Fully-automatic cargo sorting and packaging system for logistics distribution, and method thereof

A technology of logistics distribution and packaging system, applied in sorting and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

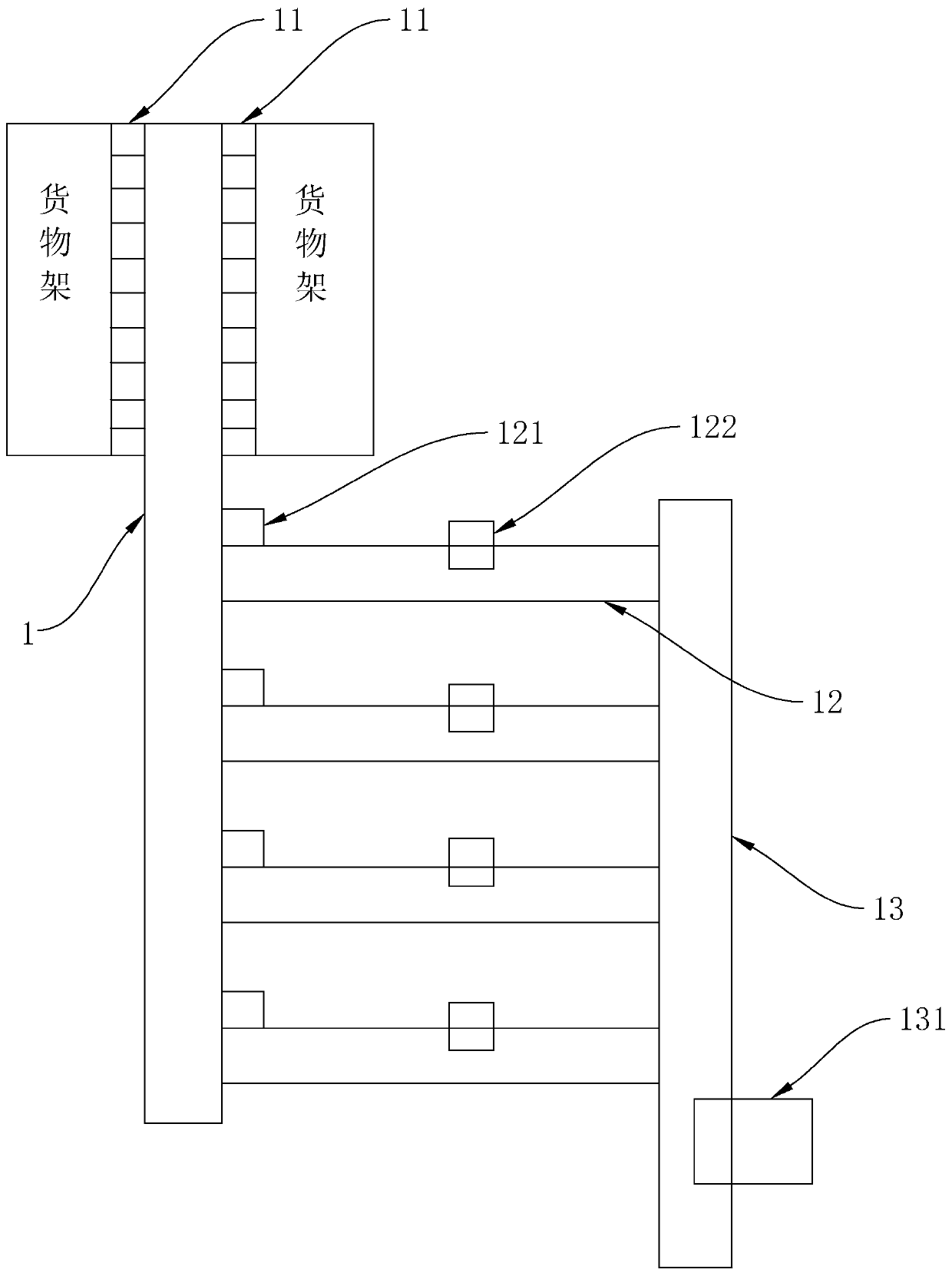

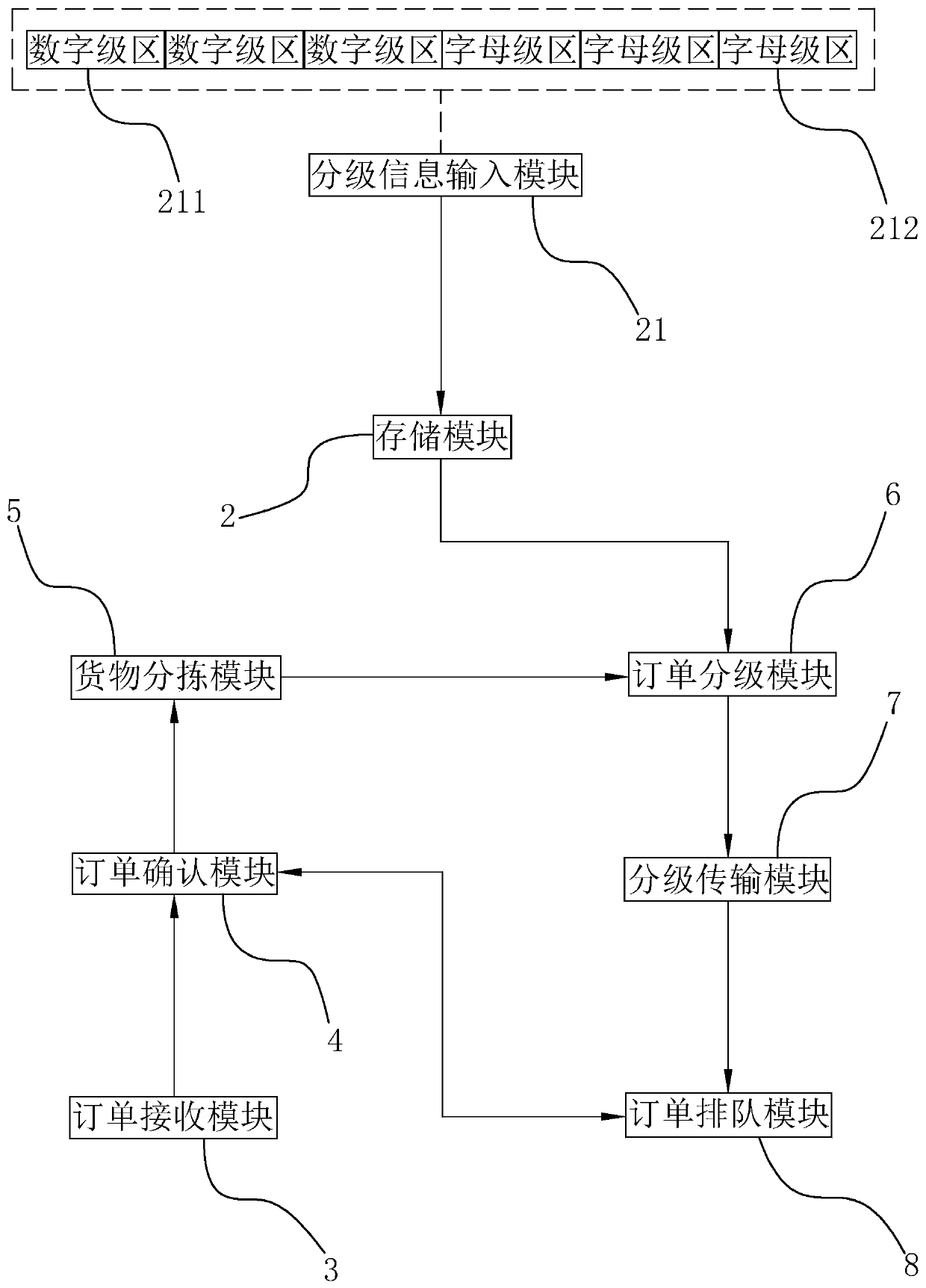

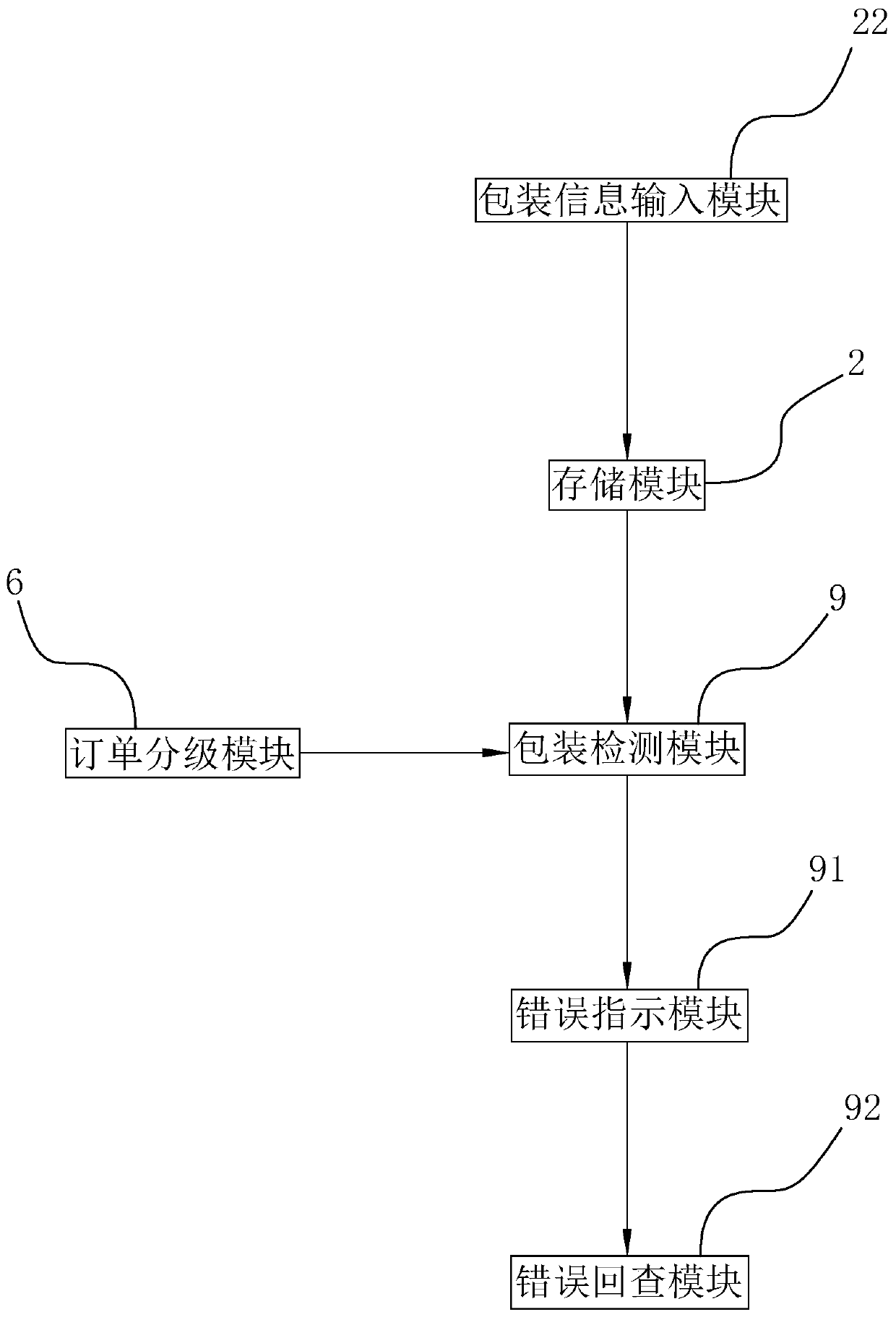

[0064] Embodiment 1: A fully automatic sorting and packaging system for logistics and distribution goods, such as figure 1 As shown, a sorting conveyor belt 1 is included, and a pick-up manipulator 11 for grabbing goods from a shelf to the sorting conveyor belt 1 is arranged on the sorting conveyor belt 1 . A plurality of packaging conveyor belts 12 are arranged on one side of the sorting conveyor belt 1, and each packaging conveyor belt 12 is provided with a position close to the sorting conveyor belt 1 for grabbing goods from the sorting conveyor belt 1 to the packaging conveyor belt 12 The grading manipulator 121 is equipped with an automatic packaging machine 122 with different packaging styles on each packaging conveyor belt 12. The sorting conveyor belt 1 is set through the shelf, and the packaging conveyor belt 12 is sorted according to the level along the length direction of the sorting conveyor belt 1. . All packaging conveyor belts 12 are provided with a package con...

Embodiment 2

[0074] Embodiment 2: A method for fully automatic sorting and packaging of logistics distribution goods, the specific steps are as follows:

[0075] In the first step, a sorting conveyor belt 1 is set near the cargo rack, and a pick-up manipulator 11 for grabbing goods from the cargo rack to the sorting conveyor belt 1 is set on the sorting conveyor belt 1 . A plurality of packaging conveyor belts 12 are arranged on one side of the sorting conveyor belt 1, and each packaging conveyor belt 12 is provided with a position close to the sorting conveyor belt 1 for grabbing goods from the sorting conveyor belt 1 to the packaging conveyor belt 12 Grading manipulator 121 of. Automatic packaging machines 122 with different packaging styles are arranged on each packaging conveyor belt 12 . A wrapping conveyor belt 13 is arranged at one end of all the wrapping conveyor belts 12 away from the sorting conveyor belt 1 , and a three-dimensional scanner 131 is arranged on the wrapping convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com