Composite air-drying hardened wallboard and manufacturing method and using method thereof

A production method and self-drying technology, which is applied to building components, buildings, building structures, etc., can solve the problems of deformation and cracking of wall panel joints, restricting the development of lightweight wall panels, and increasing the labor intensity of workers. The effect of reducing installation labor costs, reducing labor intensity of workers, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

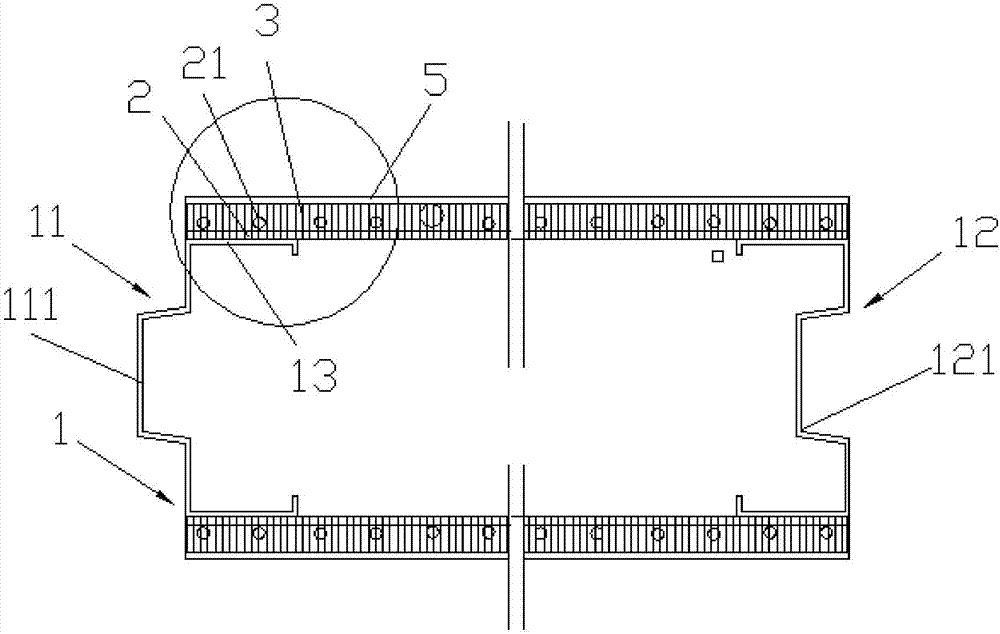

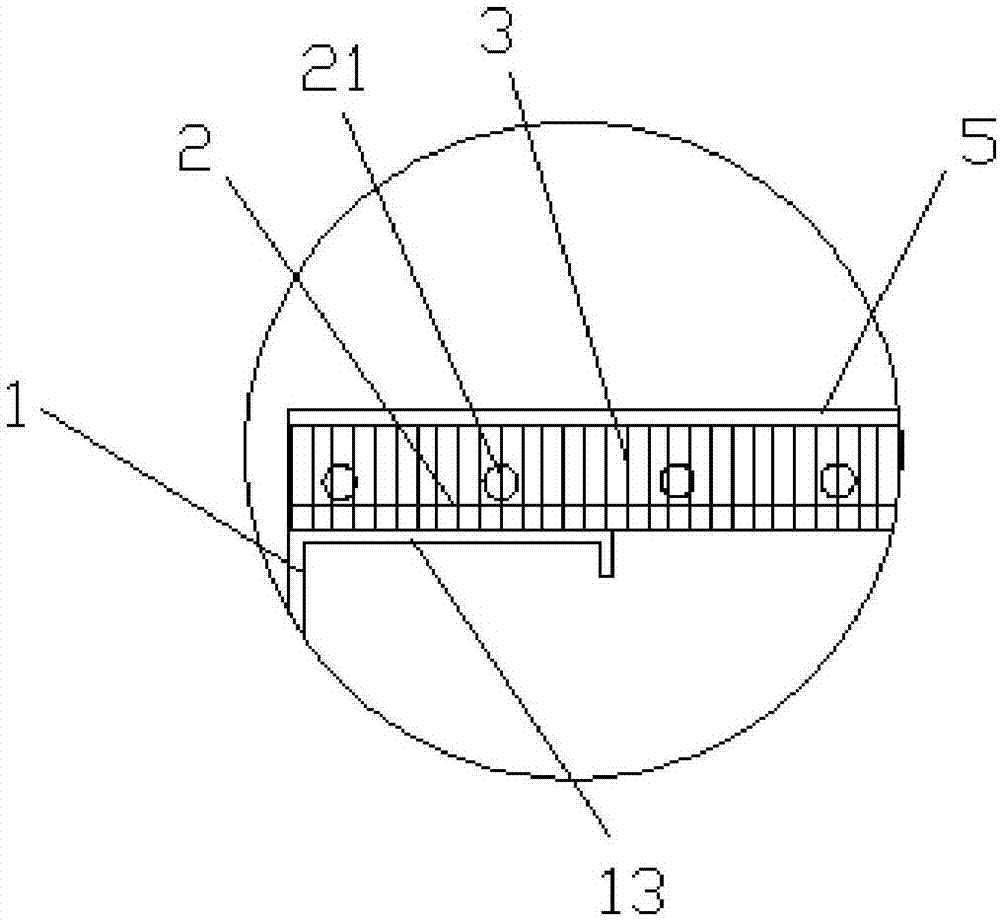

[0024] Embodiment 1: as figure 1 and figure 2 As shown, a composite self-drying hardening wallboard includes a rectangular frame 1, a steel bar composite mesh 2 and a self-drying surface layer, and the steel bar composite mesh 2 and the self-drying surface layer are located on the front and back sides of the frame 1 from the inside to the outside. For the convenience of installation, the frame 1 is formed by connecting two convex profiles 11 and two convex profiles 12, and the convex profiles 11 and the convex profiles 12 are all provided with two parallel bars for connecting the steel bar composite mesh 2. Side 13, and the butt surface between the two sides 13, the butt surface of the convex profile 11 is provided with a protruding rib 111, and the butt surface of the convex profile 12 is provided with a concave groove 121, the protruding bar 111 and groove 121 extend along the length of the profile.

[0025] Reinforcement composite mesh 2 is made up of stressed reinforcem...

Embodiment 2

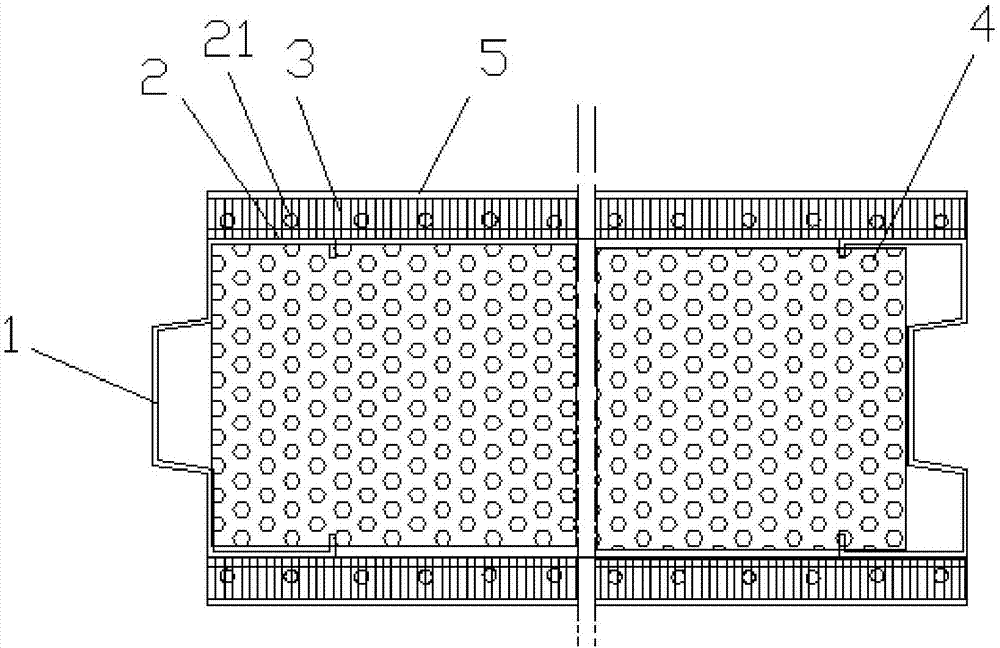

[0029] Embodiment 2: The structure of the composite self-hardening wallboard in this embodiment is basically the same as that of Embodiment 1, and the difference is as follows: image 3 As shown, in order to play a better role in flame retardancy, heat preservation, heat insulation and sound insulation, a light-weight filler board 4 for flame retardancy, heat preservation and sound insulation is installed between the frame 1 and the two reinforced steel meshes 2, The honeycomb tissue layer 3 is connected with the lightweight filler board 4 .

[0030] For the manufacture method of the compound self-drying hardening wallboard of the present embodiment, comprise the following steps: (1), the two sides of described frame 1 are respectively connected with reinforcing bar composite mesh 2, between frame 1 and reinforcing bar composite mesh 2 Place the lightweight filling board 4; (2), spray the honeycomb tissue layer 3 on the outside of the two reinforced meshes 2 respectively; (3),...

Embodiment 3

[0031] Embodiment 3: The structure of the composite self-hardening wallboard in this embodiment is basically the same as that of Embodiment 2, the difference is as follows Figure 4 As shown, the honeycomb structure layer 3 is a fireproof fiber honeycomb board, which is a prior art and can be purchased in the market, and a glass fiber honeycomb board can also be used. The honeycomb tissue layer 3 is adhered or installed on the reinforced mesh 2 . The manufacturing method of the composite self-drying hardening wallboard in this embodiment is basically the same as that in Embodiment 2, the difference is that the fireproof fiber honeycomb board is bonded or assembled on the composite steel mesh 2 .

[0032]The invention creatively sets the self-drying surface layer, which is light in weight before hardening, convenient for transportation, reduces transportation costs, reduces labor intensity of workers during installation, improves installation efficiency, and reduces installatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com