High-efficiency automatic coal-fired heating device

A heating device and coal-burning technology, applied in the direction of fuel supply, combustion chamber, combustion method, etc., can solve the problems of low load, environmental pollution of smoke and dust emissions, unfavorable health of workers, etc., and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

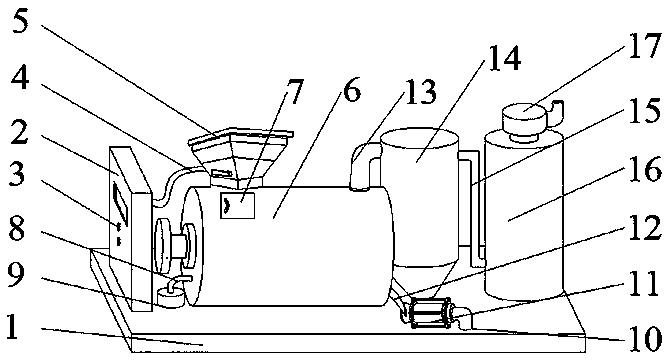

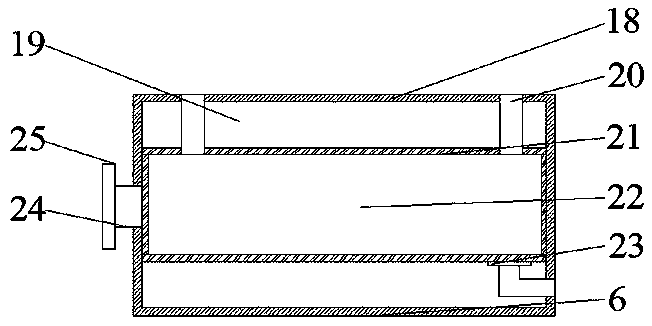

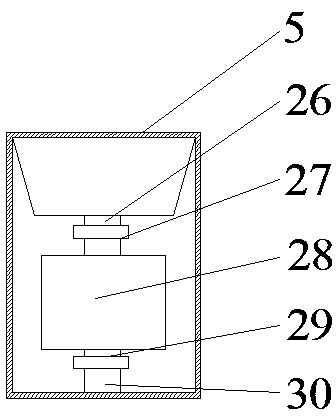

[0024] see Figure 1-4 , an efficient automatic coal-fired heating device according to an embodiment of the present invention, including a base 1, a control cabinet 2, a combustion body 6, an inspection door 7, a water pump 11, a high temperature resistant bag filter 14, an activated carbon box 16, and an induced draft fan 17. Sound insulation cover 18, condensation pipe 21, combustion chamber 22 and air purification chamber 36, the base 1 is located at the bottom of the whole device, the upper end of the base 1 is provided with the control cabinet 2, and the front side of the control cabinet 2 is A control switch 3 is provided, the combustion main body 6 is provided on one side of the control cabinet 2, the sound insulation cover 18 is provided inside the combustion main body 6, and the combustion chamber 22 is provided inside the sound insulation cover 18. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com