Fiber reinforced flexible silica aerogel

A silica and fiber-reinforced technology, applied in chemical instruments and methods, clothing, protective equipment, etc., can solve problems such as powder dropping, and achieve the effects of good shape adaptability, good construction process, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments.

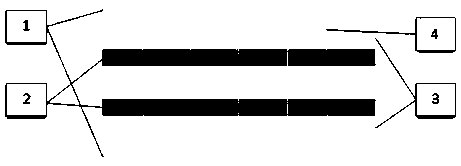

[0015] Such as figure 2 As shown, a flexible silica airgel, the inner glass fiber cloth reinforced epoxy resin sheet to the flexible SiO 2 The airgel is reinforced by interlayer overlap, and the outer surface is reinforced by glass fiber cloth. The ceramizable phenolic resin is used for flexible SiO 2 Airgel is used for reinforcement and surface protection, and quartz thread is used to sew the entire structure to improve interlayer strength and avoid delamination.

[0016] Flexible SiO 2 Airgel, a fiber mat reinforced flexible SiO 2 airgel.

[0017] The glass fiber cloth reinforced epoxy resin sheet is a composite material sheet with a single layer thickness of 0.2±0.02mm after curing.

[0018] Glass fiber cloth reinforced ceramizable phenolic resin sheet is a composite material sheet with a single layer thickness of 0.2±0.02mm after curing. The resin used is cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com