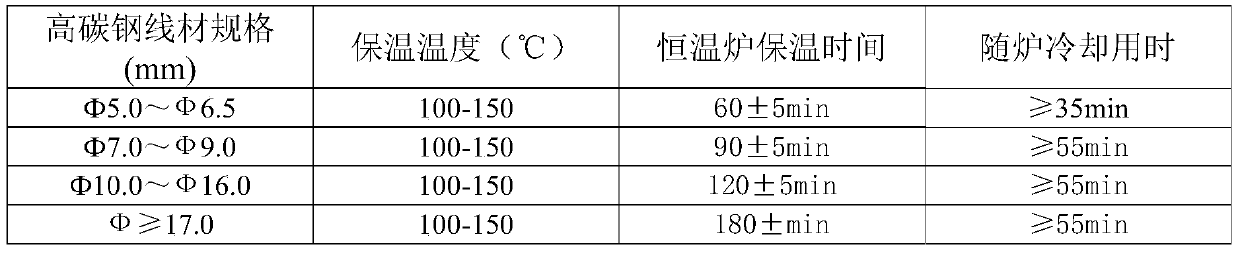

[0033] The optimal process conditions are shown in Table 1:

[0034] Table 1 Artificial aging treatment process of high carbon steel wire rods with different specifications and diameters

[0035]

[0036] Technical principle of the present invention is:

[0037] Through the method of low-temperature artificial aging of high-carbon steel mechanical samples, the r...

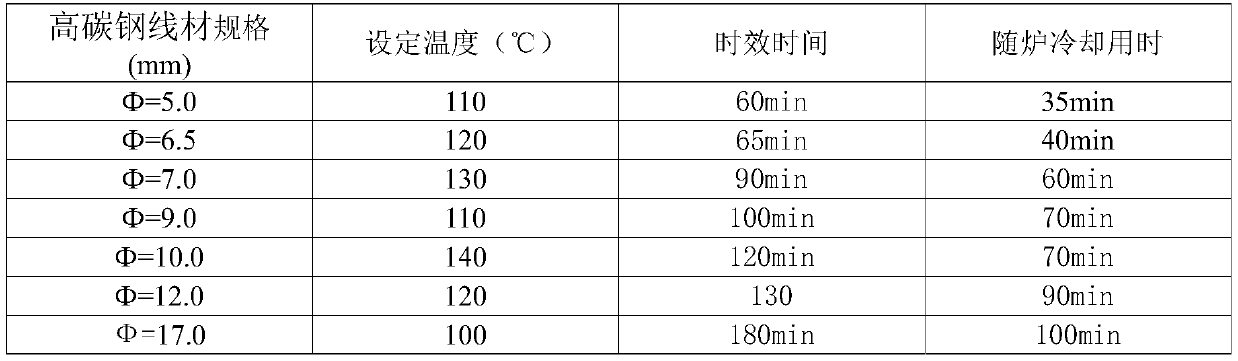

Embodiment 1~7

[0039] Embodiments 1 to 7 carry out aging treatment as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com