Preparation method and application of carbon nanotube-loaded carbon-coated silica material

A carbon nanotube and carbon coating technology, applied in the direction of negative electrodes, active material electrodes, electrical components, etc., to make up for poor conductivity, facilitate electron transfer, and avoid direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

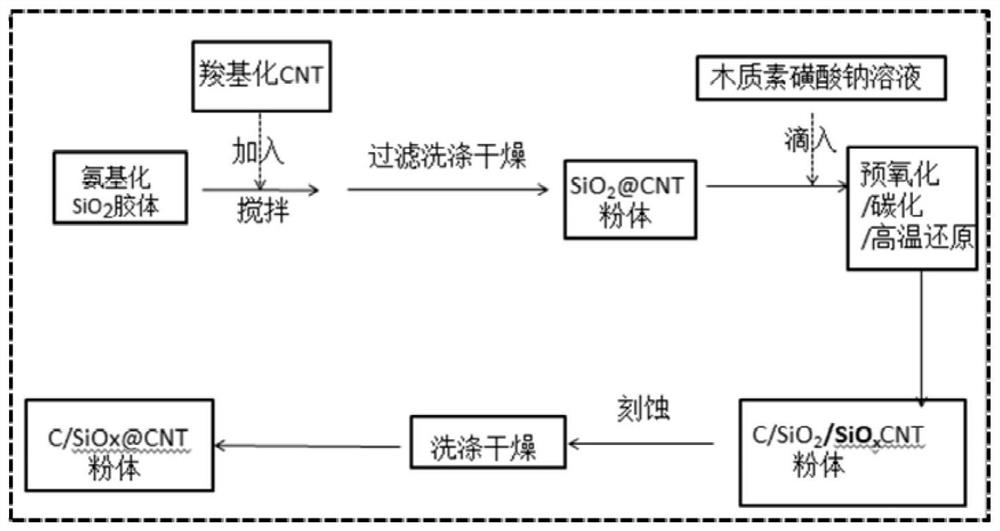

[0068] This embodiment provides a carbon nanotube-loaded carbon-coated silicon oxide material, the preparation process is as follows figure 1 As shown, the specific preparation method is as follows:

[0069] (1) 1g nano-SiO 2 Disperse in 50ml of toluene, stir vigorously for 30min, add 3ml of 3-aminopropyltriethoxysilane, and reflux the mixture at 120°C for 6h to obtain aminated SiO 2 ;

[0070] (2) Weigh 2.0g carbon nanotube (CNT) and add in the round bottom flask, add acid mixed solution (H 2 SO 4 : HNO 3 =3:1), after ultrasonication for 1 h, and then using a water bath to reflux at 80°C for a period of time to obtain carboxylated CNT;

[0071] (3) get the aminated SiO that step (1) obtains 2 1g ultrasonically dispersed in 10ml deionized water to form SiO 2 colloid, on aminated SiO 2 Add 0.3% of the carboxylated CNT obtained in step (2) to the colloidal dispersion, stir slowly for a certain period of time, filter, wash and dry in vacuum for 6 hours to obtain SiO 2 @C...

Embodiment 2

[0076] This embodiment provides a carbon-nanotube-supported carbon-coated silicon-oxygen material, and the specific preparation method is as follows:

[0077] (1) 1g nano-SiO 2 Disperse in 50ml of toluene, stir vigorously for 30min, add 3ml of 3-aminopropyltriethoxysilane, and reflux the mixture at 120°C for 6h to obtain aminated SiO 2 ;

[0078] (2) Weigh 2.0g carbon nanotube (CNT) and add in the round bottom flask, add acid mixed solution (H 2 SO 4 : HNO 3 =3:1), after ultrasonication for 1.2h, and then use a water bath to reflux at 85°C for a period of time to obtain carboxylated CNT;

[0079] (3) get the aminated SiO that step (1) obtains 2 1g ultrasonically dispersed in 10ml deionized water to form SiO 2 colloid, on aminated SiO 2 Add 0.4% of the carboxylated CNT obtained in step (2) to the colloidal dispersion, stir slowly for a certain period of time, filter, wash and dry in vacuum for 5 hours to obtain SiO 2 @CNT.

[0080] (4) Sodium lignosulfonate with a soli...

Embodiment 3

[0083] The only difference between this embodiment and embodiment 1 is that the high temperature heating in step (4) is 800° C., and other conditions and parameters are exactly the same as those in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com