High-corrosion-resistant water soluble zinc aluminium multielement alloy-based nano anticorrosion paint as well as preparation method and application thereof

A multi-element alloy and anti-corrosion coating technology, which is applied in the direction of anti-corrosion coatings, coatings, devices for coating liquid on the surface, etc., can solve the problem that the corrosion resistance and hardness are not as good as Dacromet, and the corrosion resistance of coatings is reduced. , the medium is difficult to disperse and other problems, and achieve the effects of good wind erosion resistance, high corrosion resistance, and strong salt spray corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

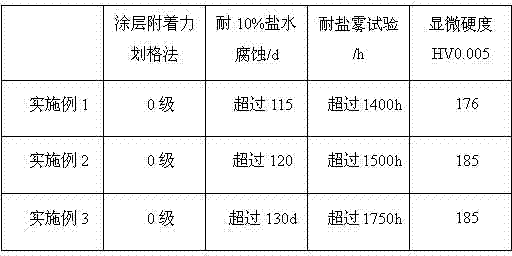

Examples

Embodiment 1

[0043] 1. Take a certain amount of γ-glycidyl etheroxypropyltrimethoxysilane and dissolve it in water-methanol solution. After ultrasonic dispersion at room temperature, add a certain amount of nano powder, stir and heat to a certain temperature. After a period of constant temperature, Suction filtration, drying in a vacuum drying oven at 60° C., and grinding to obtain modified nanopowder with an average particle size of about 40 nm.

[0044] 2. Back up according to the following mass percentage content: 15%Al-Zn-4%Si alloy powder: 30wt%, modified Al 2 o 3 Nano powder: 2wt%, γ-glycidyl etheroxypropyl trimethoxysilane: 10wt%, ethylene glycol: 12wt%, chelating phosphate titanium coupling agent: 0.5wt%, Tween-20: 3.6wt% %, sodium phosphomolybdate: 1.0 wt%, lanthanum nitrate 0.8%, quaternary ammonium titanate: 3 wt%, hydroxyethyl cellulose 0.4%; isooctyl diethylhexanol about 0.1%; ionized water. Among them, the 10%Al-Zn-Si%Mg alloy powder is in the form of scales, with a diam...

Embodiment 2

[0051] 1. Take a certain amount of γ-glycidyl etheroxypropyltrimethoxysilane and dissolve it in water-methanol solution. After ultrasonic dispersion at room temperature, add a certain amount of nano powder, stir and heat to a certain temperature. After a period of constant temperature, Suction filtration, drying in a vacuum oven at 60°C, and grinding to obtain modified nanopowder with an average particle size of about 45 nm.

[0052] 2. Back up according to the following mass percentage content: 30%Al-Zn-2.5%Mg alloy powder: 20wt%, modified Al 2 o 3 and TiO 2 (where Al 2 o 3 : TiO 2 The mass ratio is 1:1~3) Nanopowder: 1wt%, β-(3,4-epoxycyclohexyl) ethyltrimethoxysilane: 5wt%, ethylene glycol: 8wt%, composite phosphate monoalkane Oxygen titanate: 1.5wt%, Tween-20: 1.8wt%, lanthanum nitrate: 0.9wt%, modified sodium silicate 0.5%, quaternary ammonium titanate: 3wt%, hydroxyethyl cellulose 0.5 %; about 0.05% isooctyl alcohol diethylhexanol; the balance is deionized water....

Embodiment 3

[0059] 1. Take a certain amount of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane and dissolve it in water-methanol solution, after ultrasonic dispersion at room temperature, add a certain amount of nano powder, stir and heat to a certain temperature , after constant temperature for a period of time, suction filtration, drying in a vacuum drying oven at 60°C, and grinding to obtain modified nanopowder with an average particle size of about 50nm.

[0060] 2. Backup according to the following mass percentage content: 55Al-Zn-1%Mn-4.0%Ti -1.6%Ce alloy powder: 15wt%, modified SiC and Al 2 o 3 Nano powder (where SiC: Al 2 o 3 The mass ratio is 1:1~3) 0.5wt%, β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane: 5wt%, ethylene glycol: 6wt%, chelating phosphate titanium coupling Agent: 1wt%, OP-10: 2wt%, zirconium nitrate 0.6wt%, sodium phosphomolybdate: 0.8wt%, quaternary ammonium titanate: 1wt%, hydroxyethyl cellulose 0.65%; Base hexanol is about 0.05%; the balance is deionized water. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com