Patents

Literature

150 results about "Zinc aluminium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc-aluminium (ZA) alloys are alloys whose main constituents are zinc and aluminium. Other alloying elements include magnesium and copper. This type of alloy was originally developed for gravity casting. Noranda, New Jersey Zinc Co. Ltd., St. Joe Mineral Co. and the International Lead Zinc Research Organization (ILZRO) were the main companies that pioneered the ZA alloys between the 1950s and the 1970s. They were designed to compete with bronze, cast iron and aluminium using sand and permanent mold casting methods. Distinguishing features of ZA alloys include high as-cast strength, excellent bearing properties, as well as low energy requirements (for melting).

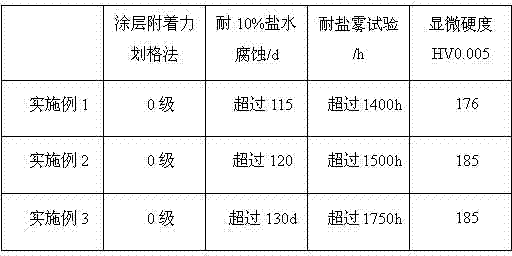

Watery zinc-aluminium heavy-duty coating in compounding squama shape and preparation method thereof

InactiveCN101525505AAchieve complete chrome-freeImprove bindingAnti-corrosive paintsPotassium hydroxideHeavy duty

The invention relates to a watery zinc-aluminium heavy-duty coating in a compounding squama shape and a preparation method thereof. The watery zinc-aluminium heavy-duty coating belongs to a bi-component coating and is prepared from organic-inorganic modified base stock and pigment according to a certain proportion by weight, wherein the organic-inorganic modified base stock contains silica sol, potassium hydroxide, silicone-acrylate emulsion, a pigment dispersing agent, a film forming addition agent and an antifoaming agent, and the balance is deionized water or distilled water; the pigment comprises squama-shaped zinc powder and squama-shaped aluminium powder; and the weight ratio of the organic-inorganic modified base stock to the pigment is 5: 1-2. The watery zinc-aluminium heavy-duty coating contains no chrome, can be solidified at the normal temperature, has environmental protection and low energy consumption and can be used for preparing thin coatings with high corrosion resistance, and the like.

Owner:HOHAI UNIV +1

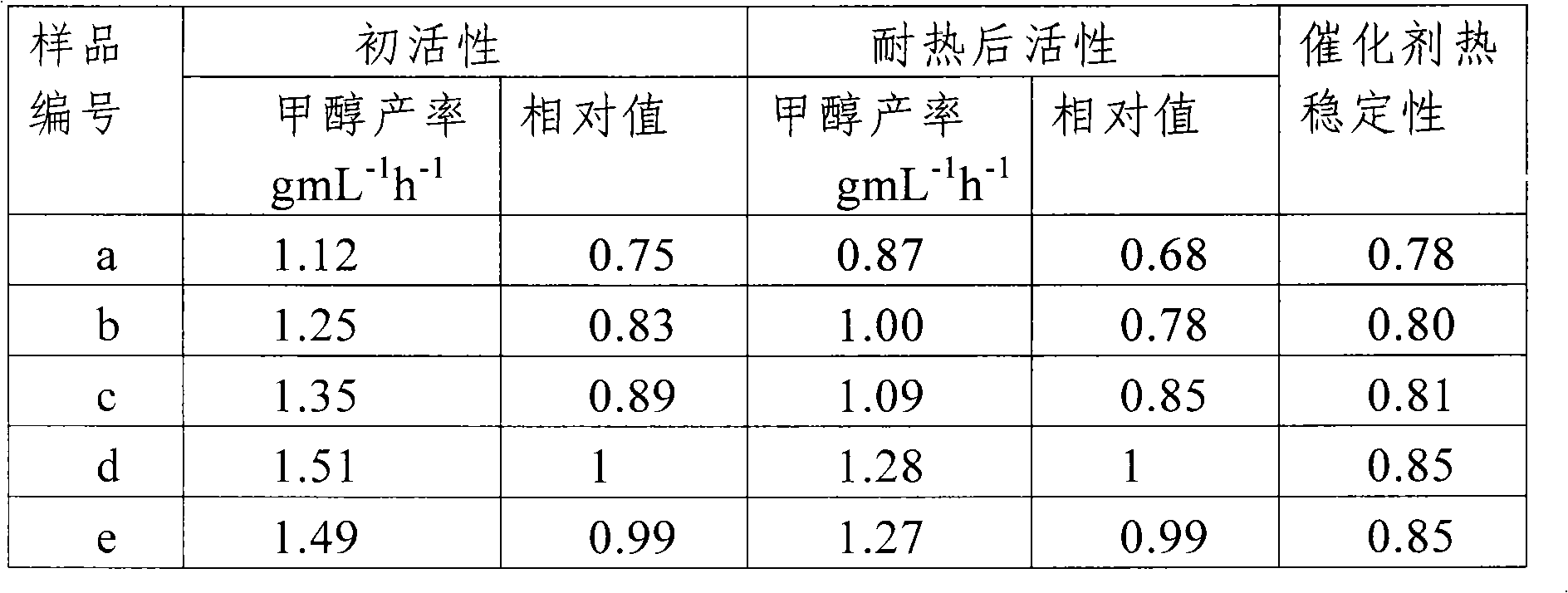

Process for preparing synthetic methanol catalyst

InactiveCN101327431ALarger than surfaceImprove activity stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHeat resistanceGraphite

The present invention provides a preparation method of methanol synthesis catalyst. The catalyst has the preparation technical process as follows: firstly, copper-zinc coprecipitate is prepared; secondly, zinc-aluminium coprecipitate with a spinel structure is prepared; thirdly, copper-aluminium coprecipitate is prepared; then three coprecipitates are mixed and aged and then are washed, dried and calcined; graphite is added into calcined material to be tabletted into the methanol synthesis catalyst. In weight percentage, the catalyst prepared by the present invention consists of 25 percent to 65 percent of CuO, 15 percent to 45 percent of ZnO and 5 percent to 15 percent of Al2O3. The activity and the heat resistance of the catalyst prepared by the present invention are better than that of the catalyst prepared by the prior technical production method.

Owner:XIAN ORIGIN CHEM TECH

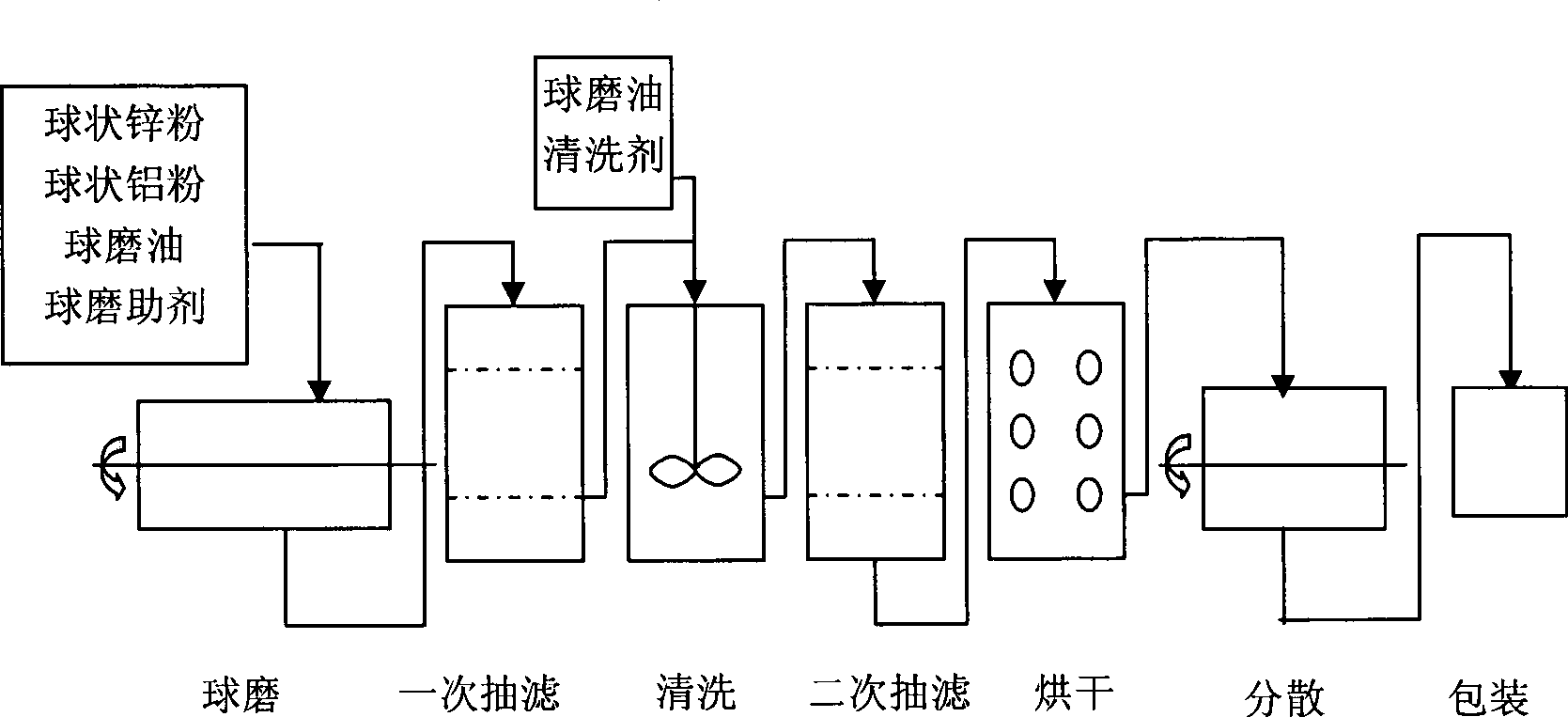

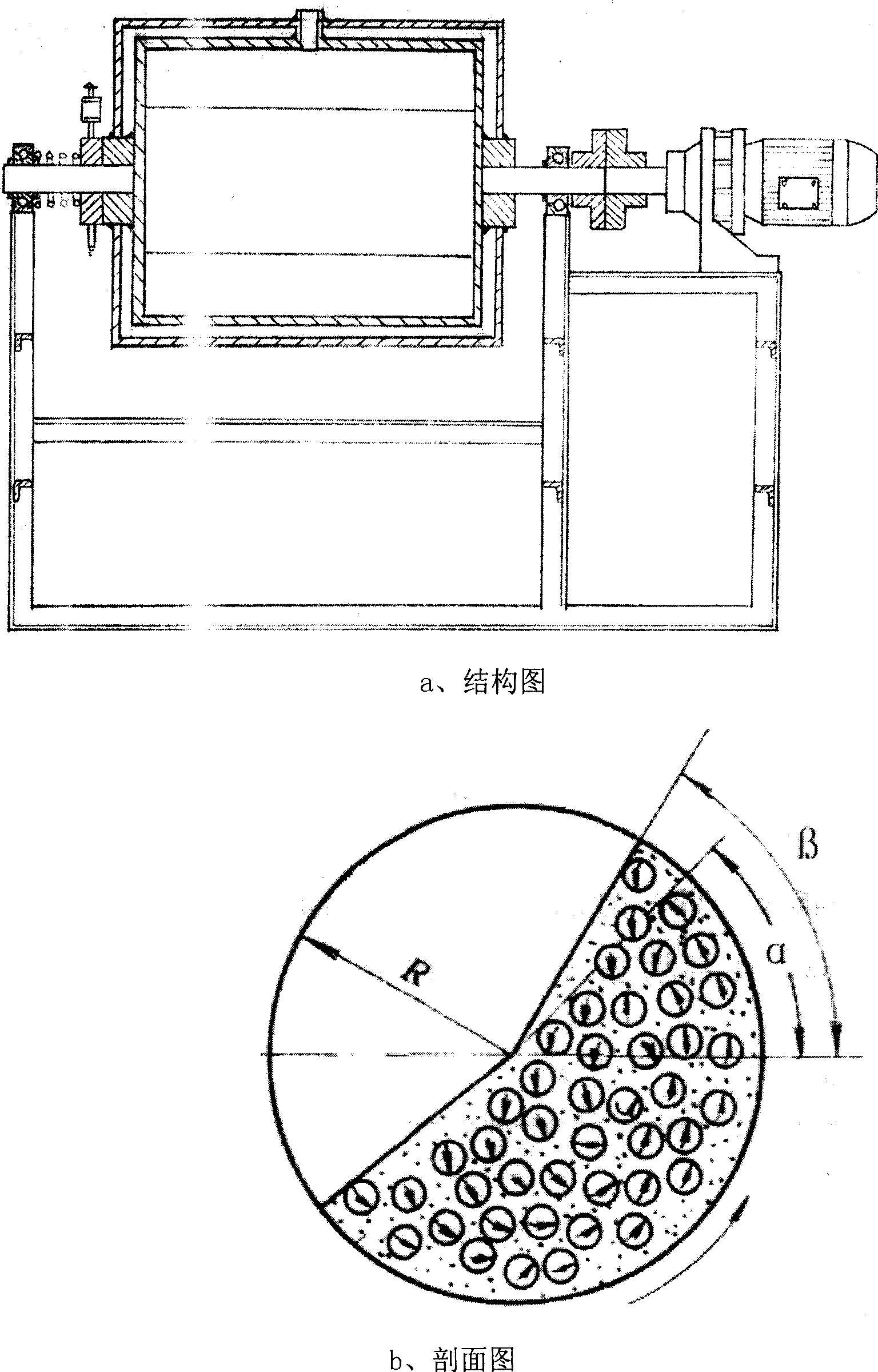

Preparation method of scale type aluminum zinc powder using high-energy ball milling

A method for preparing scale type zinc-aluminium powder by wet high energy ball milling comprises the following working procedures: (1) ball milling; (2) primary suction filtration; and / or (3) pasty product packing; (4) cleaning; (5) secondary suction filtration; (6) baking; (7) dispersion; and / or (8) dry powdery product packing.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

High-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint as well as preparation method and application thereof

InactiveCN103242686AOvercome the Difficulty of ScatteringEvenly distributedPretreated surfacesAnti-corrosive paintsSurface-active agentsDefoaming Agents

The invention discloses a high-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint as well as a preparation method and application thereof and belongs to the technical field of metal surface anticorrosion paints. The high-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint comprises the following components in percentage by weight: 15-30wt% of Zn-Al-based multielement alloy powder, 0.5-2wt% of modified nano powder, 2.5-20wt% of methyl alcohol, 6-12wt% of sintering protective agent, 0.5-1.5wt% of titanate coupling agent, 1.8-3.6wt% of non-ionic surface active agent, 0.9-1.8wt% of corrosion inhibitor, 1-3wt% of adhesive force enhancer, 0.4-0.65wt% of thickener, 0.05-0.1wt% of defoaming agent and the balance of deionized water, wherein the Zn-Al-based multielement alloy powder is in a scale shape, the scale diameter is less than 20 micrometers, and length-diameter ratio is more than 30. The high-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint is more uniform in Zn-Al element distribution in micro scale and has high corrosion resistance, wear resistance and erosion resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Zinc-aluminium embedding co-penetrating method for iron and steel products and its penetrant

InactiveCN1428454AImprove corrosion resistanceImprove abrasion resistanceSolid state diffusion coatingMaterials scienceZinc aluminium

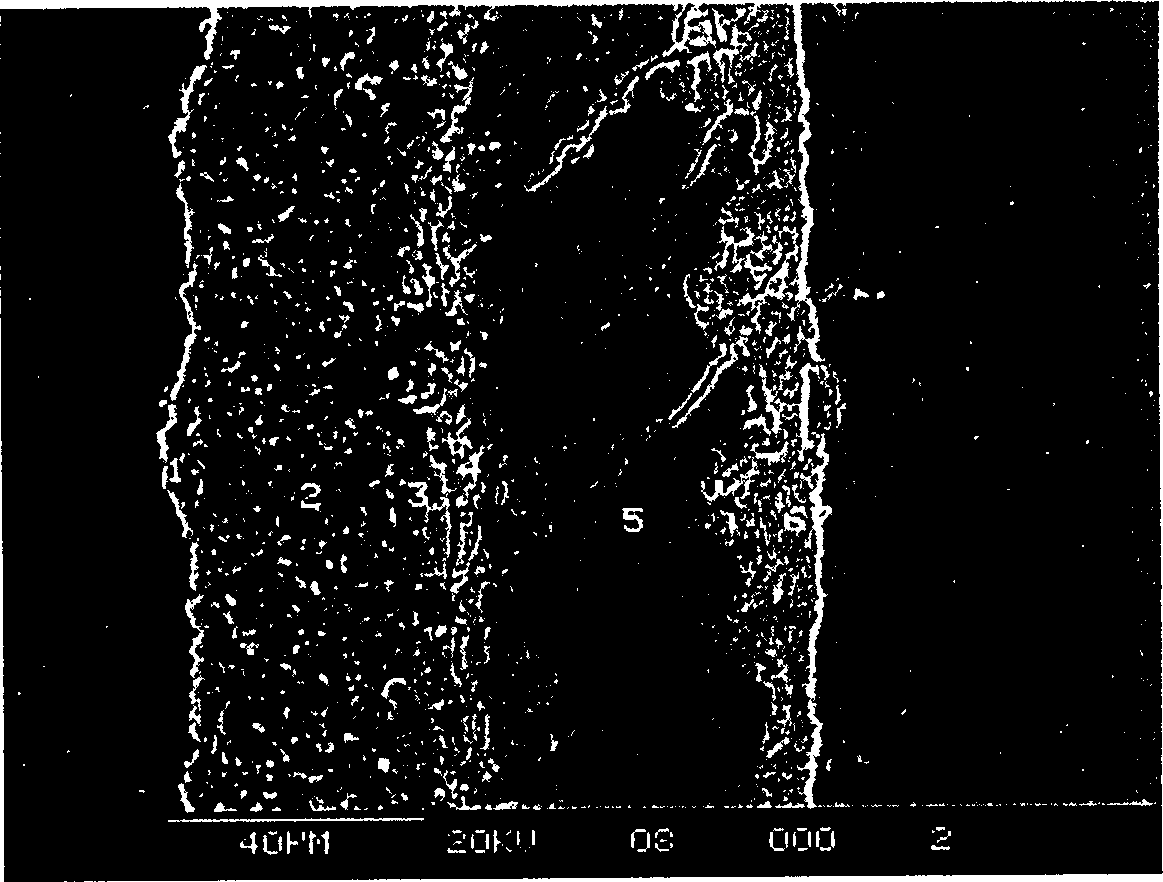

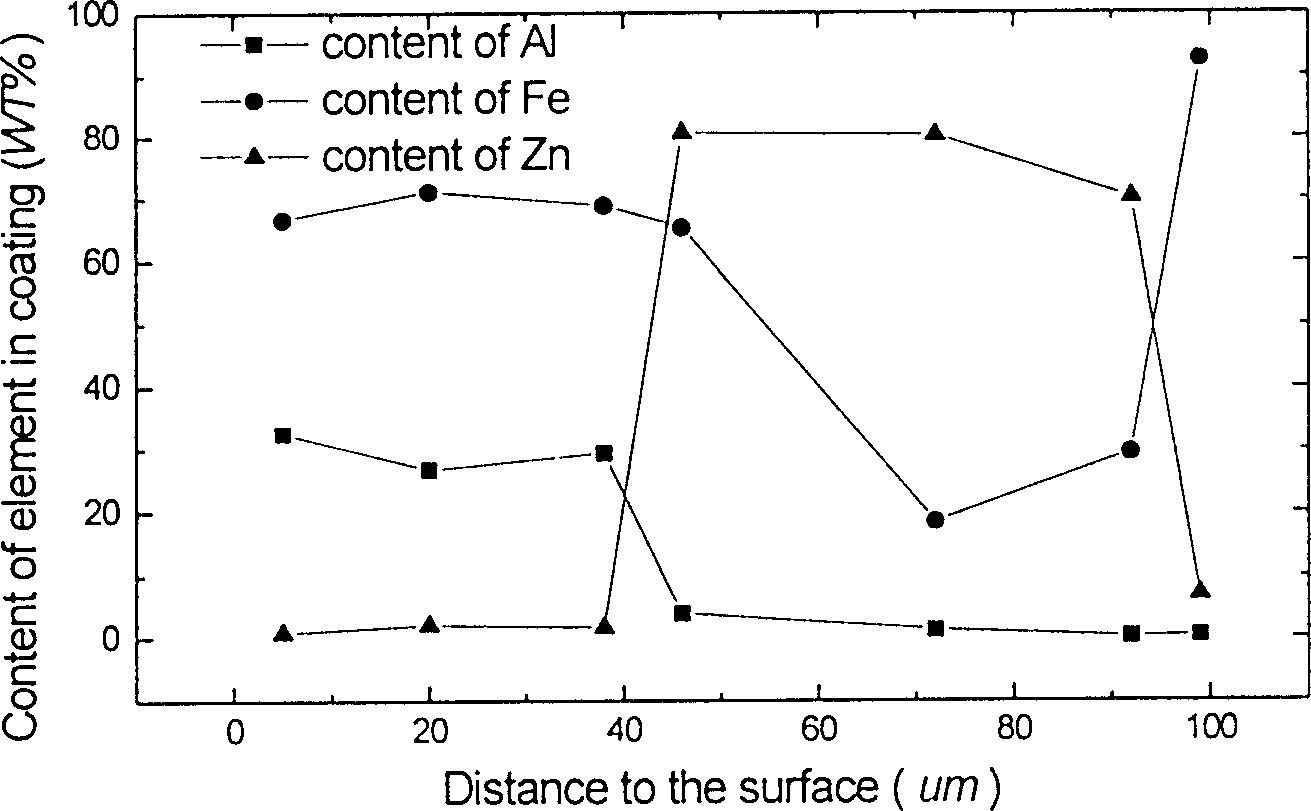

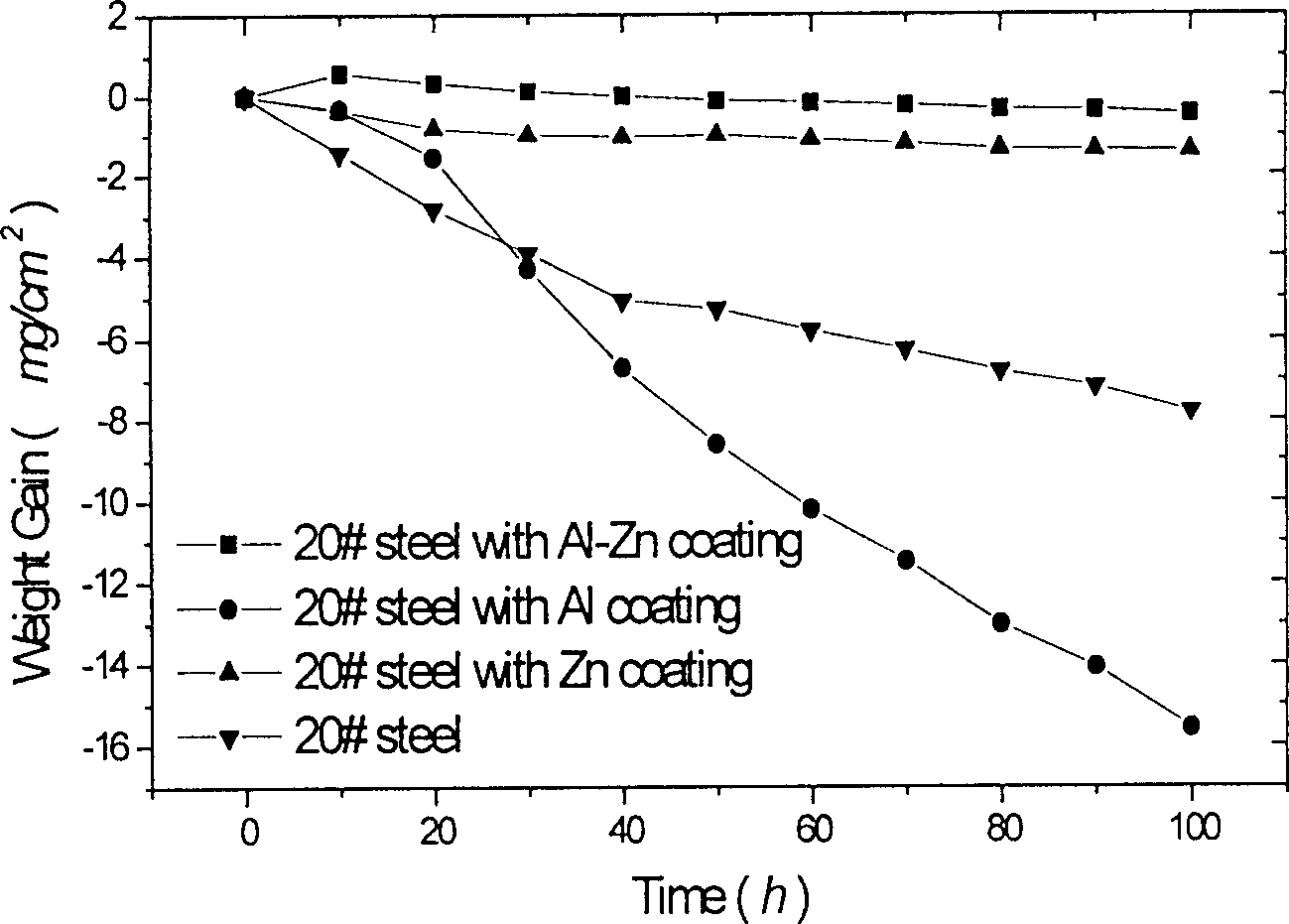

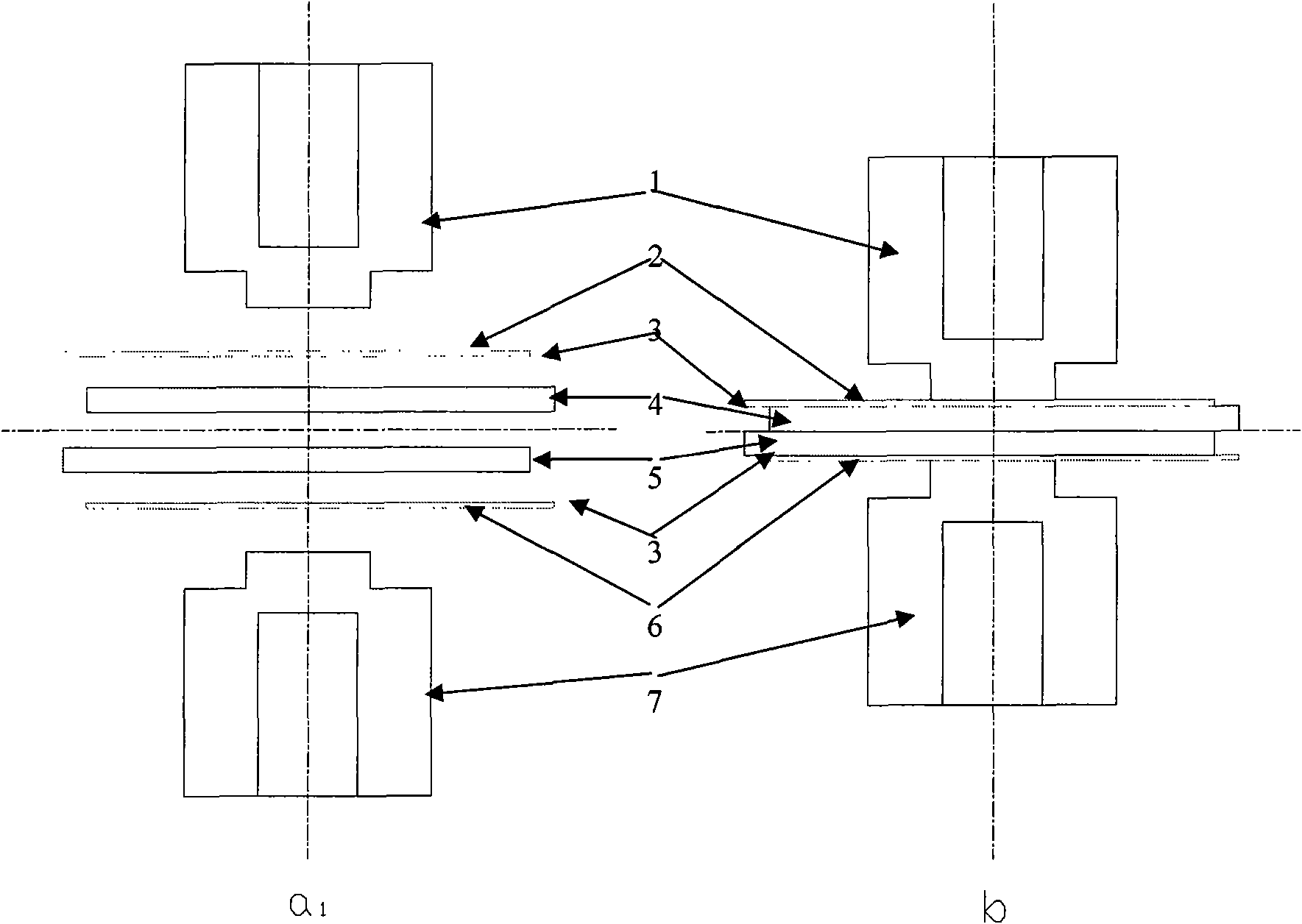

The present invention relates to a zinc-aluminium embedding copenetrating method of iron and steel products and its penetrant. Its method includes the following steps: embedding iron or steel product in the penetrant, heat-insulating treatment for 3-10 hr at 400 to 600 deg.C, then a zinc-aluminium copenetrated layer with double-layer structure whose external layer is enriched with aluminium and internal layer is enriched with zinc is formed on the surface of iron or steel product, so that the iron or steel product can have more excellence anticorrosion property and resistance to abrasion.

Owner:中国石油乌鲁木齐石油化工有限公司 +1

Method for performing spot welding on Al-Zn hot-coated steel plate

InactiveCN101961814ASolder joint appearance is goodQuality improvementWelding/cutting media/materialsWelding/soldering/cutting articlesPlanar electrodePower flow

The invention provides a method for performing spot welding on an Al-Zn hot-coated steel plate. In the method, a foil belt is arranged between a copper electrode and an Al-Zn hot-coated steel plate workpiece; a step type large-contact planar electrode is adopted, a two-section welding current mode is adopted; and the two-section welding current adopts a constant current control mode, so that the foil belt is not adhered to the workpiece and the electrode and each welding spot has fine appearance and stable quality. The copper electrode is only contacted with a non-tinplated surface of the foil plate, so the method solves the problem that the electrode is alloyed by a zinc aluminium coating fundamentally, prolongs the service life and improves the welding spot quality of a spot-welding electrode of the zinc aluminium plated steel plate, prolongs the service life of the electrode and has favorable popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Zinc-aluminium alloy silk containing rare earth and producing process thereof

The present invention is RE containing Zn-Al alloy wire and its preparation process, and the RE containing Zn-Al alloy is used as the end spraying material for metallized film capacitor. The RE containing Zn-Al alloy contains Al 4-16 wt%, RE mixture with light RE as main components 0.01-0.12 wt%, and impurity not more than 0.025 wt% except Zn. The preparation process includes pouring Al molt into Zn molt, raising the temperature for melting while stirring, adding intermediate RE alloy, and smelting while stirring to obtain the RE containing Zn-Al alloy. The RE containing Zn-Al alloy wire of the RE containing Zn-Al alloy has compact structure, improved machining performance and use performance, and improved welding condition.

Owner:戴国水

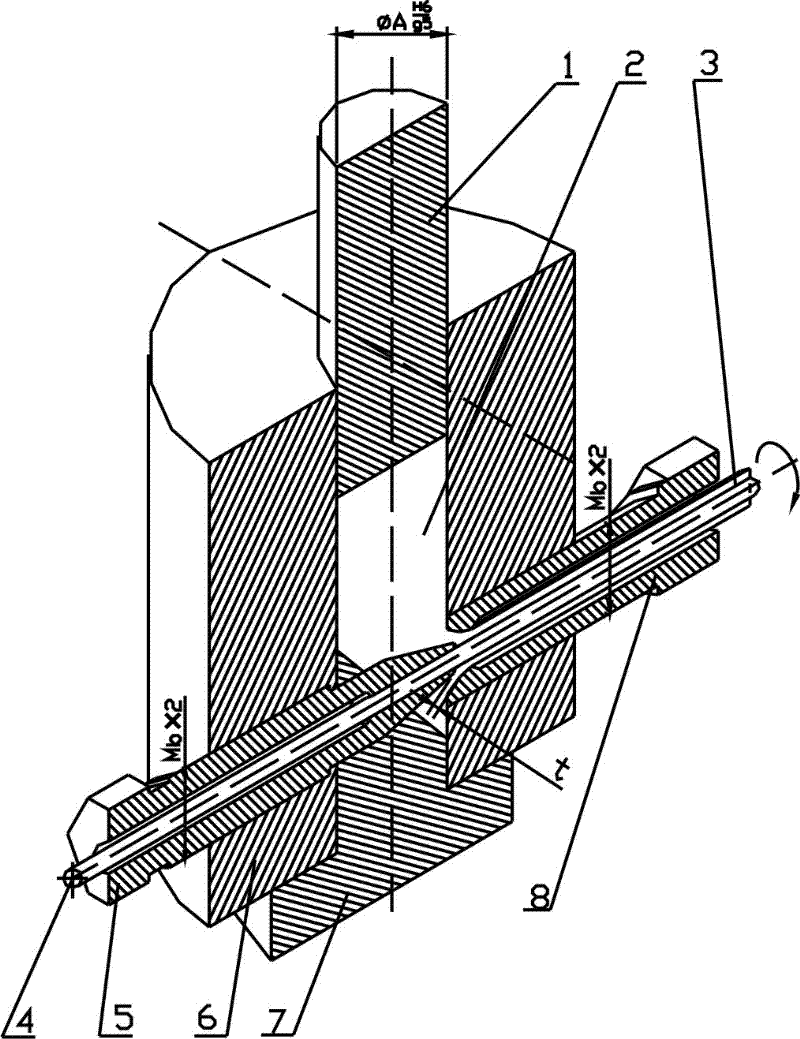

Preparation method of zinc-aluminium seamless flux-cored wire

InactiveCN102225496AContinuous and even fillingEasy to operateWelding/cutting media/materialsSoldering mediaOrganic solventSlag

The invention provides a preparation method of a zinc-aluminium seamless flux-cored wire. The method provided by the invention is characterized by comprising the following steps: smelting raw materials such as zinc, aluminium and the like, and casting the melt into an ingot; after riser removal and scalping, putting the ingot into a nitrogen protection furnace and carrying out shpheroidizing annealing in the nitrogen protection furnace at 180-230 DEG C for 1-2 hours; blending a core flux into paste by virtue of an organic solvent and filling the paste in a pressure injector; then putting the zinc-aluminium alloy ingot into a dedicated extrusion die, connecting the die to the pressure injector, and starting the extrusion die to directly extrude welding wire which has the diameter phi of 5.0-12.0mm and has a core of the flux and a sheath of the zinc-aluminium alloy; and then performing drawings many times to obtain the finished product. The flux-cored wire manufactured by the method is characterized in that the flux is filled continuously and evenly; during the use process of the flux for welding, no welding slag is left, no carbon is deposited, the operation is convenient, and the production efficiency is high, therefore, the problems such as complex processing steps, high cost and the like in the prior art are solved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Flake zinc and zinc-aluminium alloy powder wet method producing process

InactiveCN1456407AImprove surface oxidation resistanceLarge diameter-to-thickness ratioGranularitySolvent

A wet technology for preparing the flaky powder of zinc or Zn-Al alloy includes such steps as proprotioning non-flake powder of zinc or Zn-Al alloy, solvent, assistant and medium, ball grinding, polishing, classifying and solid-liquid separating. Its advantages are short time of ball grinding, high antioxidizing nature, high diameter / thickness rate, and high granularity uniformity.

Owner:肖骁

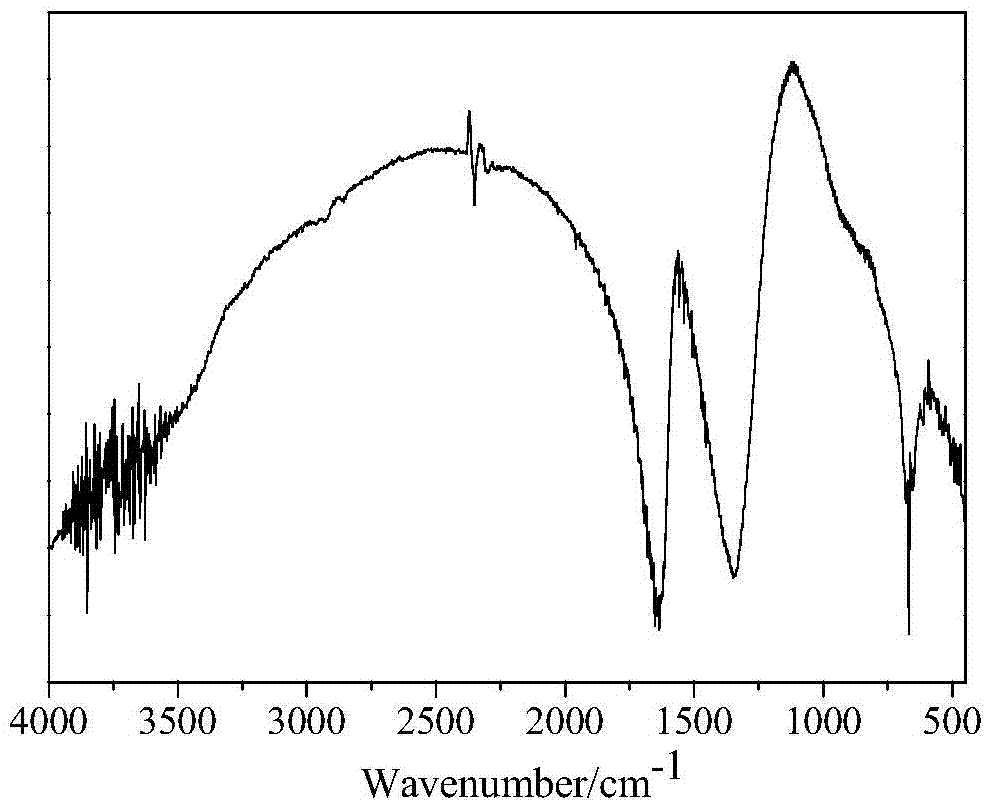

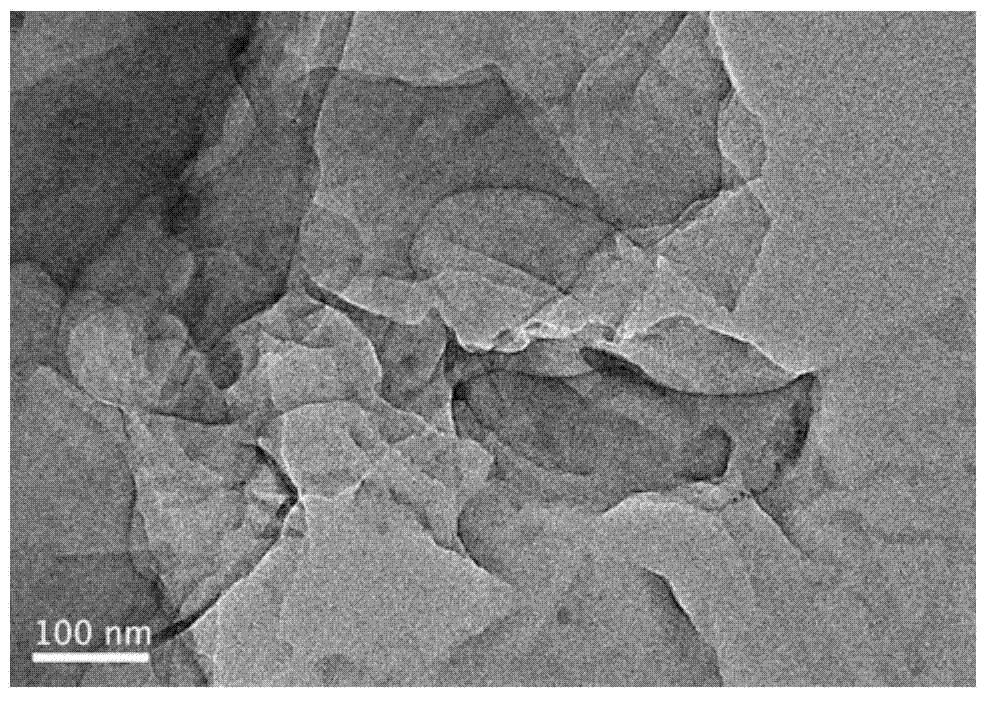

Preparation method of conductive graphene/zinc aluminium oxide composite

The invention belongs to the field of novel micro-nanomaterial preparation, relates to a conductive composite and in particular relates to a preparation method of a conductive graphene / zinc aluminium oxide composite coating. The preparation method specifically comprises the steps of firstly cold-stripping graphite oxide to prepare graphene oxide; secondly loading aluminium and alkali containing zinc carbonate on the surface of graphene oxide; finally carrying out high-temperature treatment under the condition of nitrogen to prepare the conductive graphene / zinc aluminium oxide (graphene / ZAO) composite. The preparation method is simple and convenient, and the product has excellent conductivity.

Owner:CHANGZHOU UNIV

Water base non-chrome zinc-aluminium coating and methods for preparing and using same

ActiveCN102911534AMeet the requirements of environmental regulationsHydrogen embrittlement will notLiquid surface applicatorsCoatingsWater basedHazardous substance

The invention relates to a water base non-chrome zinc-aluminium coating and methods for preparing and using the same. The coating is prepared by proportionally mixing a component A and a component B; the component A contains 50-150g / L of lamellar metal powder, 145-290ml / L of organic solvent, 10-200ml / L of deionized water, 10-36ml / L of reducing agent and 5-15ml / L of wetting agent; and the component B contains 60-240ml / L of deionized water, 20-75ml / L of binding agent, 8-22ml / L of thickening agent, 4-8ml / L of silicon compound and the balance of the organic solvent. The method for preparing the water base non-chrome zinc-aluminium coating comprises the steps of: weighing the lamellar metal powder proportionally to be mixed uniformly, and then adding the organic solvent to be mixed uniformly for later use; mixing the reducing agent with the wetting agent, adding an appropriate amount of the deionized water to be mixed uniformly, and then adding the lamellar metal powder liquid to prepare the component A; proportionally weighing the thickening agent, the binding agent and the silicon compound, and adding the organic solvent to be mixed uniformly to prepare the component B; and mixing the prepared component A and the prepared component B according to the ratio of 2:1, and stirring unit uniform, thus obtaining the coating. The method for using the water base non-chrome zinc-aluminium coating is that the coating is coated on a part to be treated, and the baking temperature is increased to 360 DEG C so as to solidify and crosslink the coating to form a dense protective layer. The coating has the corrosion resistance which reaches 840 hours of a neutral salt spray test and over 96 hours of a heat resistance test, the usage amount of harmful substances is greatly reduced, and the working environment is improved.

Owner:翊鹏(湖北)实业有限公司

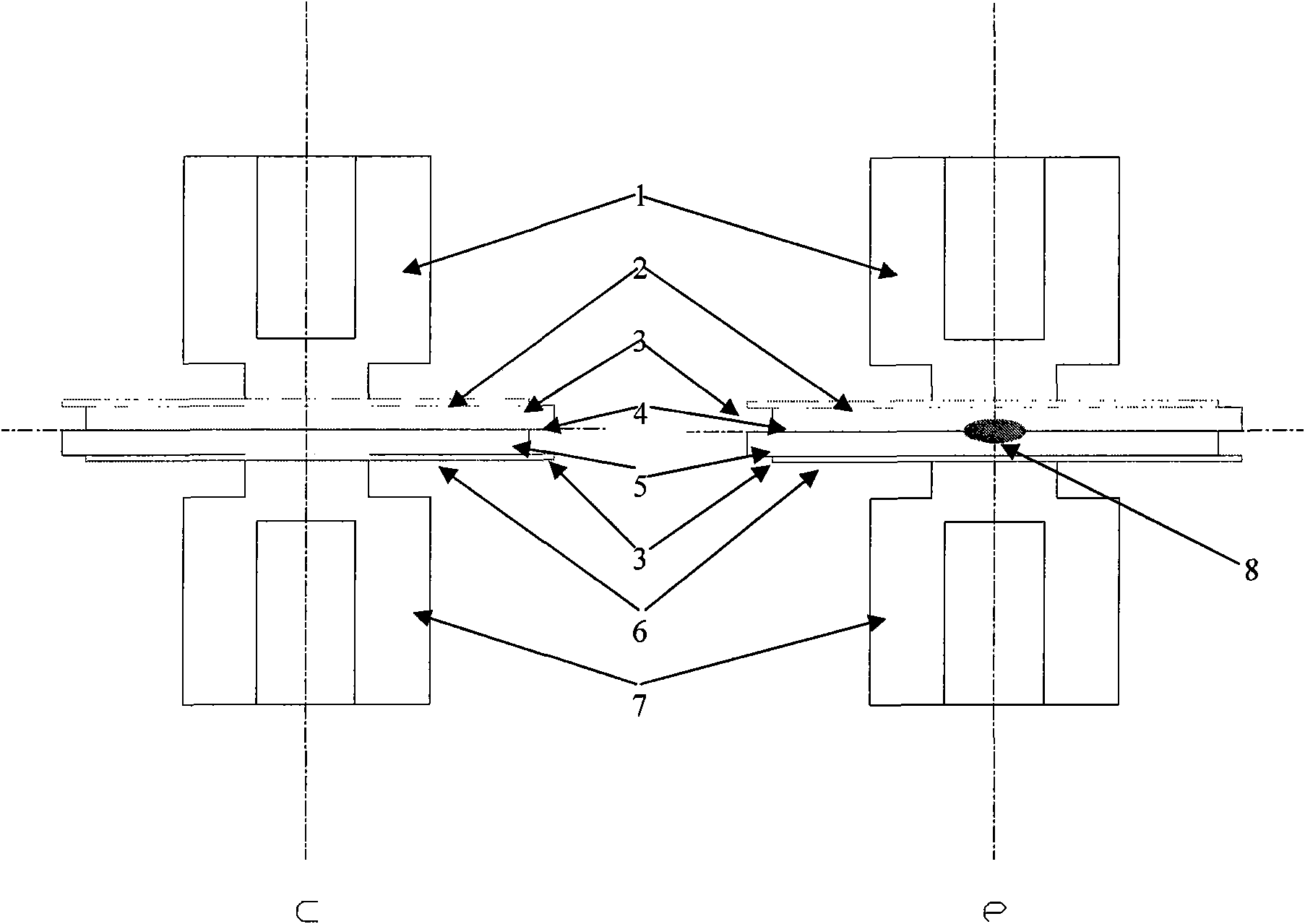

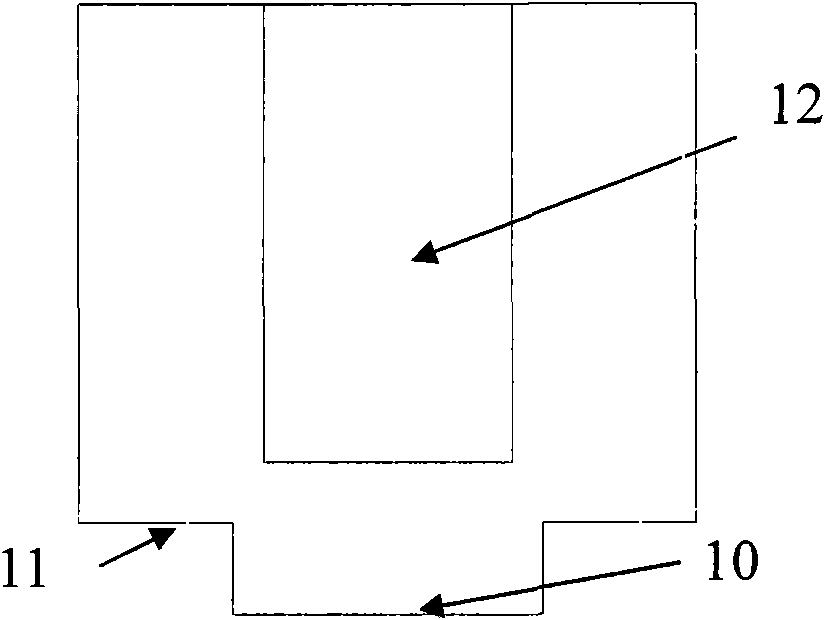

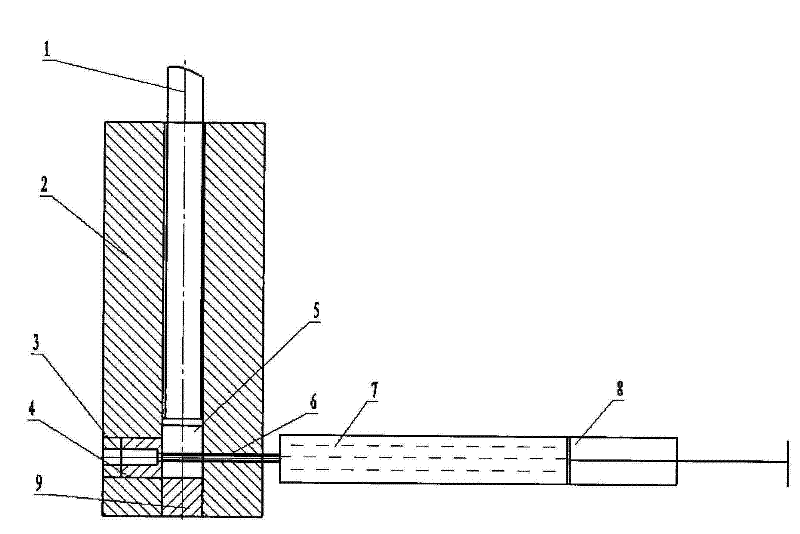

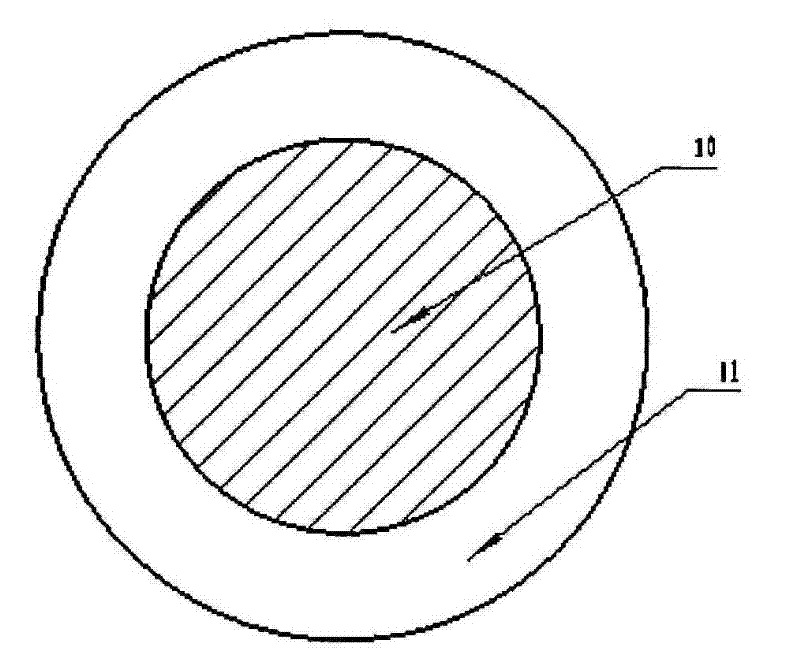

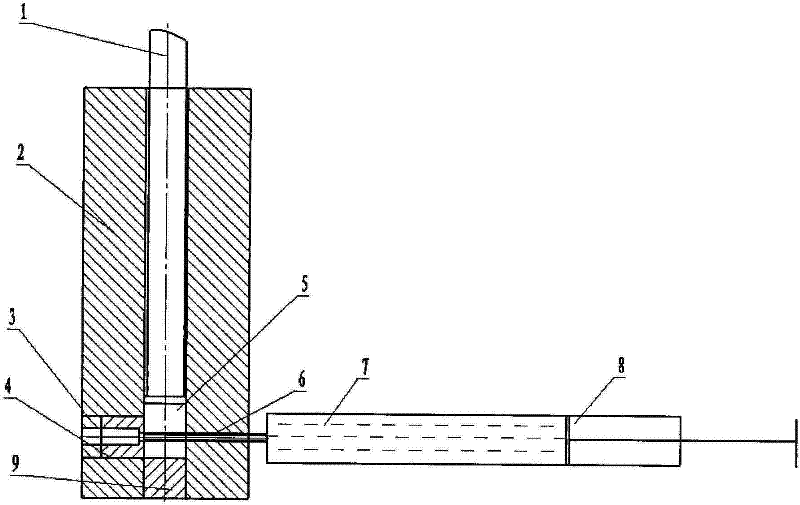

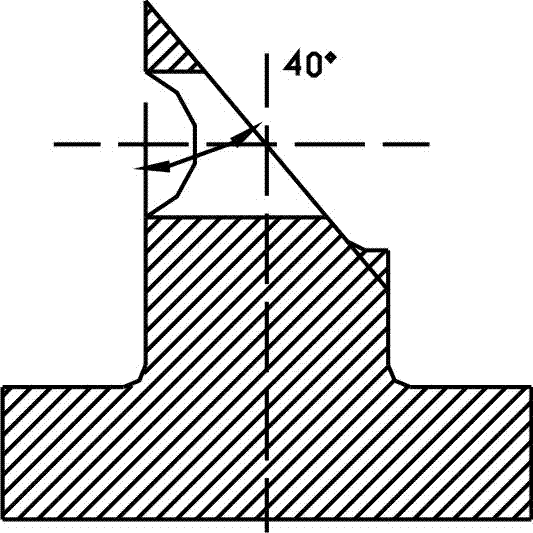

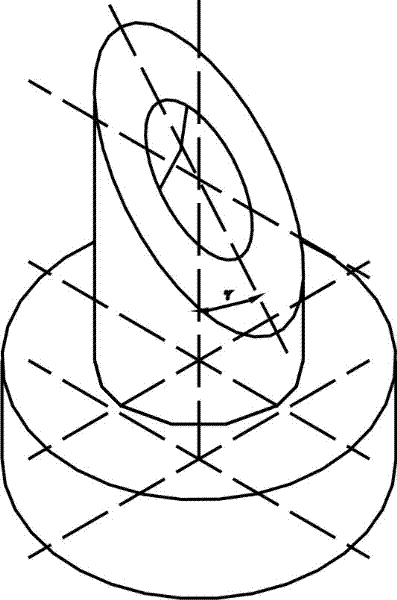

Preparation method and mold of seamless flux-cored zinc-aluminium alloy welding wire

ActiveCN102500958AImprove subsequent drawing and reducing efficiencyNot easy to crack and leak powderExtrusion diesWelding/cutting media/materialsWire rod5052 aluminium alloy

The invention discloses a preparation method of a seamless flux-cored zinc-aluminium alloy welding wire and a preparation mold. The preparation method comprises the following steps of: preparing a wire rod with a brazing flux; casting and configuring an extrusion billet; extruding the extrusion billet into a hollow pipe in the mold, and simultaneously, filling the wire rod with the brazing flux in the hollow pipe; preparing the seamless flux-cored zinc-aluminium alloy welding wire rod; and carrying out drawing and diameter reducing to the seamless flux-cored zinc-aluminium alloy welding wire rod to form the seamless flux-cored zinc-aluminium alloy welding wire. In the seamless flux-cored zinc-aluminium alloy welding wire prepared in the invention, the weight percentage of the brazing flux is 10-18%; the obtained seamless flux-cored zinc-aluminium alloy welding wire can have unlimited length, so that the following drawing and diameter reducing efficiency can be greatly improved; and the hollow pipe is radially extruded, so that certain ECAP (Equal Channel Angular Pressing) fine grain action to alloy structures can be realized, and further, the drawing property of an alloy material is better. The preparation method of the seamless flux-cored zinc-aluminium alloy welding wire and the mold, disclosed by the invention, have the advantages that mold has high production efficiency, the yield is high, and the brazing flux is less in loss, and is easy to store.

Owner:绍兴市天龙锡材有限公司

Composite resurfacing welding method for sink roller and stabilizing roller used for hot dipping

InactiveCN101596635AAccelerated corrosionImprove wear resistanceHot-dipping/immersion processesArc welding apparatusBalance testMachining

The invention discloses a composite resurfacing welding method for a sink roller and a stabilizing roller used for hot dipping. Substrates of the sink roller and the stabilizing roller are made of a stainless steel iron-based material, and the substrates are provided with cobalt-base alloy working surfaces in a resurfacing welding mode. The method comprises the following steps: preheating the manufactured substrate of the sink roller or the stabilizing roller to 500 to 650 DEG C, and keeping the temperature for 1 to 3 hours; slowly cooling the temperature of the substrate to 250 to 350 DEG C at a speed of 50 to 150 DEG per hour, and forming a cobalt-base alloy material on the substrate in a resurfacing welding mode; performing heat treatment on the substrate to eliminate the stress; and finally performing rough machining, finish machining, balancing test and detection on the sink roller or the stabilizing roller. The sink roller and the stabilizing roller work under the conditions of hot-dip aluminium, aluminium-zinc, zinc-aluminium, zinc, pure aluminium liquid and the like, and have enough performances of resistance to heat, corrosion and wear; the substrates of the sink roller and the stabilizing roller and the working surfaces have high bonding strength; and the service life of the sink roller and the stabilizing roller is improved greatly, and is 2 to 3 times that of the prior product.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Aluminium alloy engine cast iron cylinder sleeve processing technology

ActiveCN103894586AWill not negatively affectInhibitory responseHot-dipping/immersion processesMetalCast iron

The invention relates to an aluminium alloy engine cast iron cylinder sleeve processing technology. An HT250 cast iron cylinder sleeve is immersed in a plating auxiliary with the temperature ranging from 60 DEG C to 70 DEG C after surface treatment, so that plating assistant processing is conducted on the surface of the HT250 cast iron cylinder sleeve for 6-10 min in the plating auxiliary, and then drying is conducted; the HT250 cast iron cylinder sleeve is placed in zinc-aluminium alloy melt for hot dipping after plating assistant processing, and cooling is conducted; then the HT250 cast iron cylinder sleeve is placed in aluminium alloy melt for hot dipping; the HT250 cast iron cylinder sleeve plated with aluminium alloy is taken out, and aluminium alloy melt casting is conducted; cooling is conducted, mould opening is conducted, and aluminium alloy engine cylinder body composite materials are taken out. According to the technology, the cast iron cylinder sleeve is processed through the prepared plating auxiliary, two steps of hot dipping and the composite casting technology are combined to achieve more than 99.9% of metallurgical bonding between ZL101A aluminium alloy and HT250 cast iron, and the aluminium alloy engine cast iron cylinder sleeve processing technology is simple, practical, low in cost and prominent in effect.

Owner:烟台路通精密科技股份有限公司

Low melting point flux for hot dip plating

InactiveCN102002661ALow melting pointMelting point regulationHot-dipping/immersion processesSodium bicarbonateAluminium chloride

The invention provides a low melting point flux for hot dip plating. The flux is characterized by comprising the following components: 80-140g / L of zinc chloride, 0-30g / L of sodium chloride, 5-20g / L of sodium fluoride, 10-40g / L of aluminium chloride, 5-15g / L of sodium bicarbonate, 0.2-3g / L of composite surfactant and the balance water. The melting point of the flux can be lowered, the time of slag floating is controlled in 90 seconds, the efficiency of the interface reaction between flux salt film and liquid zinc is increased, the wettability between a metal part matrix to be plated and liquid zinc is improved, and the rate of skip-plating is reduced. The rate and degree of the reaction between aluminium in zinc-aluminium alloy liquid and the other chlorides in the flux can be reduced, wherein aluminium chloride is prepared by the reaction; the flux can help the aluminium content of the alloy liquid to be stabilized to a certain extent; and the application range of the low melting point ammonia-free complex salt flux can be expanded in the hot dip plating technological process of the zinc-aluminium alloy liquid, and the stability of the flux can be increased.

Owner:KUNMING UNIV OF SCI & TECH

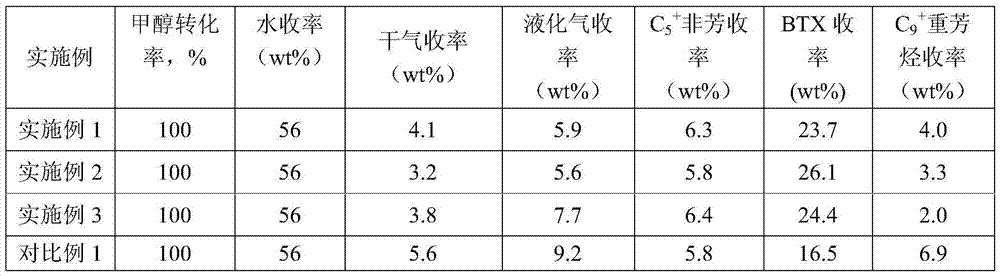

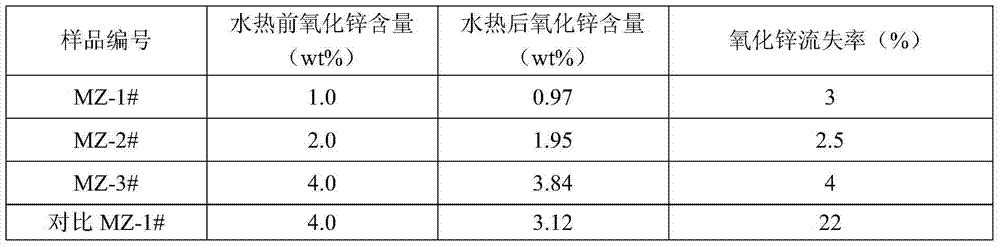

Methanol to aromatic catalyst containing two molecular sieves and preparation method

ActiveCN105435839AReduce manufacturing costSuppress generationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveActive component

The invention relates to a methanol to aromatic catalyst containing two molecular sieves and a preparation method. The methanol to aromatic catalyst comprises, based on the weight of the catalyst, 40 wt%-85 wt% of the total content of a zinc-aluminium compound modified ZSM-5 molecular sieve and a nickel modified Y-shaped molecular sieve, 0.5 wt%-5.0 wt% of rare earth oxide and the balance aluminium oxide binder, wherein the ratio of the weight content of the zinc-aluminium compound modified ZSM-5 molecular sieve to the modified Y-shaped molecular sieve is 9:1-1:1. The invention further discloses a method for preparing the catalyst. The methanol to aromatic catalyst is used in a methanol to aromatic process, has high light weight aromatic yield and is low in dry gas and liquefied gas productivity. The wastage rate of zinc oxide active components of the catalyst is low, and the stability is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

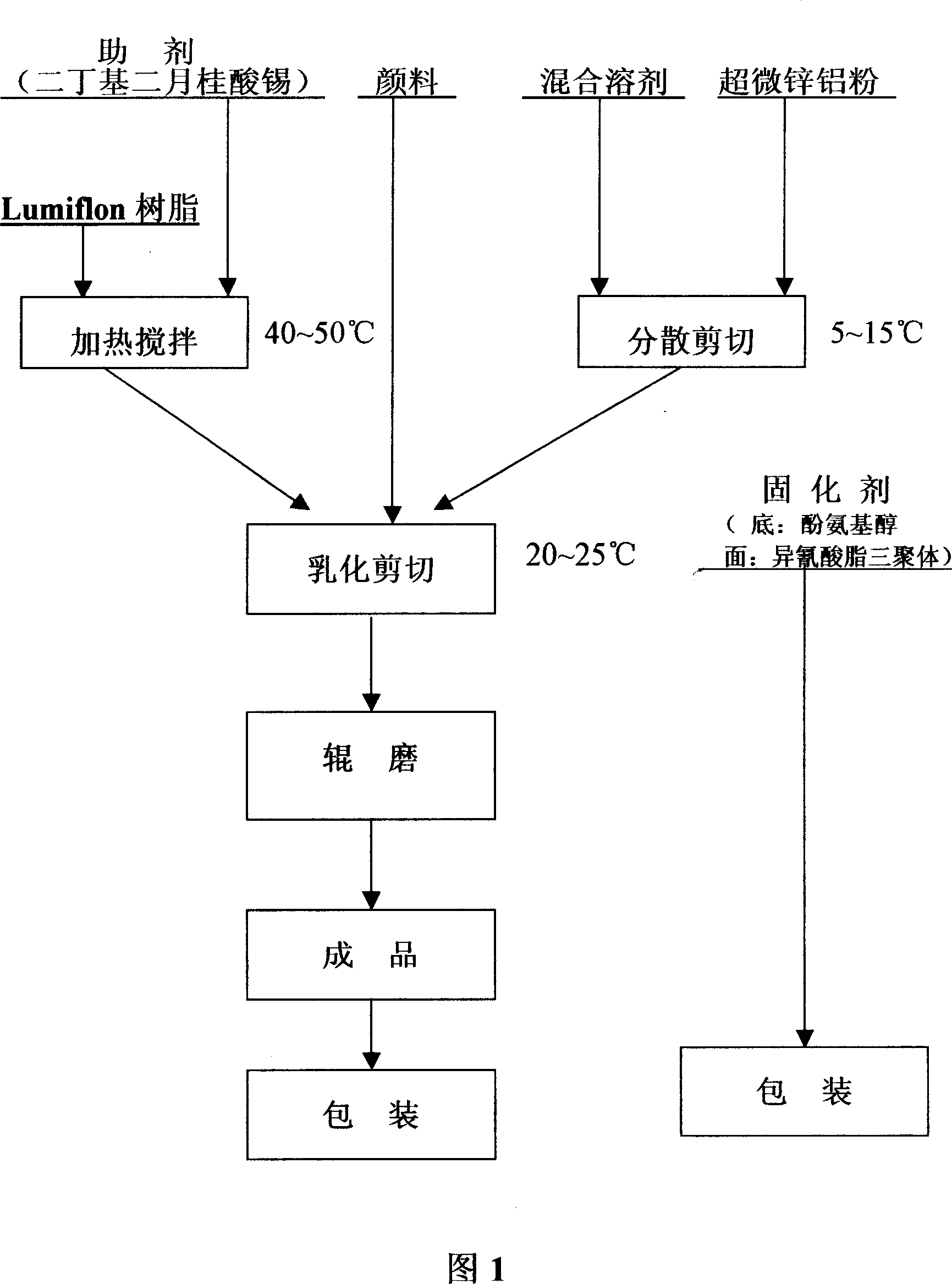

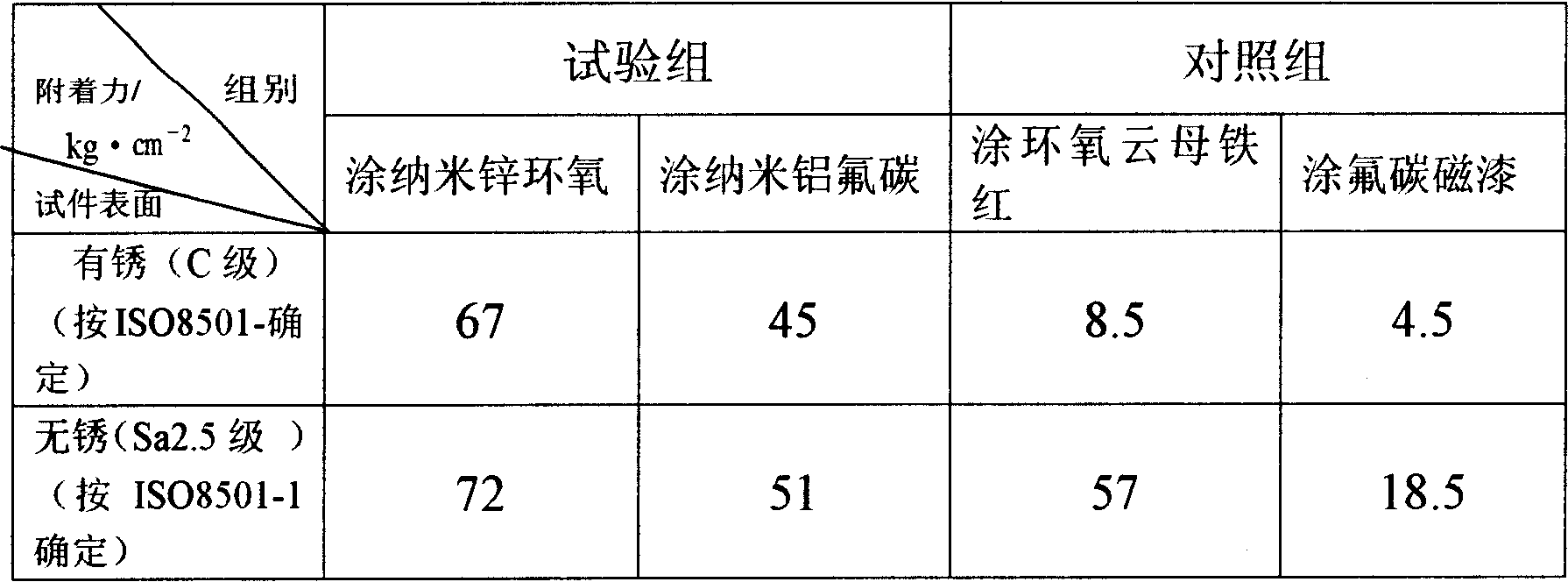

Nano zinc aluminum modified epoxy-fluorocarbon coating

The invention provides a nano zinc-aluminium modified epoxy fluorocarbon coating which is characterized by strong adhesion force with surface of base material and excellent corrosion resistance performance. It comprises primary coating and surface coating, primary comprises: epoxy resin 80- 100, organosilicon resin 20- 30, nano zinc powder 1- 2, sub-micron zinc powder 4- 6, mixed solvent 20- 30, phenol amino alcohol 50- 67; surface coating comprises: Lumiflon resin 90- 100, dimethylbenzene 20- 25, sub-micron aluminum powder 2-5, butyl acetate 70- 75, nanometer aluminum powder 1-2, dibutyl lauric acid tin 0.00035, pigment 15- 20, and isocyanic acid ester trimer 9- 9.5.

Owner:SHENYANG QINGCHEN CORROSIONPROOF ENG TECH

Green corrosion inhibitor for hot-dip zinc-aluminium alloy steel, and application thereof

The invention discloses a green corrosion inhibitor for hot-dip zinc-aluminum alloy steel and an application thereof, wherein a main component of the green corrosion inhibitor is vitamin B1. The application is that: a pickle of dilute hydrochloric acid or dilute sulfuric acid having a concentration of 0.1M to 2M is added with the corrosion inhibitor within a concentration range of 0.01kg / m3 to 0.2kg / m3, the temperature being controlled to be maintained at a room temperature of about 25 DEG C, and zinc, zinc-aluminum alloy or hot-dip zinc, zinc-aluminum alloy coating steel for pickling are added and submerged for 0.5h to 3h. Products of the invention are applied to industrial pickling of zinc, zinc-aluminum alloy or hot-dip zinc, zinc-aluminum alloy coating steel and products thereof, allowing an avoidance of general corrosions and local corrosions of metal or coatings during a pickling process. As few researches on similar pickling corrosion inhibitors are taken at present, the product has significant advantages of low price, low dosage, high corrosion inhibition efficiency and good ability of continuous reaction. The product of the invention is a natural plant extract, which is nontoxic and harmless to environment and creatures, fitting the developing trend of pickling corrosion inhibitors and providing a promising application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Natural environment-friendly cleaning agent and application therefor

InactiveCN1880425AWide variety of sourcesLow costOrganic non-surface-active detergent compositionsNiacinCleansing Agents

The invention discloses a green abluent and appliance with niacin and vitamin B3, which is characterized by the following: adopting 0.10-1.0mol / L dilute hydrochloric acid or dilute sulphuric acid as cleaning fluid; adding abluent according to the quantity at 0.010g / L-2.0g / L; immersing the uncleaned hot-dip galvanizing, zinc-aluminium alloy and zinc-aluminium alloy coated steel for 15 min to 3h at indoor temperature. The invention is a soluble vitamin without damaging environment and biology, which satisfies developing trend of abluent.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Zinc-aluminium based coated steel sheet, manufacturing method thereof, thermoforming method and component

PendingCN109112360ACause liquid phase erosionImprove the protective effectHot-dipping/immersion processesThermoformingEvaporation

The invention discloses a zinc-aluminium based coated steel sheet, a manufacturing method thereof, a thermoforming method and a component. After hot press forming, the strength of the steel sheet is greater than 1500 MPa, and the elongation is greater than 5%. A coating is completely transformed into a ferroalloy layer, no evaporation of the coating is generated, no liquid-phase erosion phenomenonis generated, and no hard Fe-Al intermetallic compound is generated. The structure of the component is martensite, ferrite, and retained austenite.

Owner:ANGANG STEEL CO LTD

Zinc aluminium oxide ceramic target material suface indium coating method

A process for attaching an indium layer on the surface of zinc aluminium oxide ceramic target includes preparing silver slurry from silver oxide, 70-80 % wt, SiO2 10-15 % wt. and turpentine 10-20% wt, spraying it on the surface of said target, drying, heating at 550-580 deg.C for 15 min, cooling heating to 180-220 deg.C, spraying indium powder to smelt it. Its advantage is low cost.

Owner:TSINGHUA UNIV

Zinc-aluminium terres rares hydrotalcite compound heat stabilizer for polyvinyl chloride (PVC) as well as preparation and application of compound heat stabilizer

The invention relates to a zinc-aluminium terres rares hydrotalcite compound heat stabilizer for polyvinyl chloride (PVC) as well as preparation and application of the compound heat stabilizer. The compound heat stabilizer is obtained by optimally complexing zinc-aluminium terres rares hydrotalcite and magnalium hydrotalcite in a certain proportion. After surface modification by sodium stearate, the zinc-aluminium terres rares hydrotalcite and magnalium hydrotalcite have good compatability with the PVC. In the compound heat stabilizer, the synergistic effect between two hydrotalcites and the synergistic effect between zinc and rare-earth elements in the zinc-aluminium terres rares hydrotalcite are utilized, and the excellent property of the rare-earth element is also utilized, thereby greatly improving the heat stability of the PVC. The zinc-aluminium terres rares hydrotalcite compound heat stabilizer has the advantages of no toxicity, high efficiency, simple preparation process and low price; and the dosage of an additive in the course of processing does not influence the property of the product. The static thermal degradation test result indicates that the heat stabilizing time (blackening time of a sample) of the optimally complexed heat stabilizer for the PVC is 210 minutes.

Owner:CENT SOUTH UNIV

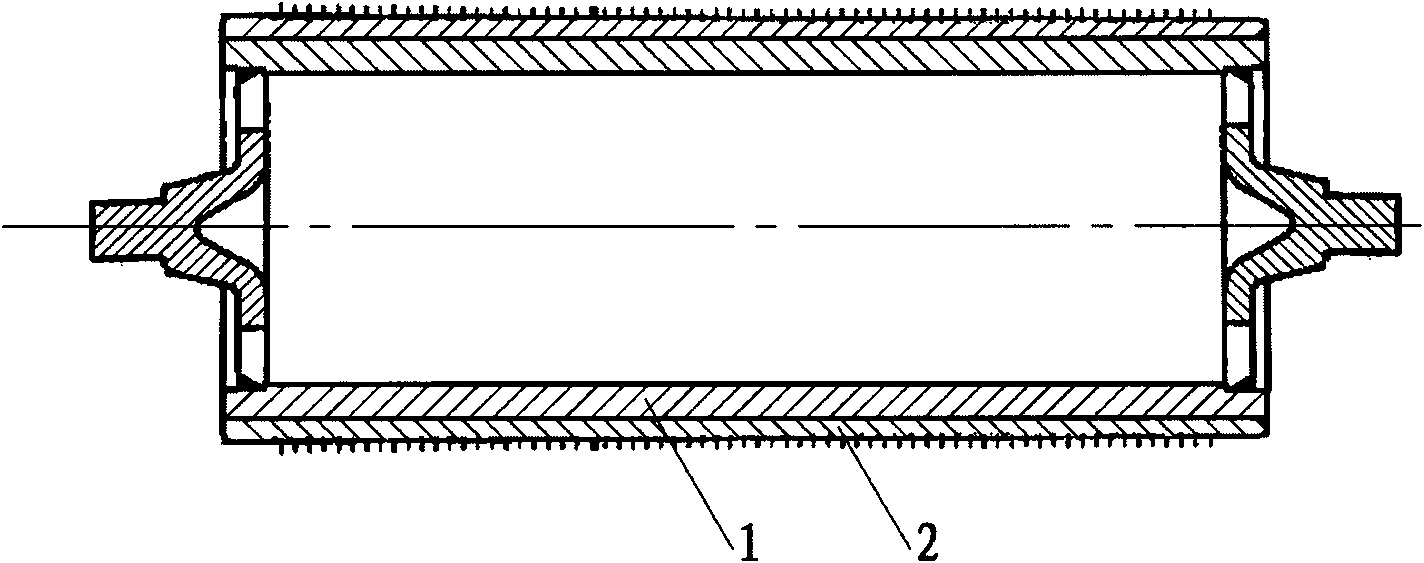

Preparation method for high-power thin-film capacitor

ActiveCN105914035AHigh dielectric constantUniform depositionThin/thick film capacitorFixed capacitor dielectricEpoxyPhenyl Ethers

The invention discloses a preparation method for a high-power thin-film capacitor. A plastic film is placed in a vacuum high-temperature environment, wherein the temperature of the vacuum high-temperature environment is 1080 to 1120 DEG C and the air pressure of the vacuum high-temperature environment is 0.20 to 0.35 Pa; compound ceramic powder is fused and evaporated and covers a surface of a substrate film; a piece of zinc-aluminium composite metal is evaporated and covers a composite ceramic layer surface to obtain a metalized film electrode; and then the metalized film electrode is wound to obtain a high-power thin-film capacitor. In addition, the plastic film includes the following raw materials, by weight: 55 to 60 parts of polypropylene, 35 to 38 parts of epoxy resin, 22 to 25 parts of terpolycyantoamino-formaldehyde resin, 13 to 16 parts of chlorosulfonated polyethylene, 16 to 19 parts of phenyl ether silicone rubber, 11 to 14 parts of copper oxide, 5 to 8 parts of titanium diboride, 12 to 15 parts of barium sulfate, 6 to 9 parts of glass fibers, 3 to 6 parts of zirconia whisker, 2 to 5 parts of potassium titanate fibers, and 5 to 5.5 parts of silane coupling agents.

Owner:安徽源光电器有限公司

Catalysts

InactiveUS7732370B2Large specific surface areaGood effectOrganic compound preparationHydrocarbon by hydrogenationCobalt metalHydrogenation reaction

A catalyst including cobalt, zinc oxide and aluminium is described, having a total cobalt content of 15-75% by weight (on reduced catalyst), an aluminium content ≧10% by weight (based on ZnO) and which when reduced at 425° C., has a cobalt surface area as measured by hydrogen chemisorption at 150° C. of at least 20 m2 / g cobalt. A method for preparing the catalyst is also described including combining a solution of cobalt, zinc and aluminium with an alkaline solution to effect co-precipitation of a cobalt-zinc-aluminium composition from the combined solutions, separating of the co-precipitated composition form the combined solutions, heating the composition to form an oxide composition, and optionally reducing at least a portion of the cobalt to cobalt metal. The catalysts may be used for hydrogenation reactions and for the Fischer-Tropsch synthesis of hydrocarbons.

Owner:JOHNSON MATTHEY PLC

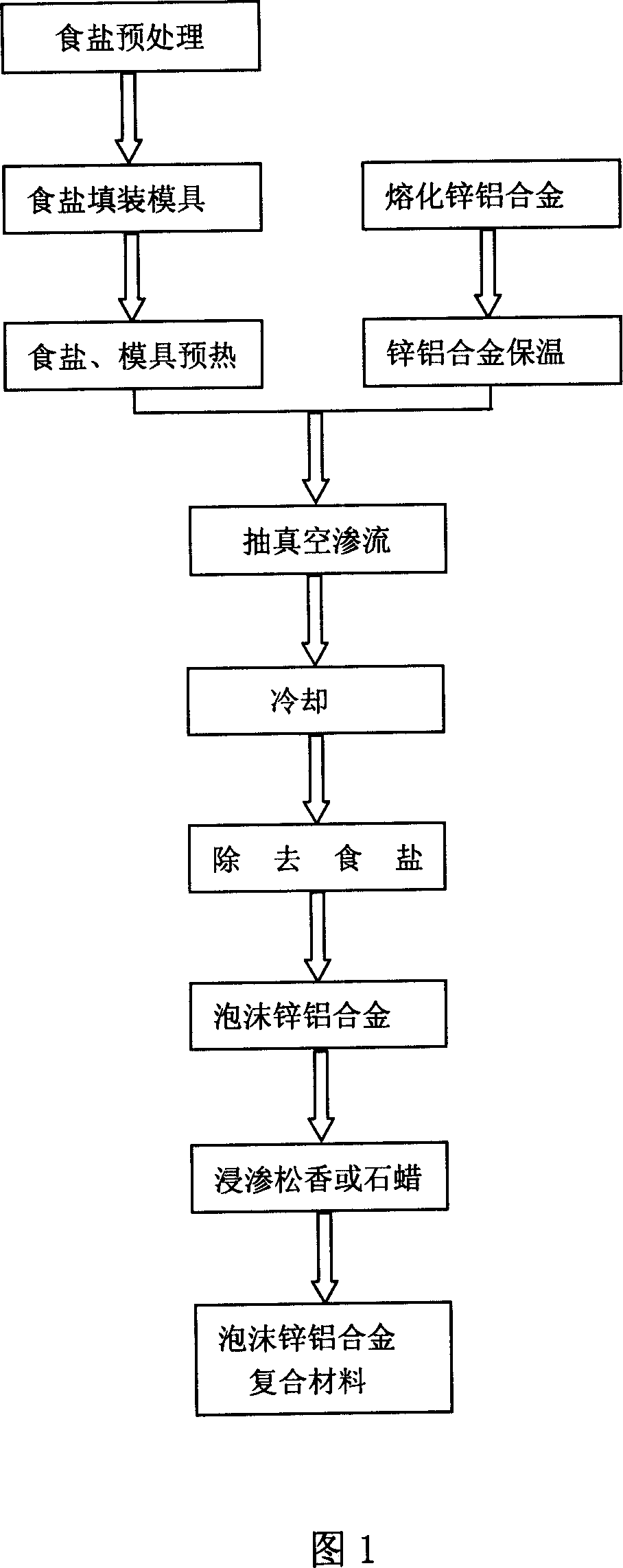

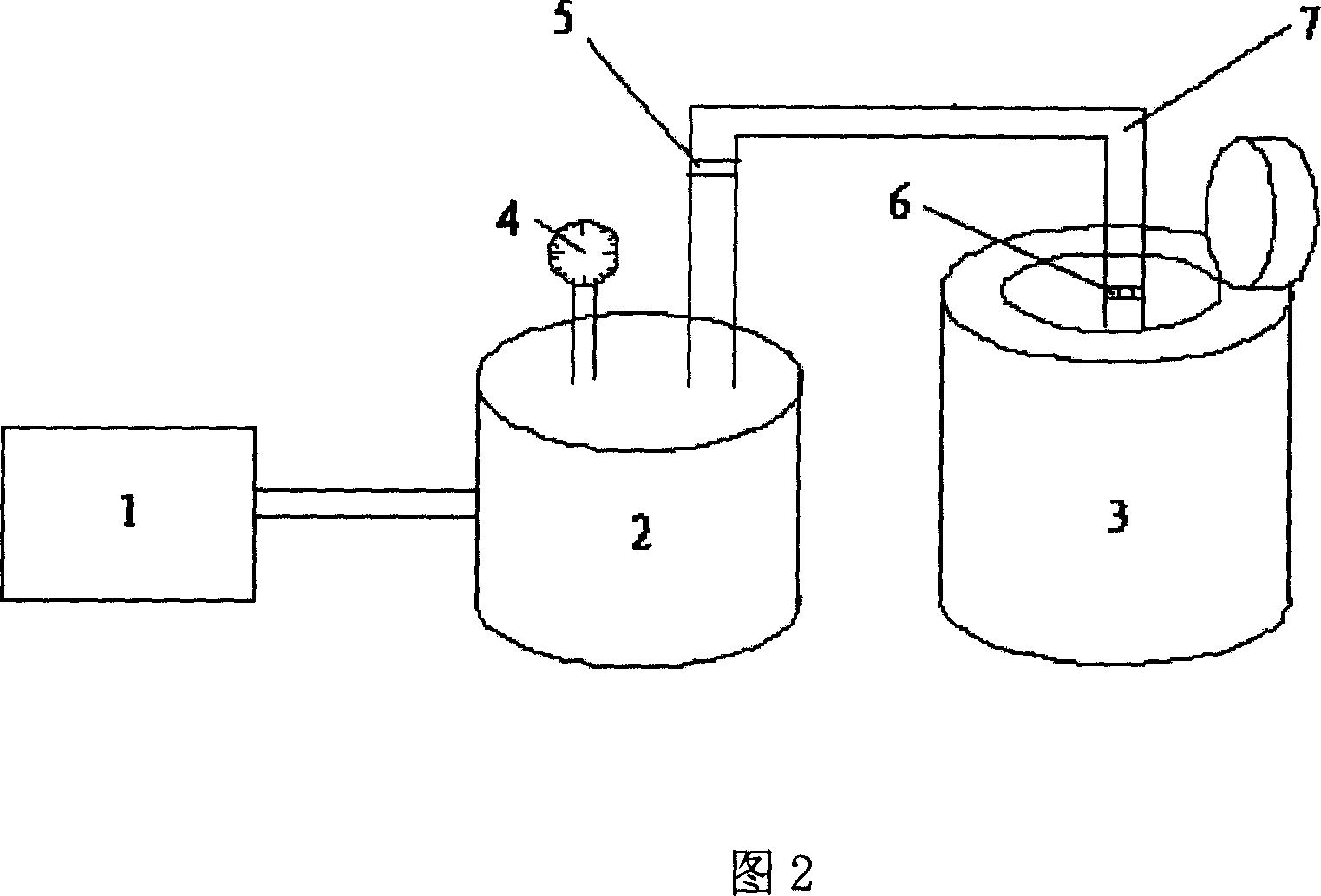

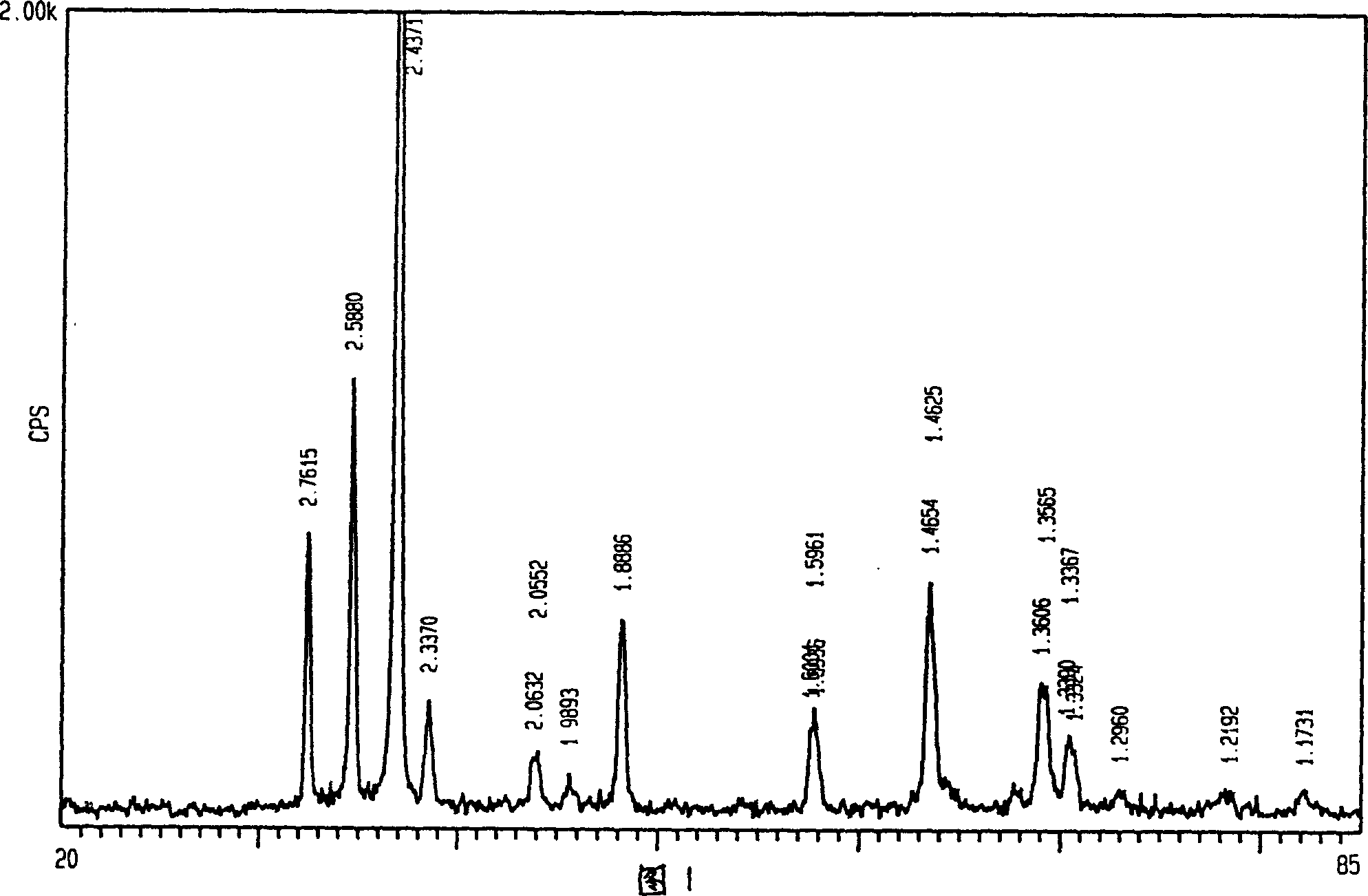

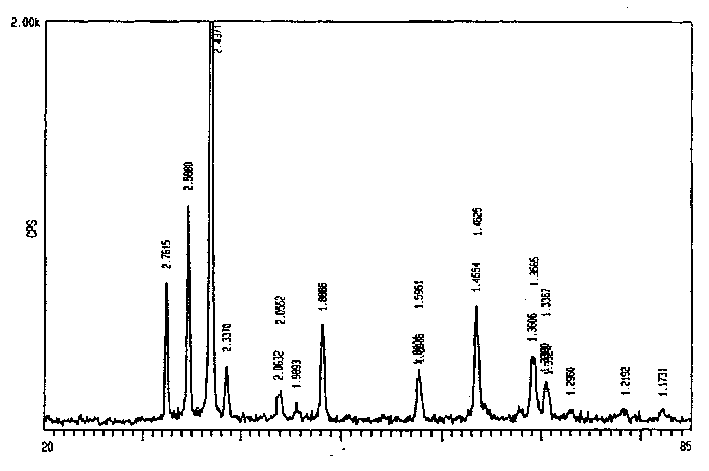

Method for preparing polymer/foam zinc-aluminium alloy composite material

The invention discloses a manufacturing method for polymer / foam allumen composite material. It includes the following steps: making foam allumen, and infiltrating high molecular material into the holes of allumen. The invention sharply improves the damping performance comparing with single identity allumen orsingle foam allumen.

Owner:XIAN UNIV OF TECH

High Zinc aluminium rare earth magnesium alloy

A high-Zn and-Al REMg alloy contains Zn (7-14 wt.%), A (3-8), RE (0.3-1.5) and Mg (rest). It is prepared through smelting in electric crucible furnace while covering with Mg alloy. It has fire point temp of more than 740 deg.c, tension strength (200-260 MPa) and elongation (1.4-3%).

Owner:WUHAN UNIV OF TECH

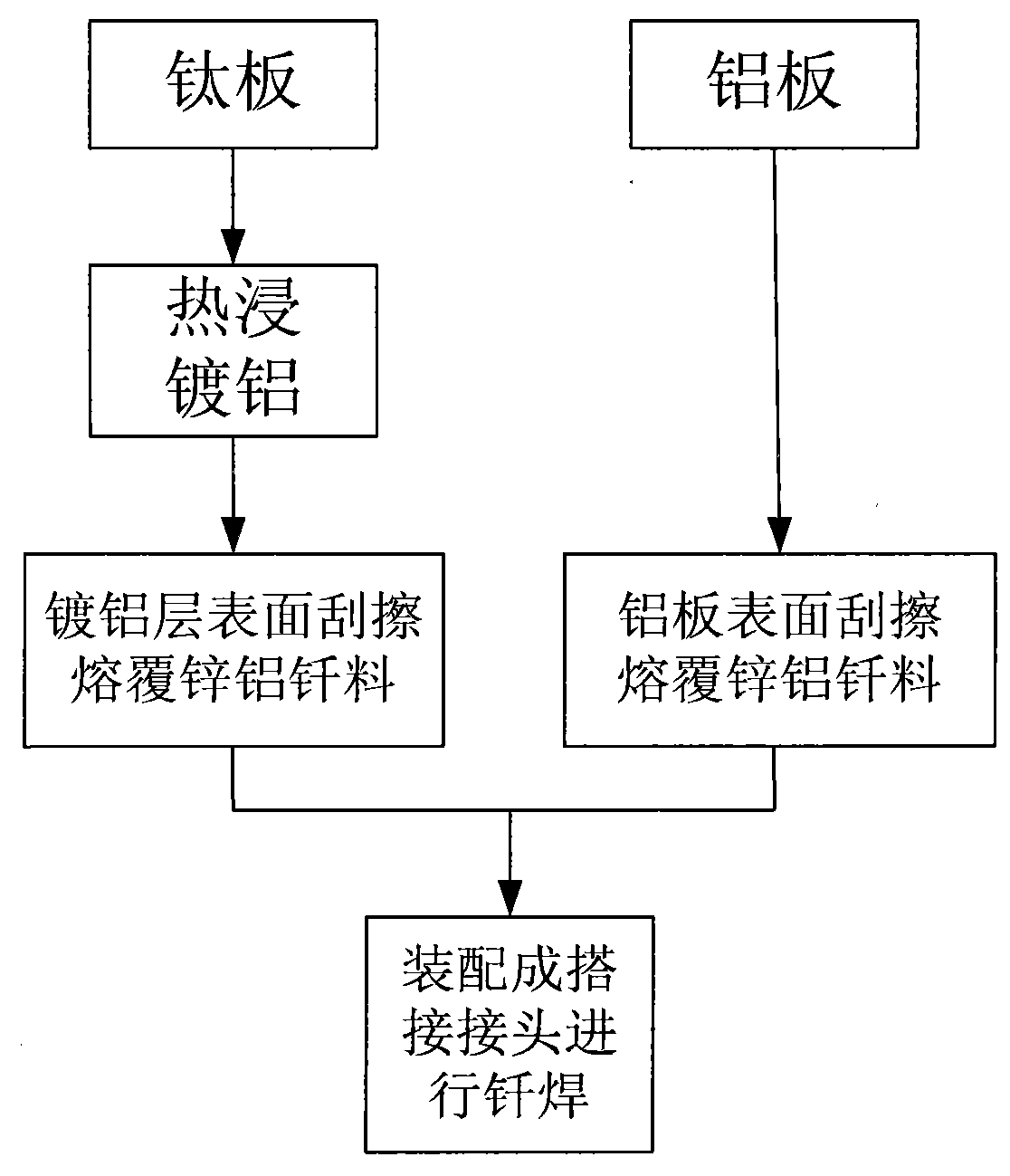

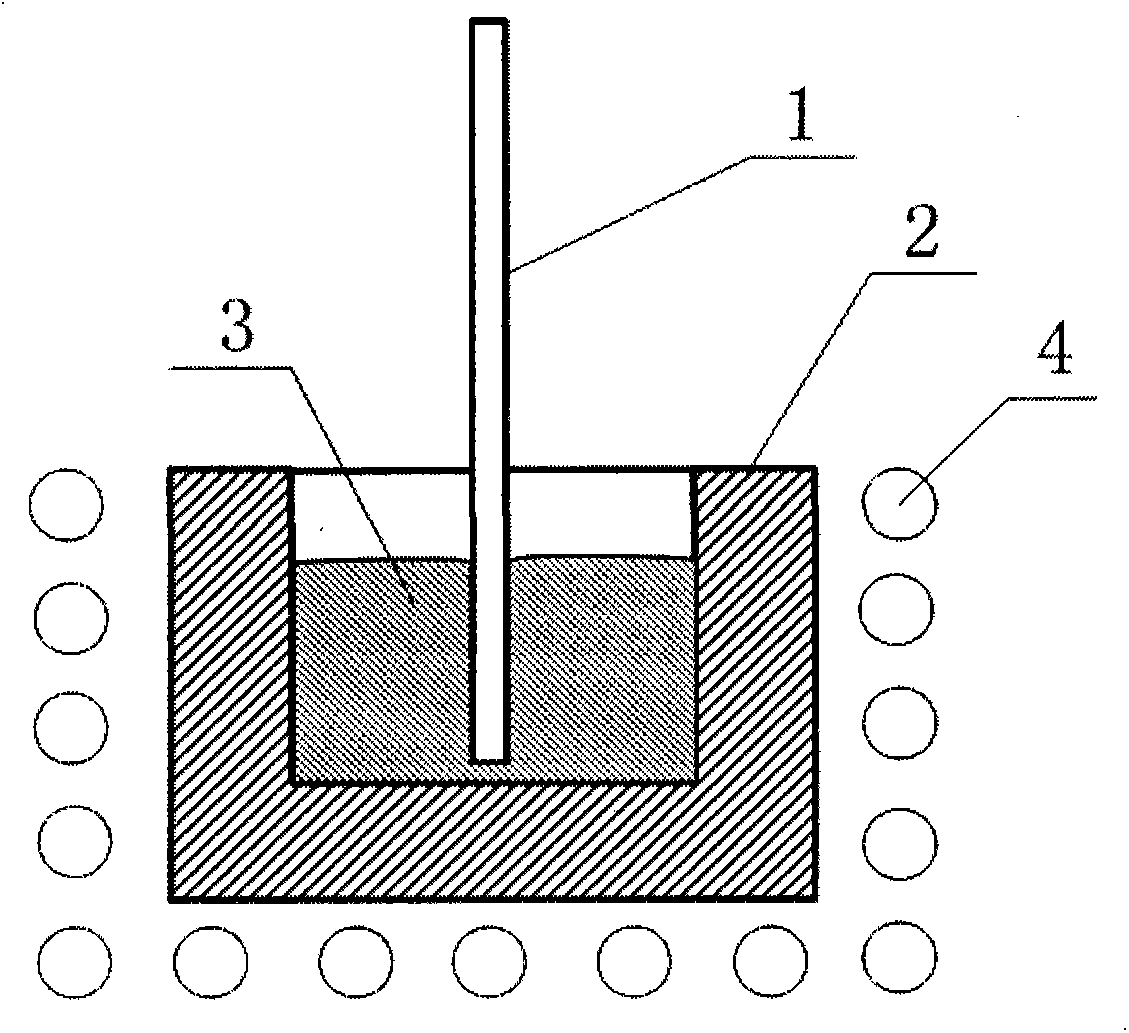

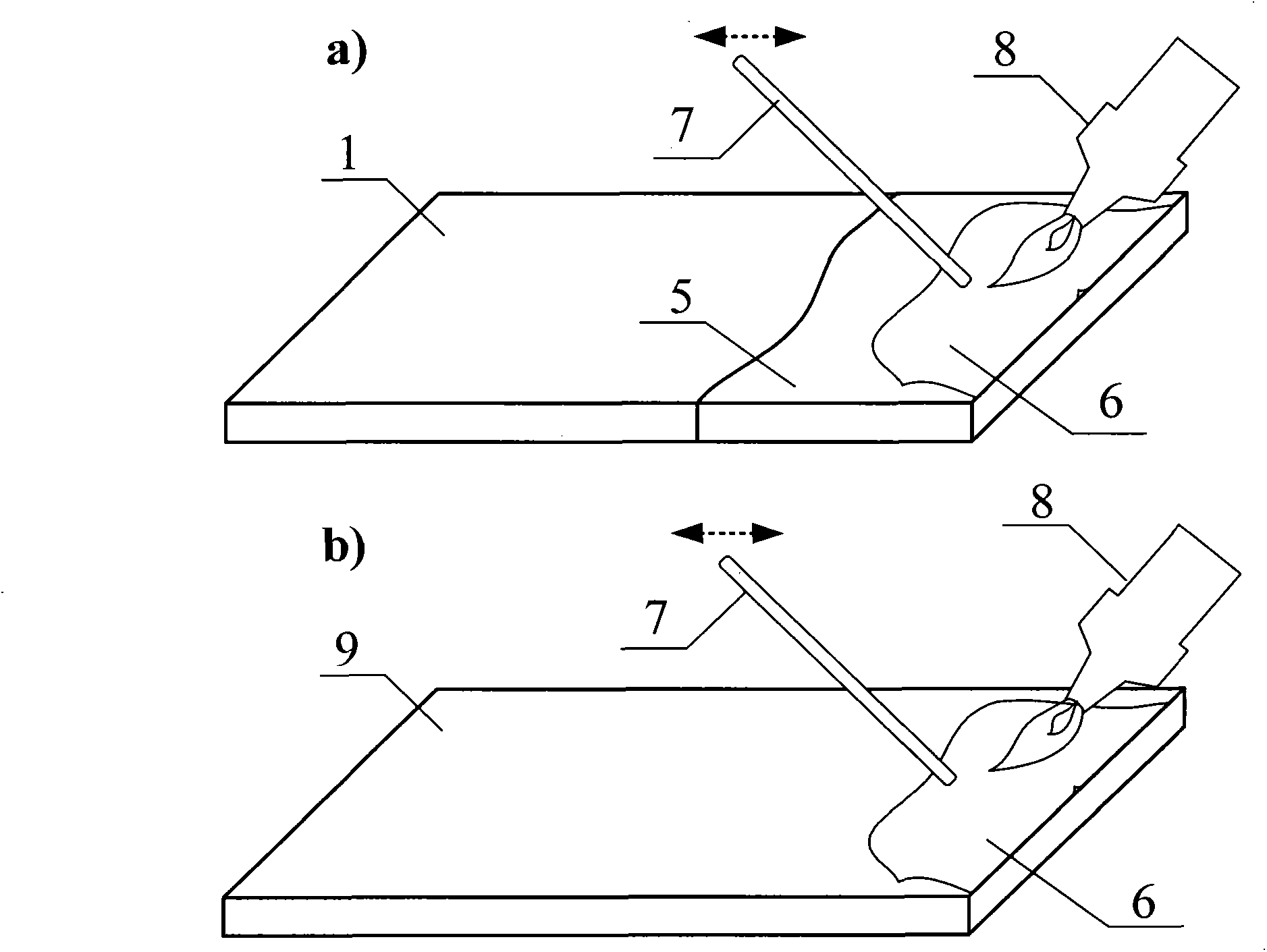

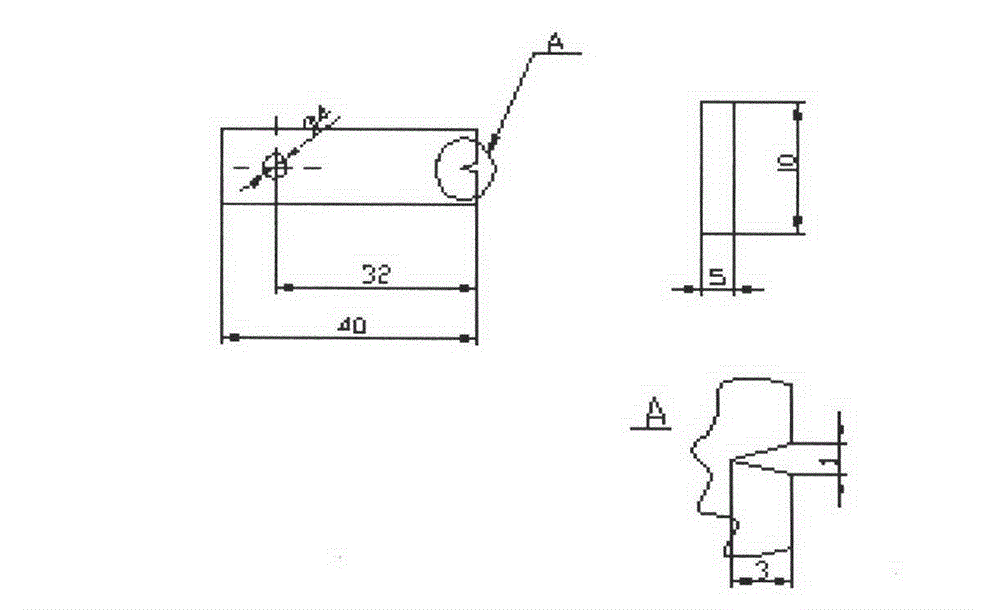

Medium-temperature brazing method of dissimilar metals of titanium and aluminium under atmospheric condition

The invention provides a medium-temperature brazing method of dissimilar metals of titanium and aluminium under the atmospheric condition. The medium-temperature brazing method comprises the following key points of: before brazing, firstly carrying out hot-dip aluminum plating on a titanium plate, forming an aluminium-plating layer with certain thickness on the surface of the titanium plate, then preparing a zinc-aluminium brazing material melting layer on the surfaces of the aluminium-plating layer of the aluminium plate and the titanium plate by a mechanical scratching and melting method, and then carrying brazing connection. The medium-temperature brazing method provided by the invention has the advantages that oxidation films are removed by mechanical scratching, so that the zinc-aluminium brazing materials can be wet and spread on the surfaces of the aluminium-plating layers of the aluminium plate and the titanium plate to form uniform melting, and brazing materials do not need to be added in the following brazing process; due to lower brazing temperature, a large amount of titanium-aluminium friable intermetallic compounds on the interface can be limited from generating to a certain extent, and further the toughness of joints is improved; the medium-temperature brazing method is simple and easy in operation, can be carried out under the atmospheric condition, does not need special atmosphere for protection and is suitable for practical engineering application.

Owner:HARBIN INST OF TECH

Zinc base alloy used for hot galvanizing on steel wire

The invention discloses a zinc base alloy used for hot galvanizing on a steel wire. The zinc aluminium alloy comprises the following components in percentage by weight: 4.5-5% of aluminium, 0.02-0.04% of magnesium, 0.003-0.005% of strontium, 0.001-0.002% of indium and the balance of zinc. By adopting the zinc aluminium alloy disclosed by the invention, once alloy plating weight can reach 420-450g / m<2>, and the coating is compact and uniform and has good corrosion resistance.

Owner:无锡常安通用金属制品有限公司

Multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property

ActiveCN102719705AImprove plasticityImprove thermal fatigue resistanceThermal fatigueMedium frequency

A multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property belongs to the technical field of zinc-aluminium alloy preparation and is characterized in that No.A00 industrial aluminium ingots, No.0 zinc ingots, electrolytic copper, composite modifier (including 20 to 30 percent of Ni, 15 to 25 percent of Ti, 5 to 15 percent of Mn, 5 to 15 percent of Cr, 5 to 10 percent of Si, 5 to 10 percent of Ce, 5 to 10 percent of La, 1 to 6 percent of Y, 1 to 6 percent of Nb, 1 to 6 percent of V and the balance of aluminium) and pure magnesium are adopted as materials. Calculated according to percentage by weight, 27 to 29 percent of Al, 2 to 2.5 percent of Cu (added in the form of aluminium-copper master alloy containing 50 percent of copper), 0 to 1.2 percent of composite modifier, 0.01 to 0.02 percent of Mg and the balance of Zn are weighed and then smelted in a medium-frequency induction smelting furnace. An ordinary metal mold is adopted to cast round rod-shaped billets, the round bar-shaped billets are machined into test bars which come up to national standard, and thermal fatigue samples are then taken from the billets.

Owner:SHENZHEN MINGLIDA PRECISION MACHINERY

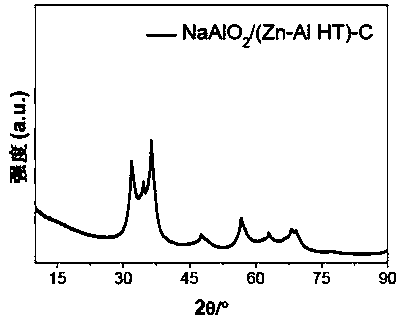

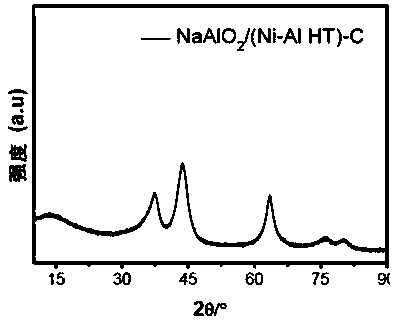

Solid base catalyst and preparation method and application thereof

ActiveCN109772286ASolve the harsh reaction conditionsHigh activityOxygen-containing compound preparationOrganic compound preparationActive componentSodium aluminate

The invention discloses a solid base catalyst. The solid base catalyst is structurally prepared from a carrier and an active component loaded on the carrier; the active component is selected from sodium aluminate; the carrier is a composite metal oxide, and the composite metal oxide is selected from at least one of a composite zinc-aluminium metal oxide, a composite nickel-aluminum metal oxide anda composite cobalt-aluminum metal oxide. The solid base catalyst is high in stability, long in service life, high in low-temperature catalysis activity, and short in reaction time. The invention further discloses a preparation method and application of the solid base catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com