Film-coated base paper and production process thereof

A technology of coated base paper and production process, which is applied in the field of papermaking, can solve the problems of production cost of added products and large material consumption, and achieve the effects of reduced production cost, high stiffness, and good edge seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

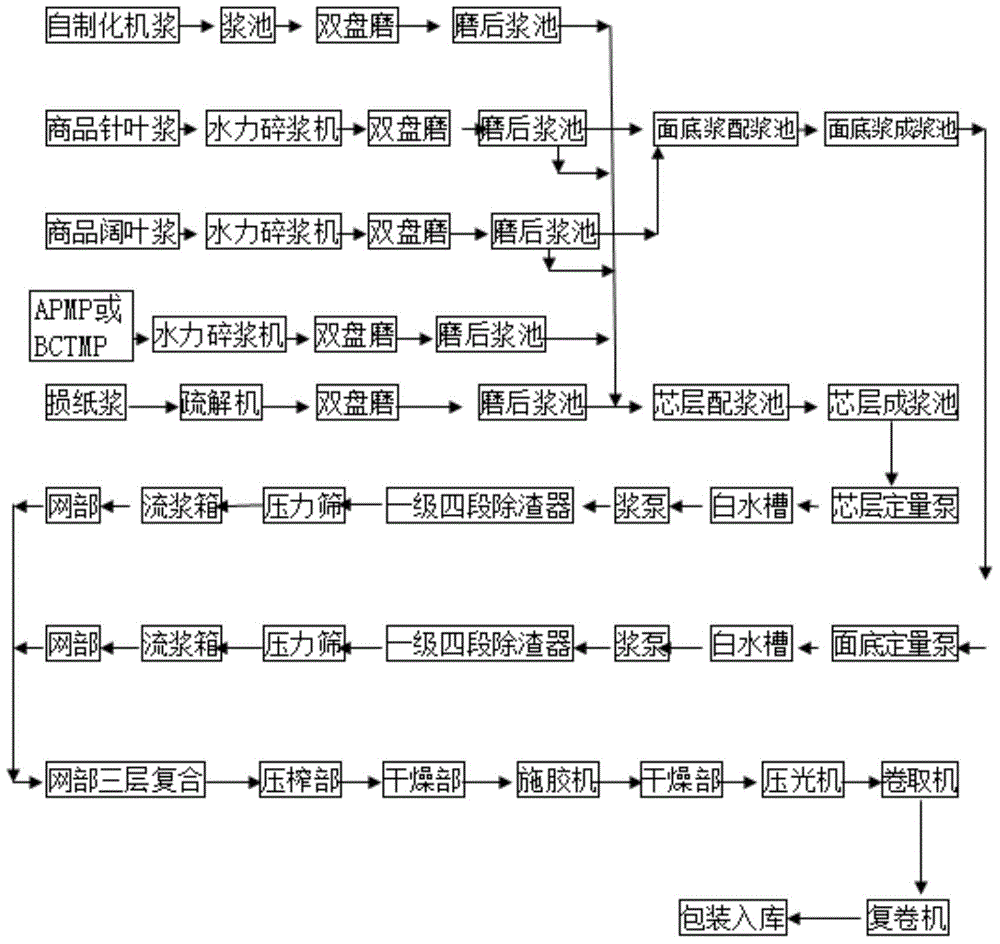

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 Shown, a kind of coated base paper production process of the present invention is characterized in that, obtain coated base paper core layer pulp with chemical-mechanical pulp, coniferous pulp, broadleaf pulp and broke pulp proportioning; The surface layer slurry is obtained by proportioning; and the surface layer slurry is obtained by the ratio of softwood pulp and broadleaf pulp; the three parts of slurry enter the headbox through quantitative pumps, and then enter the three-layer compounding of the net part through the net part, and then After pressing, drying, sizing, drying and calendering in sequence, the finished product is obtained.

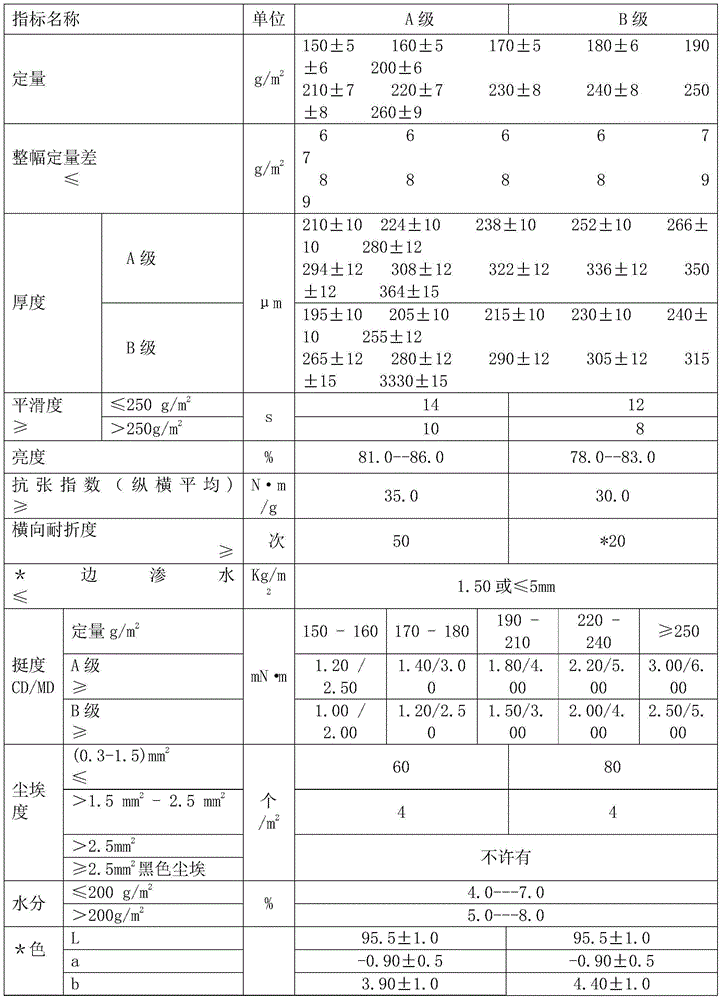

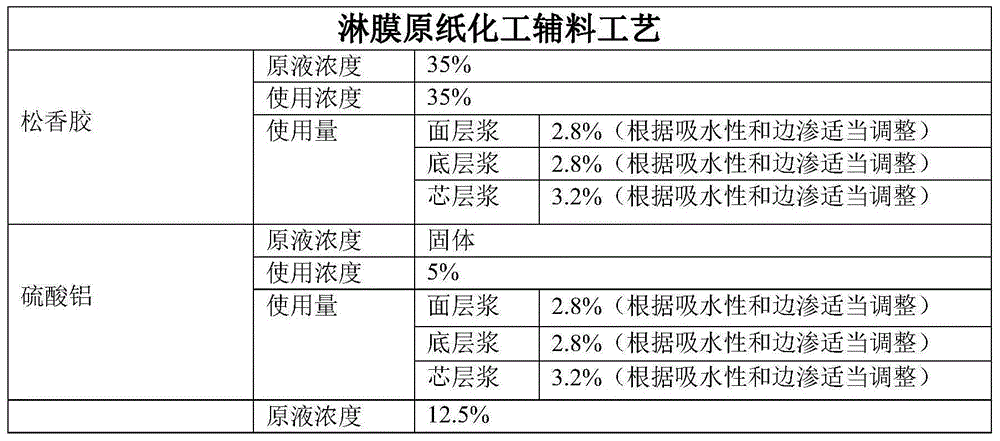

[0023] The further improvement of the present invention includes: the concentration of the surface layer slurry is 2.5-3.0%, the degree of knocking is 27-33°SR, and the wet weight is not less than 3g; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com