Composite insulation board and preparation method thereof

A composite thermal insulation and composite felt technology, which is applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc. Avoid low bond strength and delamination, improve bond strength, smooth and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

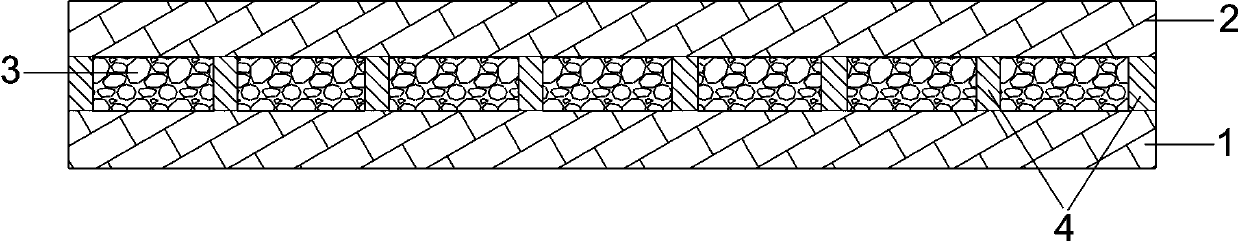

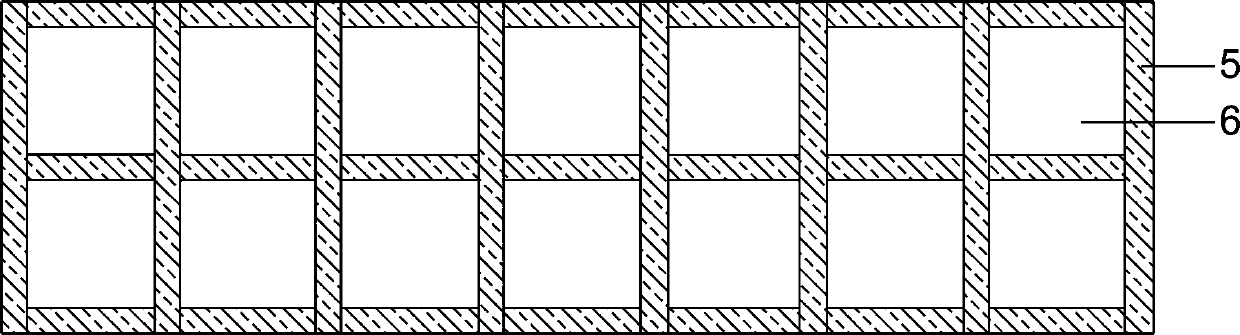

[0033] Such as figure 1 As shown, a composite thermal insulation board includes a first panel layer 1, a second panel 2, a sandwich layer, and a skeleton support layer 4. The sandwich layer includes several fiber-reinforced airgel composite felts 3, and the skeleton support layer 4 is Grid shape, the skeleton support layer 4 is arranged between the first panel layer 1 and the second panel layer 2, the fiber reinforced airgel composite felt 3 is filled in the grid of the skeleton support layer 4, the skeleton support layer 4 and the The first panel layer 1 and the second panel 2 are integrally cured and molded;

[0034] The first panel layer 1, the second panel 2 and the skeleton support layer 4 are glass fiber reinforced unsaturated polyester composite materials; the fiber reinforced airgel composite felt 3 is a glass fiber reinforced silica airgel composite material. Felt; the thickness of the first panel layer 1 is 5 mm, the thickness of the second panel 2 is 5 mm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com