Packaging system based on double-arm robot

A packaging system and robot technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of scattered functional modules of automated packaging equipment, high operation and maintenance costs, low production efficiency, etc., to achieve a small footprint and reduce operation. cost, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

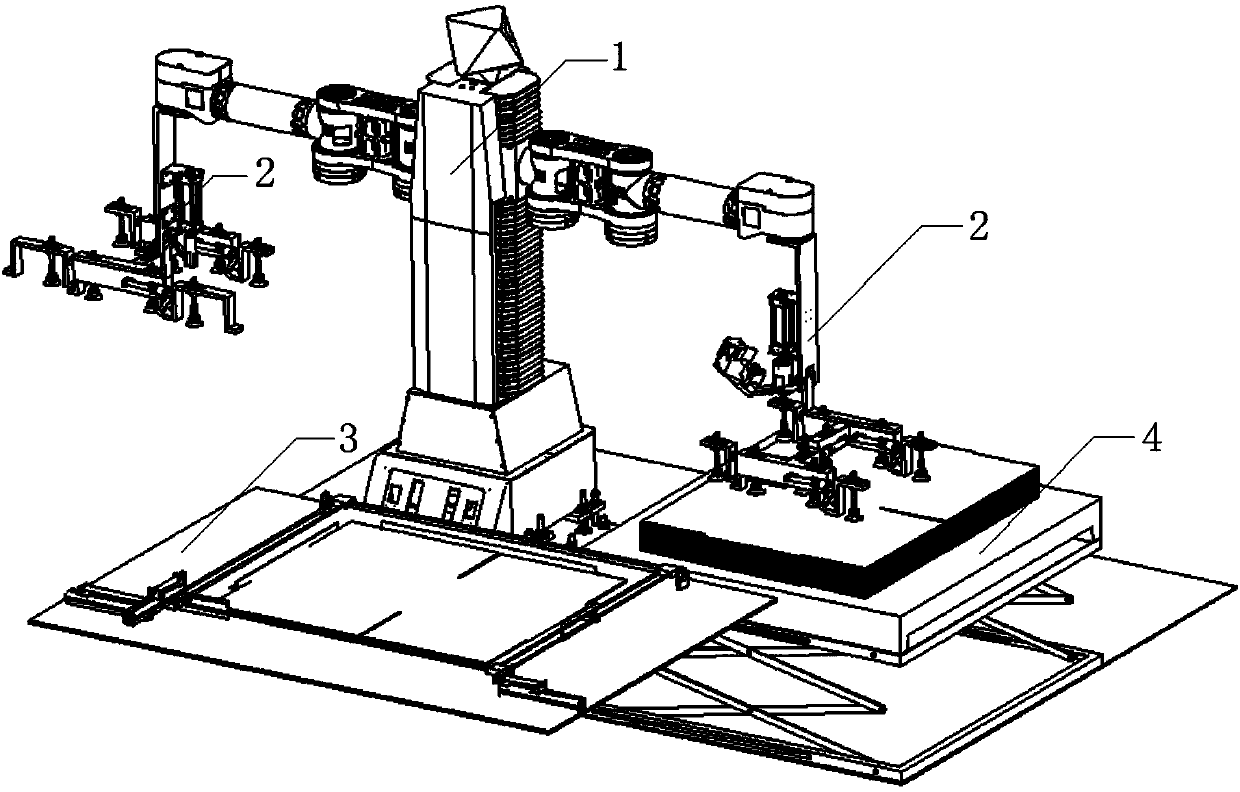

[0033] Such as Figure 1-11 As shown, the present invention includes a dual-arm robot 1, a folding finger mechanism 2 and a positioning mechanism 3, the free ends of the mechanical arms on both sides of the dual-arm robot 1 are provided with a folding finger mechanism 2, and the positioning mechanism 3 is arranged on the dual-arm robot 1 On the packaging station on the front side, the carton is placed in the positioning mechanism 3 and positioned by the positioning mechanism 3, and then the two folding finger mechanisms 2 cooperate to simulate human hands to complete the carton folding and pasting and sealing operations.

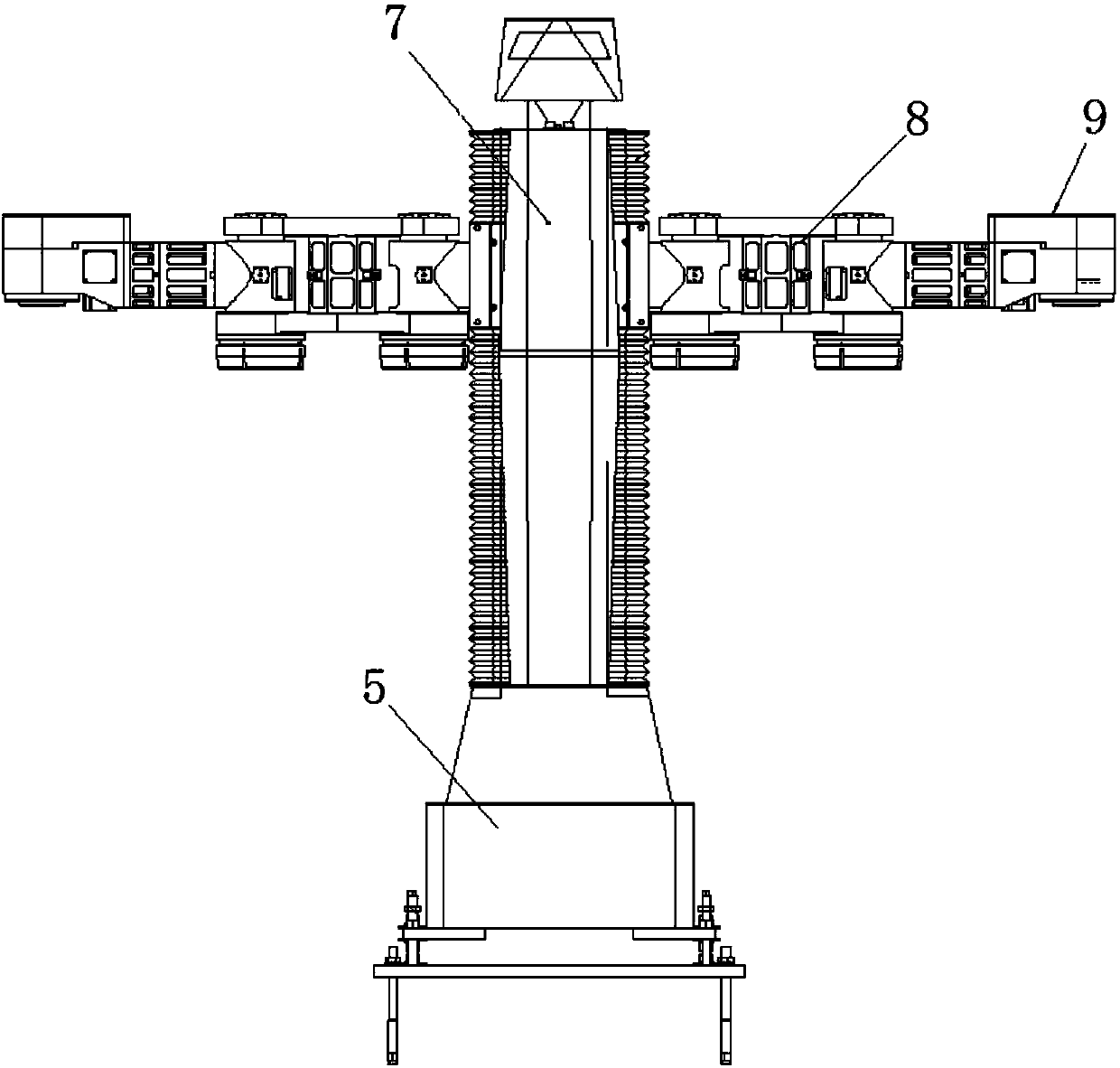

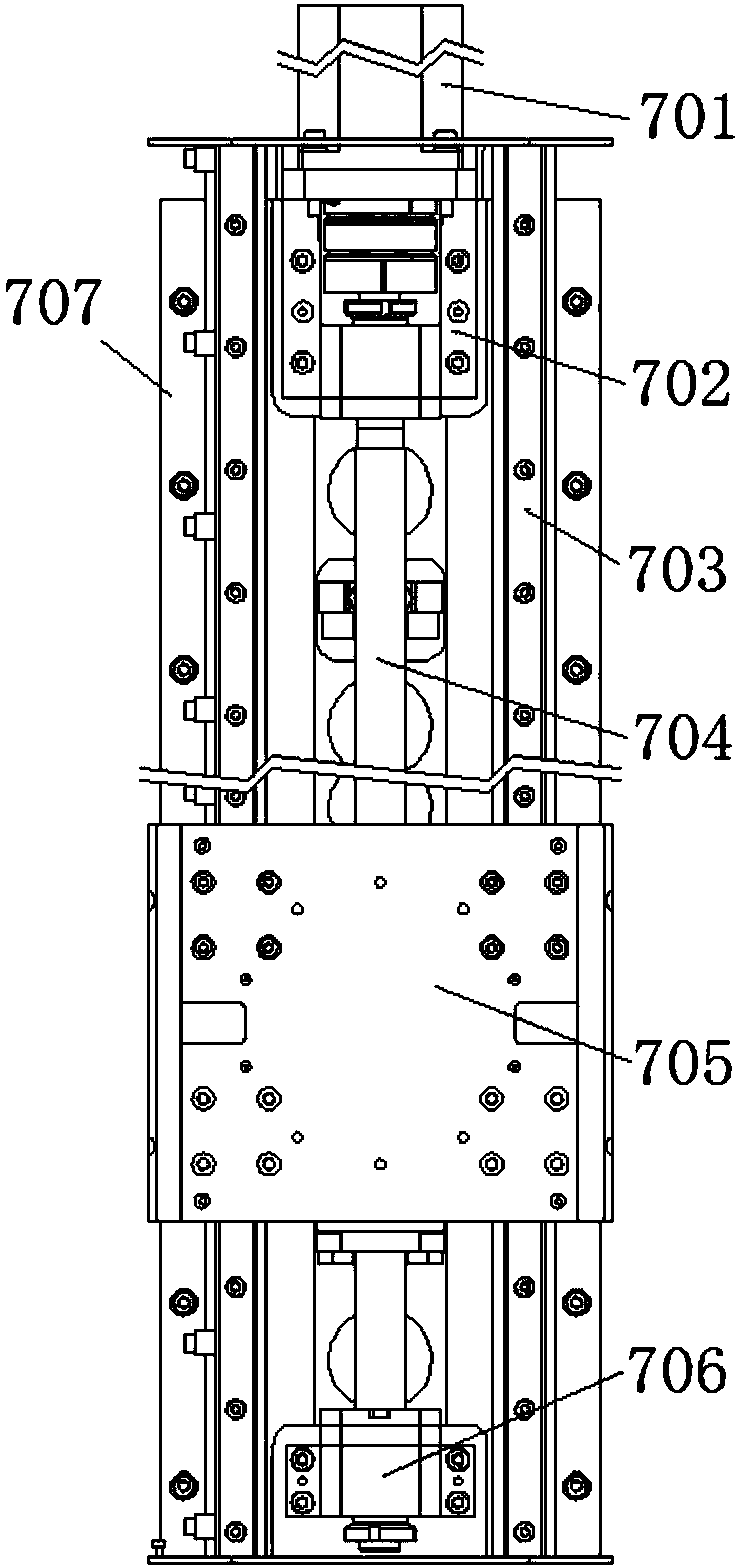

[0034] Such as figure 2 As shown, the dual-arm robot 1 includes a base 5, a mechanical arm lifting mechanism 7 and mechanical arms on both sides, and the mechanical arm lifting mechanism 7 is arranged on the base 5, as image 3As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com