Ceramic diaphragm printing pore filling machine

A technology of ceramic diaphragm and porous ceramic plate, which is applied in the direction of printing machine, rotary printing machine, screen printing machine, etc., can solve the problems of finished product qualification rate and reliability, low qualification rate of multilayer chip inductors, internal electrode Poor connection and other problems, to achieve the effect of good connection, excellent reliability and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

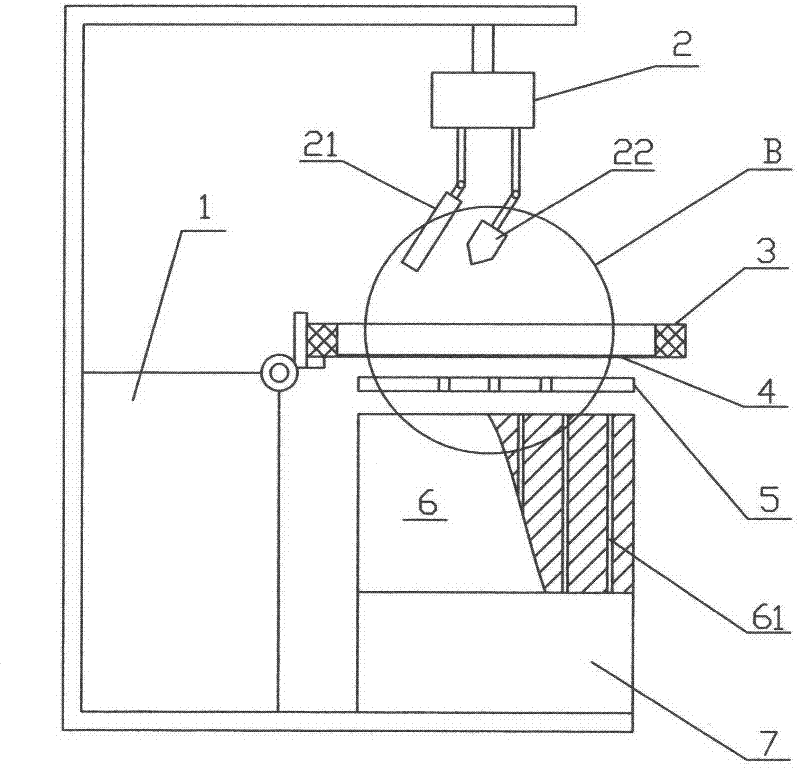

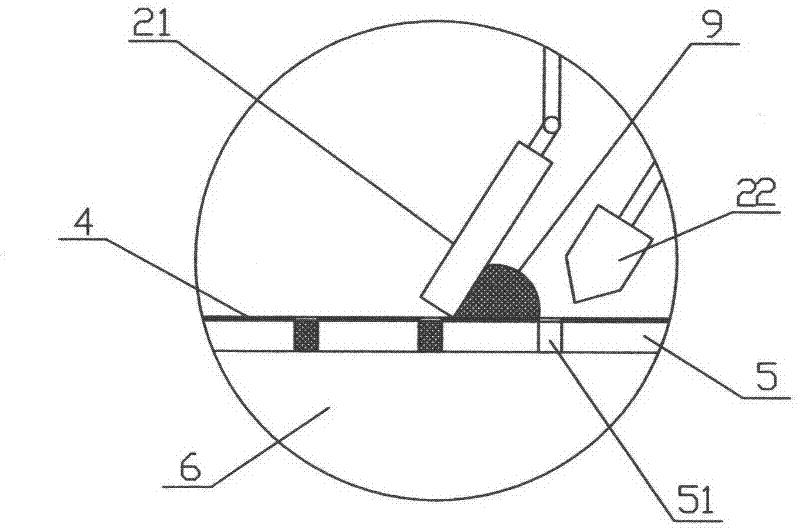

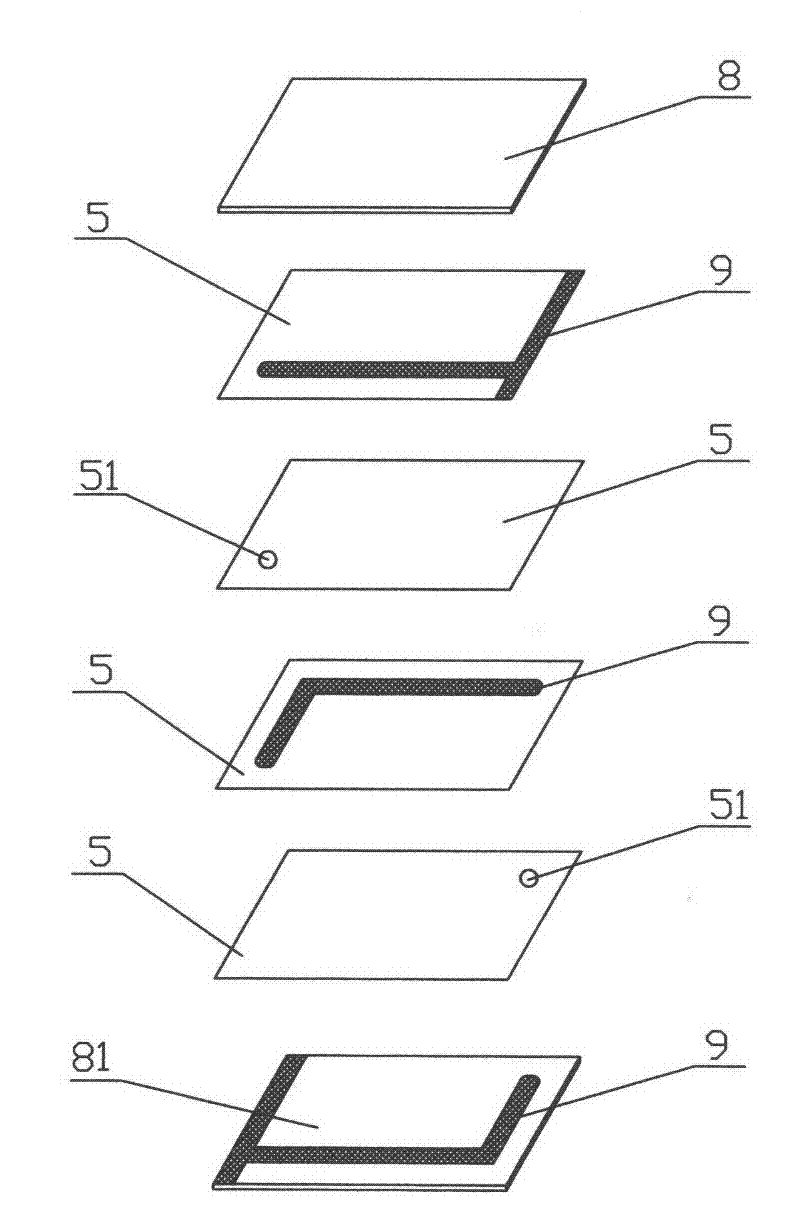

[0024] figure 1 It is a schematic diagram of a ceramic membrane printing and filling machine of the present invention. A ceramic diaphragm printing hole filling machine, which includes a suction cup mechanism, a screen frame, a printing scraper mechanism and a frame. The suction cup mechanism includes a porous ceramic plate and a vacuum system. The porous ceramic plate is connected to the vacuum system. When the vacuum system is turned on, the porous ceramic The plate holds the ceramic diaphragm. The lower part of the suction cup mechanism is equipped with a screw rod and a guide rail, which can be freely entered and exited from the rack for easy operation.

[0025] The screen frame is composed of a frame and a screen. There is a pattern on the screen, and the conductive paste is distributed on the screen pattern. The edge of the frame is provided with hinges to connect with the frame. When printing and filling holes, the screen is tightly attached to the ceramic diaphragm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com