High-strain hardening index hot-dip galvanized high-strength steel and production method thereof

A hardening index and hot-dip galvanizing technology, which is applied in the field of hot-dip galvanized high-strength steel and hot-dip galvanized steel sheet, can solve the problems of poor drawing performance and galvanizing performance, achieve good elongation and drawing performance, and alleviate cracks Effect of formation and expansion, high strength and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

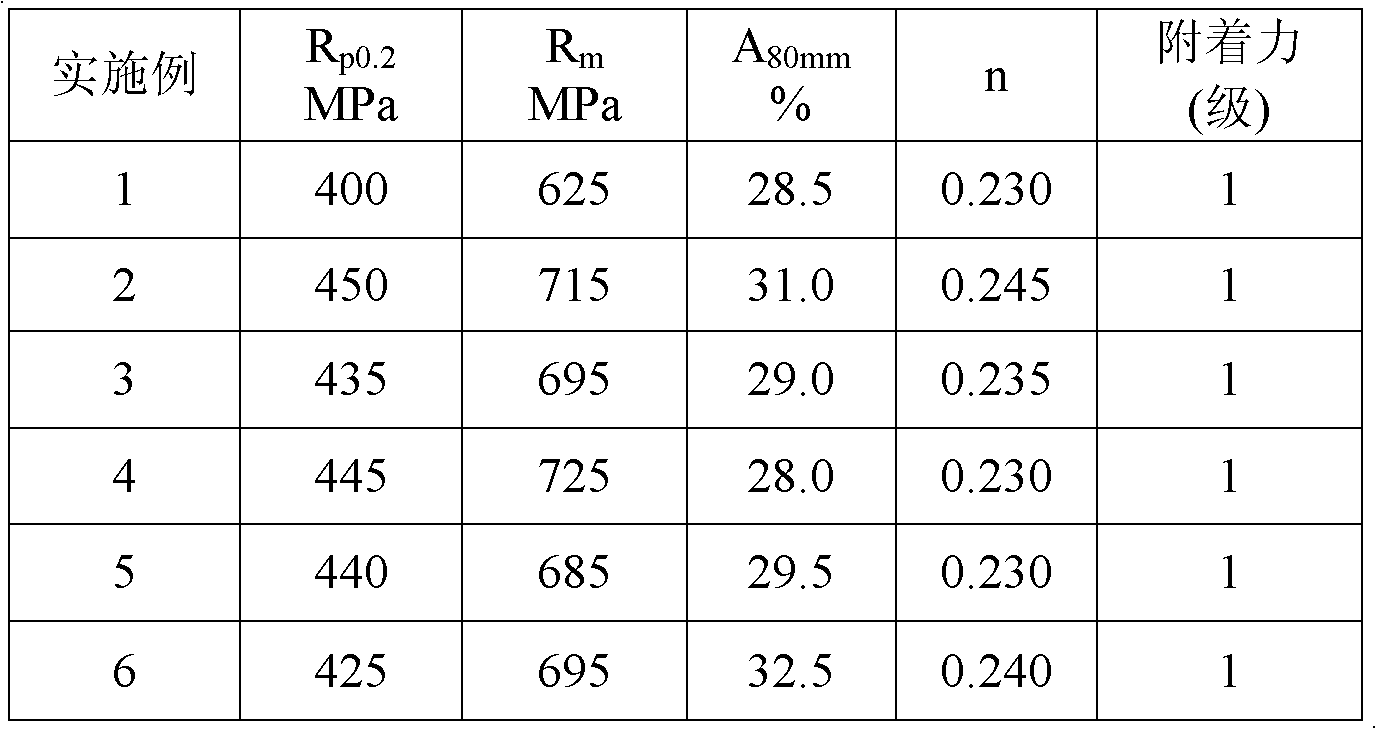

Examples

Embodiment 1

[0039] For hot-dip galvanized high-strength steel with high strain hardening index, the composition and weight percentage of the substrate are: C: 0.11, Al: 1.22, Mn: 1.55, Si: 0.07, Cr: 1.0, P: 0.013, S: 0.008, Yu The amount is Fe and unavoidable impurities.

[0040]A method for producing hot-dip galvanized high-strength steel with a high strain hardening index, the steps of which are:

[0041] 1) The smelting is carried out under the condition of a vacuum degree of 80Pa, the smelting temperature is controlled at 1590-1595°C, and the blank is continuously cast;

[0042] 2) Heating the continuous casting slab to 1200-1210°C and keeping it at this temperature for 160 minutes;

[0043] 3) Rough rolling is carried out, and the rough rolling temperature is controlled to be 1080-1096°C;

[0044] 4) Carry out finish rolling, control its finish rolling temperature to be 860~875 ℃, plate thickness is controlled at 3 millimeters;

[0045] 5) Carry out coiling, control its coiling te...

Embodiment 2

[0054] For hot-dip galvanized high-strength steel with high strain hardening index, the composition and weight percentage of the substrate are: C: 0.15, Al: 1.10, Mn: 1.75, Si: 0.21, Cr: 1.26, P: 0.015, S: 0.009, Yu The amount is Fe and unavoidable impurities.

[0055] A method for producing hot-dip galvanized high-strength steel with a high strain hardening index, the steps of which are:

[0056] 1) The smelting is carried out under the condition of vacuum degree of 67Pa, the smelting temperature is controlled at 1600-1610°C, and the blank is continuously cast;

[0057] 2) Heating the continuous casting slab to 1220-1235°C and keeping it at this temperature for 170 minutes;

[0058] 3) Rough rolling is carried out, and the rough rolling temperature is controlled to be 1090-1105°C;

[0059] 4) Carry out finish rolling, control its finish rolling temperature to be 880~890 ℃, plate thickness is controlled at 3.2 millimeters;

[0060] 5) Carry out coiling, control its coiling ...

Embodiment 3

[0069] For hot-dip galvanized high-strength steel with high strain hardening index, the composition and weight percentage of the substrate are: C: 0.15, Al: 1.00, Mn: 1.76, Si: 0.15, Cr: 1.50, P: 0.012, S: 0.010, Nb : 0.10, the balance is Fe and unavoidable impurities.

[0070] A method for producing hot-dip galvanized high-strength steel with a high strain hardening index, the steps of which are:

[0071] 1) The smelting is carried out under the condition of vacuum degree of 105Pa, the smelting temperature is controlled at 1620-1630°C, and the blank is continuously cast;

[0072] 2) Heating the continuous casting slab to 1260-1270°C and keeping it at this temperature for 178 minutes;

[0073] 3) Carry out rough rolling, and control the rough rolling temperature to be 1110-1120°C;

[0074] 4) Carry out finish rolling, control its finish rolling temperature to be 890~900 ℃, plate thickness is controlled at 3.5 millimeters;

[0075] 5) Carry out coiling, control its coiling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strain hardening exponent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com