Hydrogel patch for skin care and preparation method thereof

A technology for skin care and hydrogel stickers, which is applied in the directions of skin care preparations, cosmetic preparations, medical preparations with inactive ingredients, etc. problems, to achieve the effect of reducing the water separation rate, improving the water separation phenomenon, and promoting percutaneous absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

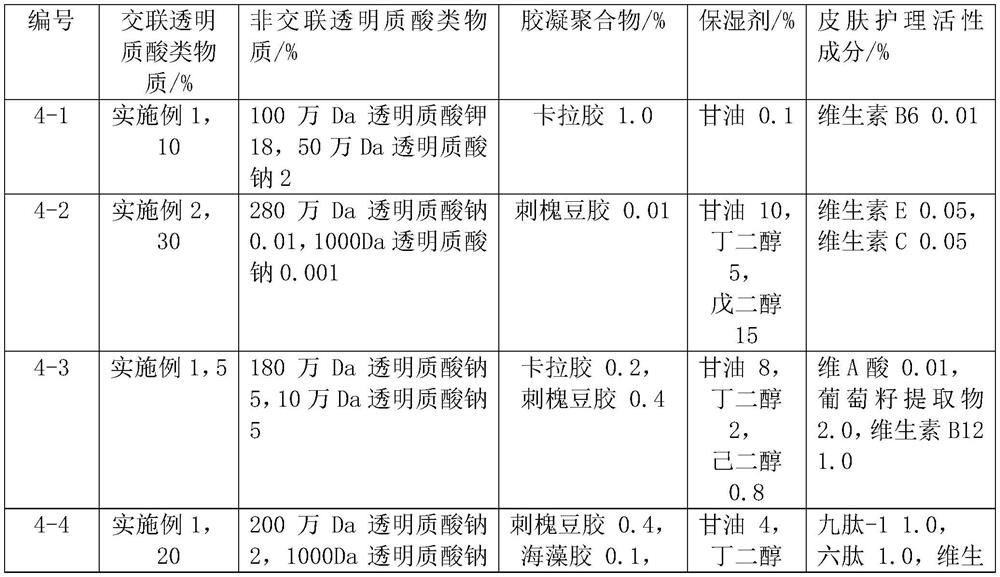

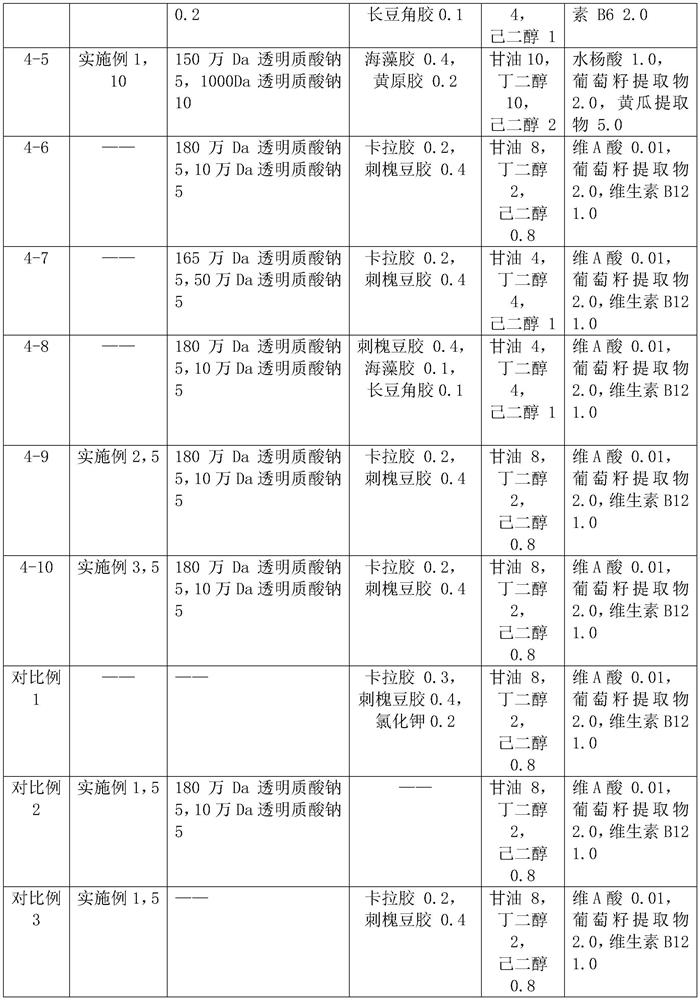

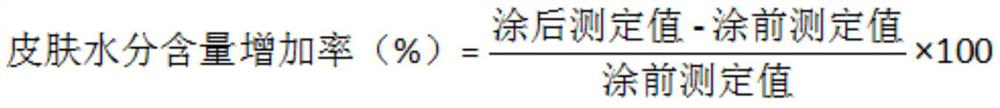

Examples

Embodiment 1

[0050] Preparation of cross-linked sodium hyaluronate: Accurately take 5 μL of 1,4-butanediol diglycidyl ether and add it to 100 mL of sodium chloride solution (50 mg / mL). After mixing, weigh 1 g of sodium hyaluronate (molecular weight 1000 Da ) was dissolved in the above solution, and after the sodium hyaluronate was fully dissolved, 186ml of ethanol was gradually added until the sodium hyaluronate precipitated a white precipitate. After the whole reaction system showed a solid-liquid suspension system, it was stirred and reacted at 30° C. for 6 hours. Then let stand and discard the supernatant. Finally, wash and dehydrate with ethanol for 3 times, suction filter and discard the filtrate, put the wet powder into a vacuum drying oven at 25°C and dry to prepare cross-linked sodium hyaluronate.

Embodiment 2

[0052] Preparation of cross-linked sodium hyaluronate: 1 wt% aqueous solution of sodium hyaluronate (1 g, molecular weight: 2.8 million Da) was configured in a 100 mL beaker, and then stirred at room temperature for 24 hours to completely dissolve the sodium hyaluronate. Polyvinyl alcohol grafted styryl pyridinium salt (PVA-SbQ) was used as macromolecular photocrosslinking agent. Add the two substances into a beaker wrapped with tin foil according to the ratio of m (sodium hyaluronate): m (PVA-SbQ) = 2: 1, stir for 30 minutes to mix the two evenly, and then use a 3000 rpm Centrifuge at a rotating speed for 5 minutes, and directly cross-link with ultraviolet light to form a hyaluronic acid gel, and the light time is 50-500 s. The obtained hyaluronic acid gel was dialyzed with deionized water for 3 days, and the water was changed every 5 hours; the liquid nitrogen was directly frozen and then freeze-dried to obtain a dry hyaluronic acid gel, which was dried in a vacuum drying ov...

Embodiment 3

[0054] Preparation of cross-linked sodium acetylated hyaluronate: Dissolve 1 g of sterile dry powder of sodium acetylated hyaluronate (molecular weight: 50,000 Da) in 50 mL of NMP, add TEA to adjust the solution to pH=10, then add 0.03 g of CMPI and Reaction at 0°C for 2h. After completion of the reaction, wash with 40 times of volume of normal saline, then precipitate with 40 times of volume of acetone, filter, acetone / water mixed solvent (V 丙酮 / V 水 =5 / 1) washing, vacuum drying at -0.1MPa, 40°C for 8h to obtain cross-linked acetylated sodium hyaluronate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com