Apparatus and method for lifting up, compacting and forming concrete in steel-pipe column (wall)

A technology for a concrete roof and forming device, which is applied to columns, walls, piers and other directions, can solve the problems of discontinuous concrete, heavy vibrating work, complicated construction organization, etc. , pumpability and ease of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

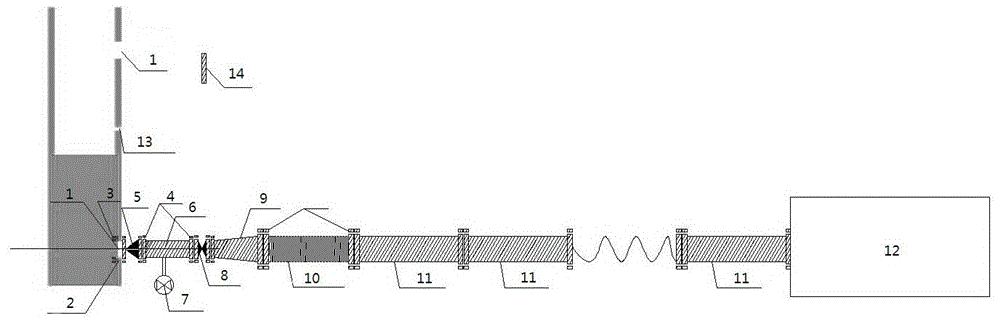

[0042] The present invention will be further described below in conjunction with accompanying drawing:

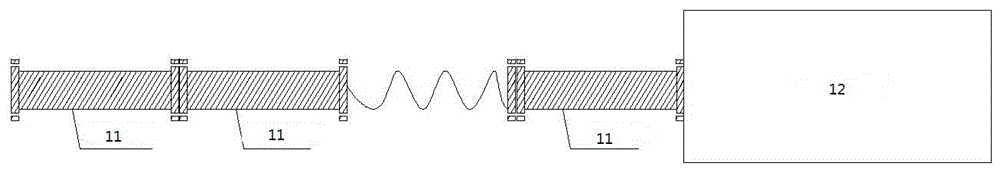

[0043] A steel pipe column (wall) concrete jacking and compacting forming device, including a pressing structure node, an anti-backflow device, a pressure regulating device, and a pumping system;

[0044] The binder structure node is arranged on the bottom side of the steel pipe column (wall), and the binder structure node is sequentially connected to the anti-backflow device, the pressure regulating device, and the pumping system.

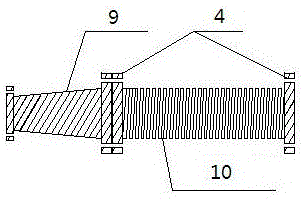

[0045] Further, the binder structure node is a material injection hole (1) arranged on the bottom side of the steel pipe column (wall), and a bolt connection hole (2) with silk thread is provided on the steel plate around the material injection hole (1) A connecting nut (3) is welded on the inner side of the steel pipe column (wall), and the connecting nut (3) is connected to the connecting flange (4) of the anti-backflow device through connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com