Composite resurfacing welding method for sink roller and stabilizing roller used for hot dipping

A sinking roll and stabilizing roll technology, applied in hot-dip plating process, welding medium, welding equipment, etc., can solve problems such as coating peeling and falling off, spray coating failure, surface groove marks, etc., to achieve corrosion resistance and wear resistance Improved damage performance, good thermal fatigue resistance, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

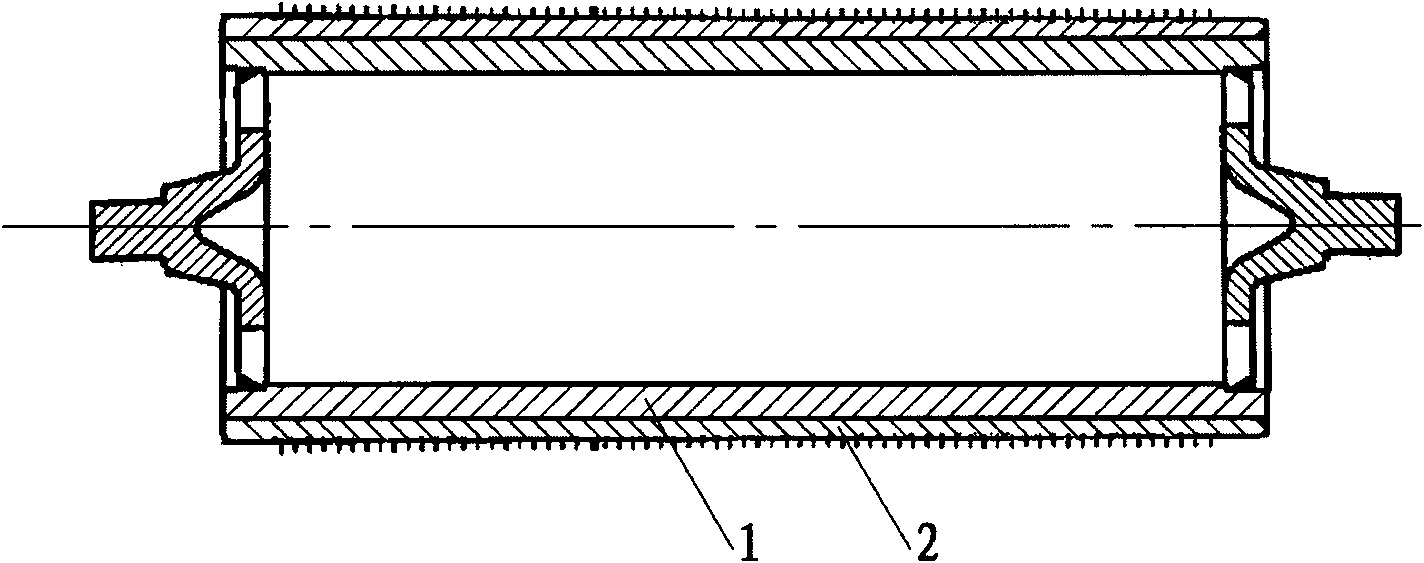

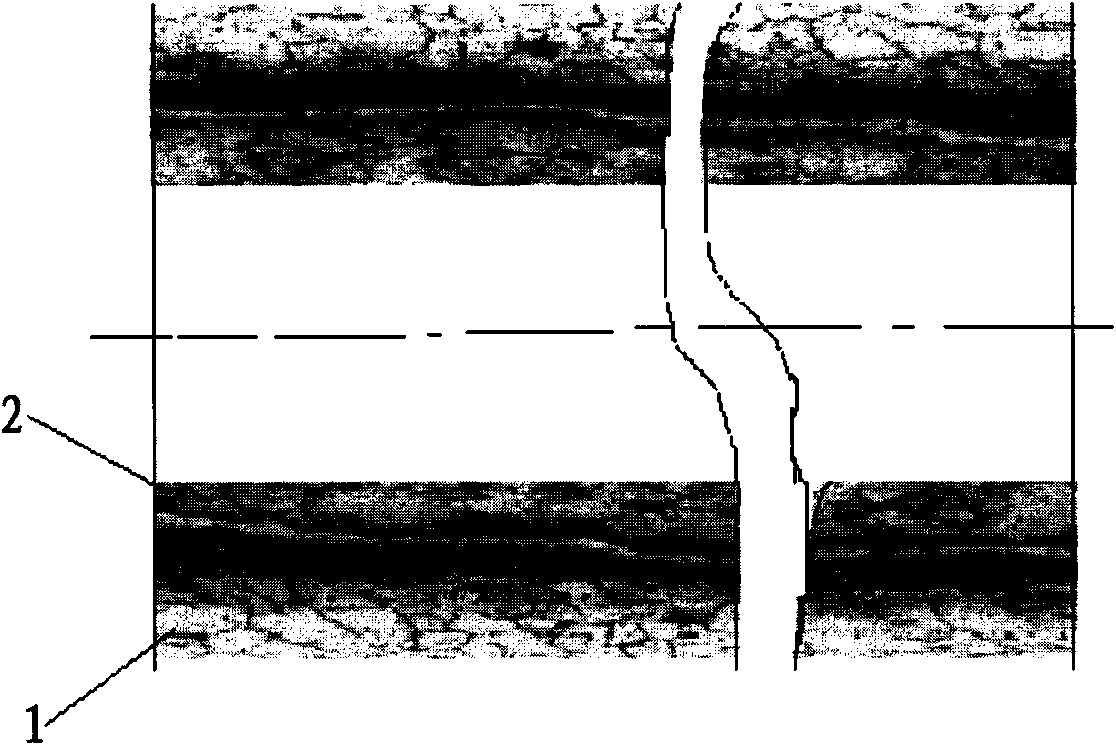

[0037] Example 1 The roller base 1 of the sinking roll was obtained by conventional centrifugal casting method, which was made of 00cr17Ni14Mo2 stainless steel iron-based material, a sinking roll base with a diameter of Φ610mm, a length of 1860mm, and a wall thickness of 50mm. The roller base 1 is preheated to 500°C by electric heating method, kept for 1h, and then slowly cooled to 250°C at a rate of 50°C / h, and a cobalt-based alloy electrode is used, the composition of which is: 25% Cr, 5% Ni, 0.1% V, 0.1% Ti, 0.8% C, 6% Fe, 5% Al, 0.3% Mn, 1.5% Nb, 0.5% Si, 0.01% RE, and the rest is Co And P and S less than 0.05, continuous surfacing welding is carried out on the base of the sinking roller with surfacing equipment, and the thickness of each layer of surfacing welding is 5mm. After the first layer of surfacing, remove the welding slag on the surface of the surfacing, and then preheat the body of the sinking roller after surfacing to 500°C, keep it warm for 1 hour, and slowly ...

Embodiment 2

[0042] Example 2 adopts a rolled stabilizer roll base 1 with a diameter of Φ200mm and a length of 1860mm, and the base is SUS316 austenitic heat-resistant stainless steel. Preheat the roller base to 650°C by means of resistance heating, keep it warm for 3 hours, and then slowly cool it to 300°C at a rate of 150°C / h, using a cobalt-based alloy electrode, the composition of which is: 20% Cr, 3% Ni, 0.2% V, 0.2% Ti, 0.5% C, 12% Fe, 0.5% Al, 0.7% Mn, 1.0% Nb, 0.4% Si, 0.02% RE, the rest is Co As well as P and S less than 0.04, the surfacing machine is used to carry out interval surfacing welding on the base of the stabilizer roll body, and the thickness of each layer of surfacing welding is 10mm. After the first layer of surfacing welding, remove the welding slag on the surface of the surfacing welding, and then preheat the stabilizer roll body after surfacing to 600°C, keep it warm for 2 hours, and slowly cool it to 300°C at a rate of 30°C / h to eliminate The stress generated dur...

Embodiment 3

[0047] Example 3 A sinking roller substrate with a diameter of Φ610mm, a length of 1860mm, and a wall thickness of 50mm is used. The substrate is ZG07Cr19Ni9 heat-resistant stainless steel. The roller substrate is preheated to 600°C by gas and electromagnetic induction heating methods and kept for 2 hours. , and then slowly cooled to 350°C at a rate of 100°C / h, using a cobalt-based alloy electrode whose composition is: 26% Cr, 3% Ni, 1.0% V, 1.0% Ti, 1.5% C, 15% of Fe, 1.0% of Al, 1.0% of Mn, 2.0% of Nb, 1.0% of Si, 0.03% RE, the rest is Co and less than 0.04 of P and S, on the base of the sinking roller, use surfacing welding The machine carries out continuous surfacing welding, and the thickness of each layer of surfacing welding is 3mm. After the first layer of surfacing welding, remove the welding slag on the surface of the surfacing welding, and then preheat the stabilizer roller body after surfacing welding to 600 ° C, keep warm 2h, slowly cooling to 300°C at a rate of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com