Bag supporting and bag holding mechanism of secondary packaging machine

A secondary packaging and machine bag technology, which is applied in packaging and other directions, can solve the problems of poor bag stability, low efficiency, and easy deformation of packaged items, so as to improve the stability of bag bags and improve work efficiency , the effect of preventing deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

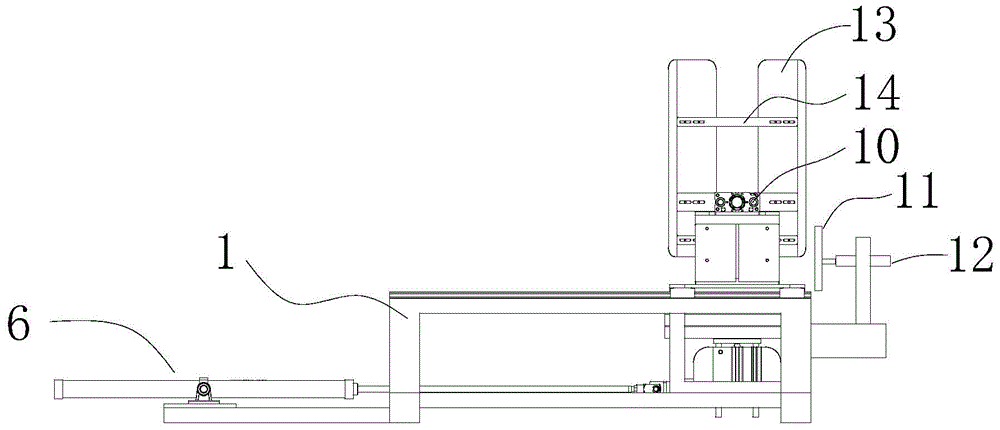

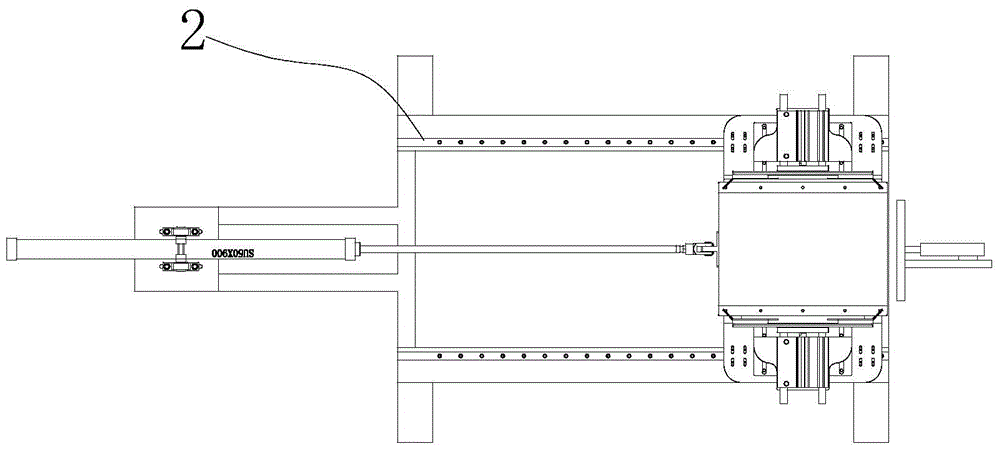

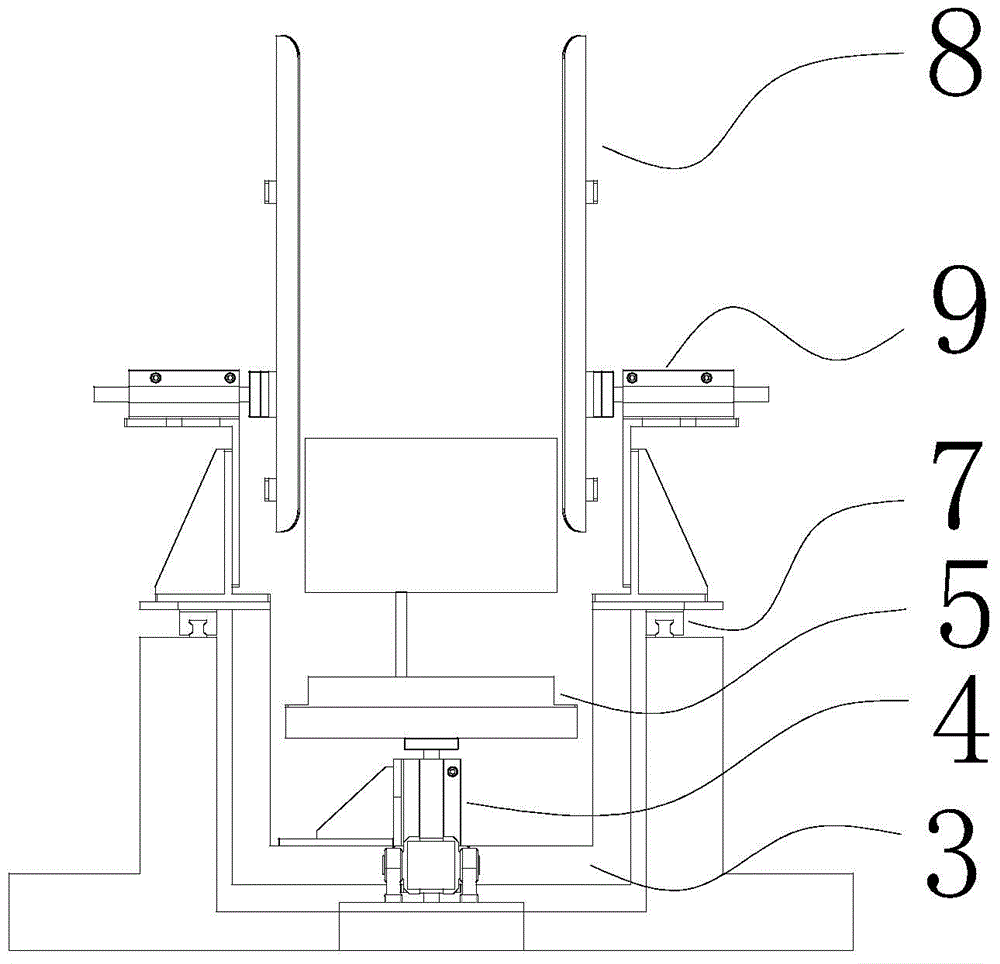

[0014] The bag holding mechanism of the secondary packaging machine includes a mechanism base, a horizontal guide rail, a bag support bottom plate bracket, a bottom plate cylinder, a bag support bottom plate on the bottom plate cylinder, a bag moving cylinder, and a card slot on the bag support bottom plate bracket. The clamping grooves are respectively provided with splint cylinders, and the plywood cylinders are fixed with bag holding splints, the inner side of the bag holding splints is provided with sensors, and one end of the bag holding bottom plate is provided with a pusher along the direction of the horizontal guide rail. plate, and the outside of the push plate is connected with a push plate cylinder.

[0015] The bag-holding splint is composed of two arc-shaped plates and a horizontal plate.

[0016] The sensor is installed between the inner sides of two arc-shaped plates.

[0017] Such as figure 1 As shown, the bag-holding splint is directly connected to the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com