Automatic secondary bagging device and operating method thereof

A bagging device and automatic technology, which is applied in the field of automatic secondary bagging devices, can solve the problems of high labor intensity and low production efficiency, and achieve the effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

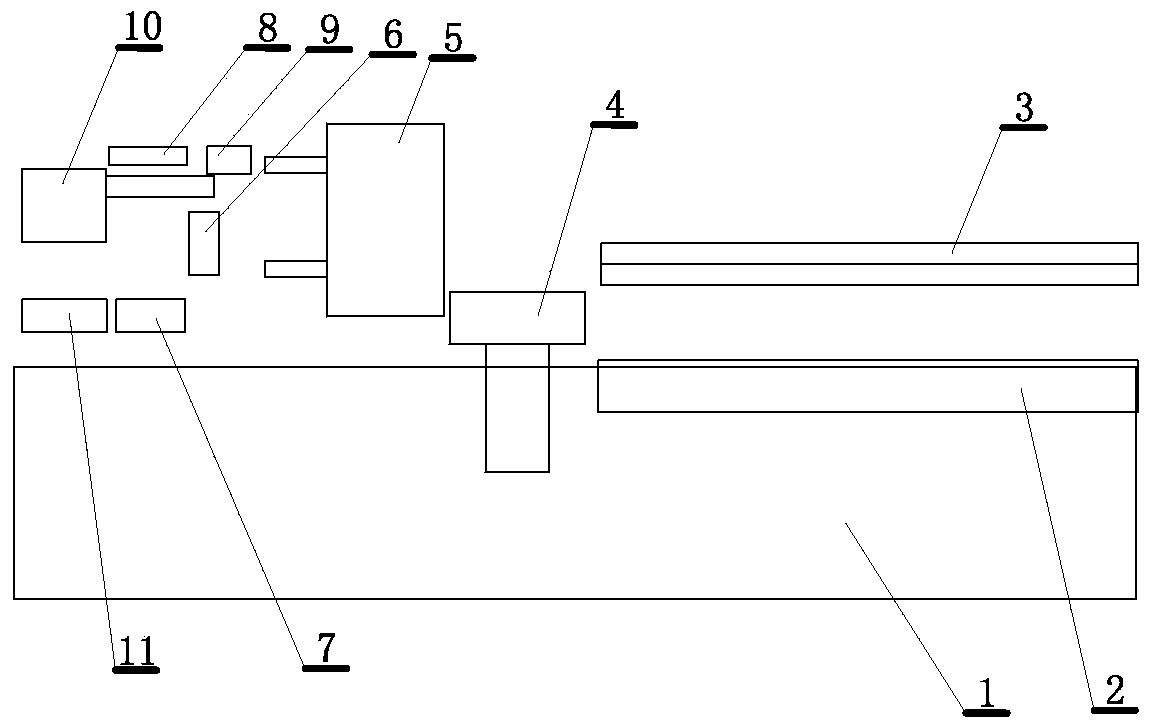

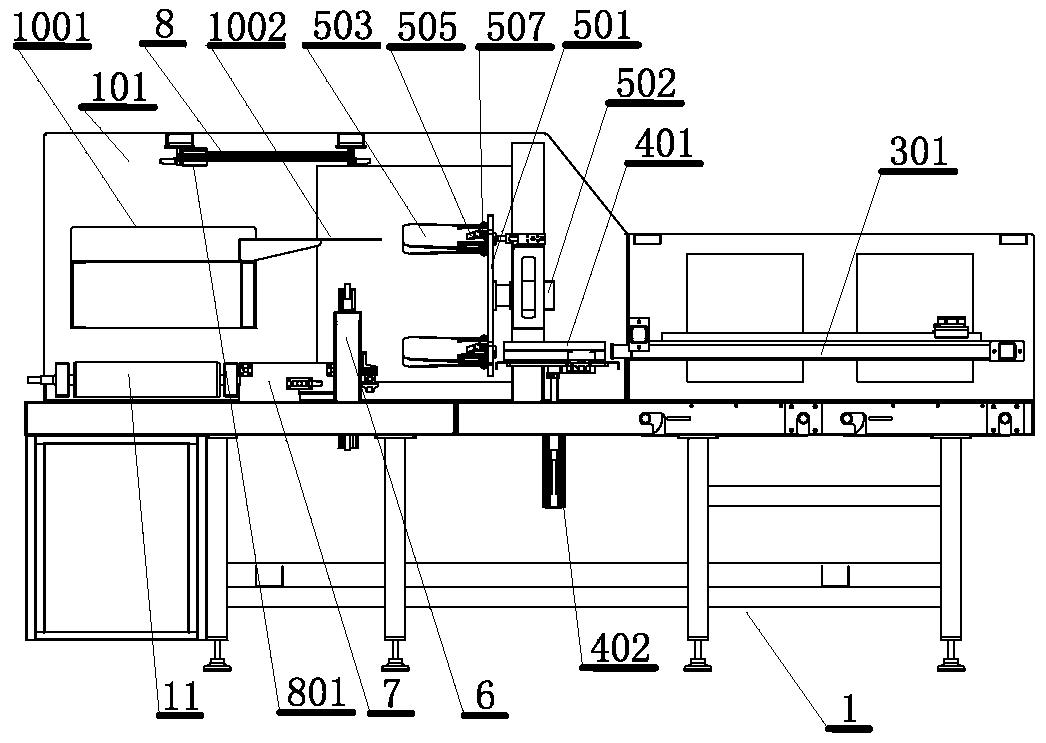

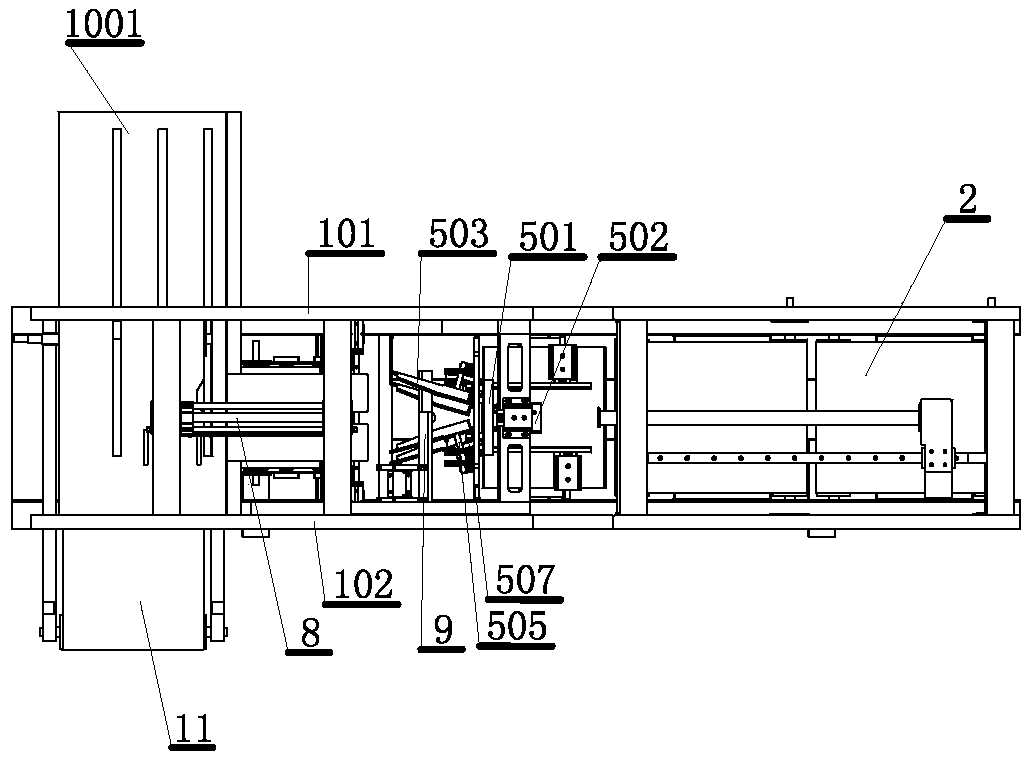

[0033] An automatic secondary bagging device, figure 1 The block diagram of the device structure is illustrated, the automatic secondary bagging device includes a supporting frame 1, and a feeding conveyor belt 2, a bag pushing mechanism 3, a bag supporting mechanism 4, a bag supporting mechanism 5, and a sealing machine 6 are arranged on the frame , a finished product conveyor belt 7, a bag taking mechanism 8, a bag opening mechanism 9, a bag supply mechanism 10 and a storage conveyor belt 11, the feeding conveyor belt 2 is arranged on the front end side of the supporting frame 1, and the feeding conveyor belt front end and the rice brick packaging line Or the conveyor belt is connected, wherein, the bag pushing mechanism 3 is arranged above the feeding conveyor belt 2, the bag supporting mechanism 4 is connected with the rear end of the feeding conveyor belt 2, the bag supporting mechanism 5 is arranged next to the bag supporting mechanism 4, and the sealing machine 6 is tig...

Embodiment 2

[0044] This embodiment is based on the working method of a kind of automatic secondary bagging device described in embodiment 1, so the content of embodiment 1 should be regarded as the content of this embodiment, and it is known from the working principle of embodiment 1 that the method is The rice bricks are sent to the feeding conveyor belt, and the bag-taking arm of the bag-taking mechanism takes out the bag from the bag storage platform at intervals, moves forward and puts it on the bag-opening tray, and the mouth of the bag is placed on the bag-opening tray. Between the upper and lower bag opening suction cups of the mechanism, the bag opening mechanism opens the bag mouth and moves forward to put the packaging bag on a group of bag support arms on the upper side of the turntable. The bag support arms open the bag mouth through the spread mechanism, and the turntable rotates 180 The stretched packaging bags are transferred from the upper end of the turntable to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com