Smooth coating liquid for aluminum plastic thin film and coating process thereof

A technology of aluminum-plastic film and smooth coating, which is applied to devices, coatings, polyurea/polyurethane coatings and other directions for coating liquid on the surface, which can solve the problems of poor drawing performance and powder drop, and reduce the friction coefficient. , The effect of saving economic cost and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

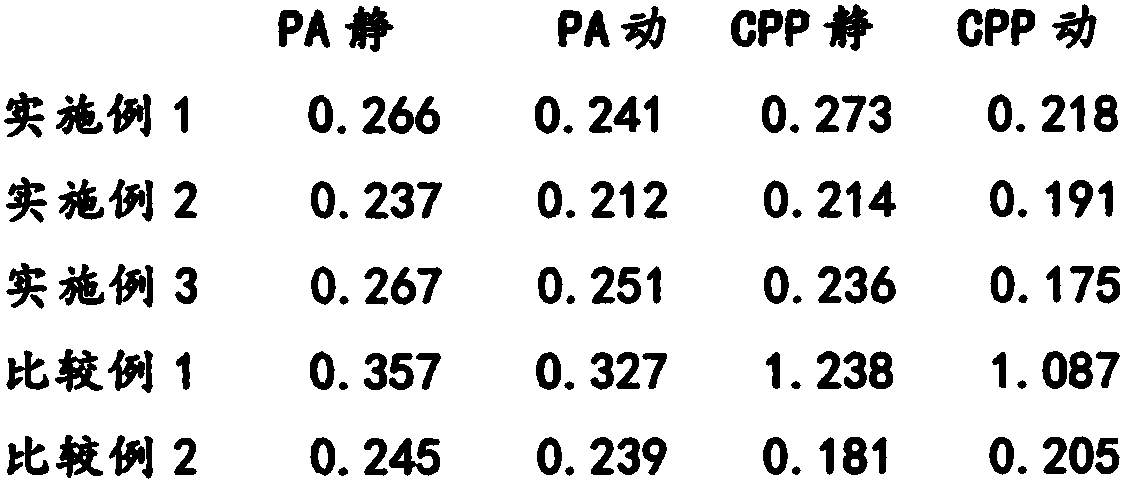

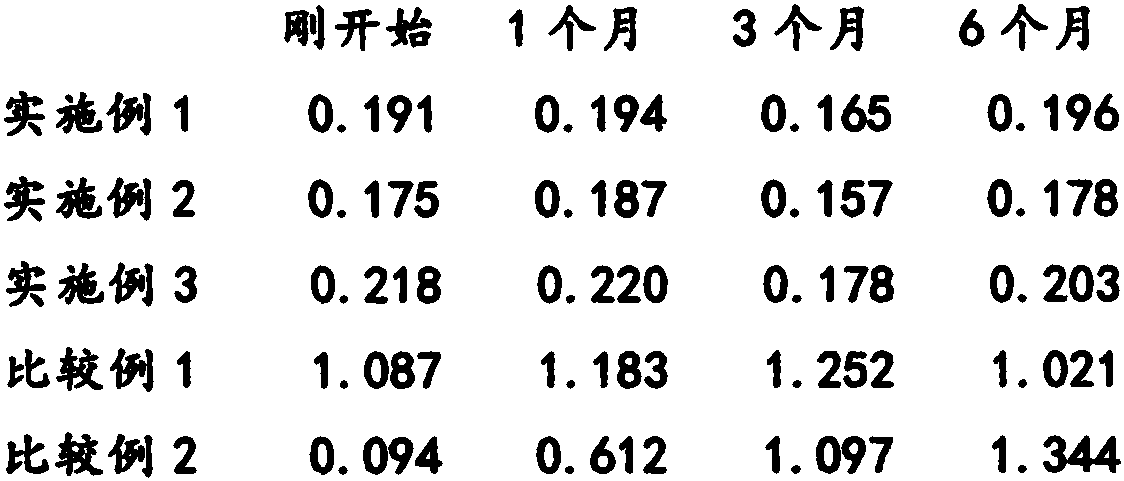

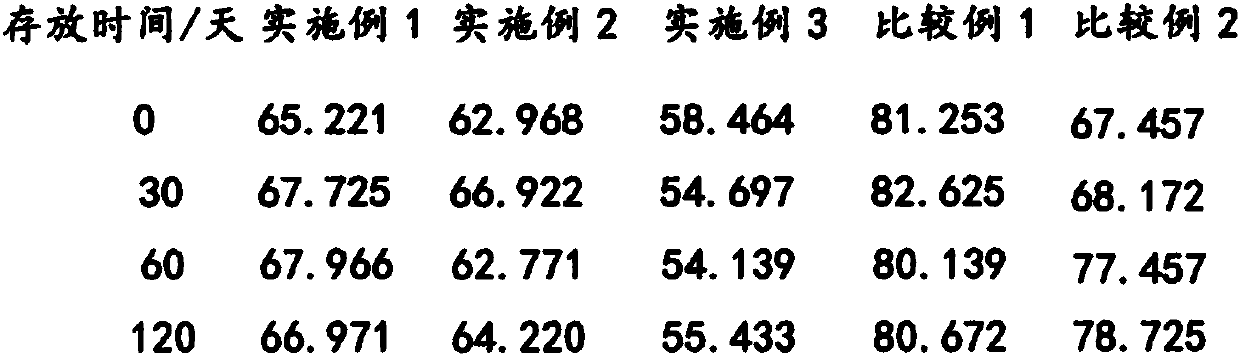

Examples

Embodiment 1

[0023] The punching coating solution is composed of 0.05wt% of organosiloxane, 0.05wt% of leveling agent, 0.05wt% of silicone resin, 98.85% of ethyl ester and 1.0wt% of water; the production speed is 50m / min, and the amount of wet glue is 20.0g / m 2 .

Embodiment 2

[0025] The punching coating solution is composed of 0.5wt% organosiloxane, 0.1wt% leveling agent, 0.1wt% silicone resin, 89.3% ethyl ester, 5.0wt% ethanol and 5.0wt% water; production speed 45m / min, wet Glue amount 5.0g / m 2 .

Embodiment 3

[0027] The punching coating solution is composed of 0.5wt% organosiloxane, 0.1wt% leveling agent, 0.5wt% silicone resin, 88.9% ethanol and 10.0wt% water; the production speed is 35m / min, and the wet glue amount is 10.0g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com