Alloy structural steel for welding wire, wire rod and manufacturing method thereof

A technology of alloy structural steel and manufacturing method, which is applied in the field of structural steel, can solve problems such as poor welding performance, poor strength and toughness, and poor purity, and achieve the effects of good strength and toughness and good drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

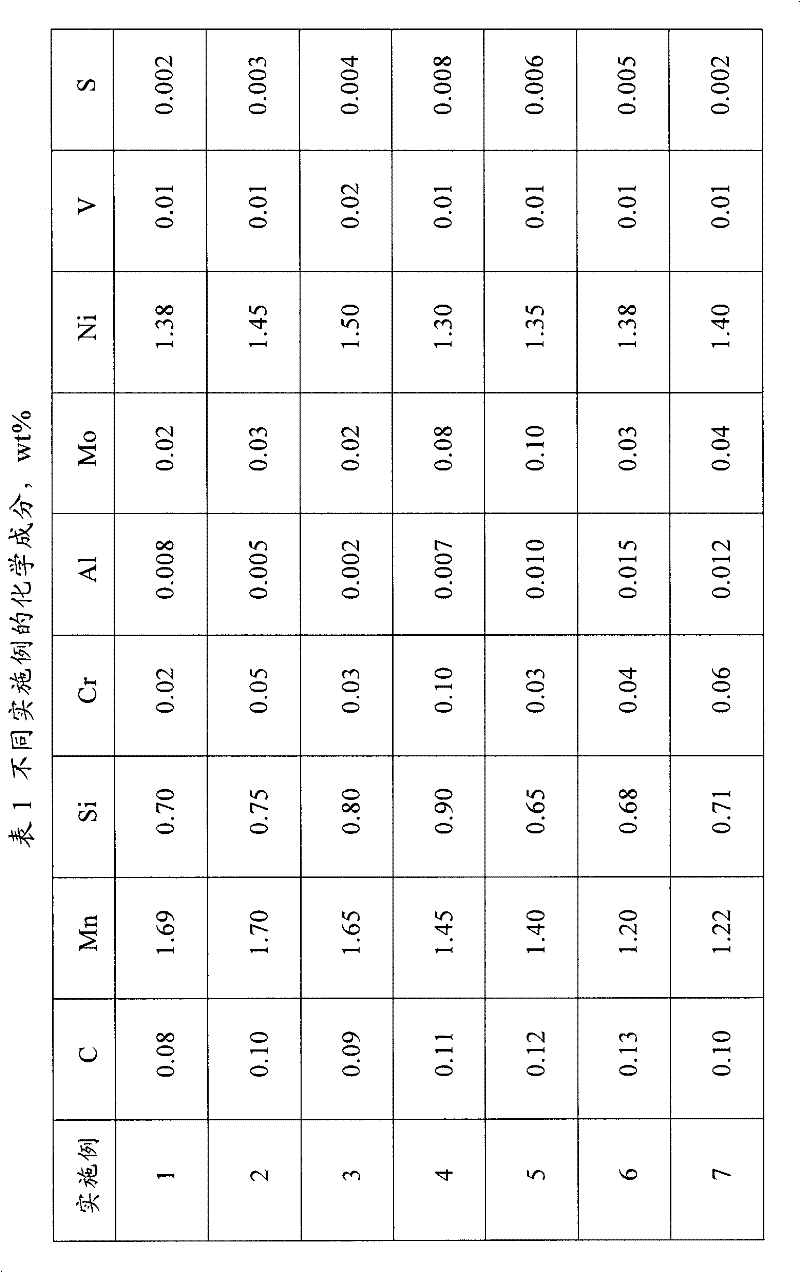

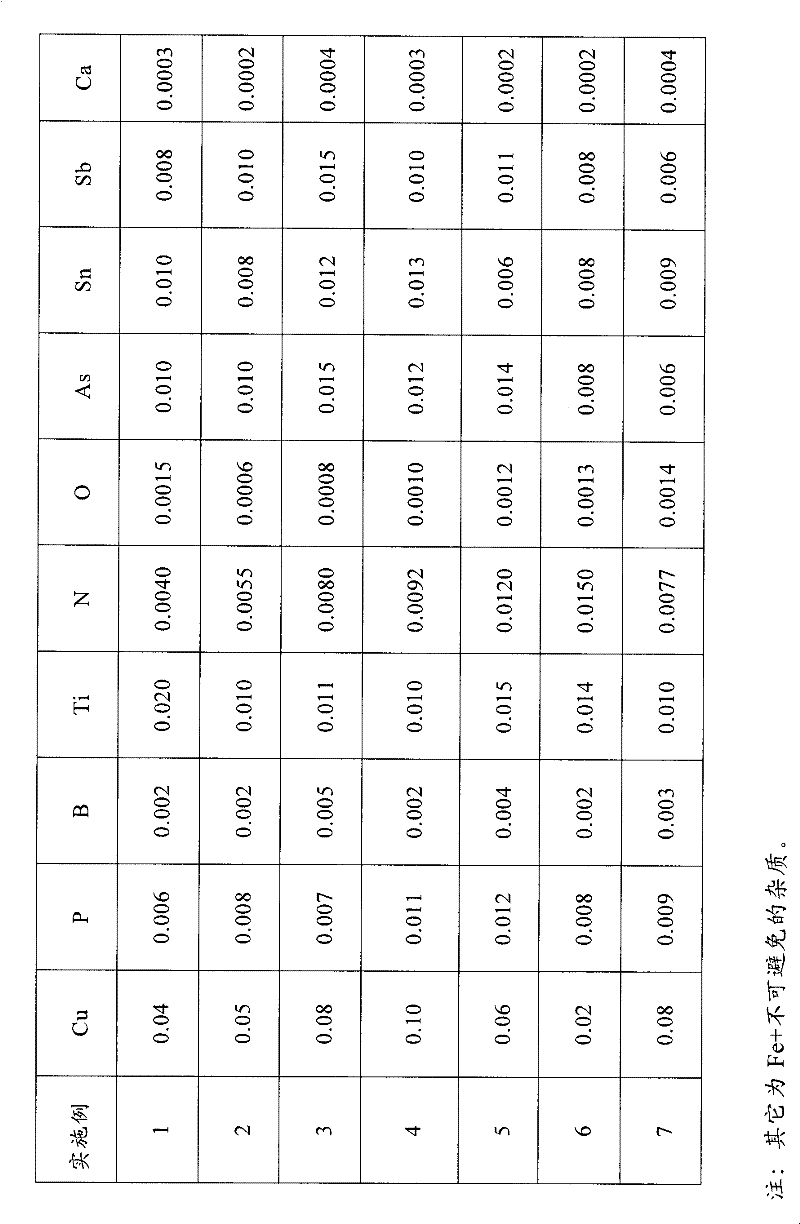

[0037] Table 1 shows the mass percent of the chemical composition of different embodiments of the alloy structural steel for welding wire of the present invention;

[0038] Table 2 shows the process parameters and mechanical properties of specific embodiments of different embodiments of the alloy structural steel for welding wires of the present invention.

[0039] The manufacturing method of the alloy structural steel for welding wire of the present invention will be described in detail below.

[0040] The first step, electric arc furnace smelting - ladle refining

[0041] (1) Electric arc furnace smelting

[0042] High-quality pure steel scrap is used, and the EBT tap hole must be intact to ensure smooth steel flow. The slag is made in advance during the melting period to prevent the molten steel from absorbing nitrogen from the atmosphere. The oxidation process must ensure a certain amount of decarburization and decarburization speed, remove gas and inclusions, minimize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com