A bud-opening drug filling device

A filling device and bud-opening technology, which is applied to offensive equipment, pyrotechnics, weapon types, etc., can solve the problems of low production efficiency, inaccurate positioning, safety accidents, etc., and achieve the effect of simple structure and difficult to store materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art may make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

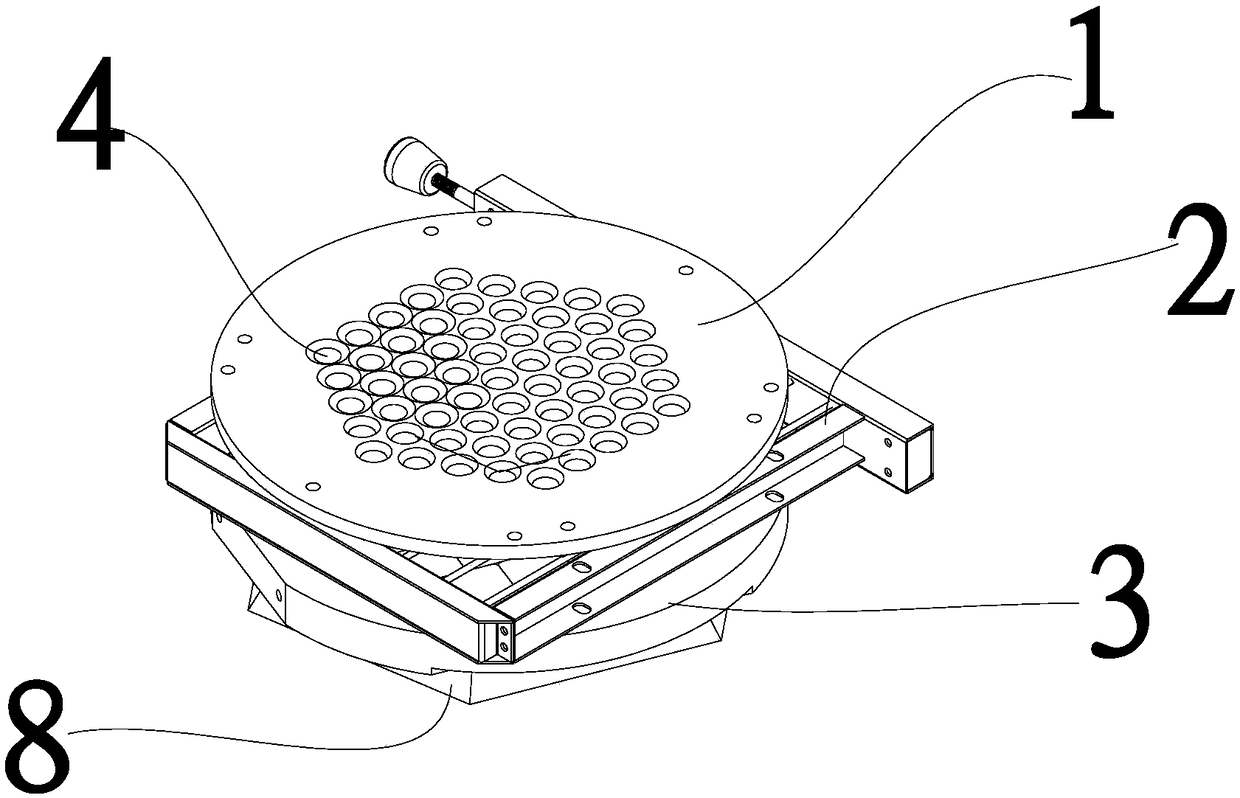

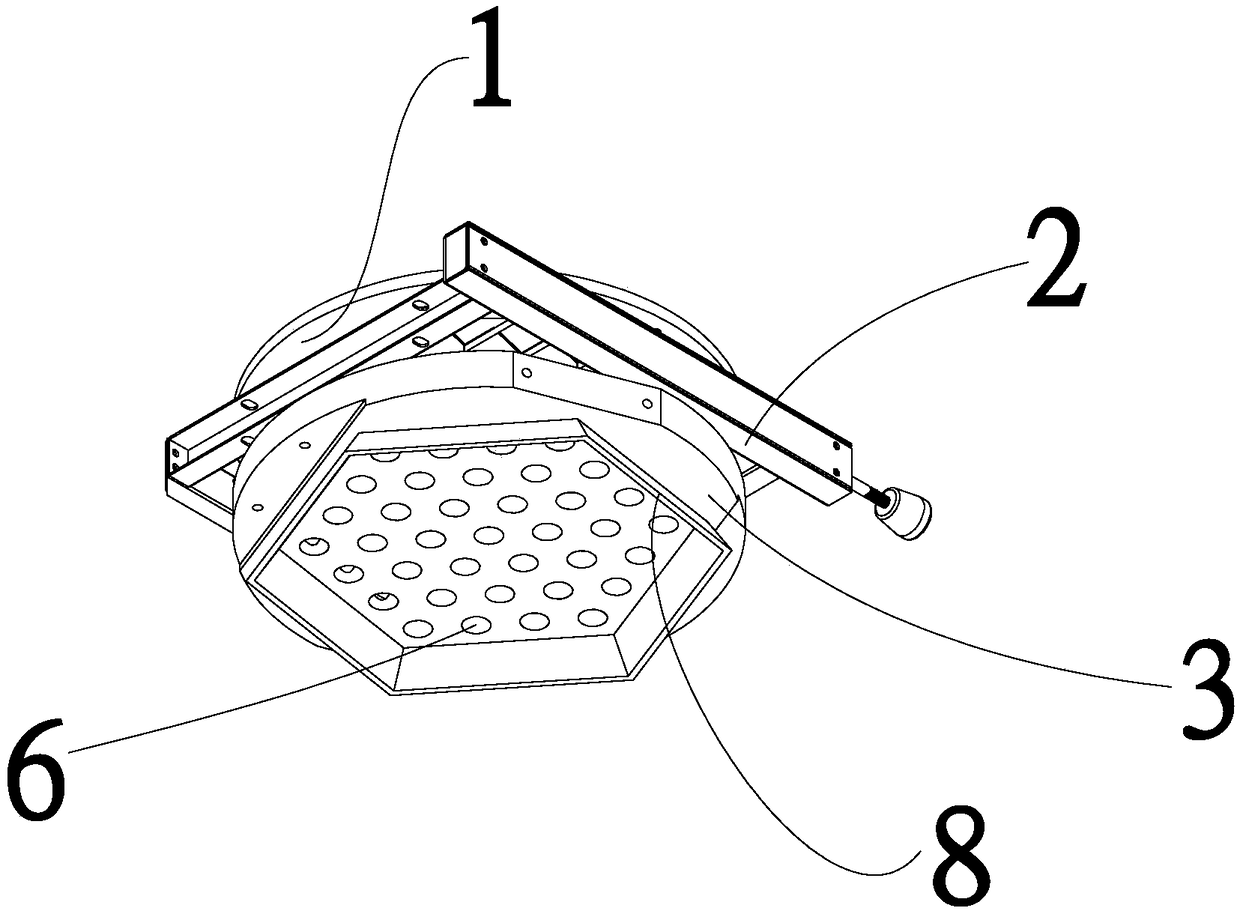

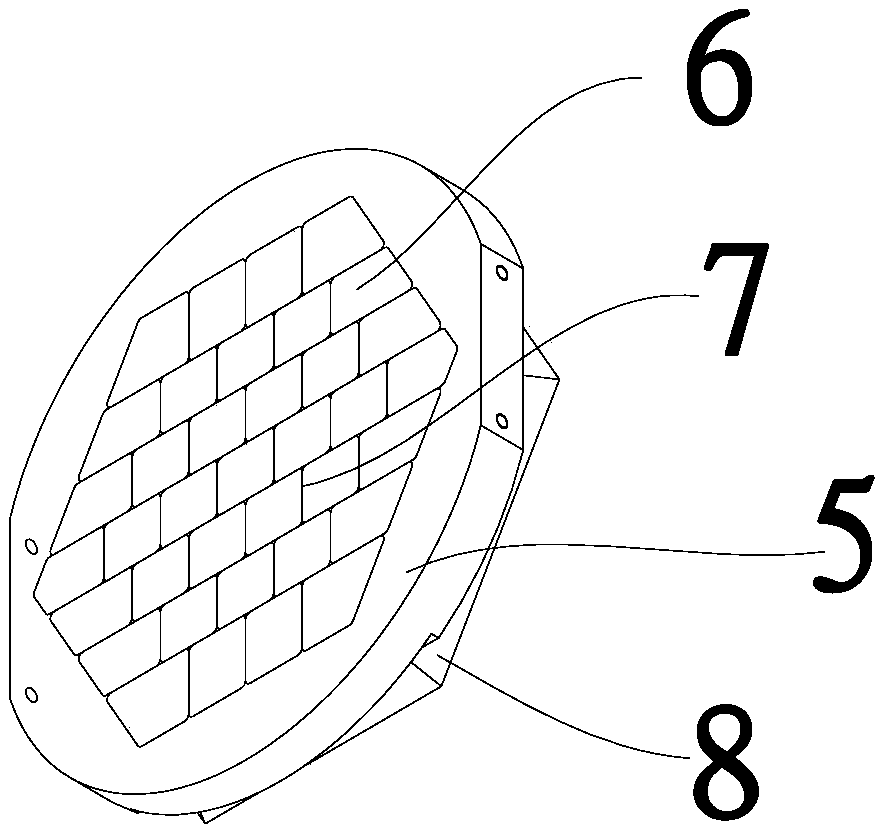

[0048] Embodiments of the present invention are as follows, as Figure 11 and Figure 12 As shown, a budding drug filling device is used for filling the budding drug of the fireworks tube cake, including a budding drug supply device (not marked in the figure), a budding drug quantitative device 20 and a material receiving device 21. Feeding device 21 is connected with the motor that is fixed on the frame 22 through bearing 23, and two bud-opening drug quantitative devices 20 are embedded and installed at least on the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com