Normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces and preparation method of composition

A room temperature curing, flexible epoxy technology, applied in the field of polymer materials, can solve the problems of inability to meet the requirements of polymer thin layer paving, low mechanical properties, low shrinkage, water resistance, insufficient driving comfort, etc., to achieve excellent wettability and Adhesive properties, improved flexibility and weather resistance, high chemical reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

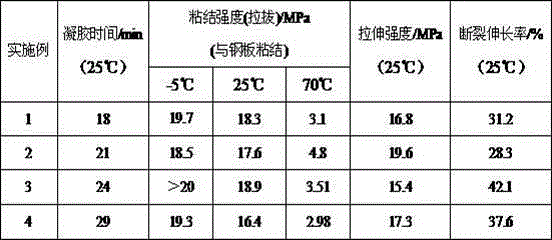

Examples

preparation example Construction

[0023] The invention provides a room-temperature-curable flexible epoxy composition for road and bridge deck thin-layer pavement, which is formed by mixing component A and component B according to the mass ratio (1-2): The number of parts includes 10-100 parts of flexible epoxy resin, 0-80 parts of standard epoxy resin, 2-10 parts of diluent and 5-10 parts of a curing accelerator; the B component includes modified 40-100 parts of permanent alicyclic amine curing agent, 10-70 parts of toughening modifier, 1-10 parts of b curing accelerator, 1-3 parts of coupling agent and 0.1-1 part of defoaming agent. The preparation method of the room-temperature-curable flexible epoxy composition for road and bridge deck thin-layer pavement includes the following steps: Step 1: Take 10-100 parts of soft epoxy resin according to the mass parts of corresponding raw materials, standard epoxy resin 0 to 80 parts, 2 to 10 parts of diluent, 5 to 10 parts of a curing accelerator, add to the mixing ...

Embodiment 1

[0034] Embodiment 1, the preparation method of room temperature curing flexible epoxy composition for road and bridge deck thin layer pavement, it comprises the steps:

[0035] 1) Mix 70 parts of flexible epoxy resin, 20 parts of standard epoxy resin, 5 parts of diluent, and 5 parts of a curing accelerator according to the mass ratio, and mix them uniformly at room temperature to obtain component A.

[0036] The flexible epoxy resin is a prepolymer of polyurethane modified epoxy resin UE-121, bisphenol A epoxy resin E-51 and castor oil triglycidyl ether. The preparation method of flexible epoxy resin is as follows: Weigh 60 parts of bisphenol A epoxy resin E-51, 30 parts of polyurethane modified epoxy resin UE-121, and 10 parts of castor oil triglycidyl ether according to the mass parts of the corresponding raw materials. Parts, sequentially added to the mixing tank and heated to 40 ℃ mechanically stirred for 20 to 30 minutes to obtain a flexible epoxy resin. The polyurethane...

Embodiment 2

[0046] Embodiment 2, the preparation method of room temperature curing flexible epoxy composition for road and bridge deck thin layer pavement, it comprises the steps:

[0047] 1) Mix 50 parts of standard epoxy resin, 40 parts of flexible epoxy resin, 5 parts of diluent, and 5 parts of a curing accelerator according to the mass ratio, and mechanically stir and mix at room temperature to obtain component A.

[0048] The standard epoxy resin is CYD-128 bisphenol A epoxy resin, which has low viscosity and high epoxy value, and is suitable for solvent-free coatings, adhesives, floor coatings and other fields.

[0049] The flexible epoxy resin is a prepolymer of polyurethane modified epoxy resin UE-121, bisphenol A epoxy resin CYD-128 and castor oil triglycidyl ether. The preparation method of flexible epoxy resin is as follows: Weigh 35 parts of bisphenol A epoxy resin CYD-128, 50 parts of polyurethane modified epoxy resin UE-121, and 15 parts of castor oil triglycidyl ether accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com