Preparation method of zinc-aluminium seamless flux-cored wire

A seamless flux-cored welding wire, zinc-aluminum technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of uneven flux filling, high cost, complicated processing procedures, etc., and achieve continuous and uniform flux filling and high production efficiency High, solve the effect of complex processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

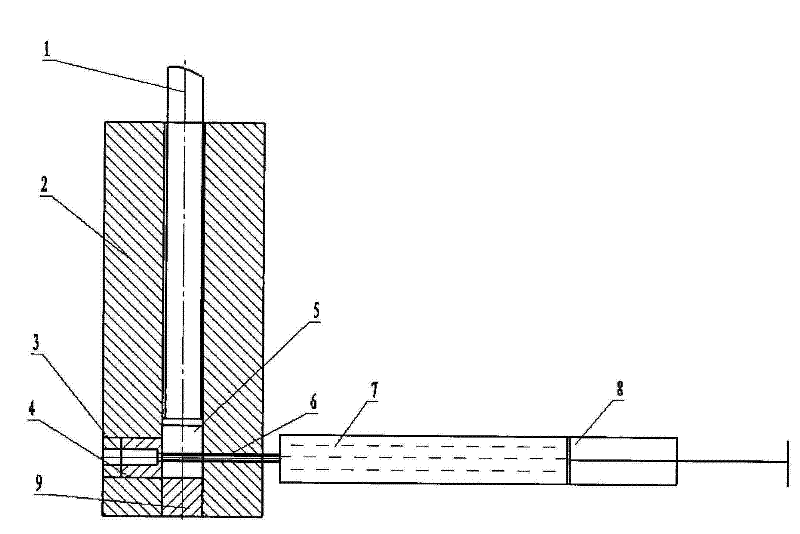

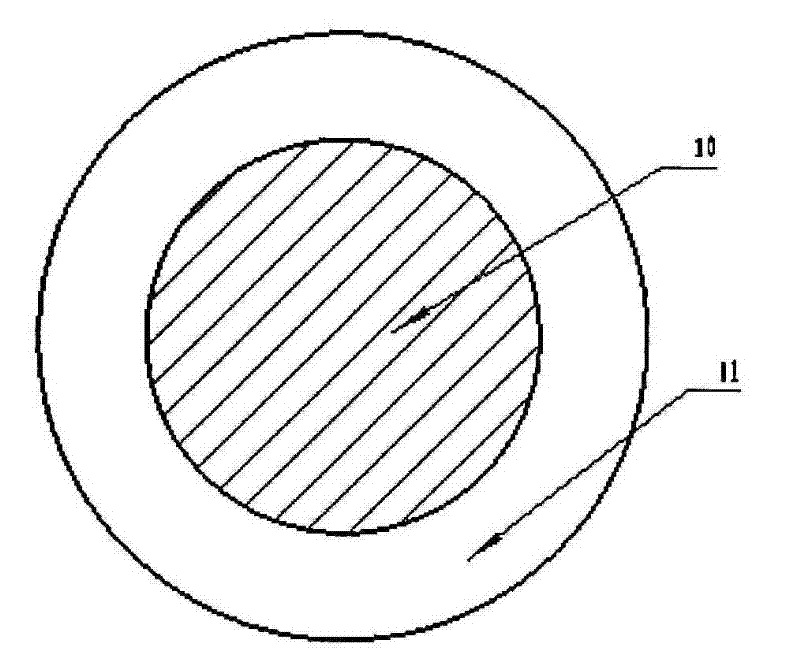

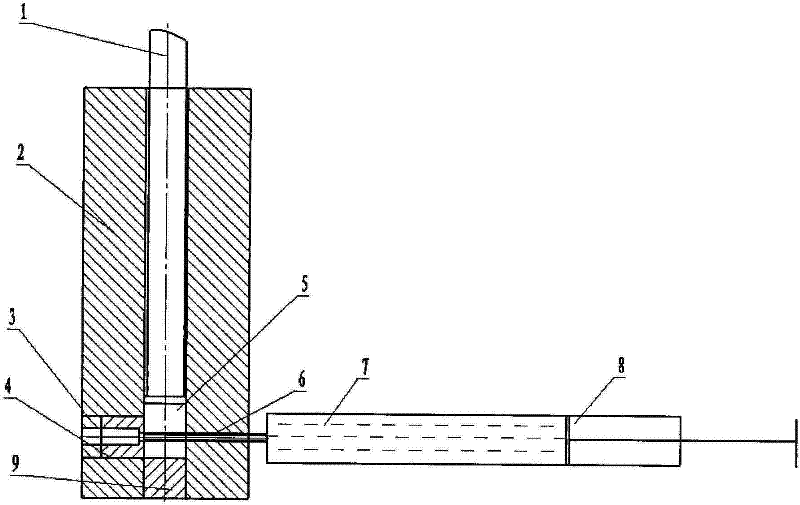

[0018] Example 1: The raw materials Zn80%, Al19.5%, Ag0.5% are smelted into ingots by conventional technology, the riser is removed, the skin is peeled off, and the spheroidizing annealing is carried out in a nitrogen protection furnace at 220 °C for 1.5 hours. The flux-cored flux cesium fluoroaluminate is prepared into a paste with vaseline and loaded into a pressure injector, then the alloy ingot is put into a special extrusion mold, and the pressure injector is connected to the special extrusion mold. The extrusion temperature is 200 °C, The pressing speed is 0.3m / s, and the Φ10mm welding wire whose core is flux and zinc-aluminum alloy is extruded, and then drawn in a wire drawing machine for many times, the processing rate of the first pass is 18%, and put into a nitrogen protection furnace for 180 ℃ annealing; the processing rate of the second pass is 12%, and it is placed in a nitrogen protection furnace for annealing at 180°C; the processing rate of other passes is 6% un...

Embodiment 2

[0019] Example 2: The raw materials Zn95%, Al3.7%, Ag1%, Mn0.3% were smelted into ingots, the riser was removed, the skin was peeled off, and spheroidizing annealing was carried out at 220°C in a nitrogen protection furnace for 1.5 hours. The flux-cored flux, cesium fluoroaluminate, is made into a paste with vaseline and loaded into a pressure syringe, then the zinc-aluminum alloy ingot is put into a special extrusion mold, and the pressure syringe is connected to the special extrusion mold, and the extrusion temperature is 200°C , the extrusion speed is 0.3m / s, and the Φ10mm welding wire whose core is flux and zinc-aluminum alloy is extruded, and then drawn on the wire drawing machine for many times, the processing rate of the first pass is 18%, and then put into nitrogen protection Annealing at 180°C in the furnace; the processing rate of the second pass is 12%, and then placed in a nitrogen protection furnace for annealing at 180°C; the processing rate of the other passes is...

Embodiment 3

[0020] Example 3: The raw materials Zn80%, Al18%, Ag1.7%, and rare earth 0.3% were smelted into an ingot, the riser was removed, the skin was removed, and the spheroidizing annealing was performed at 260 ° C for 2 hours, and the flux cored flux cesium fluoroaluminate 95%, Potassium Fluoroaluminate 5% is made into a paste with polyethylene glycol and put into a pressure syringe, then the zinc-aluminum-silver alloy ingot is put into a special extrusion mold, and the pressure syringe is connected to the special extrusion mold , the extrusion temperature is 180°C, the extrusion speed is 0.5m / s, and the Φ12mm welding wire whose core is flux and zinc-aluminum alloy is extruded, and then drawn on the wire drawing machine for many times, the processing rate of the first pass is 15 %, and then placed in a nitrogen protection furnace for annealing at 200°C; the processing rate of the second pass is 10%, and then placed in a nitrogen protection furnace for annealing at 200°C; the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com