Medium-temperature brazing method of dissimilar metals of titanium and aluminium under atmospheric condition

A technology of atmospheric conditions and dissimilar metals, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problem that aluminum-based solder is difficult to wet titanium base material, etc., to promote wetting and spreading, easy operation, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

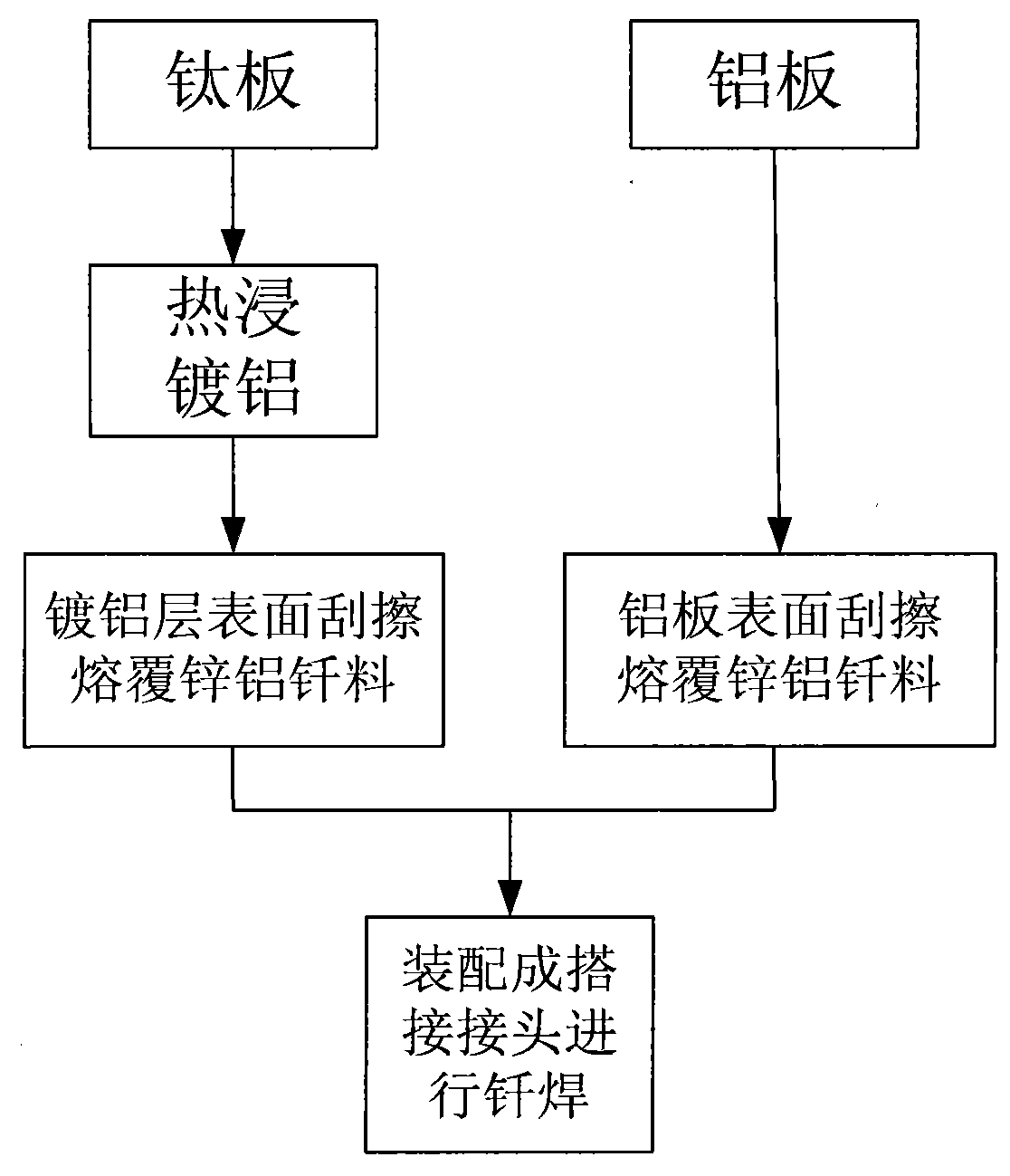

[0036] A kind of medium temperature brazing method under atmospheric conditions of titanium, aluminum dissimilar metals, it comprises the following steps:

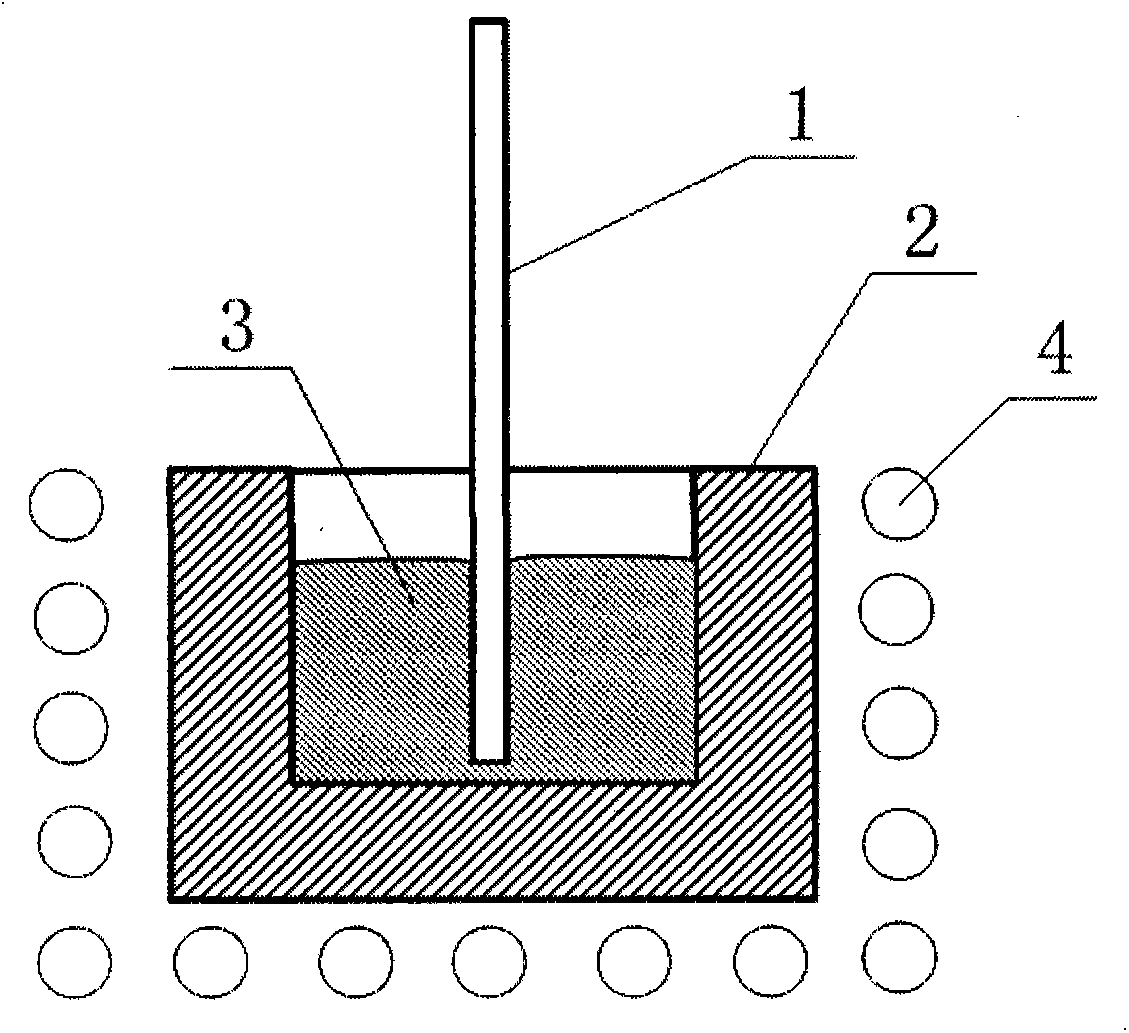

[0037] (1) Hot-dip aluminum plating

[0038] Cut the pure aluminum welding wire that has been wiped with acetone to remove oil stains into small pieces and put it into the graphite crucible 2, put the graphite crucible 2 into a furnace with a heating wire 4 and heat it to 700°C to melt the pure aluminum welding wire, and keep it warm for more than half an hour to ensure The temperature of molten aluminum 3 is homogenized. Clean the end of the connected titanium plate 1 with sandpaper and wash with acetone to remove the oxide film and oil. Dissolve NOCOLOK brazing flux in acetone to form a suspension, and brush it on the front and back surfaces with a width of 10 mm at the end of the titanium plate 1 . After the acetone is volatilized, the titanium plate 1 on the side coated with the flux is vertically immersed in the alu...

Embodiment 2

[0044] A kind of medium temperature brazing method under atmospheric conditions of titanium, aluminum dissimilar metals, it comprises the following steps:

[0045] (1) Hot-dip aluminum plating

[0046] Cut the pure aluminum welding wire that has been wiped with acetone to remove oil stains into small pieces and put it into the graphite crucible 2, put the graphite crucible 2 into a furnace with a heating wire 4 and heat it to 750°C to melt the pure aluminum welding wire, and keep it warm for more than half an hour to ensure The temperature of molten aluminum 3 is homogenized. Clean the end of the connected titanium plate 1 with sandpaper and wash with acetone to remove the oxide film and oil. Dissolve NOCOLOK brazing flux in acetone to form a suspension, and brush it on the front and back surfaces with a width of 20 mm at the end of the titanium plate 1 . After the acetone is volatilized, the titanium plate 1 on the side coated with the flux is vertically immersed in the alu...

Embodiment 3

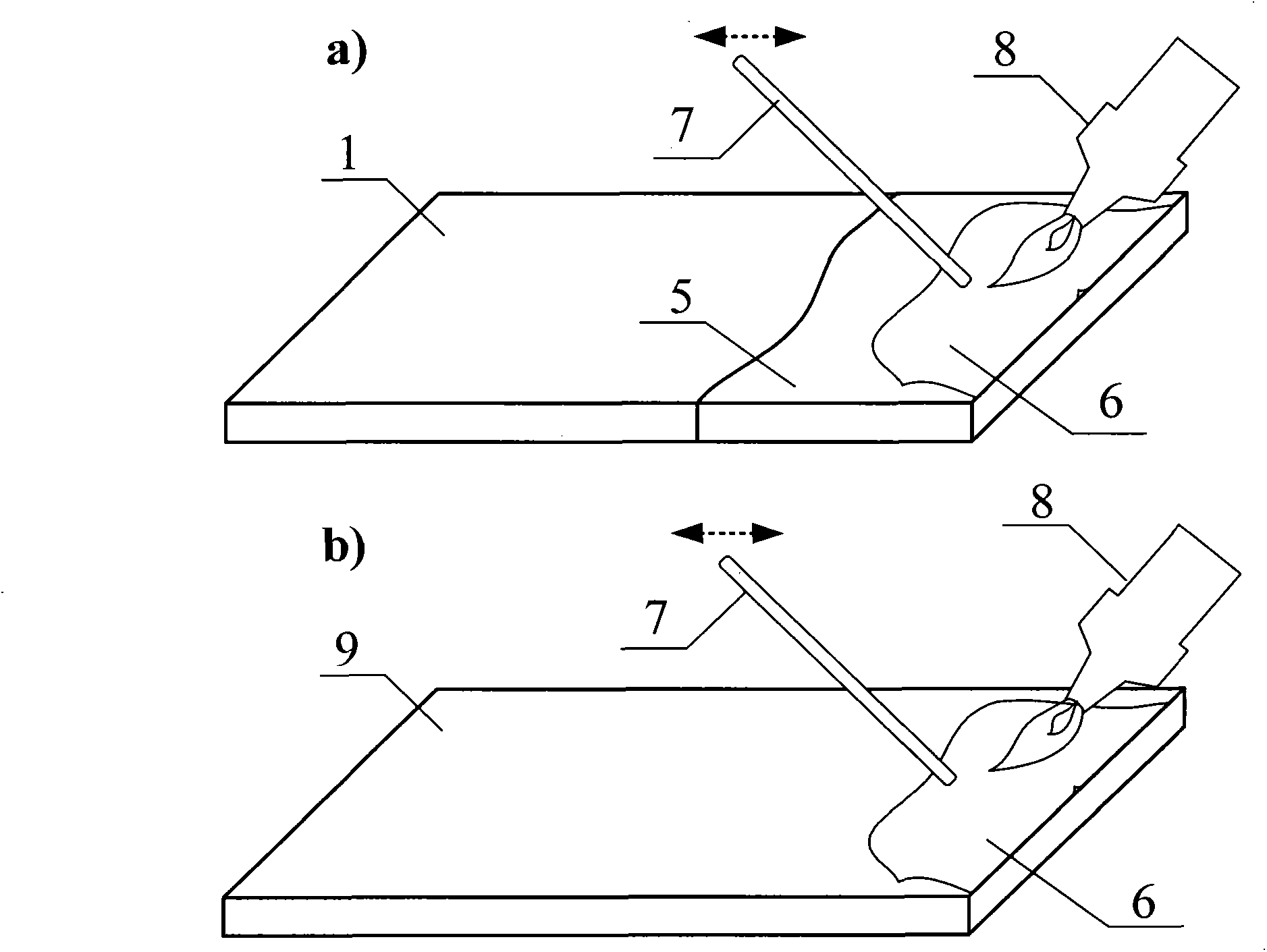

[0052] The base material is 50mm×40mm×2mm TC4 titanium alloy plate and LF6 anti-rust aluminum plate. Cut the cleaned pure aluminum welding wire into small pieces and put them into a graphite crucible. Put the crucible into an electric furnace and heat it to 750°C. Keep it warm for one hour to make the aluminum Homogenize the liquid temperature. Dissolve chloride, fluoride mixed flux or NOCOLOK flux in acetone to make a suspension, and then apply it to the front and back sides within 15mm of the edge of the titanium plate. After air-drying, immerse the flux-coated side of the titanium plate vertically In the molten aluminum, after dipping for 1 min, the titanium plate is pulled out at a constant speed of 2 cm / s, and cooled naturally. Evenly scrape and clad the zinc-aluminum solder on the end of the aluminum plate and the surface of the TC4 aluminum coating, and assemble the aluminum plate and the TC4 plate after cladding the zinc-aluminum solder into a lap joint, the lap length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com