Patents

Literature

110results about How to "Excellent drawing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

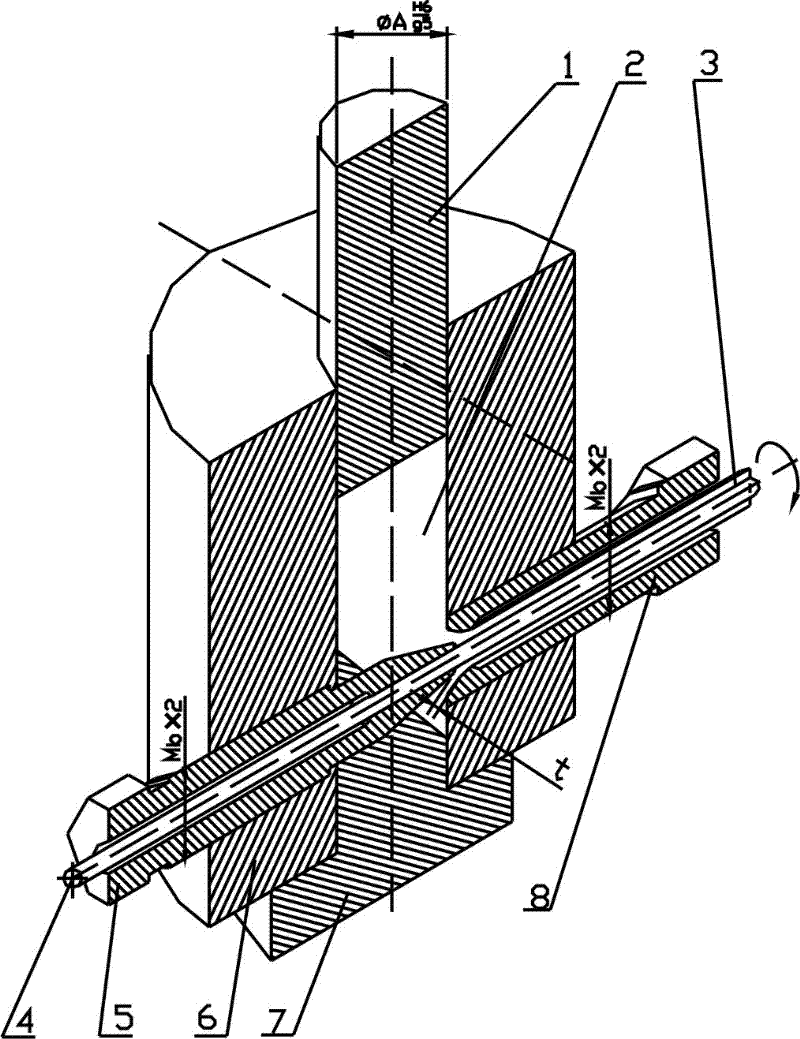

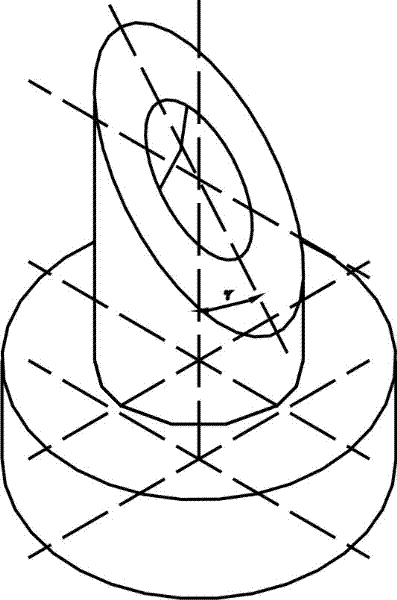

Preparation method and mold of seamless flux-cored zinc-aluminium alloy welding wire

ActiveCN102500958AImprove subsequent drawing and reducing efficiencyNot easy to crack and leak powderExtrusion diesWelding/cutting media/materialsWire rod5052 aluminium alloy

The invention discloses a preparation method of a seamless flux-cored zinc-aluminium alloy welding wire and a preparation mold. The preparation method comprises the following steps of: preparing a wire rod with a brazing flux; casting and configuring an extrusion billet; extruding the extrusion billet into a hollow pipe in the mold, and simultaneously, filling the wire rod with the brazing flux in the hollow pipe; preparing the seamless flux-cored zinc-aluminium alloy welding wire rod; and carrying out drawing and diameter reducing to the seamless flux-cored zinc-aluminium alloy welding wire rod to form the seamless flux-cored zinc-aluminium alloy welding wire. In the seamless flux-cored zinc-aluminium alloy welding wire prepared in the invention, the weight percentage of the brazing flux is 10-18%; the obtained seamless flux-cored zinc-aluminium alloy welding wire can have unlimited length, so that the following drawing and diameter reducing efficiency can be greatly improved; and the hollow pipe is radially extruded, so that certain ECAP (Equal Channel Angular Pressing) fine grain action to alloy structures can be realized, and further, the drawing property of an alloy material is better. The preparation method of the seamless flux-cored zinc-aluminium alloy welding wire and the mold, disclosed by the invention, have the advantages that mold has high production efficiency, the yield is high, and the brazing flux is less in loss, and is easy to store.

Owner:绍兴市天龙锡材有限公司

Waterable fingerpaint pigment and production method thereof

InactiveCN101469146ANo stratificationGood lookingStarch dervative coatingsArtist's paintsFlexural strengthSlurry

The invention discloses a finger painting pigment and a method for producing the same. The finger painting pigment consists of pigment base slurry and coloring matters; the compositions of the pigment base slurry comprise glycerin, modified starch and casson; a product has no phenomenon of delamination, has excellent appearance effect; simultaneously, in the painting process, the pigment is quite fluent and has no granular sensation, bright and beautiful color and strong flexural strength, also has obvious advantages in adhesion fastness and color saturation, is safe and innoxious and is easy to elute when stuck on clothes.

Owner:云之彩文创集团有限公司

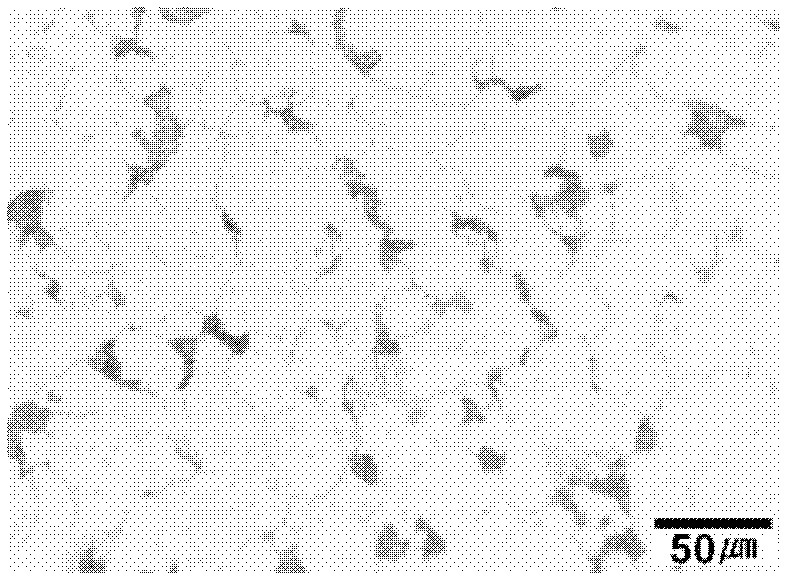

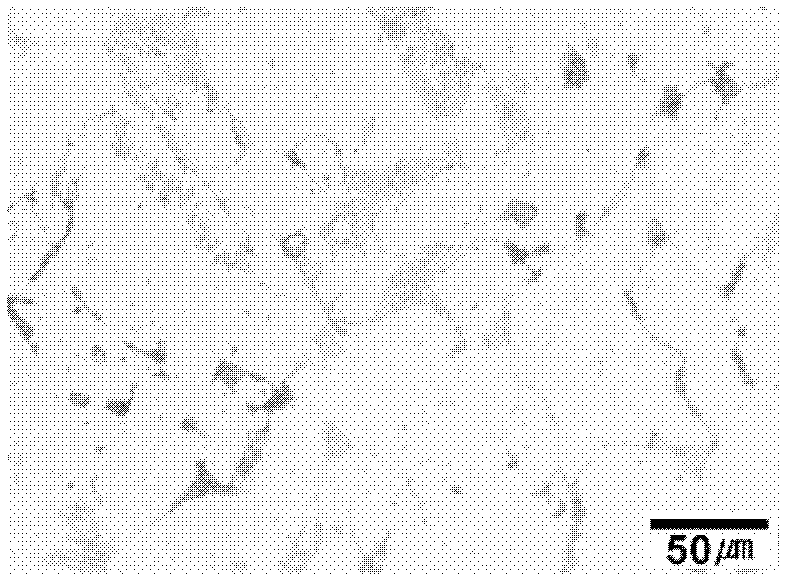

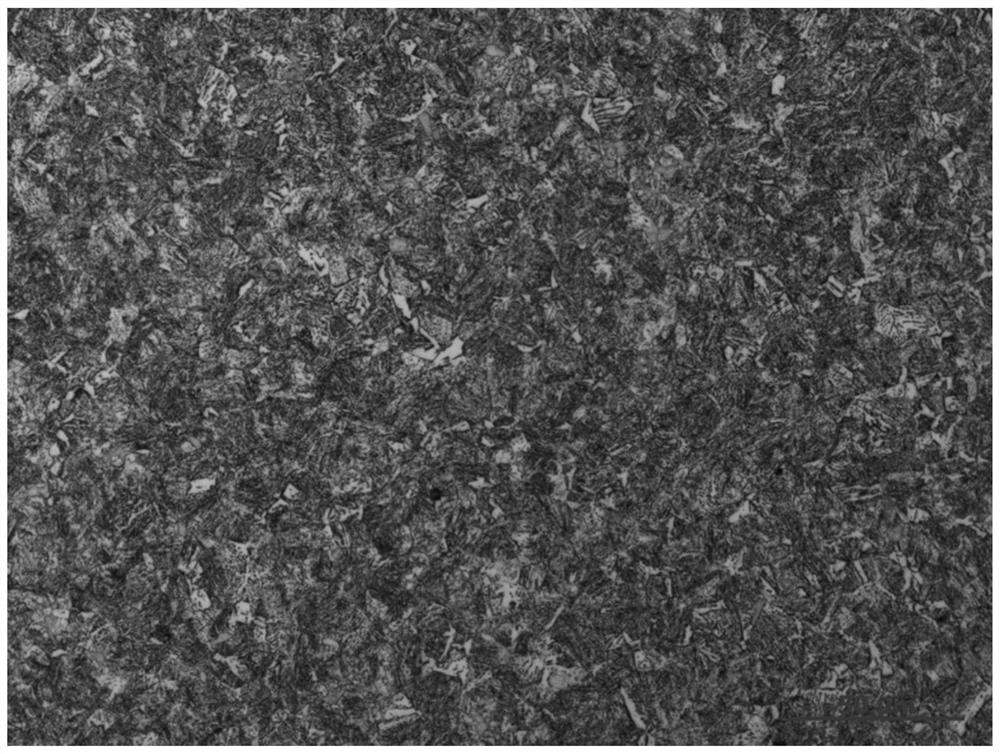

Process method for increasing surface quality and drawing property of ultra-fine high-carbon steel wire

ActiveCN103966417AQuality improvementIncrease transition timeFurnace typesHeat treatment furnacesHigh carbonSurface cleaning

The present invention relates to a process method for increasing surface quality and drawing property of an ultra-fine high-carbon steel wire. The process method comprises: carrying out rough drawing, lead bath isothermal quenching I and medium wire drawing deformation on a high-carbon steel wire rod to obtain a steel wire with a diameter of 0.7-0.95 mm, carrying out lead bath isothermal quenching II, carrying out a surface cleaning area cleaning treatment for a certain time, carrying out air cooling, adding to a brass electroplating tank, and carrying out wet drawing deformation to obtain the ultra-high strength steel wire with a diameter of 0.10-0.12 mm. According to the present invention, the process method is adopted to eliminate the lead adhered on the lead surface so as to provide the lead scraping effect; the time of conversion of austenite into perlite is prolonged, and the cooling rate is reduced, such that the conversion of the austenite is complete; the steel wire surface oxidation is eliminated so as to provide the reduction protection effect; and proeutectoid ferrite, secondary mesh cementite and other untypical untypical structures in the ultra-fine high-carbon steel wire are less, the distance between the perlite lamellas is about 70-80 nm, and the surface does not produce decarburization phenomenon.

Owner:张家港市骏马钢帘线有限公司 +1

Preparation method for producing high-toughness battery aluminum foil through short-process cast-rolled blank

PendingCN111349825AImprove barrier propertiesAvoid quality defectsMetal rolling arrangementsElectrical batteryNew energy

The invention discloses a preparation method for producing high-toughness battery aluminum foil through a short-process cast-rolled blank. The preparation method sequentially comprises the proceduresof smelting, cast rolling, cold rolling, homogeneous high-temperature treatment, intermediate rolling, longitudinal shearing edge cutting, intermediate annealing, finish rolling, foil rolling, coiling, finished product rolling, slitting and charging annealing. Compared with existing aluminum alloy material, the aluminum foil is high in barrier property, excellent in deep drawing property, good indeformability, high in puncture resistance, good in sealing property, fine and smooth in surface, high in cleanliness and short in process, meanwhile, through an innovative segmented multistage mode,online degassing and a filtering purifying device, the content of hydrogen and oxidized slag inclusions in molten aluminum is effectively reduced, and quality defects, caused by the generation of holes and pinholes, of the battery aluminum foil are prevented; the aluminum foil has the advantages of good sealing performance, no liquid leakage, safety in use and the like; the technical requirementsof the battery aluminum foil with high deep drawing forming property, high cleanness, high toughness are met; and the aluminum foil has important practical value in production of a new energy lithiumbattery industry.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

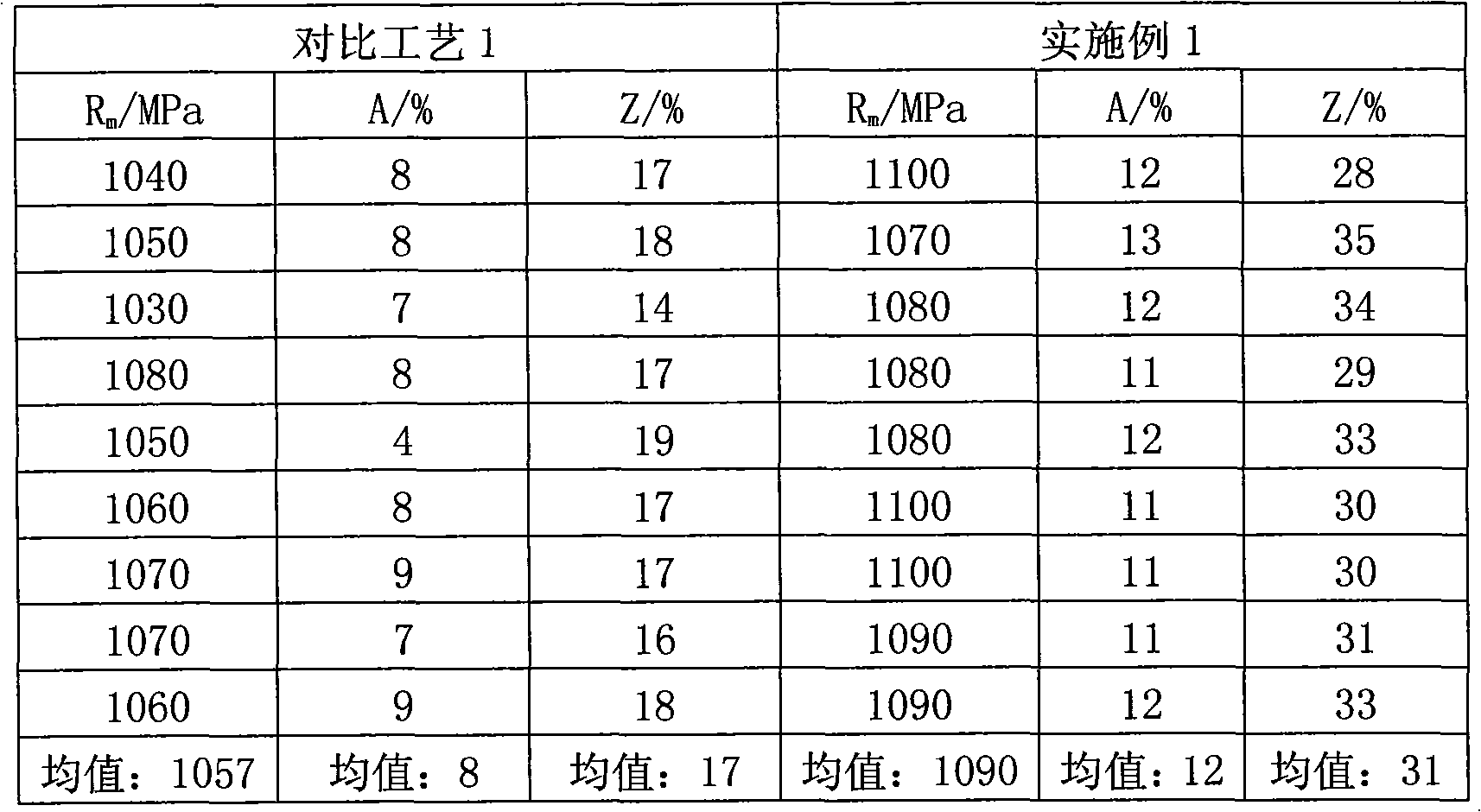

Production method for optimizing drawing performance of steel wire rod for carbon steel welding wire

ActiveCN102218448AExcellent drawing performanceControl microstructureTemperature control deviceMetal rolling arrangementsCarbon steelMicrostructure

The invention relates to a production method for optimizing the drawing performance of a steel wire rod for a carbon steel welding wire, belonging to the technical field of steel production. The technology path comprises the following steps of billet chemical composition control and inspection, heating of a walking heating furnace, rough rolling, top cutting by a flying shear, middle rolling, precision rolling in advance, high-speed precision rolling, sending and clamping, as well as spinning, temperature controlling, and disperse coil cooling, collecting coils, and steel wire rod inspection. The method is characterized in that through optimizing the technology parameters of operation key points, the effective control to microstructure of the steel wire rod for the carbon steel welding wire on a high-speed wire rod production line short of slow cooling capability is realized, and the frequent brittleness problem caused by the common structure reason in the drawing process, especially the high-speed drawing process of the steel wire rod for the carbon steel welding wire on produced on the production line is solved. The method has the advantages that the effective control of the steel wire rod structure for the carbon steel wire on the traditional high-speed line material production line can be realized without prolonging the length of slow cooling, and the generation of the low-temperature hard phase structure is avoided, thus the drawing performance of the steel wire rod is changed, and the requirement of drawing use of the type of the steel wire rod is met.

Owner:SHOUGANG CORPORATION

Steel wire rod for copper clad steel composite shielded wire and production method of steel wire rod

ActiveCN108062992AExcellent drawing performanceReduce thicknessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsWire rodChemical composition

The invention relates to a steel wire rod for a copper clad steel composite shielded wire and a production method of the steel wire rod and belongs to the technical field of steel for communication cables. The chemical components of the steel wire rod include C, Si, Mn, P, S, Al, Ti and B; the balance of the steel wire rod includes Fe and unavoidable impurities; the mass percentage of C is smallerthan or equal to 0.010%; the mass percentage of Si is smaller than or equal to 0.010%; the mass percentage of Mn is smaller than or equal to 0.07%; the mass percentage of P is smaller than or equal to 0.010%; the mass percentage of S is smaller than or equal to 0.010%; the mass percentage of Al is smaller than or equal to 0.004%; the mass percentage of Ti is smaller than or equal to 0.003%; and the mass percentage of B ranges from 0.0060 to 0.0120%. The production method includes a billet smelting process, a billet heating process, a wire rod rolling process and a wire rod cooling process. According to the heating process, continuous casting billet heating and hot billet secondary heating are adopted, and the temperature of a heating furnace ranges from 1140 to 1160 DEG C. According to the wire rod cooling process, a slow cooling technique is adopted. The steel wire rod for the shielded wire has excellent drawing performance and excellent conductive performance; the steel wire rod canbe drawn to 0.08 mm with wire fracture avoided; and the conductivity of the steel wire rod can reach 16.3% or more.

Owner:XINGTAI IRON & STEEL

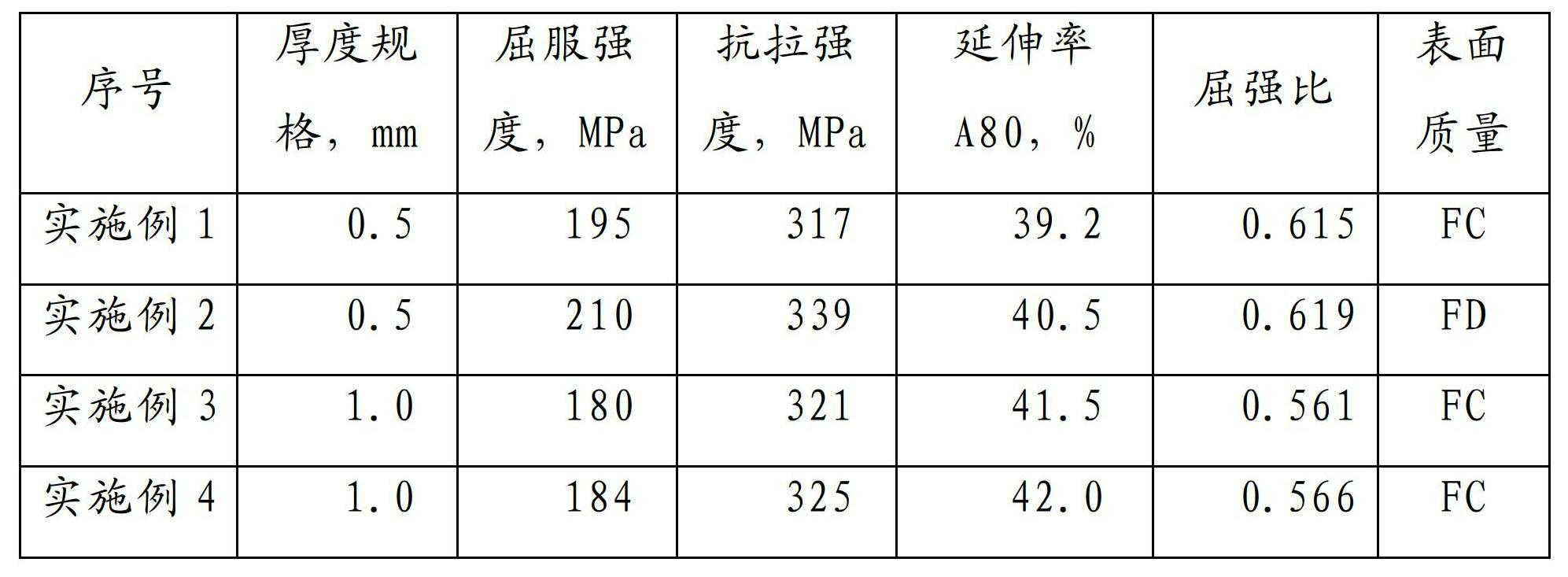

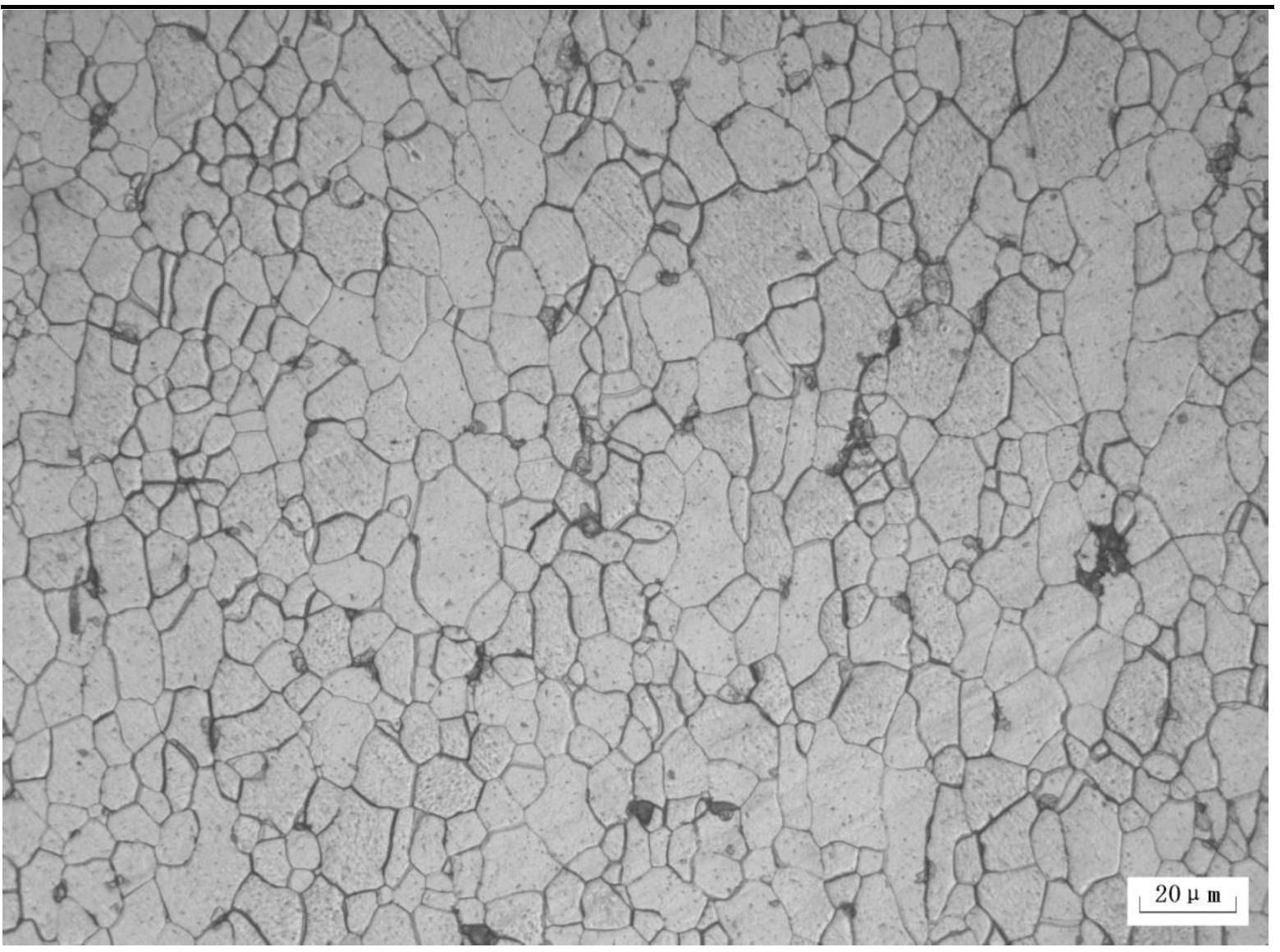

Preparation method of aluminium alloy strip for stamping and stretch forming of cell phone shell

InactiveCN102352457AImprove surface qualityExcellent drawing performanceTemperature control deviceRoom temperatureMechanical property

The invention discloses a preparation method of an aluminium alloy strip for the stamping and stretch forming of a cell phone shell. The preparation method comprises the following steps of: smelting, pouring, homogenizing annealing, hot rolling and cold rolling. By optimizing the alloying components, formulating and optimizing the homogenizing annealing technology after pouring and accurately controlling the temperatures of hot rolling and cold rolling, the performances of the designed alloy can be fully realized, namely the comprehensive mechanical property of the aluminium alloy strip is excellent, the room temperature tensile strength is 285-320MPa, the elongation rate is more than 25% and the cupping test value is more than 10nm. Therefore, the aluminium alloy strip can fully meet the use demand of the stamping and stretch forming of the cell phone shell.

Owner:YONGXIN PRECISION MATERIAL WUXI

Drahtstahl for high strength fastening piece and production method thereof

InactiveCN101787491AWith energy savingReduce manufacturing costMetal rolling arrangementsWire rodHigh intensity

The invention relates to a drahtstahl for a fastening piece and a production method thereof, and the drahtstahl comprises the following components by weight percent: 0.39-0.48 % of C, 0.15-0.35% of Si, 0.30-0.90% of Mn, 0.60-1.20% of Cr, 0.010-0.07% of Als, less than or equal to 0.035% of P, less than or equal to 0.035% of S and the balance Fe and unavoidable impurity; and the production method comprises the following steps: smelting with a clean steel process and casting into a blank, and adding Si-Ca line in the refining; heating the continuous casting to 980-1,080 DEG C; rough rolling: controlling the deflection to be 70-80%; intermediate rolling: controlling the deflection to be 80-90%; pre-precision rolling: controlling the deflection to be 65-75%; water-cooling until the temperature is cooled to be 1,000-1,020 DEG C; precision rolling: controlling the deflection to be 60-90%; water-cooling for the second time until the temperature is cooled to be 800-900 DEG C; spinning; cooling to phase change initial temperature, namely the range from Ar3 to 50 DEG C higher than Ar3 by adopting an aerial fog mixed method; and continually cooling until the temperature is cooled to be 400-500 DEG C and naturally cooling to environment temperature. The invention can be drawn directly, has good cold deformation and is not easy to crack.

Owner:武钢集团有限公司

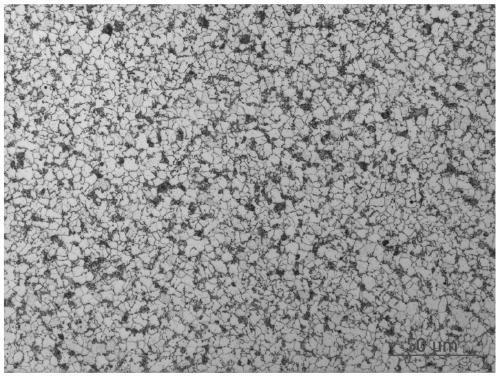

Controlled rolling and controlled cooling method for medium-carbon CrMo steel wire rod capable of being directly subjected to drawing machining in hot rolling state

ActiveCN111363975AReduced stabilityExcellent drawing performanceTemperature control deviceWire rodSpinning

The invention belongs to the technical field of rolling, and relates to a controlled rolling and controlled cooling method for a medium-carbon CrMo steel wire rod capable of being directly subjected to drawing machining in a hot rolling state. The method comprises the steps that a steel billet is heated at the temperature not higher than 1,100 DEG C for 1.5-2 hours; a finish rolling unit and a mini unit conduct rolling at the ultralow temperature not higher than 750 DEG C; the spinning temperature adopts the ultralow temperature not higher than 750 DEG C; and the cooling speed of the steel wire rod on a Stelmor controlled cooling line is not higher than 0.12 DEG C / s. According to the technology, separation of a proeutectoid structure is effectively promoted, it is guaranteed that undercooled austenite is completely converted on the Stelmor controlled cooling line, and conversion of bainite and martensite is effectively prevented; and meanwhile, the gain size of ferrite is not smaller than that of a 12-grade fine grain structure, the medium-carbon CrMo steel wire rod has the good drawing performance in the hot rolling state, cold drawing with the reduction rate not lower than 30% can be conducted at a time, and the one-time spheroidizing annealing cost is reduced for downstream users.

Owner:ZENITH STEEL GROUP CORP +1

Preparation method of cold-rolled sheet for flux-cored wire

ActiveCN102676917ALower yield strengthHigh tensile strengthFurnace typesHeat treatment furnacesChemical compositionAcid washing

The invention discloses a preparation method of a cold-rolled sheet for a flux-cored wire, belonging to the field of processing of metal materials. The cold-rolled sheet comprises the following chemical components in percentage by mass: 0.005-0.045 percent of C, less than or equal to 0.03 percent of Si, 0.15-0.26 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.010percent of S, less than or equal to 0.030 percent of Alt, less than or equal to 0.0030 percent of N and the balance of Fe. The method comprises the following steps of: performing hot rolling, acid washing and cold rolling in sequence on a steel billet to obtain a cold-rolled strip coil; and performing continuous annealing and flat processing methods. The cold-rolled sheet has the advantages of low yield strength, high tensile strength, excellent cold molding performance, excellent puling performance, high production speed, short period, high yield and high quality; and compared with the conventional process, the method has excellent advantages, and the use requirement of steel for the flux-cored wire can be better met.

Owner:SHOUGANG CORPORATION

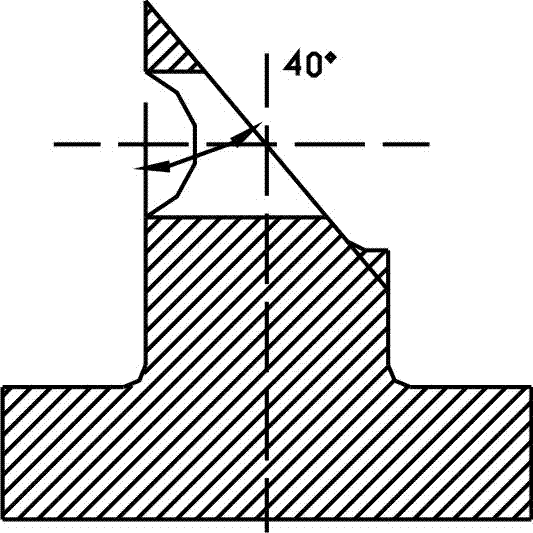

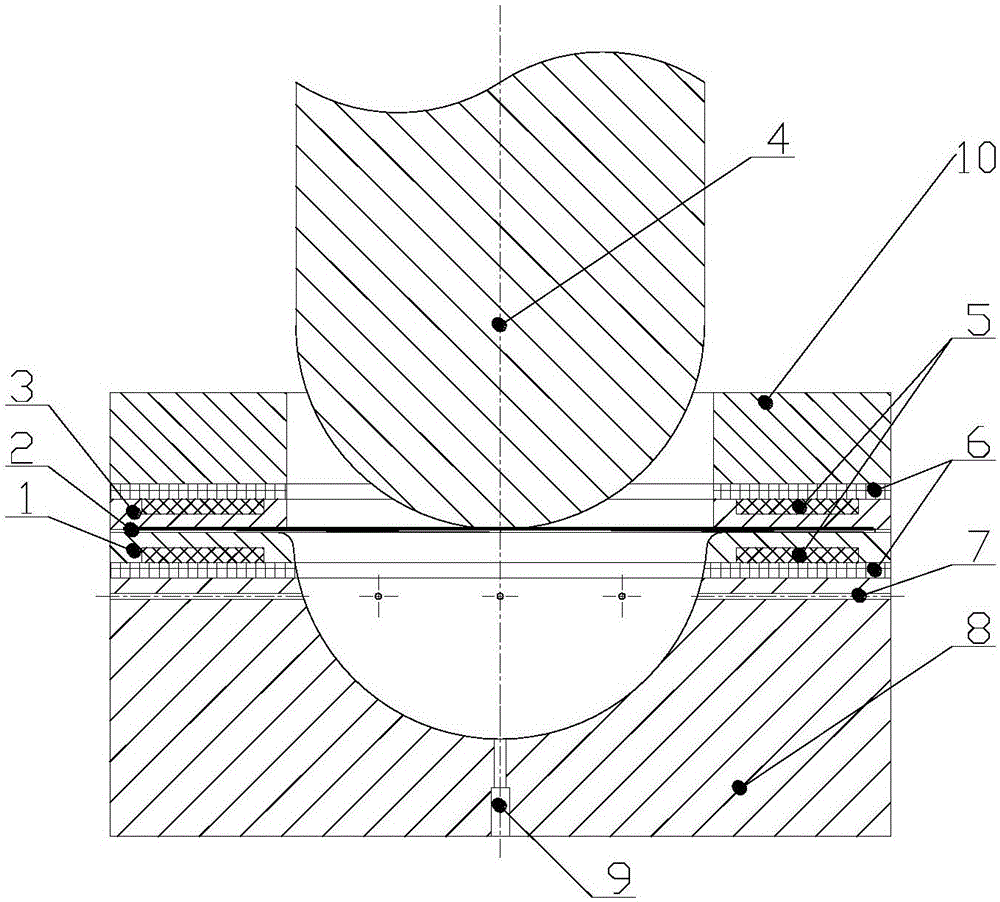

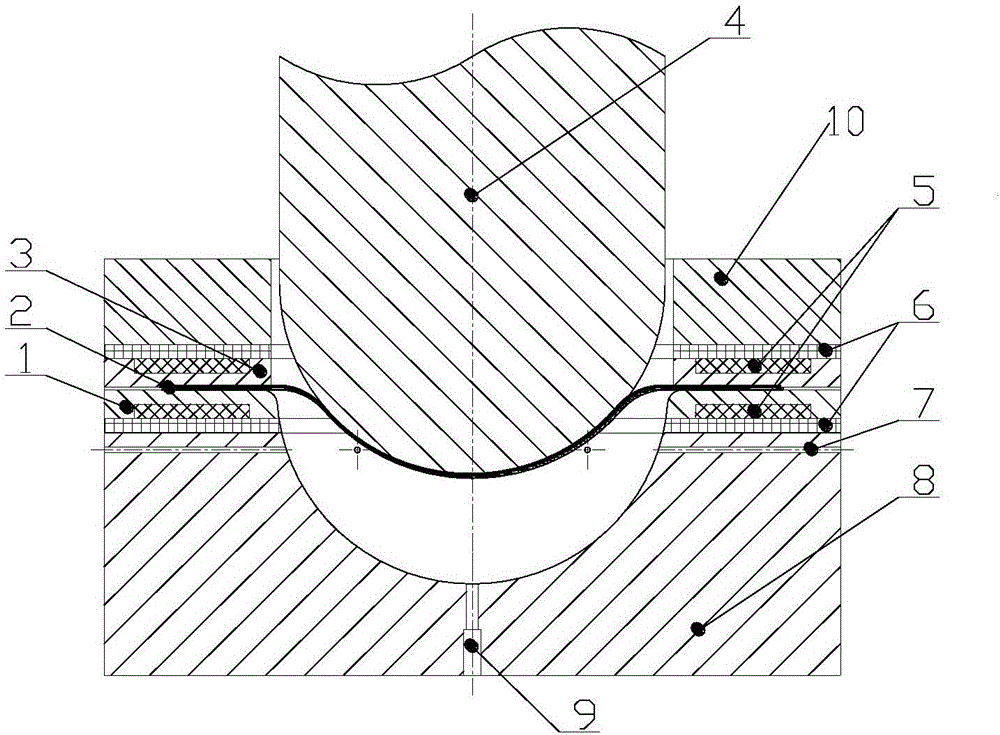

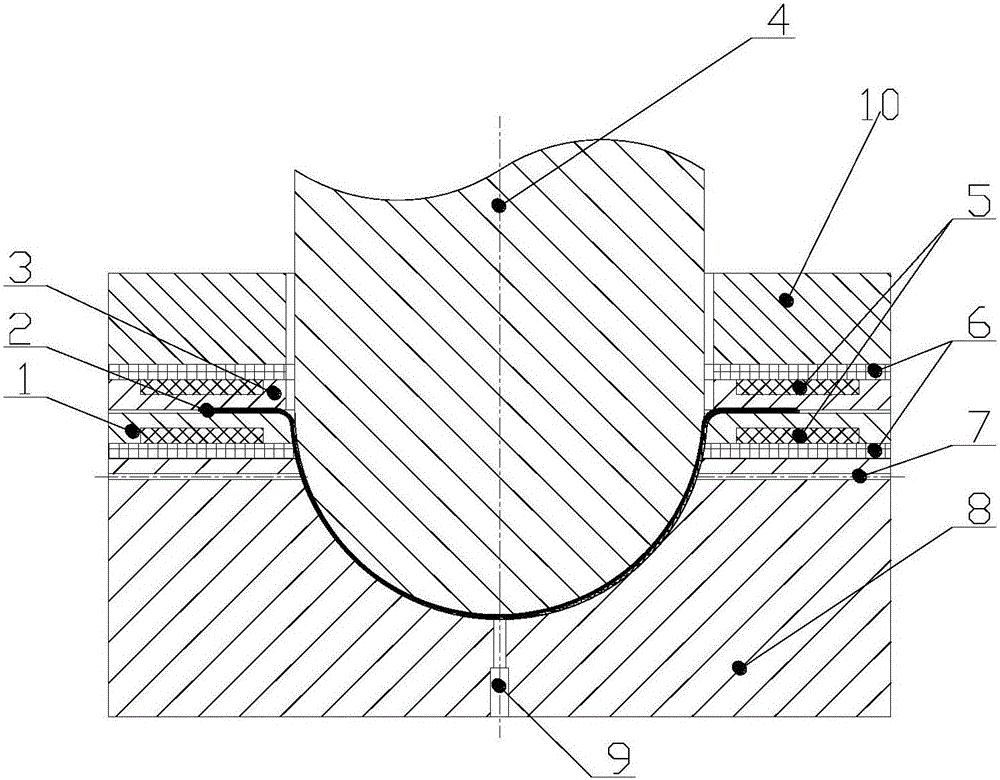

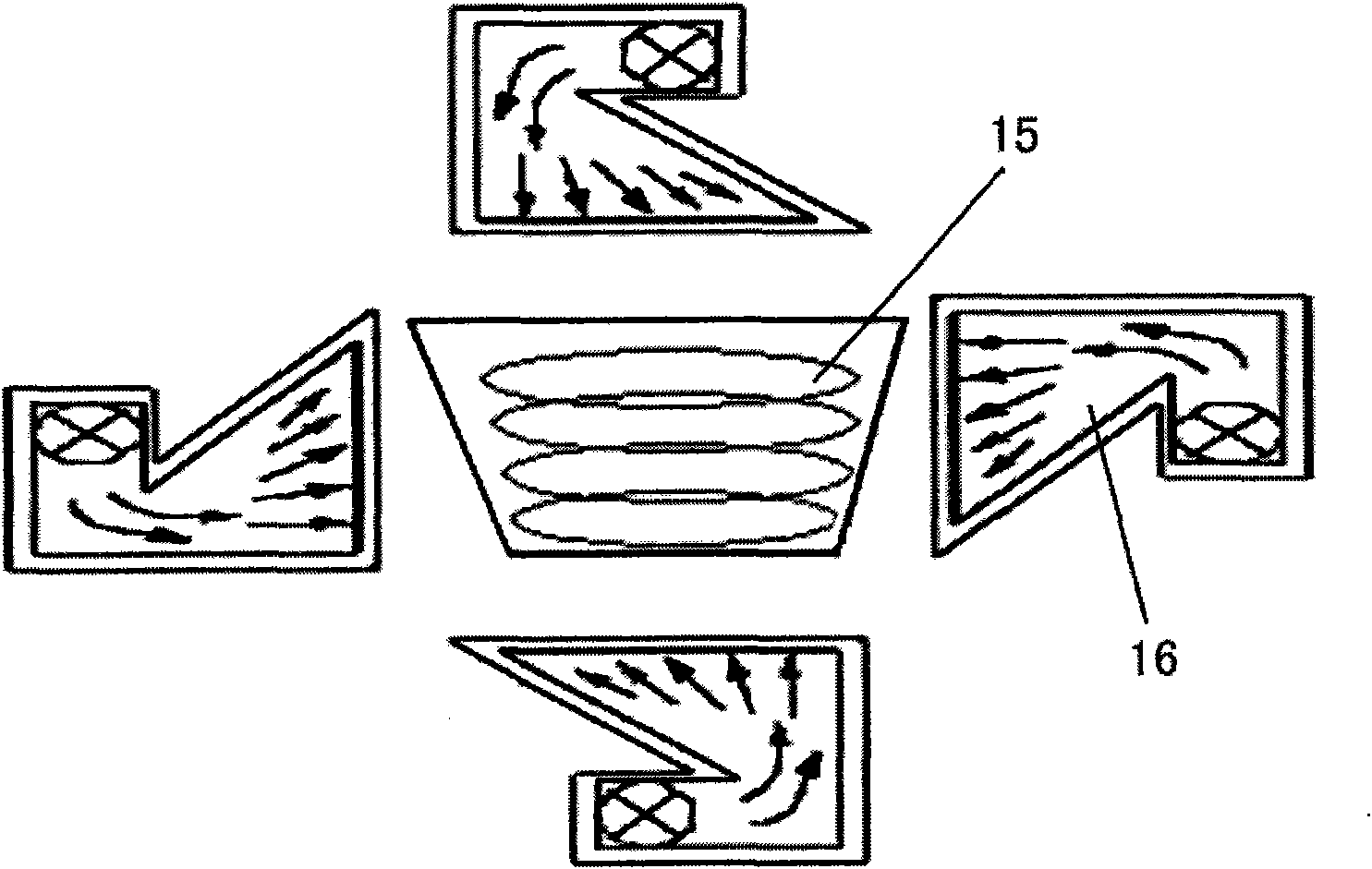

Female die, die and device for plate blank differential temperature drawing molding and drawing method

InactiveCN106180419AReduce radial tensile stressIncrease limit deformationShaping toolsMetal working apparatusCold airMetal machining

The invention relates to the technical field of metal machining, and discloses a female die, die and device for plate blank differential temperature drawing molding and a drawing method. The female die is provided with an air inlet passage used for leading cold air into a groove of the female die, and an exhaust passage used for exhausting the cold air out of the groove; and the die comprises a male die, an edge pressing device and the female die which are sequentially arranged in the vertical direction. The device comprises a pressing machine and the die. The drawing method includes the steps that firstly, a plate blank is tightly pressed between the edge pressing device and the female die; and secondly, the plate blank is drawn in the groove of the female die. By means of the technical scheme, the ultimate deformation degree of the plate blank can be improved, and the drawing performance of the plate blank is further improved.

Owner:北京普惠三航科技有限公司

Ultralow carbon coil rod for blasting fuse and production method thereof

ActiveCN105779870AImproves drawabilityImprove mechanical propertiesWire rodElectrical resistance and conductance

The invention provides an ultralow carbon coil rod for a blasting fuse and a production method thereof and belongs to the technical field of steel smelting and high-speed wire rolling. The ultralow carbon coil rod comprises the following chemical components in a percent by mass: smaller than or equal to 0.012% of C, smaller than or equal to 0.012% of Si, 0.15-0.30% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S and the balance of iron and unavoidable impurities. The production method comprises the following specific production procedures: manufacturing a casting blank of optimized components, heating a steel blank, rolling a wire material, cooling the wire material and slowly cooling. The production method ensures that the tensile strength of the coil rod is smaller than or equal to 310MPa, the elongation rate is larger than or equal to 45%, and electric conductivity is stably controlled between 14.5% and 15.0%. After drawing and thermal treatment, a blasting fuse finished product has a resilience angle which is smaller than 58 degrees and resistance being between 0.50 omega / m and 0.60 omega / m under the condition that the diameter is between 0.52mm and 0.54mm, and the processing requirements and the technical index requirements of the blasting fuse are met.

Owner:XINGTAI IRON & STEEL

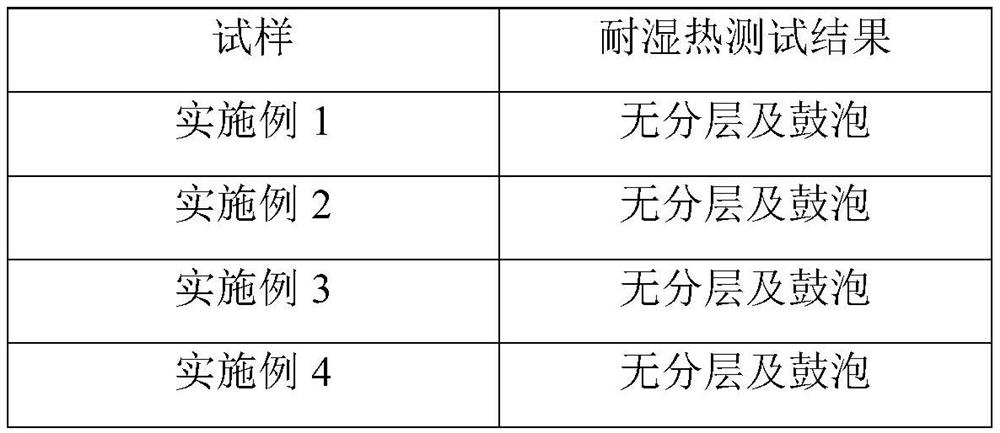

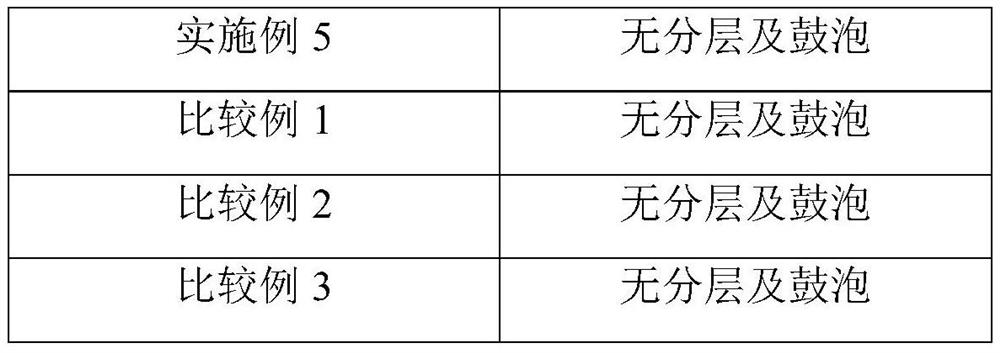

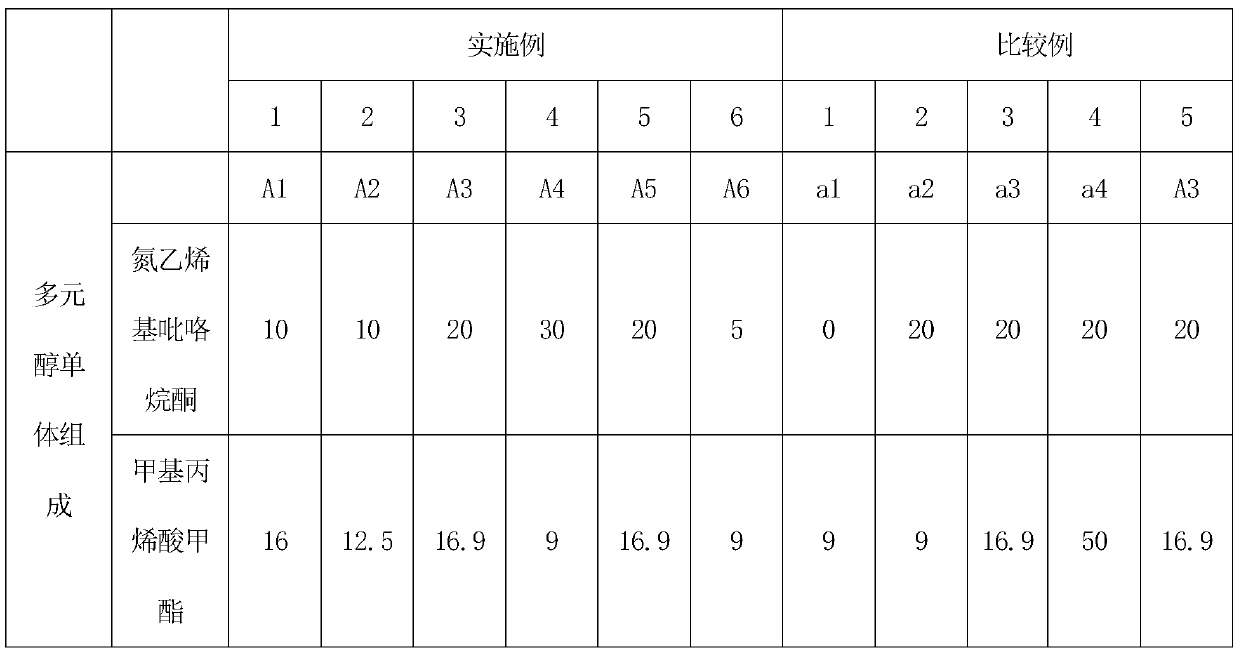

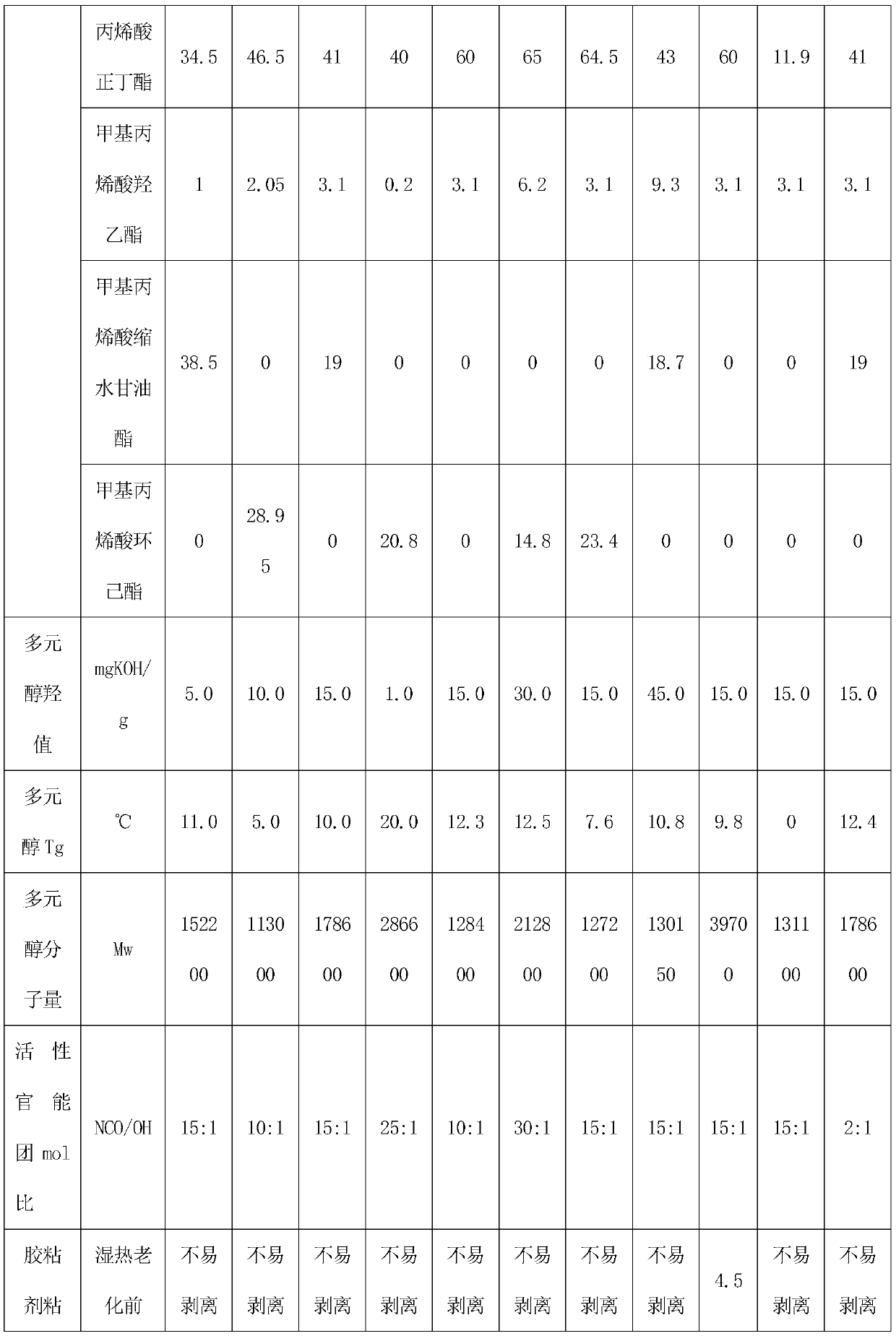

Photocuring adhesive for lithium battery aluminum plastic film and preparation method of photocuring adhesive

PendingCN112745798AGood drawing formability and heat and humidity resistanceEnvironmental friendly energy consumptionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFunctional monomerPhotoinitiator

The invention belongs to the technical field of lithium ion aluminum plastic film production, and particularly relates to a photocuring adhesive for a lithium battery aluminum plastic film. The photocuring adhesive is prepared from the following components in parts by weight: 20 to 70 parts of modified polyurethane acrylate oligomer, 5 to 20 parts of functional monomer, 20 to 70 parts of diluent monomer, 1 to 8 parts of photoinitiator and 1 to 6 parts of thiol compound. According to thephotocuring adhesive disclosed by the invention, the aluminum foil, the nylon film and the CPP film are tightly attached together, and the prepared aluminum-plastic film has good deep-punching forming performance and humidity and heat resistance; the photocuring adhesive replaces inner and outer layer glue used by a conventional aluminum plastic film, does not cause generation of volatile organic compounds (VOC) in the processing process, and is environment friendly and smaller in energy consumption; the aluminum-plastic film does not need to be cured in a drying room, so that the technological preparation period of the aluminum-plastic film is greatly shortened, the input amount of cost in the aspects of manpower, time, energy consumption and the like is reduced, and the productivity of the aluminum-plastic film is improved.

Owner:浙江华正能源材料有限公司

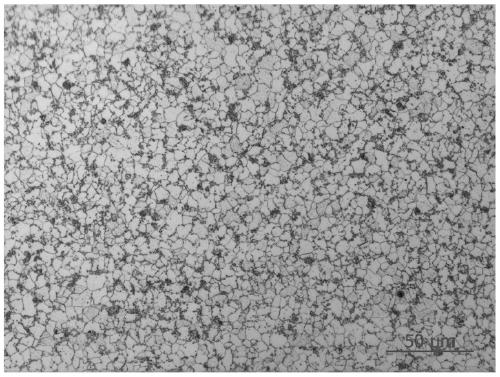

Controlled rolling and controlled cooling method for reducing martensite in microstructure of high-alloy steel hot-rolled wire rod

InactiveCN112239803AEasy to changeShorten transition timeFurnace typesHeat treatment furnacesWire rodTemperature control

The invention belongs to the technical field of steel rolling, and particularly relates to a controlled rolling and controlled cooling method for reducing martensite in a microstructure of a high-alloy steel hot-rolled wire rod. After being heated, a steel billet is subjected to rough, medium and pre-finish rolling deformation; the water flow of a water tank is adjusted, so that the temperature ofthe steel billet reaching a finish rolling mill is controlled to be 750-800 DEG C, and low-temperature controlled rolling is achieved; the flow of the water tank is adjusted after rolling, so that the spinning temperature is controlled to be 780-820 DEG C; a Stelmor fan is started so that the temperature of a wire rod is quickly reduced, and then the wire rod immediately enters an insulation cover to continue the organizational transformation; the speed of a Stelmor roller way is set to be 3-5 m / min, so that the transformation time of a bainite structure is prolonged, and the effect that onlya very small number of martensite structures are contained in the microstructure of the high-alloy steel hot-rolled wire rod is ensured; and therefore, the strength is reduced, the plasticity is improved, and it is ensured that the high-alloy steel hot-rolled wire rod has good drawing performance. By means of the controlled rolling and controlled cooling method for reducing martensite in the microstructure of the high-alloy steel hot-rolled wire rod, the martensite content in the microstructure of the obtained high-alloy steel hot-rolled wire rod is less that 2%, and the drawing performance is extremely good.

Owner:ZENITH STEEL GROUP CORP +1

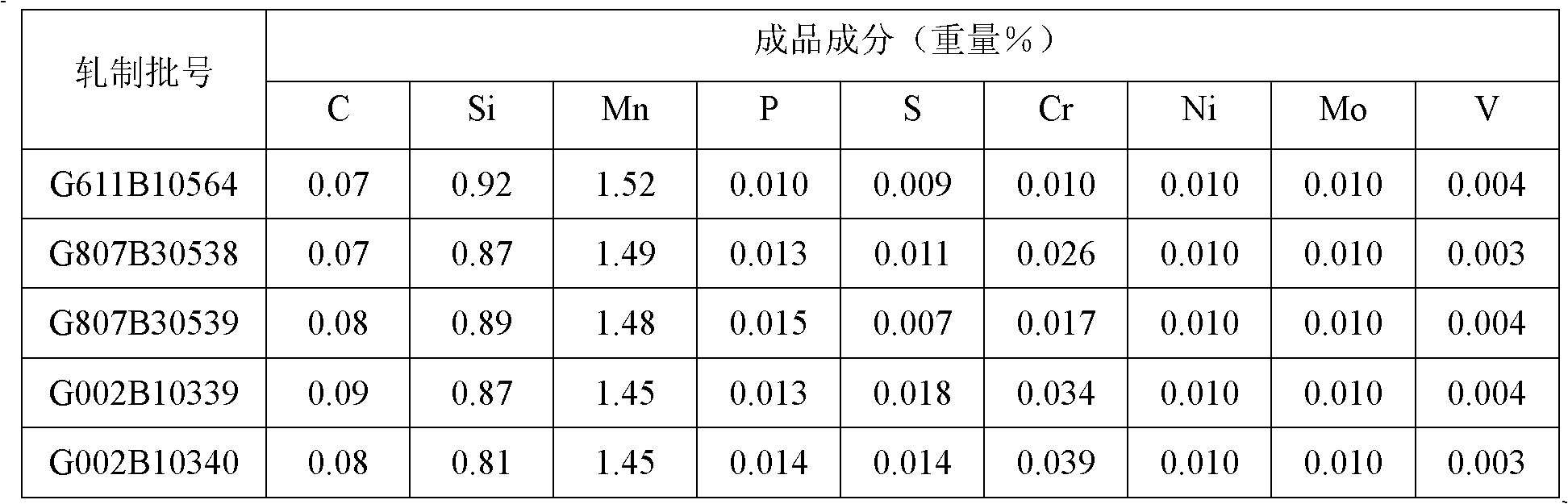

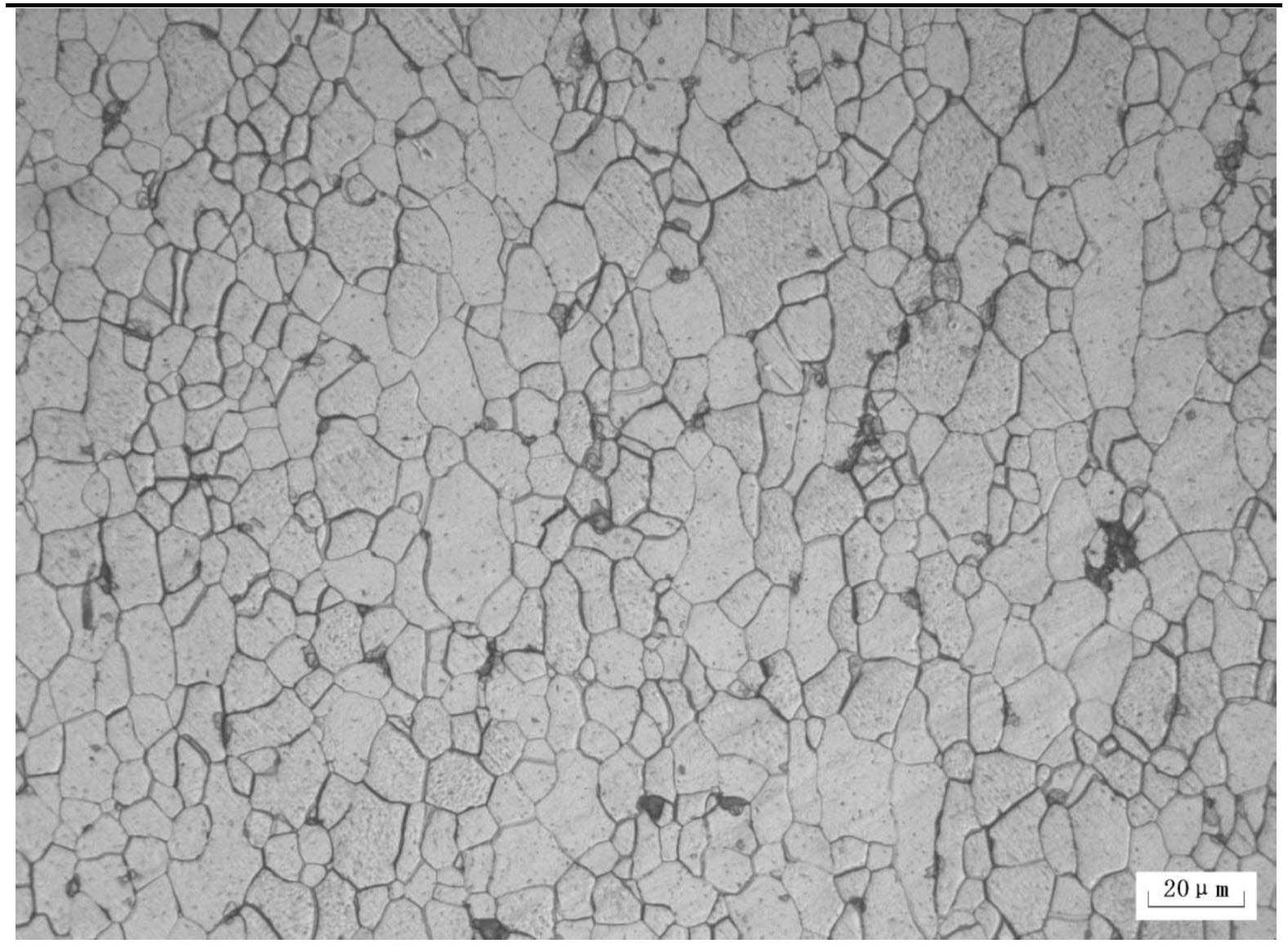

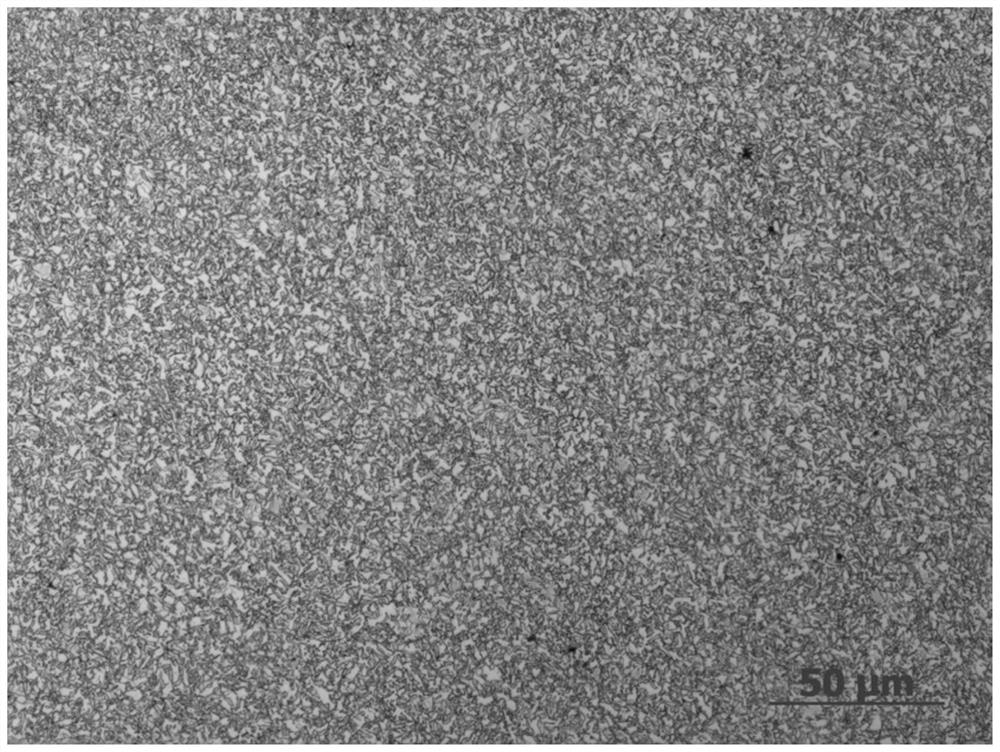

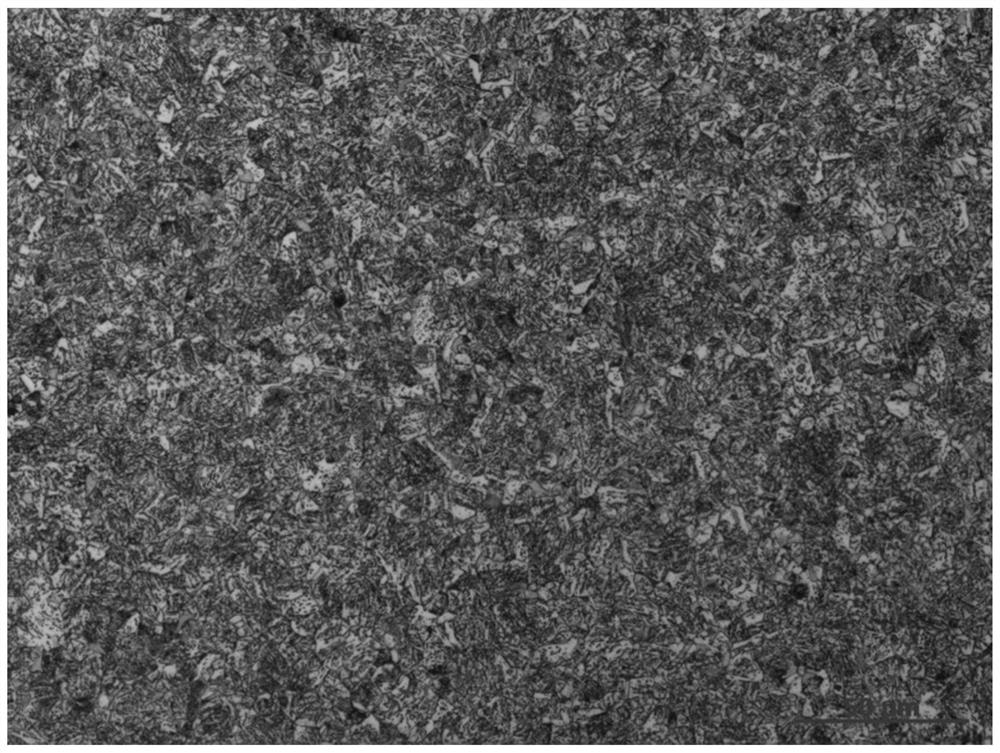

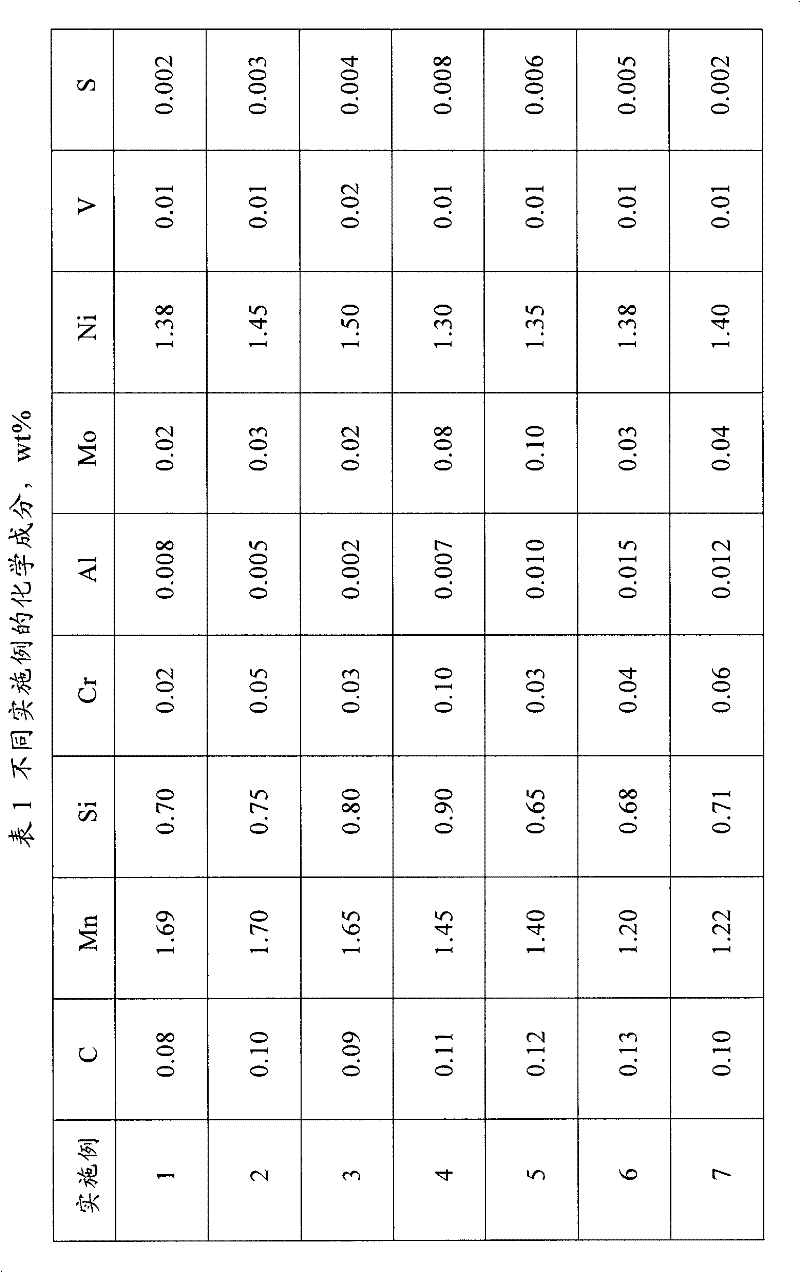

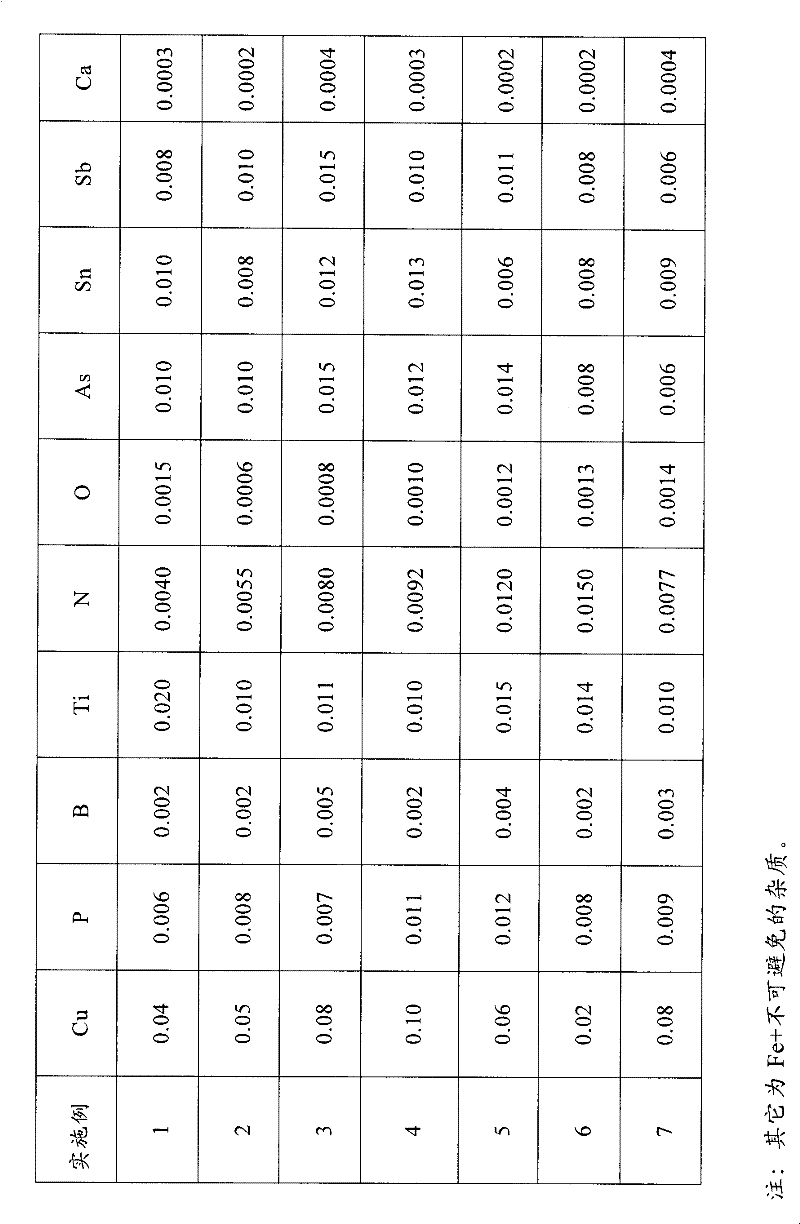

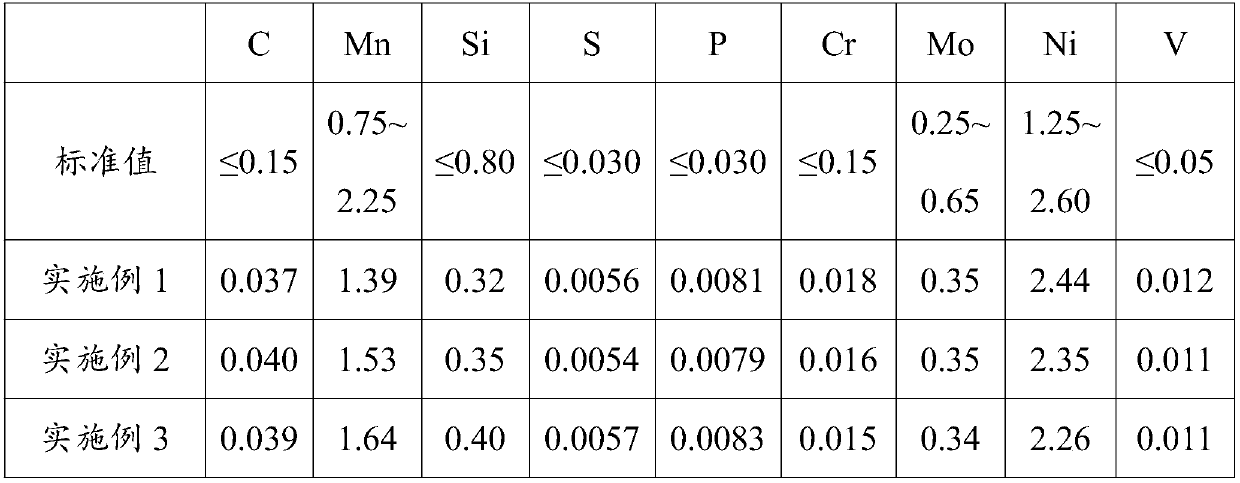

Alloy structural steel for welding wire, wire rod and manufacturing method thereof

InactiveCN102296251AImprove purityLow inclusion levelProcess efficiency improvementElectric furnaceElectric arc furnaceSlag

Alloy structural steel for welding wire, among which: C: 0.08~0.13; Mn: 1.20~1.70; Si: 0.65~0.90; Cr: ≤0.10; Al: ≤0.015; Mo: ≤0.10; 0.02; S: ≤0.008; Cu: ≤0.10; P: ≤0.012; B: ≤0.005; Ti: ≤0.020; N: 0.0040~0.0150; O: ≤0.0015; ≤0.015; Ca: ≤0.0004; the balance is Fe and unavoidable impurities. The manufacturing method includes: a. electric arc furnace smelting, tapping conditions: [C]≥0.04%; [P]≤0.006%; tapping temperature: 1620-1660°C; b. Deoxidation of powder and C powder slag surface; c. pouring; d. rolling, soaking temperature 1070-1200°C, holding time 100-160min, furnace temperature 1050-1180°C, inlet temperature 780-850°C; e. cooling, on-line Slow cooling, cooling rate 40 ~ 80 ℃ / h. The structural steel has high purity, good drawing performance and toughness.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

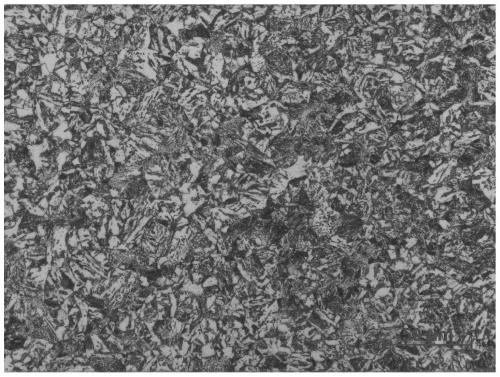

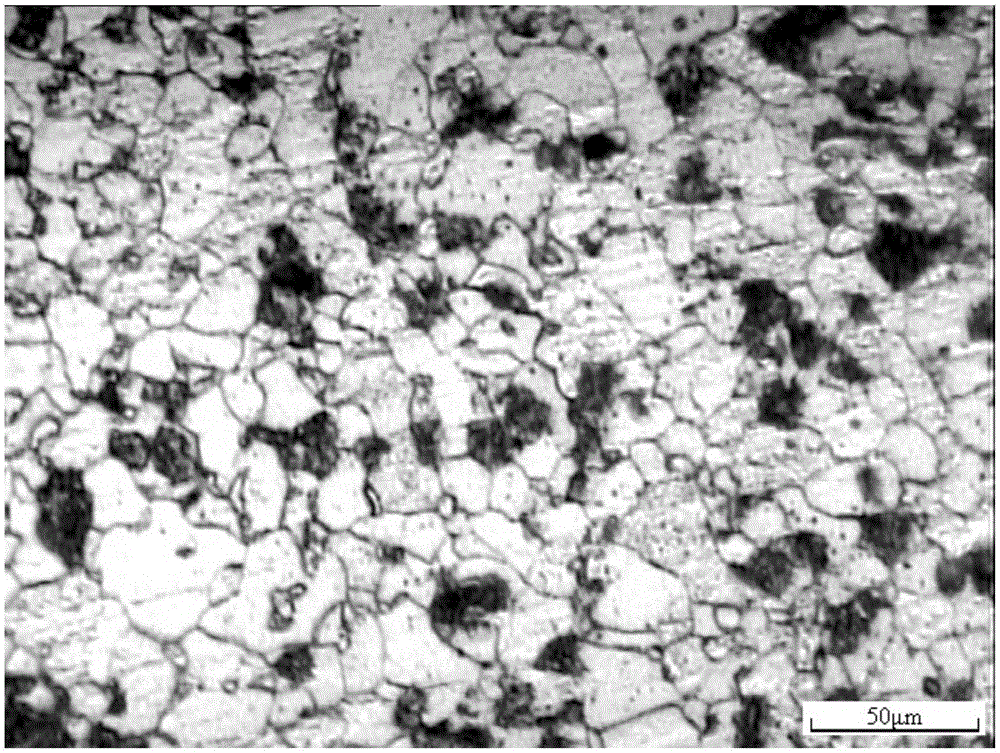

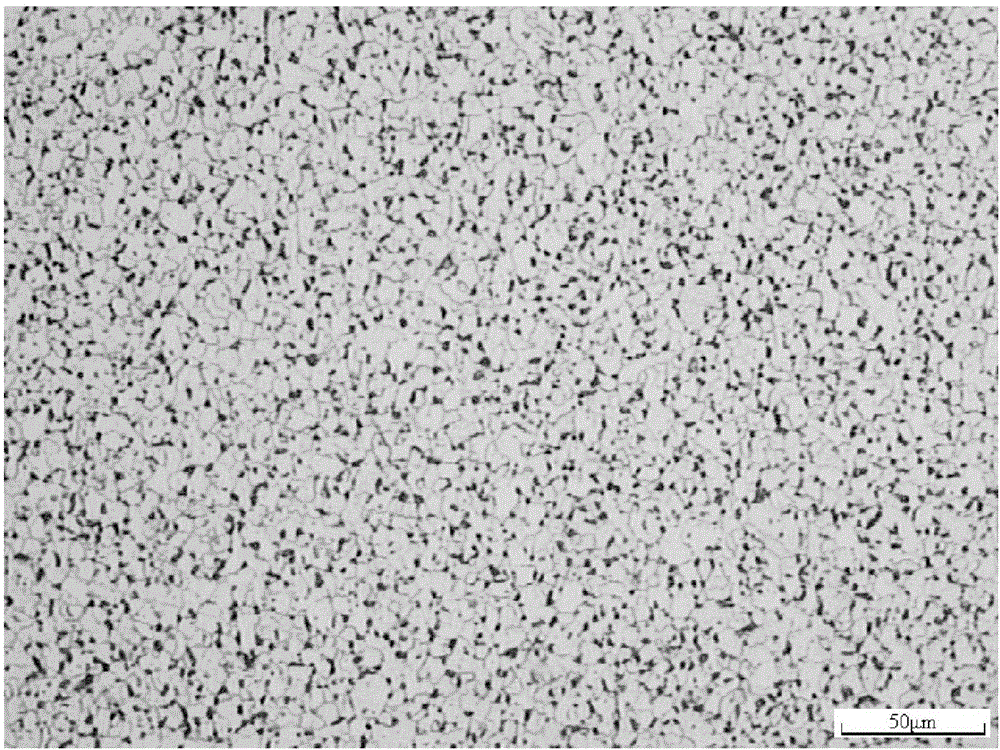

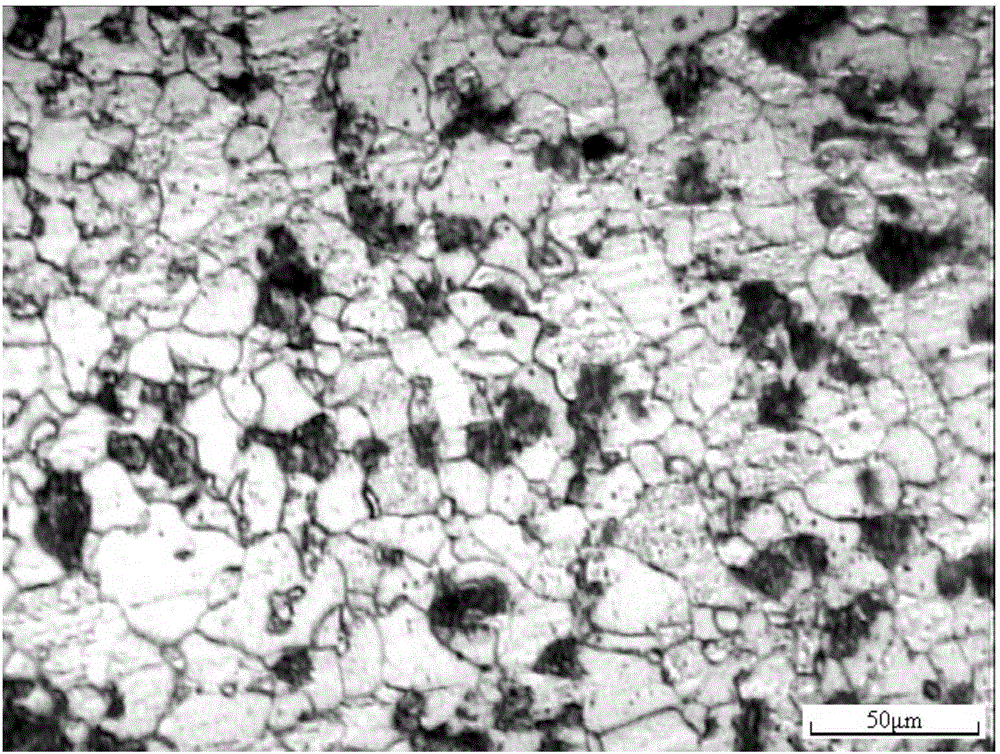

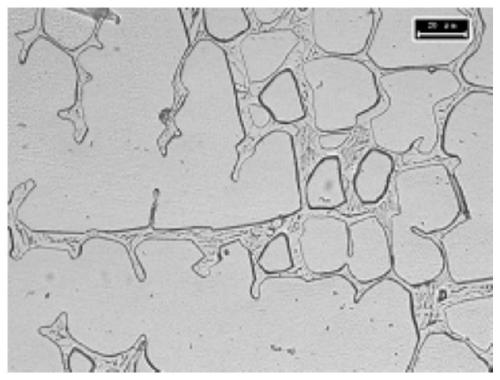

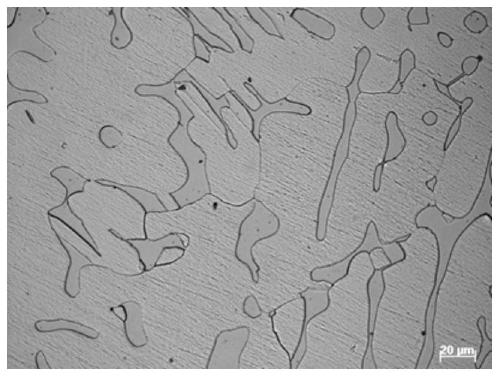

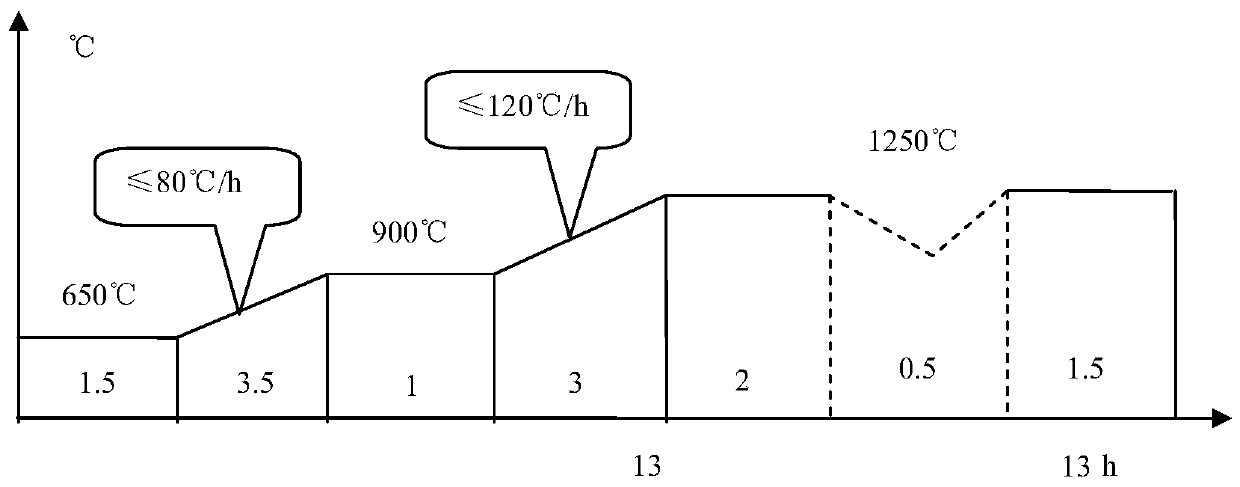

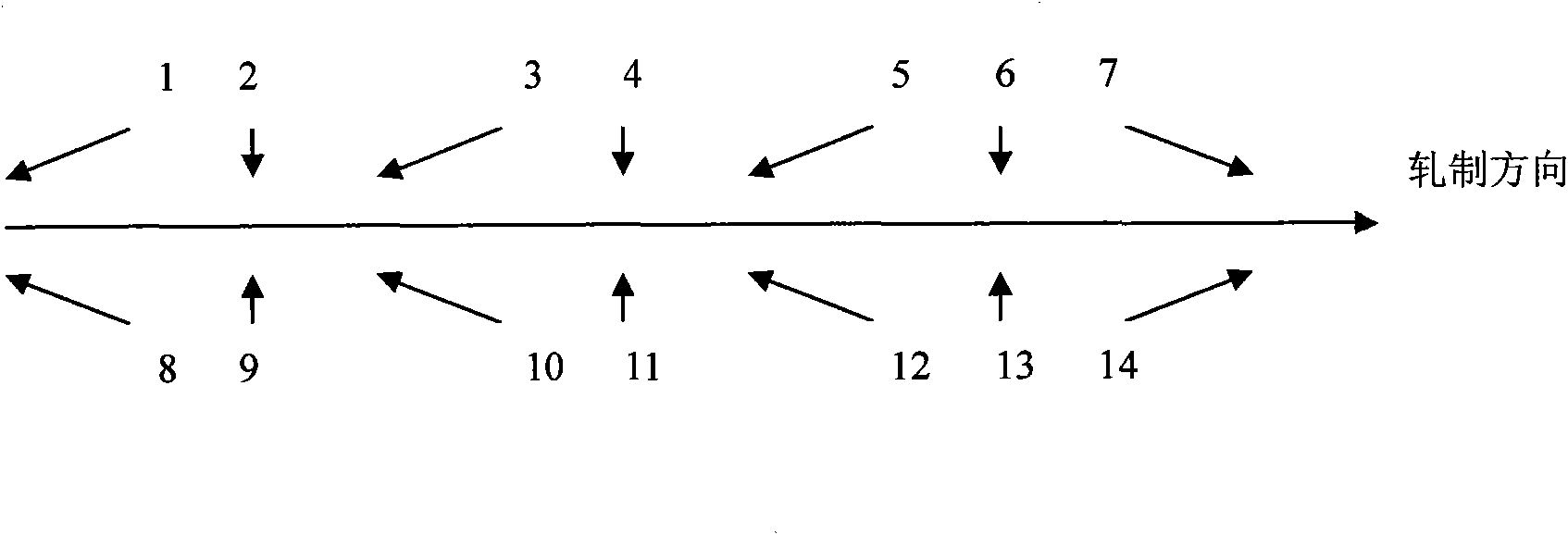

Spheroidizing annealing method for low-alloy high-strength welding wire

InactiveCN106399649AImprove plasticityReduce intensityFurnace typesHeat treatment furnacesFerritic matrixHeating time

The invention discloses a spheroidizing annealing method for a low-alloy high-strength welding wire. The spheroidizing annealing method for the low-alloy high-strength welding wire comprises the steps that firstly, the low-alloy high-strength welding wire to be drawn is heated to the annealing temperature firstly and subjected to heat preservation for a set heating time; and secondly, the low-alloy high-strength welding wire to be drawn is air-cooled to the room temperature after being cooled to a set temperature in a furnace, and thus annealing operation is completed. A welding wire rod treated through the method is subjected to recrystallization annealing, so that the structure with spheroidite distributed on a ferrite matrix is obtained; and thus the strength of materials is reduced and the plasticity of the materials is improved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

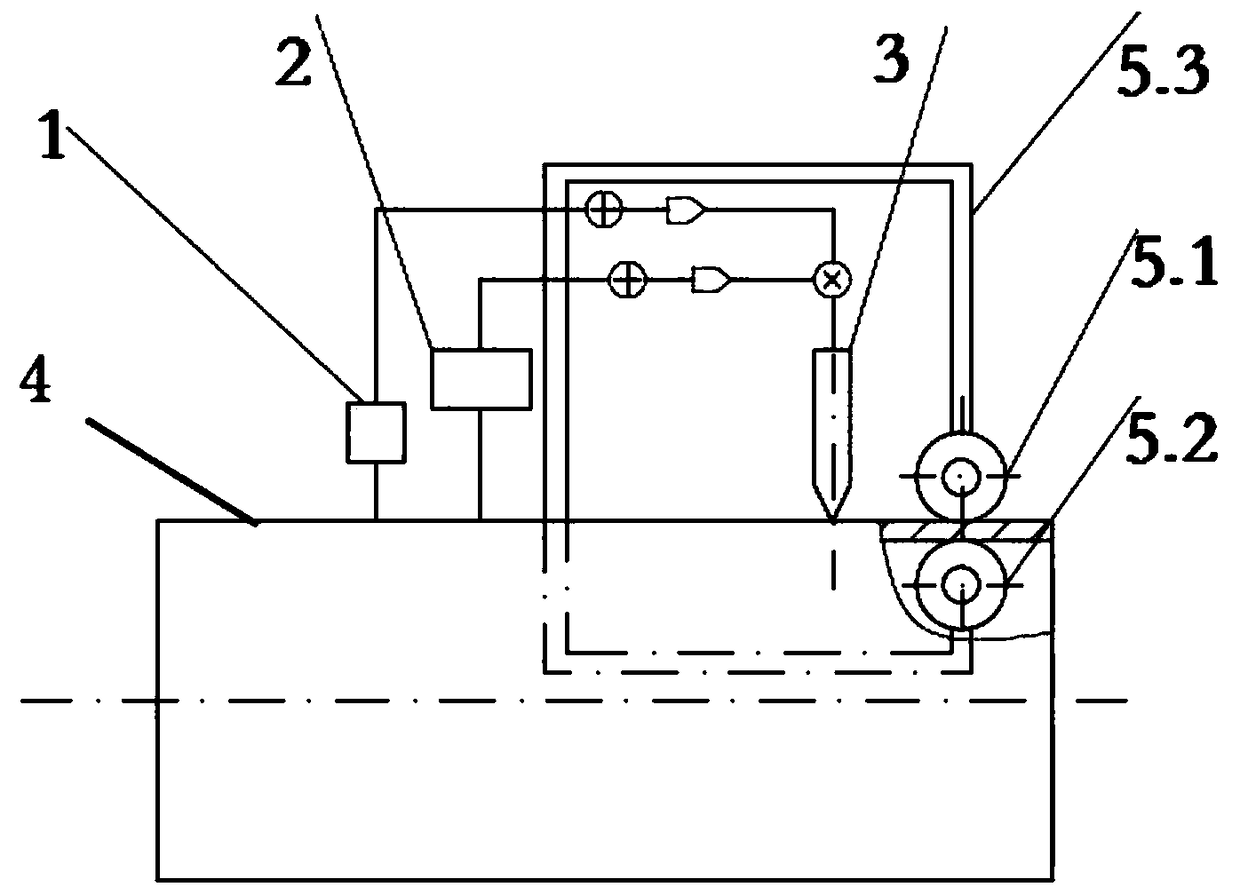

Ultrasonic arc laminating and rolling thin-wall steel tube welding device and welding method

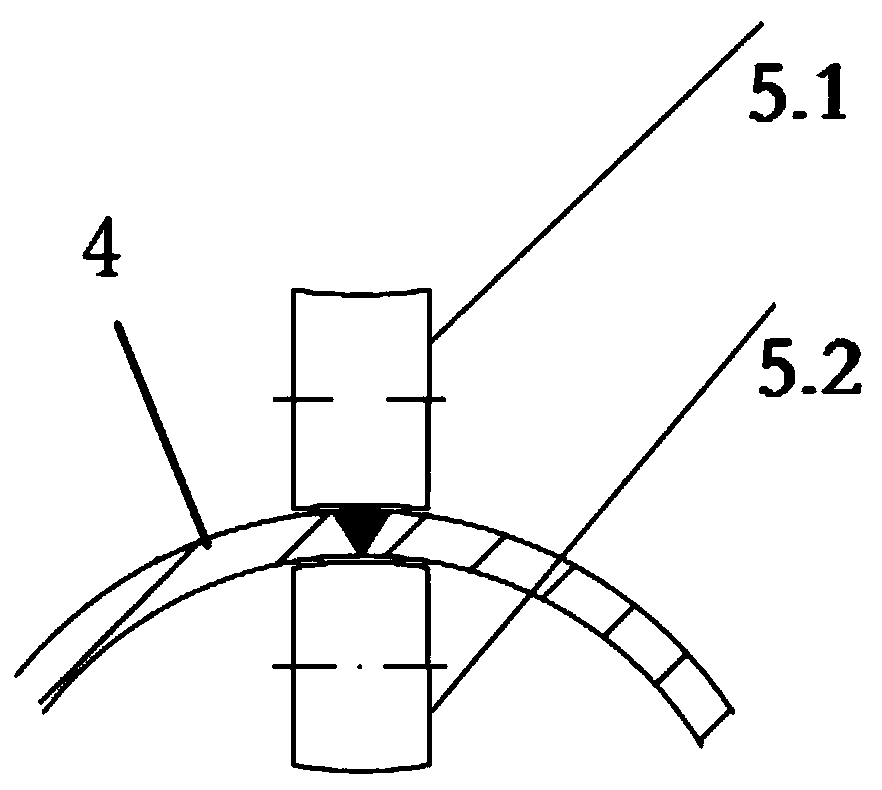

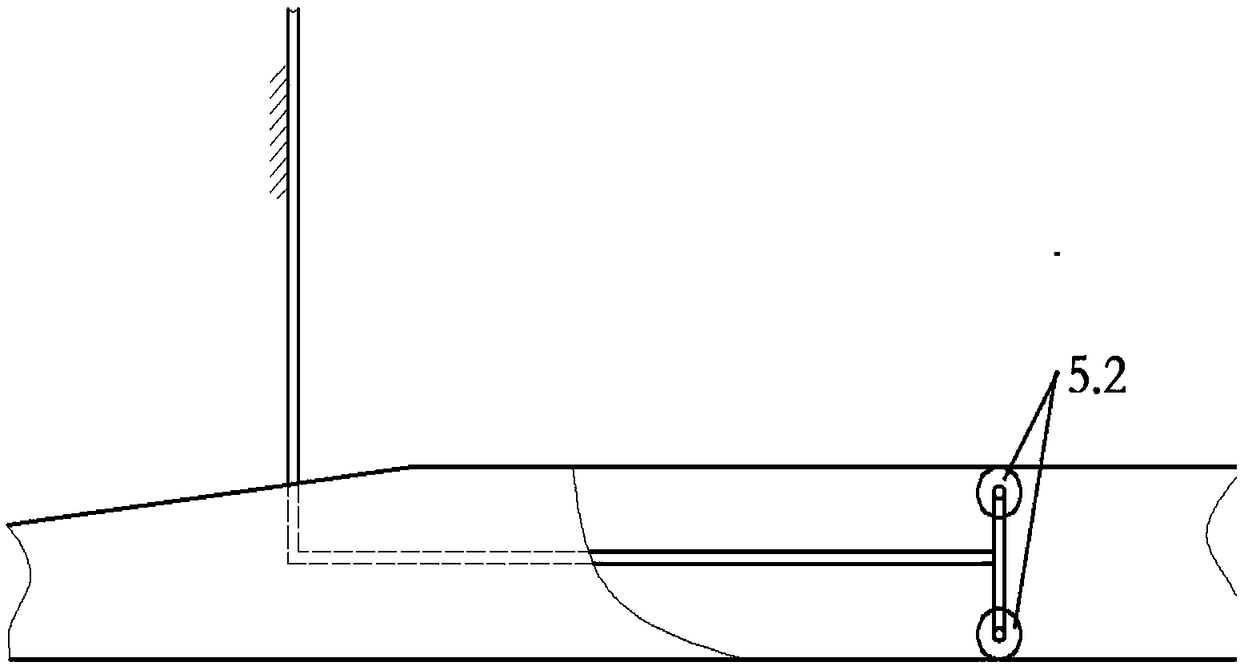

ActiveCN108817622AReduce residual stressRefine the weld grainTubular articlesWelding accessoriesSteel tubeCrystallite

The invention belongs to the field of welding processes and discloses an ultrasonic arc laminating and rolling thin-wall steel tube welding device and welding method. The device comprises an ultrasonic arc generating device and a rolling and laminating device. An upper rolling and laminating wheel (5.1) is laminated to the outer wall surface of the thin-walled steel tube with zero clearance, and the radian curvature of the upper rolling and laminating wheel (5.1) is matched with the diameter of the outer side of the thin-walled steel tube; a lower rolling and laminating wheel (5.2) is laminated to the inner wall surface of the thin-walled steel tube with zero clearance, and the radian curvature of the lower rolling and laminating wheel (5.2) is matched with the diameter of the inner side of the thin-walled steel tube; and the upper rolling and laminating wheel (5.1) and the lower rolling and laminating wheel (5.2) correspond in position. The ultrasonic arc generating device introducesultrasonic arcs into a weld pool. The upper and lower rolling and laminating wheels are laminated to the steel tube in a rolling manner without zero clearance, so that grains of a weld joint of the steel tube are refined, the ductility of the weld joint is improved, and the tearing tendency in a follow-up drawing process is reduced.

Owner:NANJING INST OF TECH

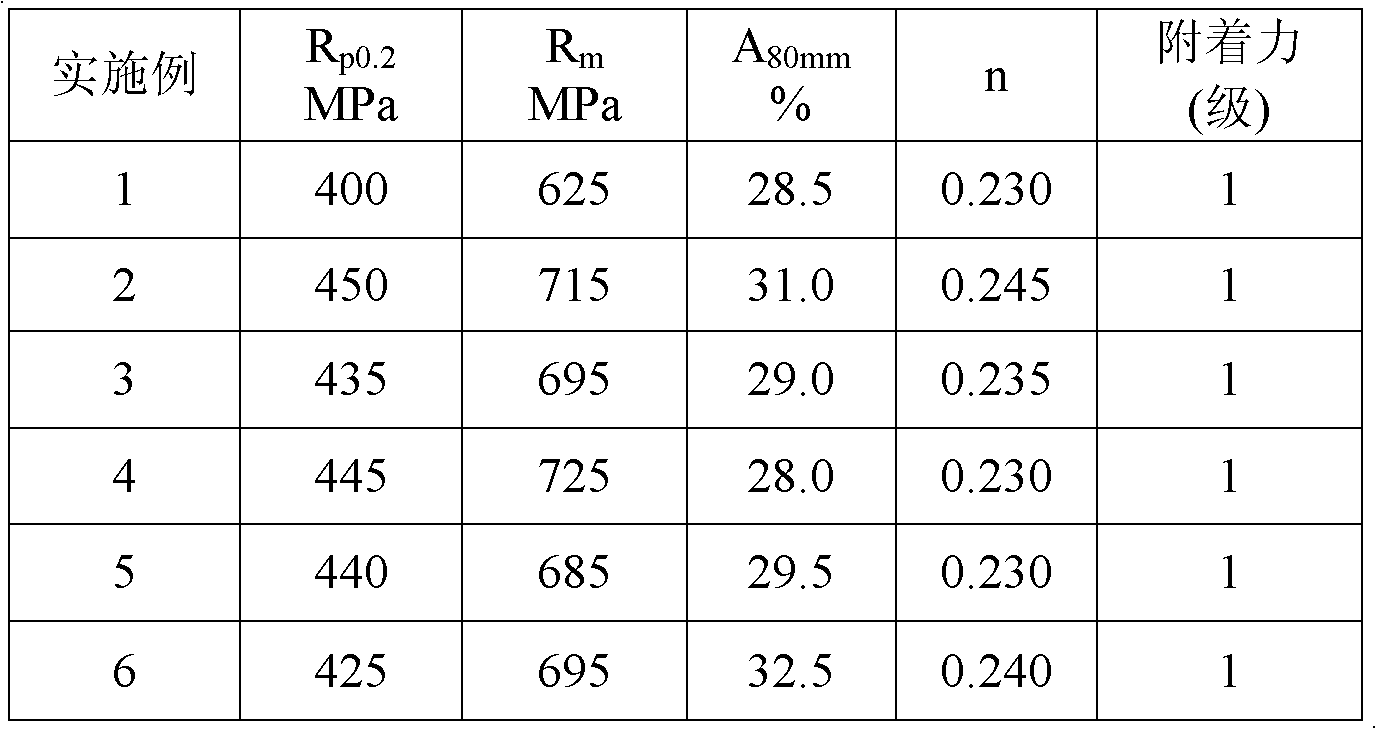

High-strain hardening index hot-dip galvanized high-strength steel and production method thereof

InactiveCN101899619AGood extensibilityImprove ductilityHot-dipping/immersion processesSocial benefitsSheet steel

The invention relates to a hot-dip galvanized high-strength steel and a production method thereof. A base plate of the steel comprises the following components in percentage by weight: 0.11-0.20% of C, 0.51-1.22% of Al, 1.50-2.00% of Mn, 0.07-0.30% of Si, 1.0-2.0% of Cr, no more than 0.015% of P, no more than 0.015% of S, the balance Fe and unavoidable impurities. The production method comprises the following processing steps: smelting and continuously casting into billets; heating the continuous casting billets and maintaining the temperature; roughly rolling; finishing rolling; coiling and carrying out cold rolling; and carrying out hot-dip galvanizing: heating the steel plate after the cold rolling, maintaining the temperature, quickly cooling to 480-510 DEG C, galvanizing and carrying out dip plating for 5-9 seconds, and then cooling to room temperature. The invention solves the problem of galvanizing difficulty of the traditional high-Si content high-strength steel, has the advantages of favorable platability, high drawing performance and good welding performance, corrosion resistance and shaping performance, and has favorable market application prospects and prominent social benefit and economic benefit.

Owner:武汉钢铁有限公司

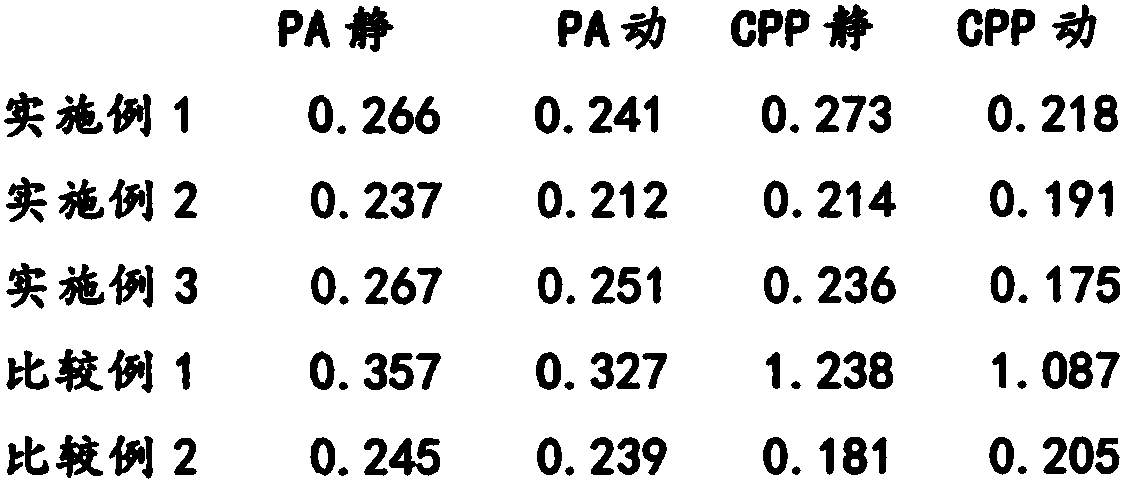

Smooth coating liquid for aluminum plastic thin film and coating process thereof

ActiveCN110760259AGuaranteed stabilityReduced stabilityPolyurea/polyurethane coatingsSpecial surfacesPolyamideOrganosolv

The invention provides smooth coating liquid for an aluminum plastic thin film and a coating process thereof. The coating liquid is prepared from ion-molecular weight organosiloxane, a flatting agent,organic silicon resin, an organic solvent and water. The smooth coating liquid for the aluminum plastic thin film provided by the invention has a favorable effect on remarkably reducing a friction coefficient of a nylon membrane so as to enable a dynamic friction coefficient to be smaller than 0.30; and can be further used for reducing a friction coefficient of a polypropylene thin film so as toenable a dynamic friction coefficient to be smaller than 0.30. The coating process is characterized by coating double surfaces at the same time, and the coating sequence is firstly coating the polypropylene thin film surface and then coating a polyamide thin film surface. The coating process of the smooth coating liquid is simple, no curing is needed, low-temperature drying can be carried out, theproduction efficiency can be effectively improved, and the economic cost can be effectively saved. After an aluminum plastic film product is coated with the smooth coating liquid, a scouring depth performance can be improved, and the stability of the friction coefficient at the high temperature is ensured at the same time.

Owner:广东广麟材耀新能源材料有限公司

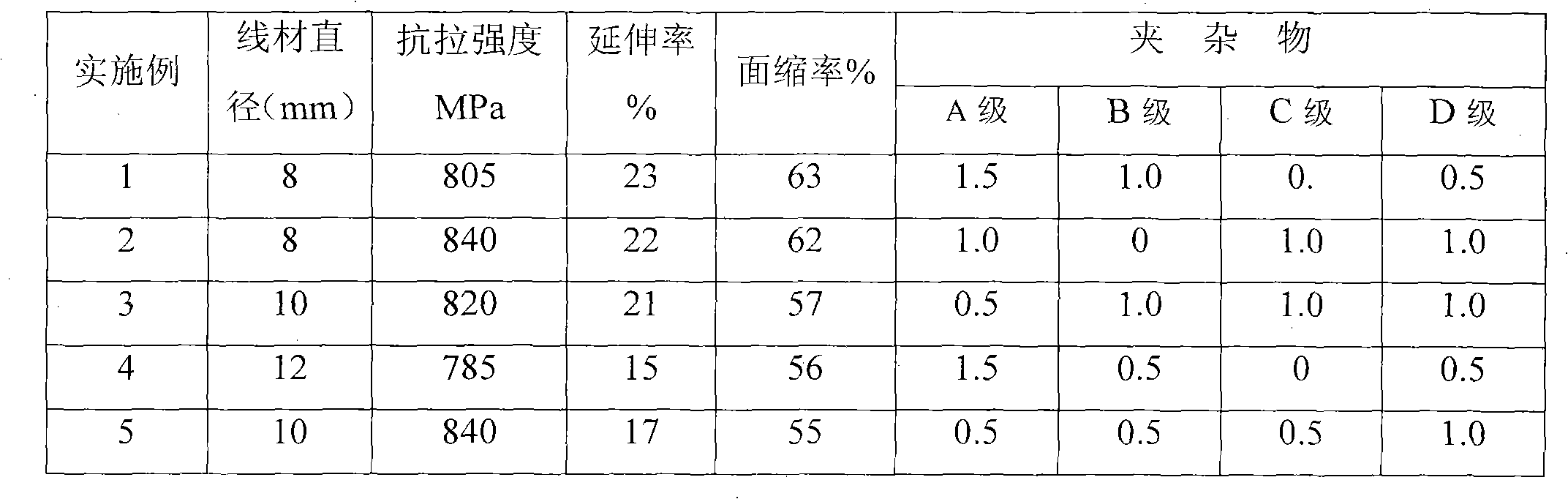

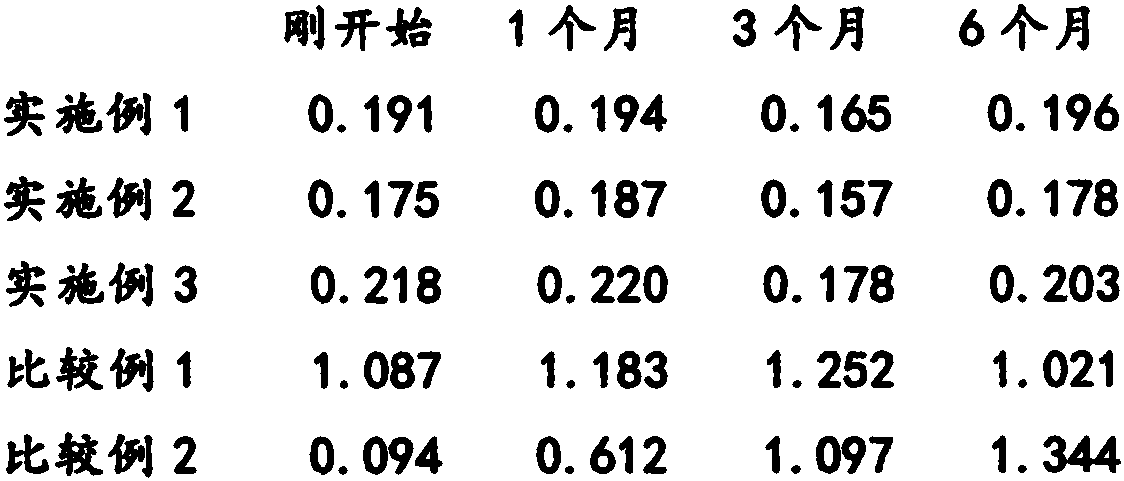

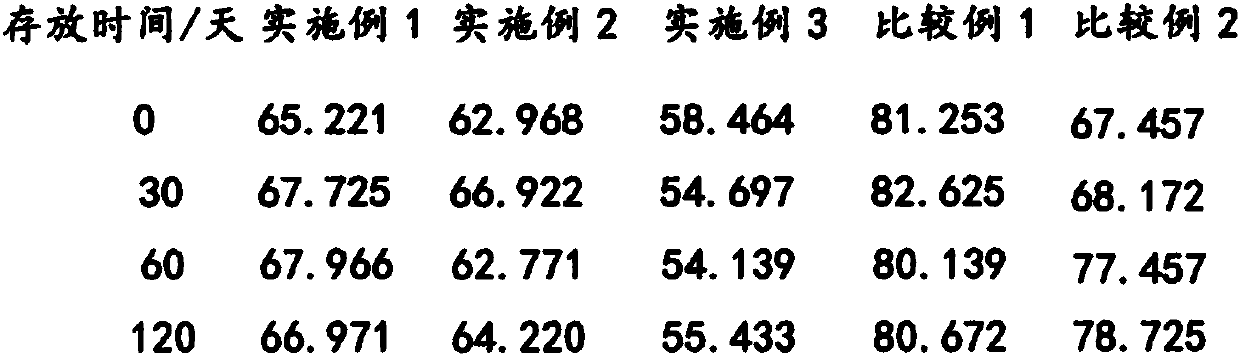

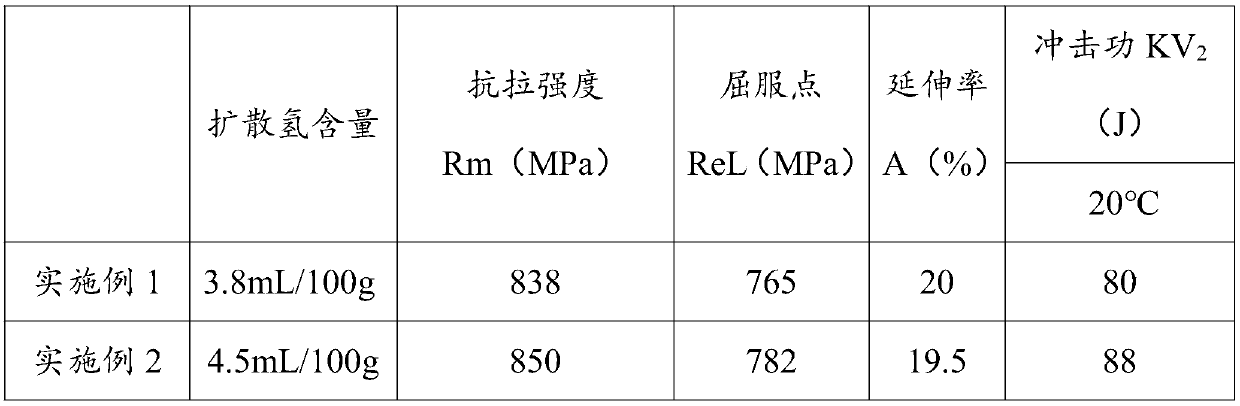

Rutile flux-cored wire with tensile strength of 800 MPa grade and preparation method thereof

ActiveCN107914099AExcellent drawing performanceReduce temper brittlenessWelding/cutting media/materialsSoldering mediaIron powderManganese

The invention discloses a rutile flux-cored wire with tensile strength of 800 MPa grade and a preparation method thereof. The flux-cored wire comprises a cover and a core; and the core comprises the following components: 20-40 weight parts of rutile, 2-10 weight parts of silicate minerals, 2-10 weight parts of magnesium powder, 0.2-4 weight parts of fluoride, 2-8 weight parts of titanium powder, 2-8 weight parts of molybdenum iron, 10-20 weight parts of nickel powder, 10-20 weight parts of electrolytic manganese, 2-8 weight parts of 75 silicon iron, 2-8 weight parts of wollastonite, and 12-17weight parts of iron powder. Compared with the prior art, the flux-cored wire is excellent in welding process performance and physical and chemical property, achieves such purposes as excellent welding process performance, stable arc, low splashing, beautiful molding of welding lines and capability of welding in all positions on process, and achieves the purpose of excellent mechanical performanceon performance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

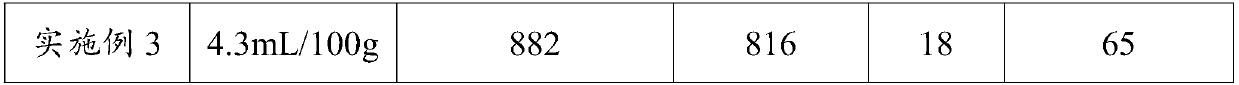

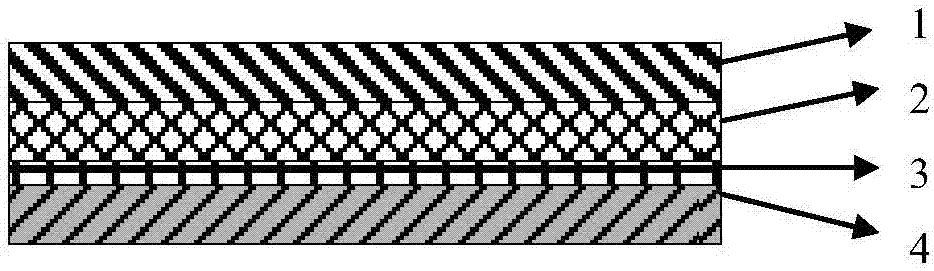

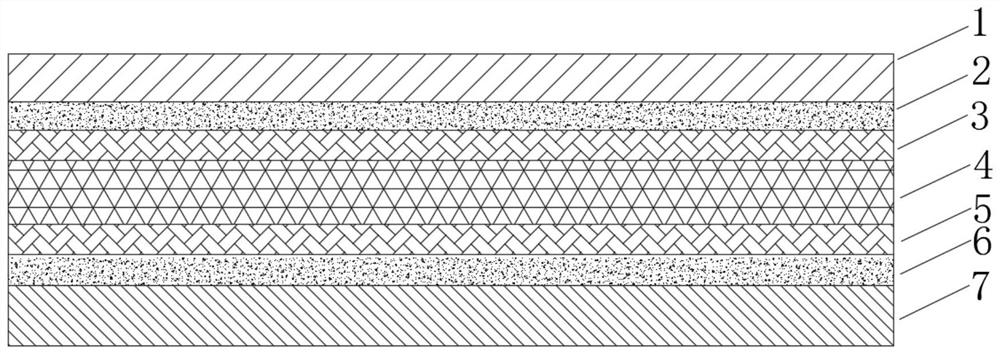

Novel lithium ion battery aluminum plastic soft packaging film

ActiveCN107134547ALayer structure is simpleExcellent chemical resistanceSecondary cellsCell component detailsAdhesive glueChemistry

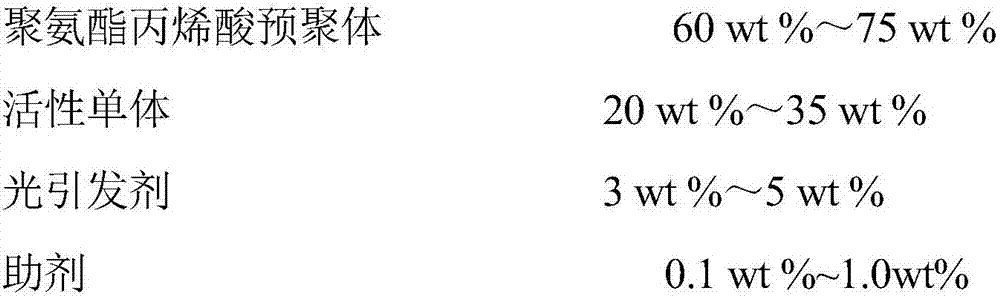

The invention relates to a novel lithium ion battery aluminum plastic soft packaging film which is sequentially provided with a heat-tolerant protection layer, an aluminum foil layer, an adhesive glue layer and a thermoplastic resin film layer from outside to inside. Polyurethane-acrylate ultraviolet curing paint is cured through ultraviolet light to form a coating which is provided with the heat-tolerant protection layer, the polyurethane-acrylate ultraviolet curing paint comprises, in weight percentage, 60wt%-75wt% of polyurethane-acrylate pre-polymers, 20wt%-35wt% of active monomers, 3wt%-5wt% of photo-initiators and 0.1wt%-1.0wt% of additives. A heat-tolerant resin layer of the aluminum plastic soft packaging film is a polyurethane-acrylate resin layer cured by the ultraviolet light, the aluminum foil layer is directly coated with the heat-tolerant resin layer, use of the adhesive glue layer is decreased, and an interlayer structure of the aluminum plastic soft packaging film is simpler.

Owner:乐凯胶片股份有限公司

Molybdenum containing stainless steel welding rod steel and preparing method thereof

ActiveCN109825769AOvercome acid prone problemsImprove stabilityProcess efficiency improvementElectric furnaceImpurityFerric

The invention discloses molybdenum containing stainless steel welding rod steel. The molybdenum containing stainless steel welding rod steel comprises, by weight percent, smaller than or equal to 0.03% of C, 0.45%-0.65% of Si, 1.5%-2.5% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.002% of S, 13.0%-14.0% of Ni, 23.0%-25.0% of Cr, 2.0%-3.0% of Mo, smaller than or equal to 0.5% of Cu, smaller than or equal to 0.07% of N and the balance iron and inevitable impurities. The invention further discloses a preparing method of the molybdenum containing stainless steel welding rod steel. Through the component optimization design and technology improvement, 309 Mo stainless steel welding rod steel which is qualified in quality and stable can be produced in batches, wherein the ferrite content is high (25%).

Owner:宝钢特钢长材有限公司

Stelmor cooling control technique

InactiveCN101664764AReduce or inhibit precipitationDestruction of the film cooling stateWork treatment devicesMetal rolling arrangementsWire rodEngineering

The invention relates to a stelmor cooling control technique comprising a wind cooling process and a water cooling process. In the water cooling process, in at least one water cooling section, each water-spraying nozzle sprays water to the wires walking on a cooling roller table at the spraying angle of 15-25 degrees in the alternating arrangement way of 85-95 degrees, wherein the spraying angle is the angle between a water-spraying nozzle axis and a wire walking direction; and in the wind cooling process, a wind-blowing nozzle blows wind to the wires walking on a cooling roller table from thedirections of up and down, left and right, of the cooling roller table. The stelmor cooling control technique can effectively destroy the cooling state of a film on the surface of a steel bar, form anuclear cooling state of directly contacting with the steel, can reduce or suppress the precipitation of reticular tissues, and ensures that the main control tissue is a homogeneous sorbite tissue, so as to obtain good drawing performance.

Owner:武钢集团有限公司

Method for improving deep drawing performance of aluminum-plastic film

InactiveCN112018276AExcellent drawing performanceImprove continuous productivitySynthetic resin layered productsElectrical equipmentAdhesive cementPolymer science

The invention relates to a method for improving the deep drawing performance of an aluminum-plastic film for a lithium battery flexible package material. The aluminum-plastic film comprises a heat-resistant resin film, an aluminum foil and a thermoplastic resin film which are arranged in sequence, wherein the heat-resistant resin film and the aluminum foil, and the thermoplastic resin film and thealuminum foil are respectively adhered through an adhesive; the thermoplastic resin film is a PP film, a 2000-10000 ppm slipping agent is added in the preparation process of the PP film, and the slipping agent is one or more of an amide slipping agent, ester with high carbon number and amine oxide. According to the method disclosed by the invention, the addition amount of the slipping agent is controlled in the preparation process of a specific layer (namely the PP film layer) of the specific aluminum-plastic film, the friction force between the PP film of the aluminum-plastic film and the surface of a die is improved, the deep drawing performance of the aluminum-plastic film is improved, the deep drawing limit depth reaches 6 mm or above, and the continuous productivity of the aluminum-plastic film can be improved.

Owner:苏州新景新材料科技有限公司

Hyperbranched modified adhesive, preparation method thereof and aluminum-plastic film

ActiveCN112812723AImprove plastic deformationFast curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention belongs to the technical field of lithium battery flexible packaging, and particularly relates to a hyperbranched modified adhesive, a preparation method thereof and an aluminum-plastic film. The hyperbranched modified adhesive is prepared from the following components by weight: 20-70 parts of matrix resin, 4-20 parts of a curing agent, 0.5-5 parts of a composition of hyperbranched polymer and epoxy resin and 20-90 parts of a solvent. Based on the performance advantages of low entanglement, low viscosity, good solubility, high-density functional groups and the like of a highly branched structure of the hyperbranched polymer, the hyperbranched polymer is used for modifying the adhesive, and a large number of holes in hyperbranched polymer are beneficial to plastic deformation of a matrix, so that an adhesive layer can be toughened; a large number of active functional groups can participate in an epoxy resin curing system, and the interface action with the matrix can be enhanced, so that the deep drawing performance can be improved while the bonding strength of the aluminum-plastic film is improved.

Owner:浙江华正能源材料有限公司

Polyurethane adhesive for flexible package of batteries

ActiveCN110819291AExcellent drawing performanceGood adhesionPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention provides a polyurethane adhesive for flexible package of batteries. The main agent of the adhesive is N-vinyl compound modified polyacrylate polyol with mass-average molecular weight of100,000-300,000, a hydroxyl value of 1-30 mgKOH / g and a glass transition temperature of -20 DEG C to 20 DEG C, and a curing agent of the adhesive is aromatic polyisocyanate. The adhesive disclosed bythe invention has excellent adhesive properties and can endow a packaging sheet with excellent formability and endow a molded packaging shell with wet heat resistance during long-term working in a wetheat environment.

Owner:CHINA LUCKY FILM CORP

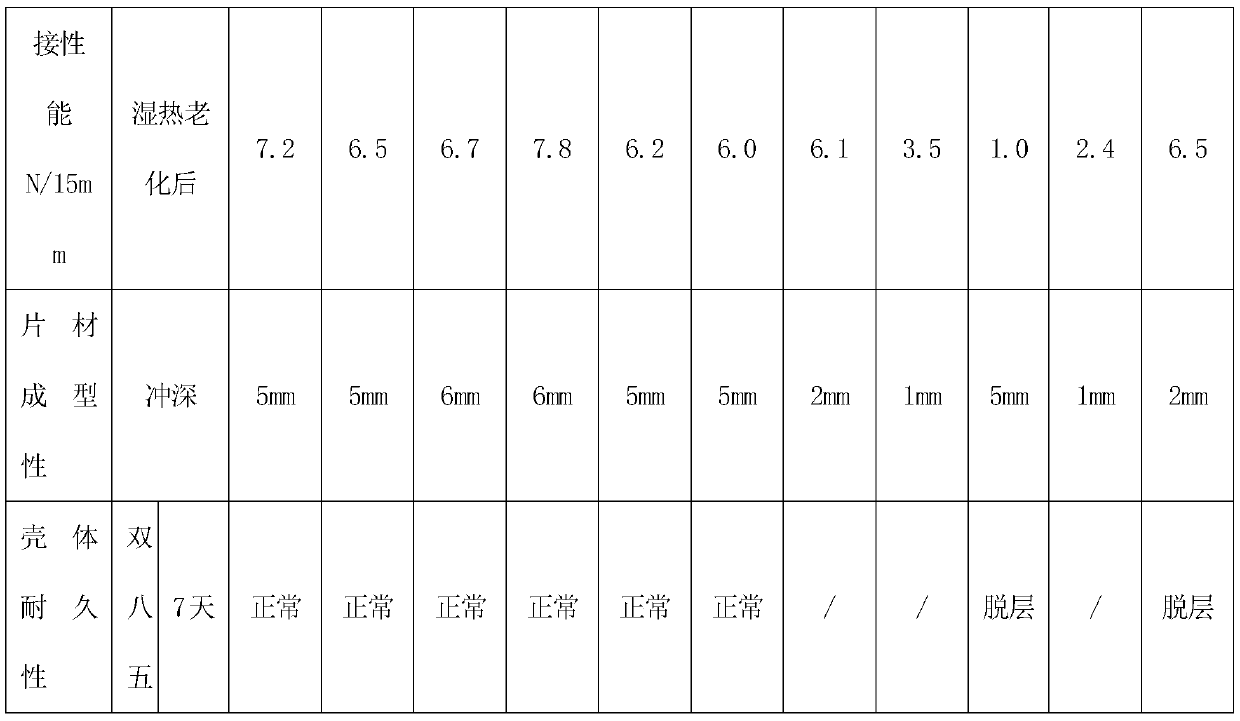

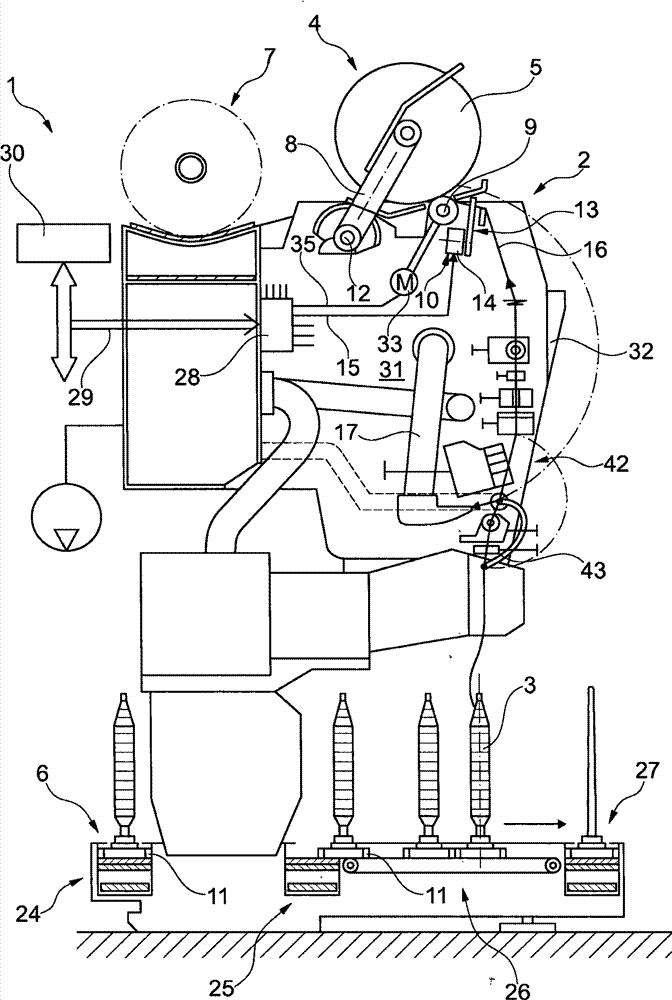

Production for conical cross winding column of S twisted yarn

The present invention relates to a method for the production of conical cross-wound bobbins (5) with S-twisted yarn. According to the invention the S-twisted yarn as a sleeve (18) wound that forms a p-winding and symmetry ratio, i.e., the ratio of the laying speed between, as seen from the operating side, left and right front side of the cheese (5 ), is increased during the bobbin travel. The invention also relates to the cross-wound bobbin produced by the process (5) and the winding device (4) for carrying out the method.

Owner:SAURER GERMANY GMBH & CO KG

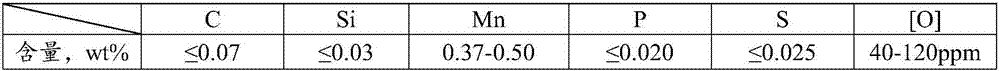

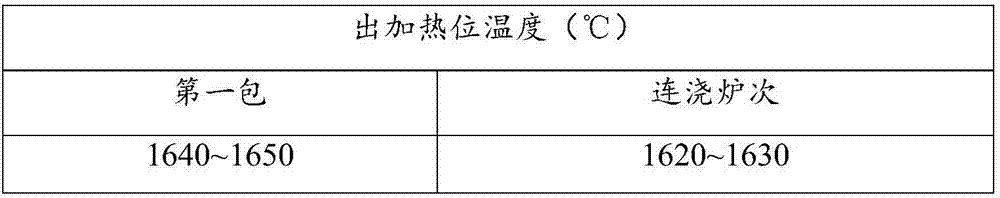

Welding rod steel and manufacturing process thereof

The invention relates to the field of metallurgy, and discloses a welding rod steel and a manufacturing process thereof. The manufacturing process of the welding rod steel comprises the smelting step, the refining step and the casting step. Refined molten steel comprises 0.06-0.08wt% of C, less than or equal to 0.03wt% of Si, 0.37-0.50wt% of Mn, less than or equal to 0.025wt% of P, less than or equal to 0.025wt% of S, 30-50ppm of [O], and the balance impurities and Fe. The casting step is used for casting the molten steel obtained in the refining step by adopting a continuous casting process, and the superheat degree of the molten steel is 30-50 DEG C. The welding rod steel manufactured by the process can have good welding performance and drawing performance and meet follow-up use and machining requirements. According to the production process, the production smoothness can be well guaranteed, and the phenomenon of nodulation of the continuous casting is not prone to be generated.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

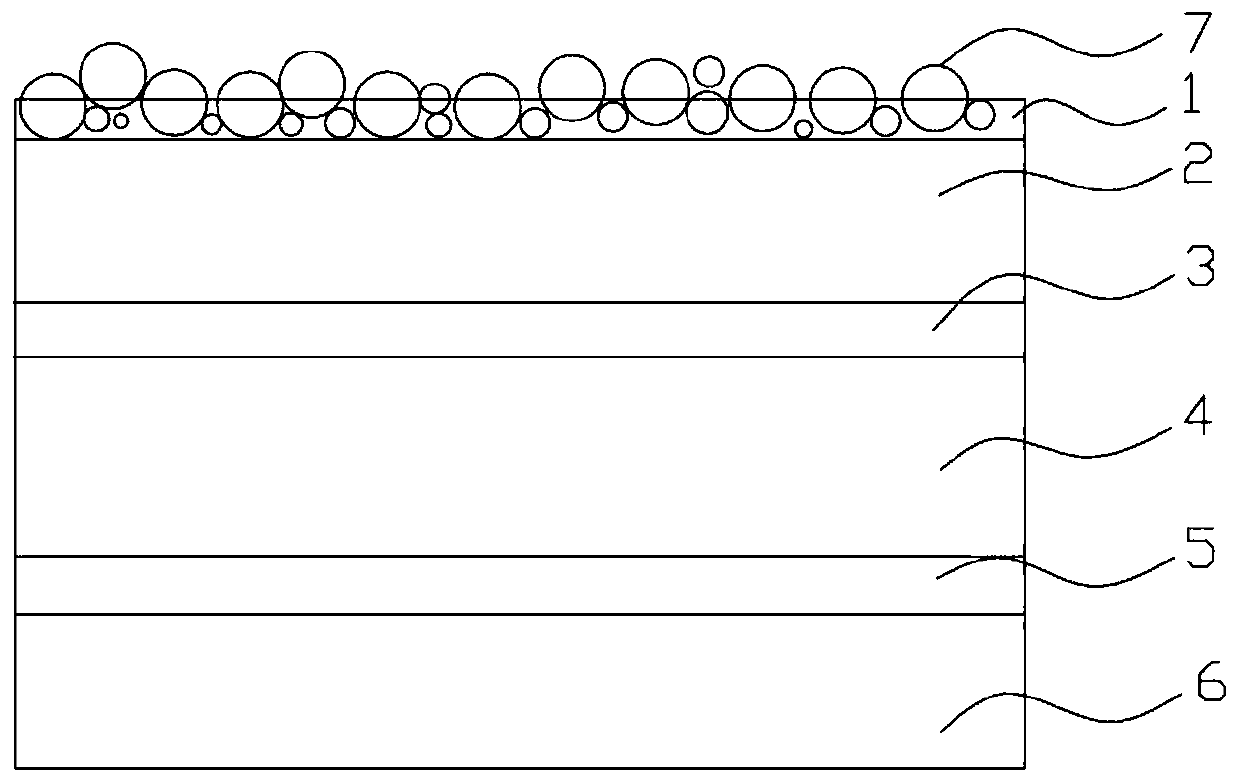

High-temperature-resistant aluminum-plastic composite film

PendingCN110539528AReduce contact areaReduce frictionSynthetic resin layered productsCoatingsTemperature resistancePlastic film

The invention provides a high-temperature-resistant aluminum-plastic composite film. The composite film includes a matte layer, a nylon layer, a first adhesive layer, an aluminum foil layer, a secondadhesive layer and a PP layer which are arranged in sequence from top to bottom; a plurality of hollow glass microbeads are arranged in the matte layer, and the hollow glass microbeads are connected with one another by an adhesive. According to the high-temperature-resistant aluminum-plastic composite film proposed by the invention, the matte layer is additionally arranged on the outer layer of the nylon layer, a filler of the coating is hollow particles, the hollow particles have high-temperature resistance and make the surface of nylon have spherical protrusions, so that a contact area of the coating with a mold during deep drawing molding is reduced, friction is reduced, and deep drawing performance is improved; the product is suitable for all existing aluminum-plastic films, and an operation method of the product is simple and easy to implement, improves the efficiency of battery manufacturers, and improves the product performance of the aluminum-plastic film.

Owner:新纶新能源材料(常州)有限公司

Method for preparing Nb3Al superconducting material by using electrical co-deoxidization method

InactiveCN101967660AHigh purityImprove ductilitySuperconductors/hyperconductorsSuperconductor devicesMetallic materialsElectrochemistry

The invention relates to a method for preparing a Nb3Al superconducting material by using an electrical co-deoxidization method, belonging to the technical filed of metal material manufacturing. The method is characterized by comprising the following steps of: mixing, pressing and sintering high-purity Nb2O5 and Al2O3 powder to obtain sintered blocks, taking the obtained niobium-aluminum oxide sintered blocks as a cathode, taking graphite as an anode, and performing electrochemical process treatment in a CaCl2-NaCl molten salt electrolyte and under the protection of Ar gas; preparing a co-deoxidized niobium-aluminum composite powder material; densifying the niobium-aluminum composite powder material through liquid-phase sintering, alloying the densified niobium-aluminum composite material at the high-temperature of 1400-1700 DEG C and under the protection of Ar gas; and finally preparing the Nb3Al intermetallic compound superconducting material.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com