Efficient electrode wire for precision mould cutting and preparing method of efficient electrode wire

A technology of precision molds and electrode wires, applied in electrode manufacturing, electric processing equipment, manufacturing tools, etc., can solve the problems of affecting cutting efficiency and cutting quality, difficult to scale, automatic production, increasing production costs, etc., to achieve the benefit of corrosion Metal parts, strong versatility, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

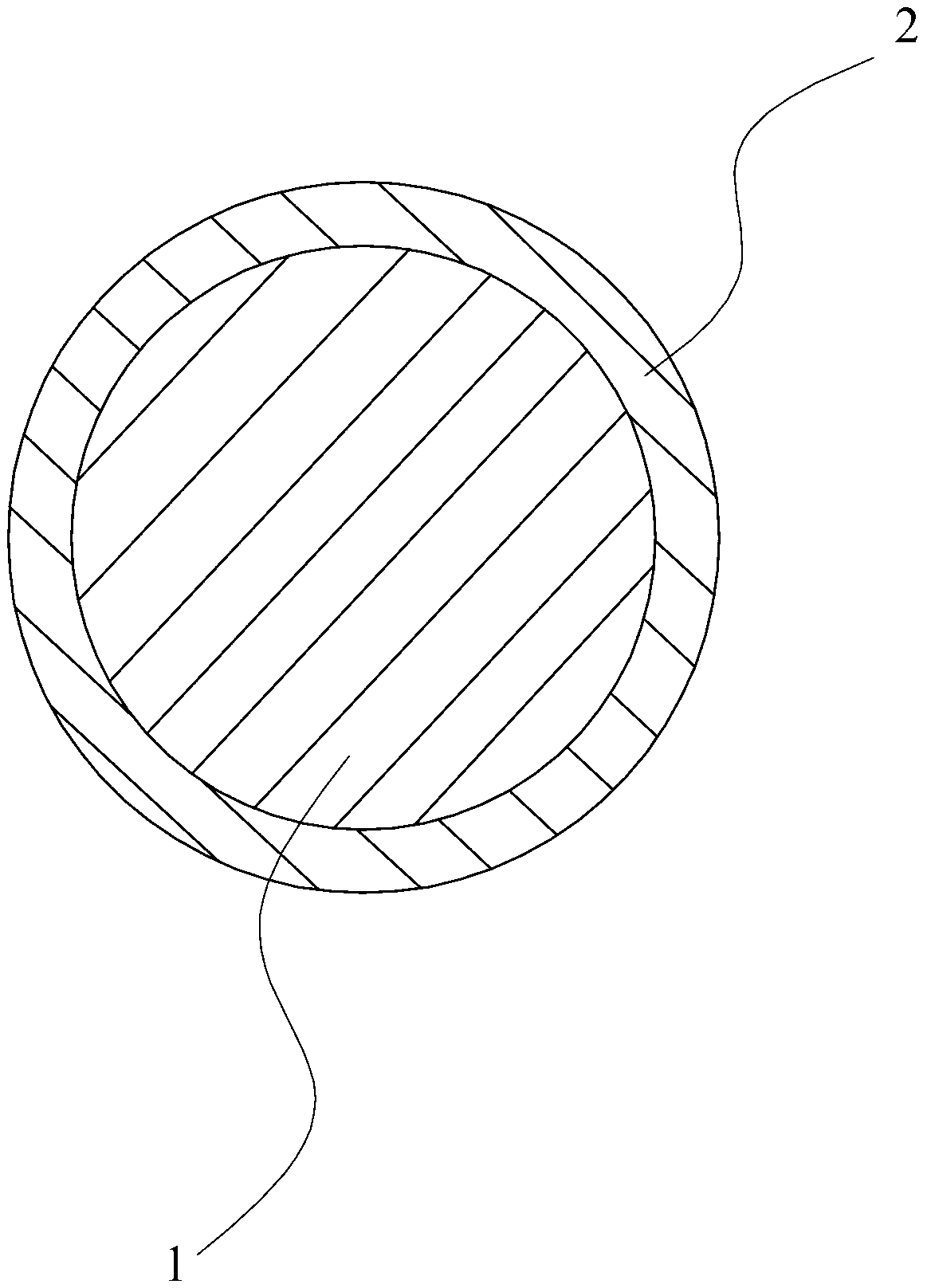

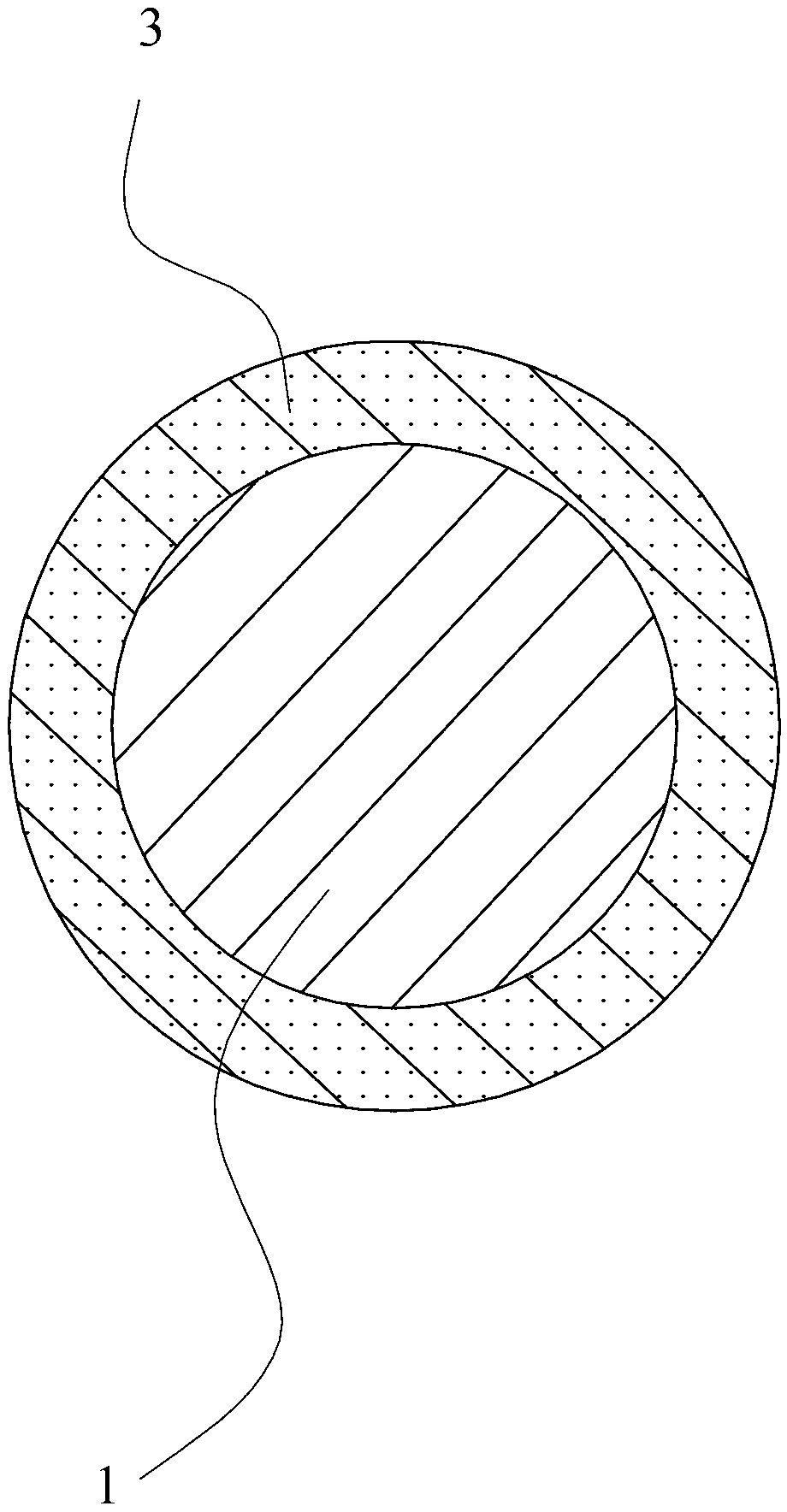

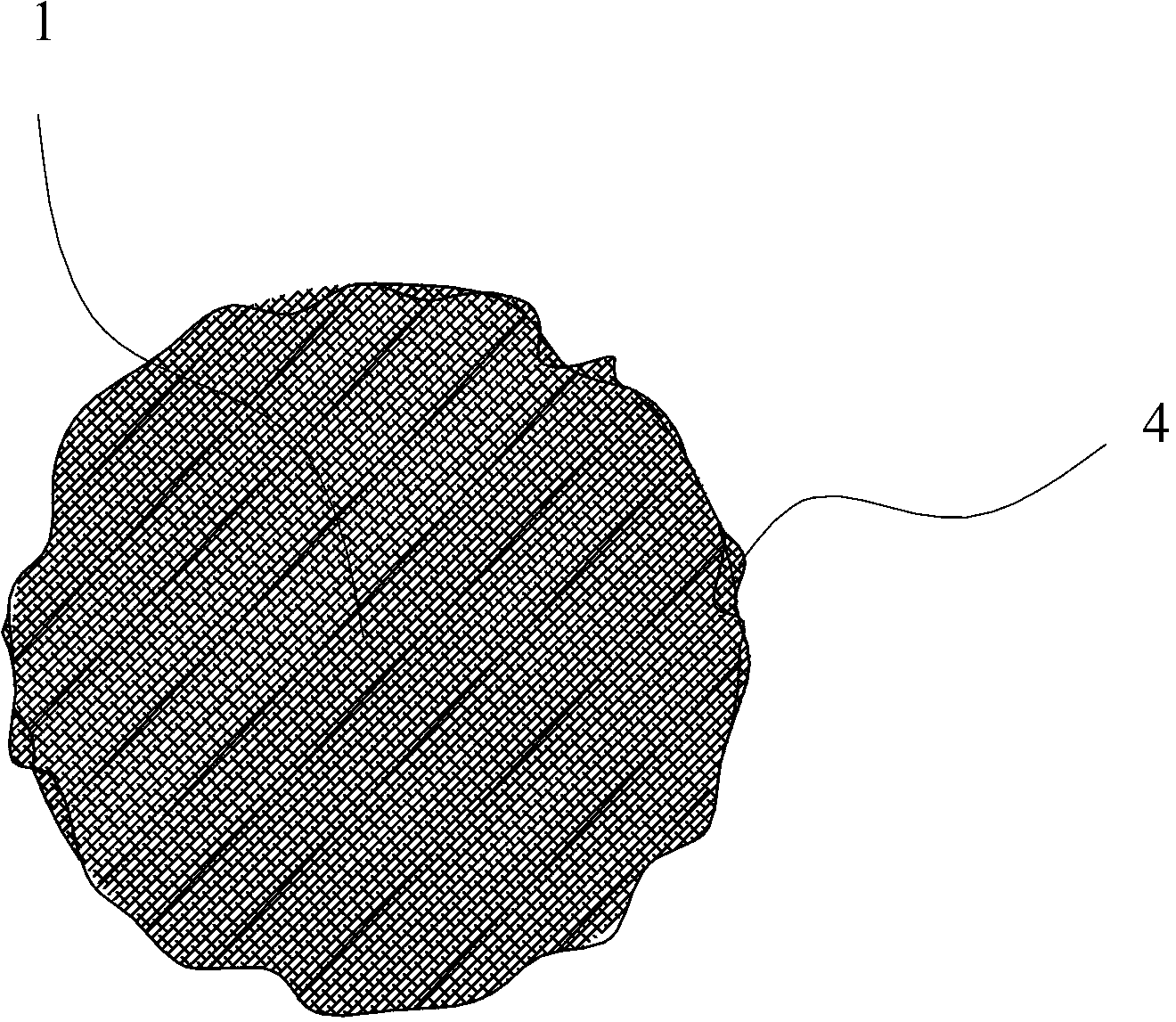

[0041] Such as figure 1 As shown above, a layer of zinc is evenly coated on the surface of the core material 1 obtained above, and the thickness of the coating layer 2 is 0.5 μm to obtain the first wire blank, and then the first wire blank is subjected to heat treatment. The temperature of the heat treatment process is 50 ° C and the time is 10 hours. ,Such as figure 2 As shown, at this time, the core material 1 and the coating layer 2 diffuse, the diameter of the core material 1 decreases and the thickness of the coating layer 2 increases, forming a stable zinc alloy shell layer 3 to obtain the second wire blank, and finally the second wire after heat treatment The billet is processed continuously, such as image 3 As shown, at this time, the surface zinc alloy shell layer 3 is redistributed and diffused on the surface of the core material 1, so that a uniform structure is formed inside the wire billet, while a discontinuous shell layer 4 is formed outside, and a high-effic...

Embodiment 2

[0044] Galvanize the surface of the core material obtained above with a coating thickness of 1 μm to obtain the first wire billet, then heat treat the first wire billet, the temperature of the heat treatment process is 150 ° C, and the time is 7.5 hours to obtain the second wire billet, and finally heat treat the first wire billet The final second wire billet is subjected to continuous drawing and continuous annealing processing to make a high-efficiency precision mold cutting electrode wire with a diameter of 0.10mm. Among them, the coverage rate of the shell layer on the surface of the core material is 80%, the maximum thickness of the shell layer is 3 μm, and the thickness of more than 95% of the shell layer is 0.8-2 μm where the shell layer is covered by shell particles. Such as Figure 5 and Figure 6 As shown, in Example 2, the radial length of the shell particles is small, the distance between the particles is small, the shell layer has a high coverage on the surface o...

Embodiment 3

[0046] Galvanize the surface of the core material obtained above, and the thickness of the coating is 4 μm to obtain the first wire billet, and then heat treat the first wire billet. The temperature of the heat treatment process is 250 ° C, and the time is 5 hours to obtain the second wire billet. The second wire blank is subjected to continuous drawing and continuous annealing processing to make a high-efficiency precision mold cutting electrode wire with a diameter of 0.20mm. Among them, the coverage rate of the shell layer on the surface of the core material is 89.6%, the maximum thickness of the shell layer is 3.5 μm, and the shell layer is covered by shell particles, and the thickness of more than 95% of the shell layer is 2-3 μm. The maximum distance between the shell particles is 20 μm, and the distance between more than 80% of the shell particles is 8-12 μm. The maximum size of the shell particles is 80 μm, and more than 80% of the shell particles have a size of 32-52 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com