Preparation method and mold of seamless flux-cored zinc-aluminium alloy welding wire

A technology of zinc-aluminum alloy and flux core, which is applied in the direction of metal extrusion dies, manufacturing tools, welding equipment, etc., can solve the problems of lower yield, no breakthrough in production process, and weight limit, etc., achieve high production efficiency, improve pull The effect of better drawing reduction efficiency and drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

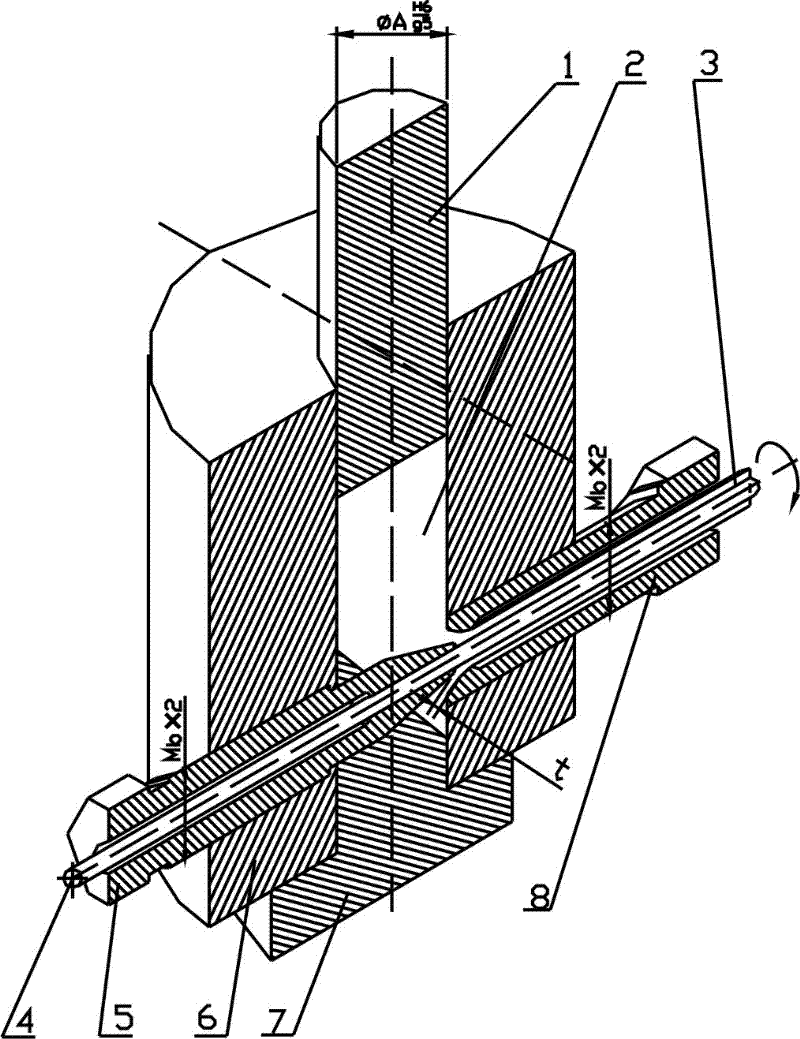

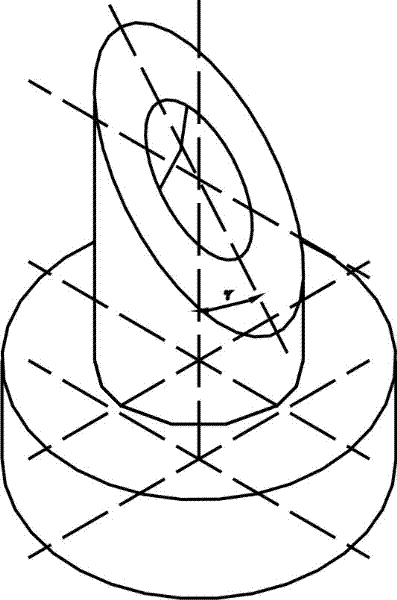

[0031] see Figure 1-3 , The seamless flux-cored zinc-aluminum alloy welding wire produced by the present embodiment has a flux weight percentage of 12%, aluminum 15%, zinc balance, a pipe diameter of Φ15mm, and a welding wire diameter of Φ2mm.

[0032]Step 1 Select a zinc-aluminum alloy strip containing 15% by weight of aluminum, 0.005% of magnesium, and the balance of zinc. The thickness of the strip is 0.7mm, the width is 27.4mm, and the diameter is Φ8.5mm to take the fluxed wire Blank 4. The zinc-zinc-aluminum alloy strip is rolled into a C-shaped groove, filled with powdered flux, closed into an O-shaped tube and drawn together (diameter reduction is 3%) to obtain a fluxed wire with a diameter of Φ8.5mm Blank 4 is for use.

[0033] Step 2 Configure an extruded ingot with a casting length of 155mm and a diameter of Φ62mm, and cut off the gate for use. Among them, the weight percentage of aluminum is 15%, and the balance is zinc.

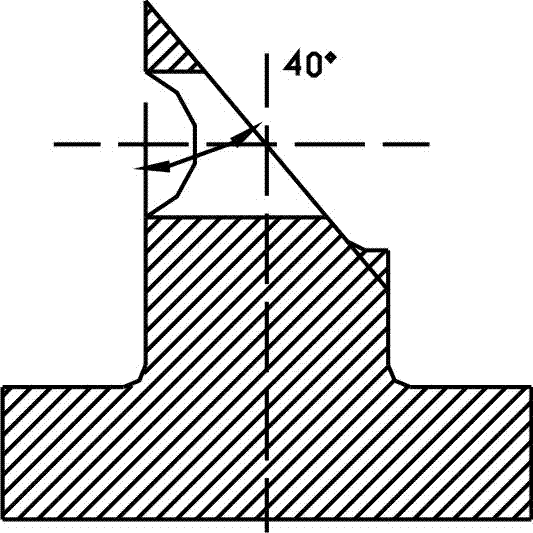

[0034] Step 3 Use figure 1 As shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com