Supporting method for gob-side entry retaining and its sliding form for injection entry

A technology of sliding form and injection roadway, which is applied in the direction of earthwork drilling, pillar/bracket, wellbore lining, etc. It can solve the problems of not being able to move as a whole, and achieve the effects of easy transportation and use, saving assembly and disassembly procedures, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

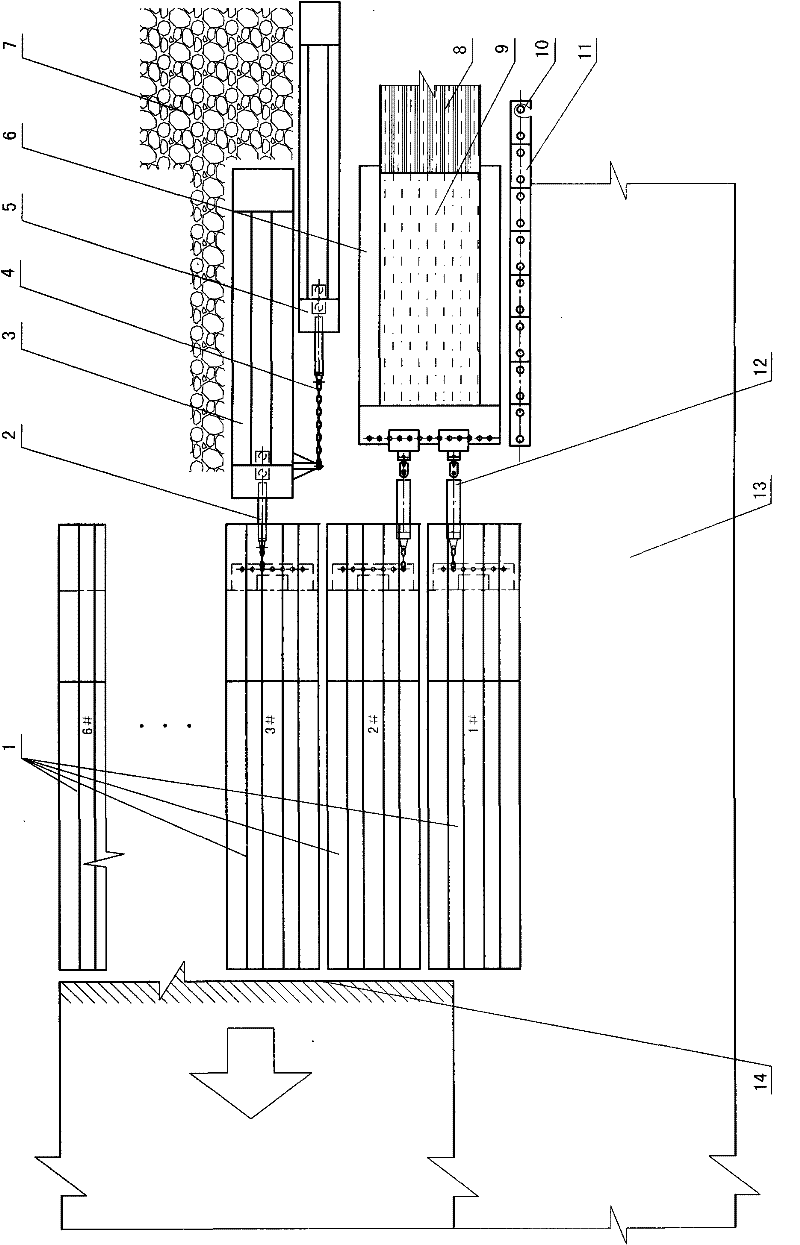

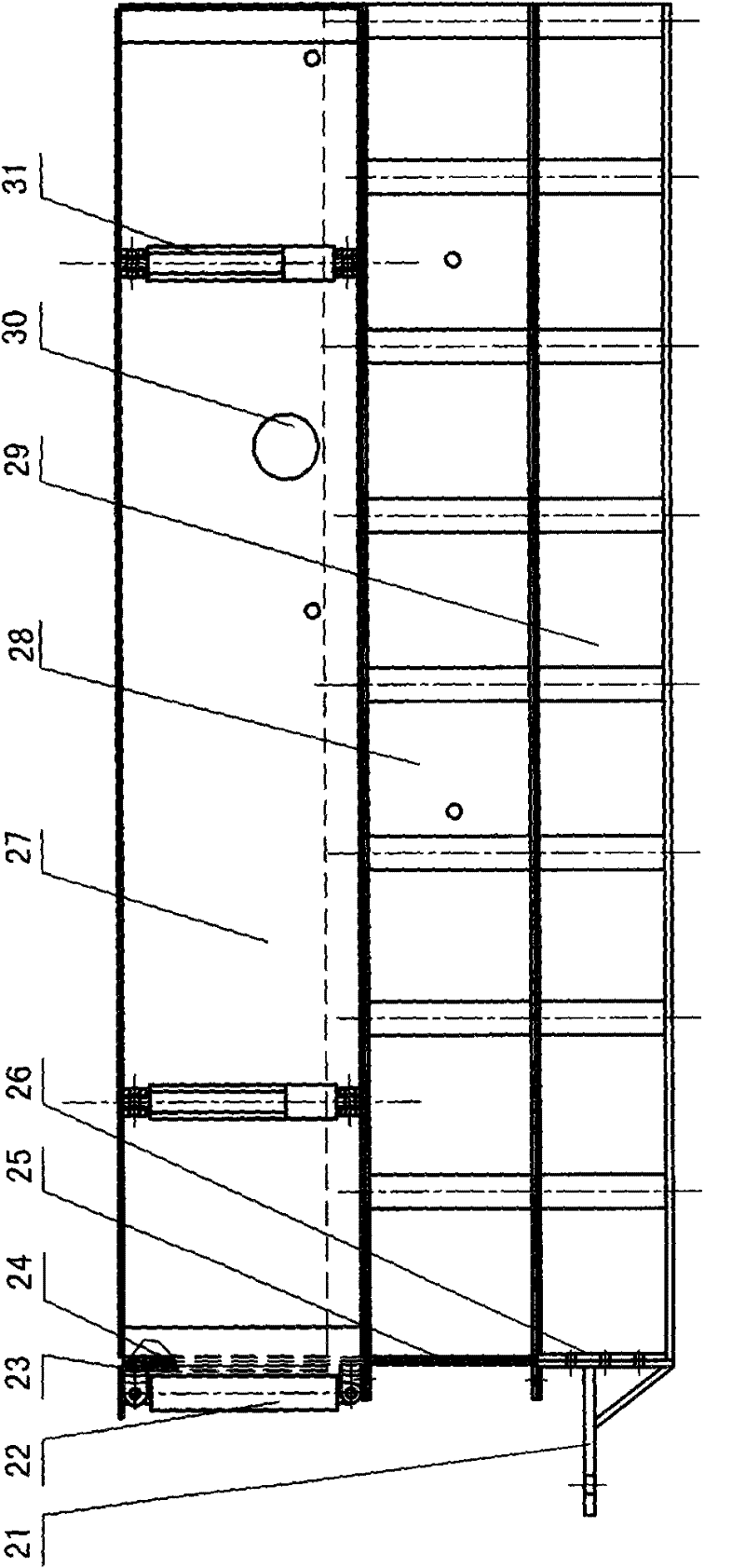

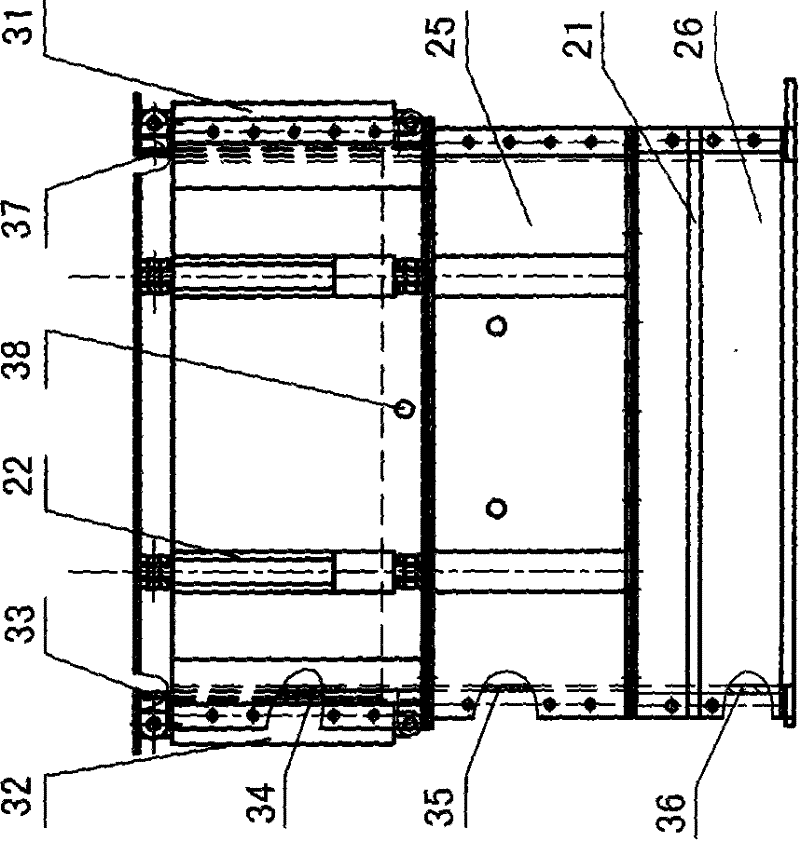

[0032] exist figure 1 Fig. 1 shows the arrangement of the entry slip form 6, bunker brackets 3 and 5, head bracket 1 and other equipment in the gob-side entry retaining support method of the present invention at the lower end of the fully mechanized mining face.

[0033] The gob-side entry retaining support method of the present invention is to move along with the fully mechanized mining face, after the header support 1, transport the goaf 7 side of the trough 13, use the concrete pump to transport the concrete long-distance through the pipeline, and pour it to the filling mold , the filling concrete 9 in the filling mold is solidified, and the roadside filling wall 8 (or the roadside filling body) is constructed to form the roadside support belt. Maintain the transport chute in the previous section and use it as the return air chute in the lower section.

[0034] For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com