Zinc-aluminium based coated steel sheet, manufacturing method thereof, thermoforming method and component

A coated steel sheet and thermoforming technology, applied in the field of coated steel sheet, can solve the problems of liquid phase metal coating eroding steel sheet, affecting the process, easy to evaporate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Describe below in conjunction with specific embodiment:

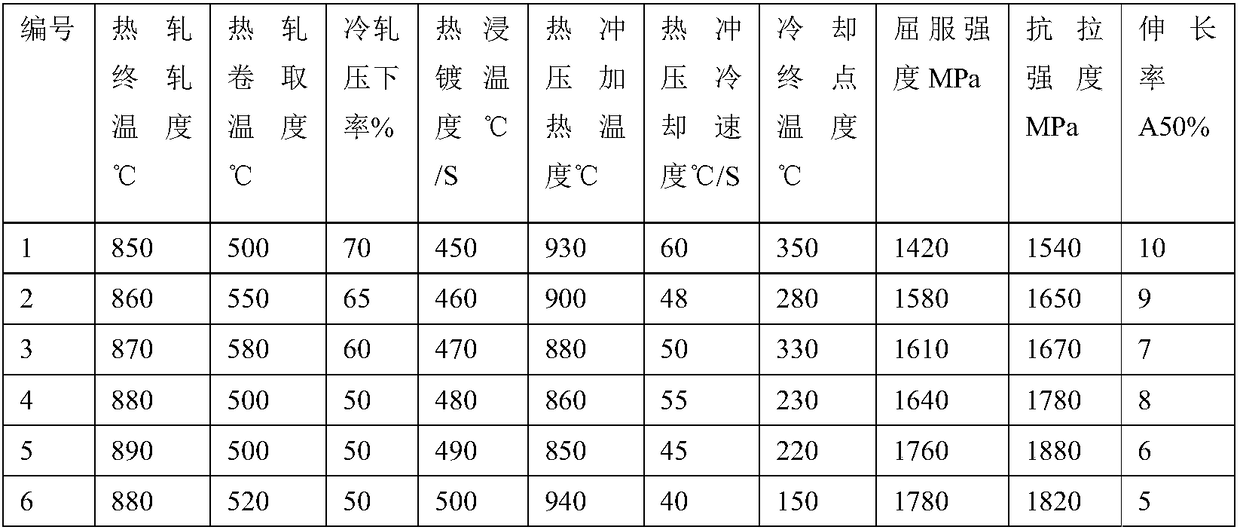

[0028] The embodiment sees attached table 1, 2, 3.

[0029] The strength of the steel plate is greater than 1500MPa, and the elongation is greater than 5%. The coating is completely transformed into an iron alloy layer, without coating evaporation, liquid phase erosion, and hard Fe-Al intermetallic compounds. The structure of the component is martensite + ferrite + retained austenite.

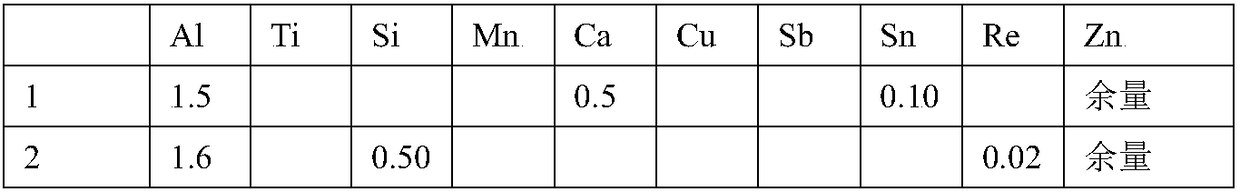

[0030] Attached table 1: the chemical element composition of embodiment coating

[0031]

[0032]

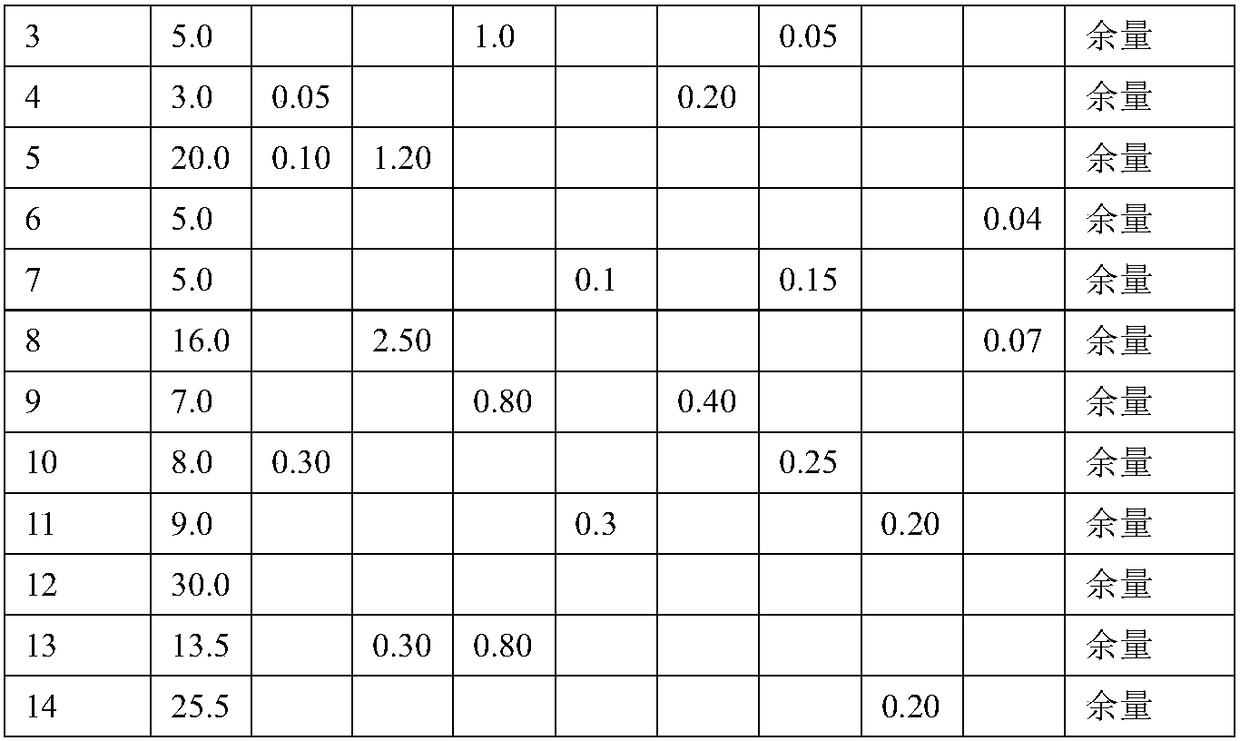

[0033] Attached Table 2: Chemical Composition of Example Steels

[0034]

C

Si

mn

P

S

Al

Ni

Cu

Cr

Mo

B

Nb

Ti

Fe

1

0.11

0.41

1.5

0.010

0.005

2.0

0.35

2.5

0.005

0.03

margin

2

0.17

2.00

6.6

0.030

0.007

0.5

0.3

0.003

margin

3

0.13

0.65

2.1

0.010

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com