Parallel robot

A robot and parallel technology, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve problems such as inability to adapt to product requirements, unreasonable bottom plate structure, and bulky overall structure, and achieve convenient assembly and disassembly, reasonable overall structure layout, Apply promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

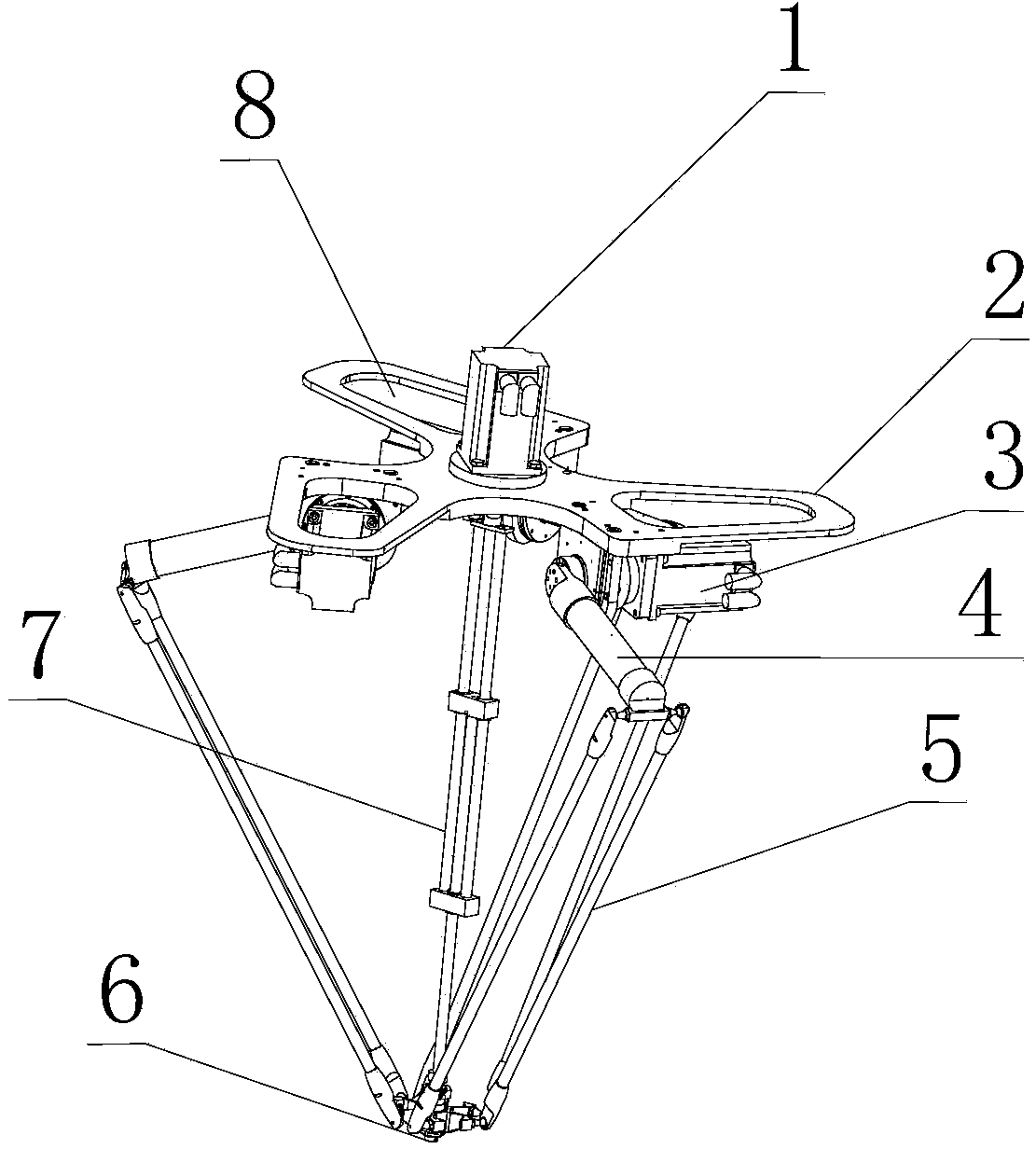

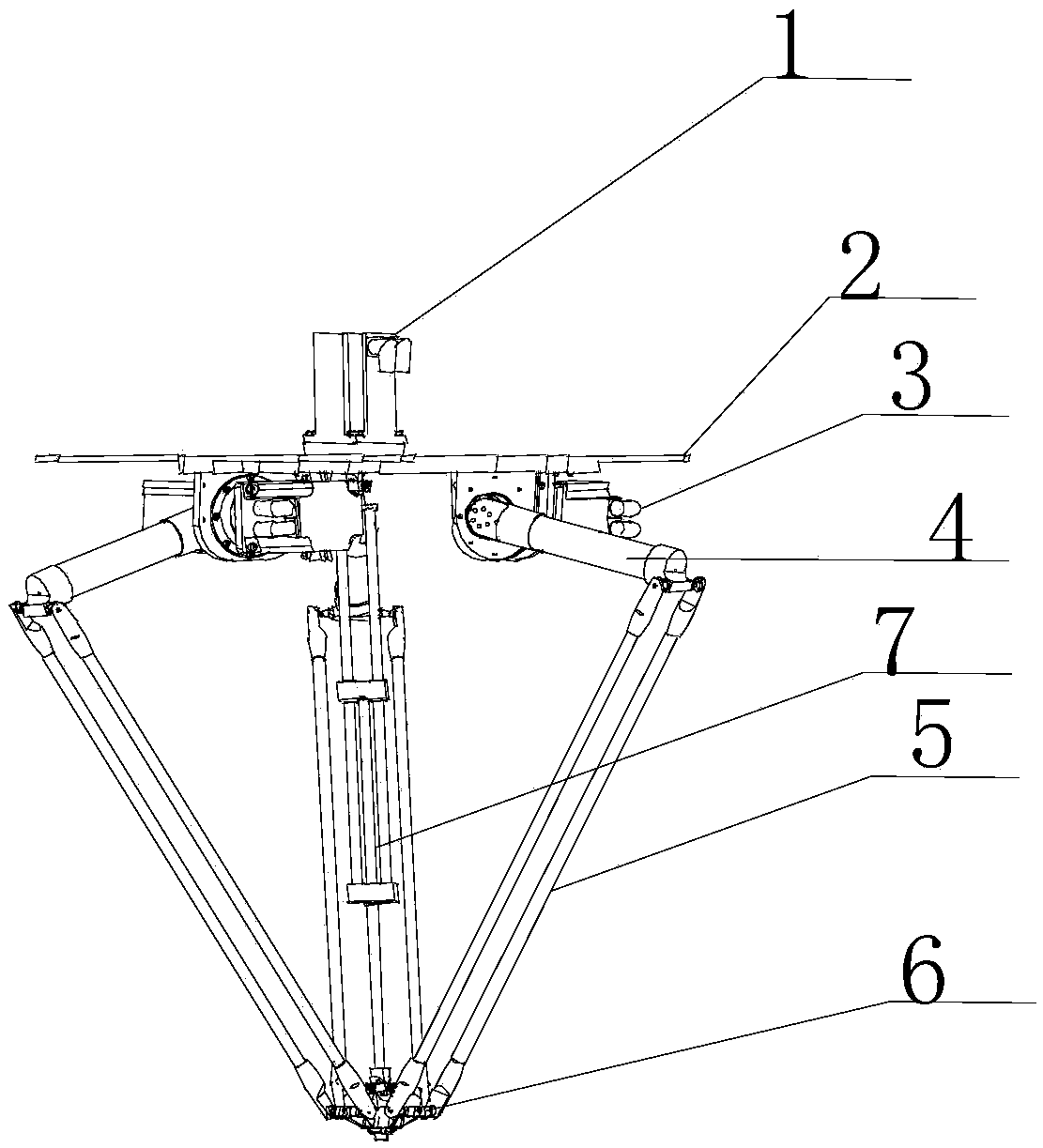

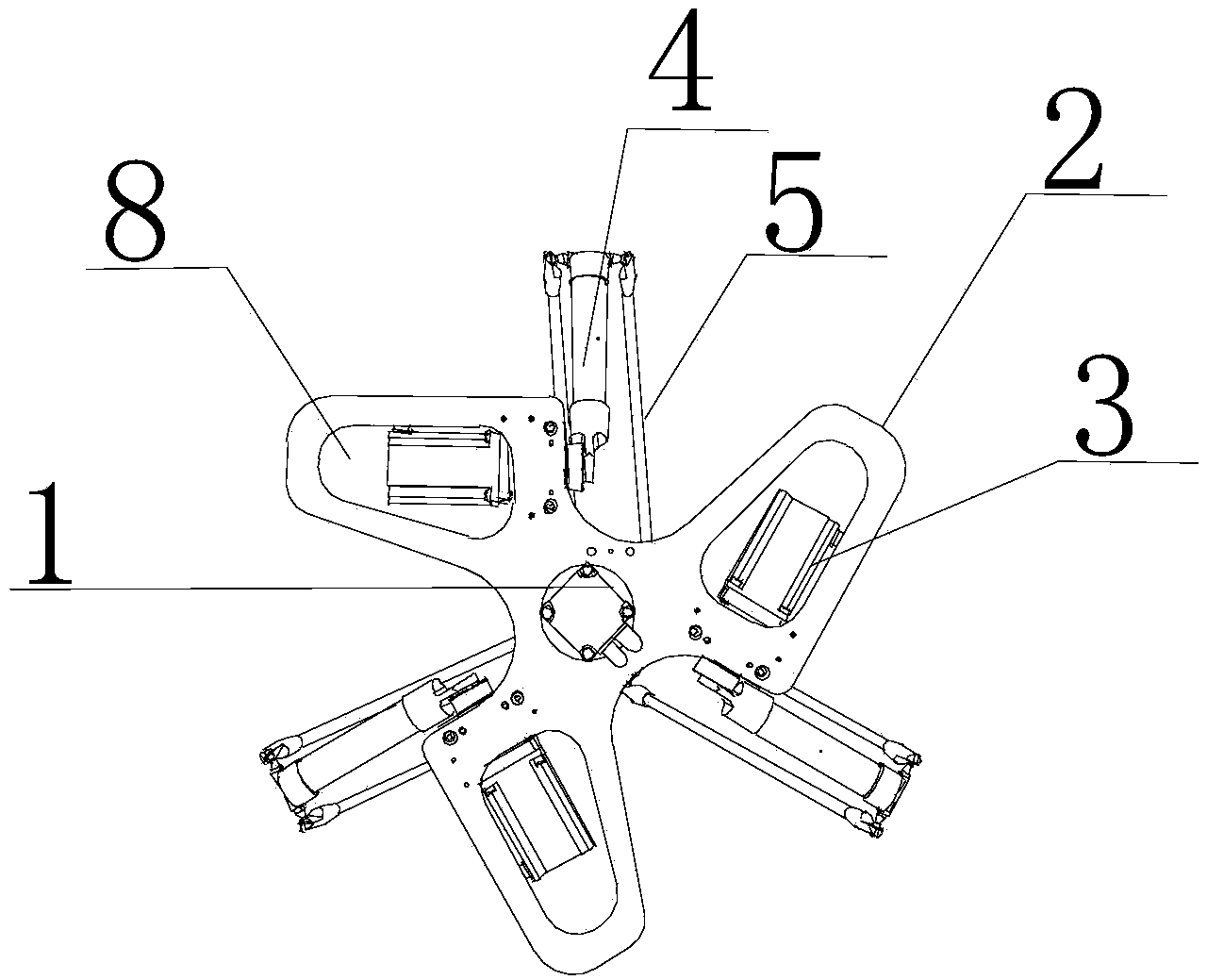

[0028] Combine below figure 1 The present invention will be further described.

[0029] A parallel robot, including a central motor 1, a robot base plate 2, a motor reducer assembly 3, an upper arm 4, a lower arm 5, a lower chassis 6, and a central telescopic rod 7, is characterized in that the motor reducer assembly 3 Installed on the bottom of the robot base plate 2, the center of the robot base plate 2 is distributed at 120 degrees. The upper arm 4 and the lower arm 5 are connected by a spherical joint to form an arm, and the motor reducer assembly 3 and the lower chassis 6 are composed of three arms. Connected, the central telescopic link 7 is connected to the central rotary shaft of the central motor 1 and the lower chassis 6.

[0030] One end of the upper arm 4 is installed on the motor reducer assembly by screws.

[0031] The upper arm 4 adopts different types of carbon fiber rods.

[0032] The central position of the robot bottom plate 2 is provided with a fixing ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com