Patents

Literature

50results about How to "No evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

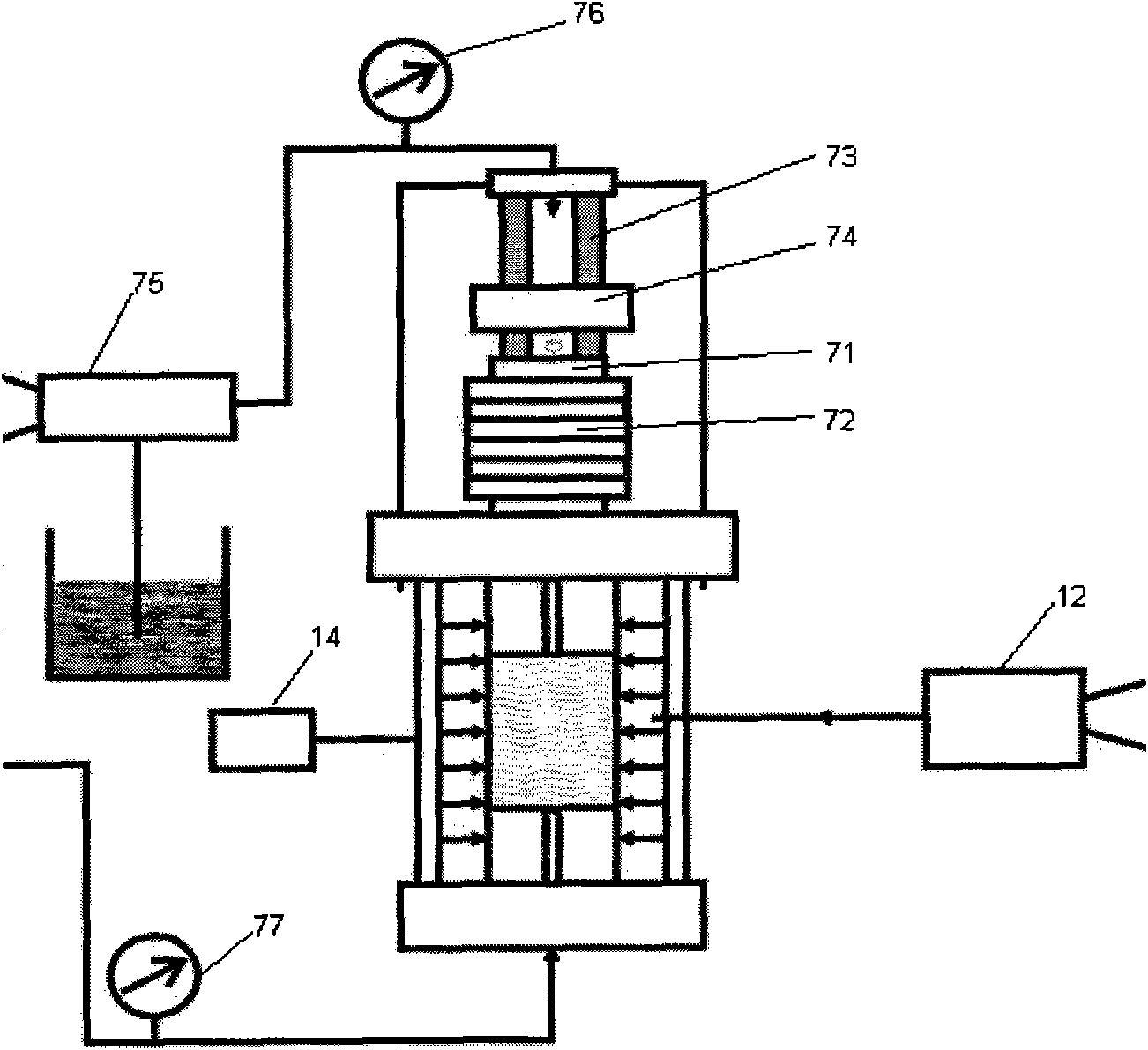

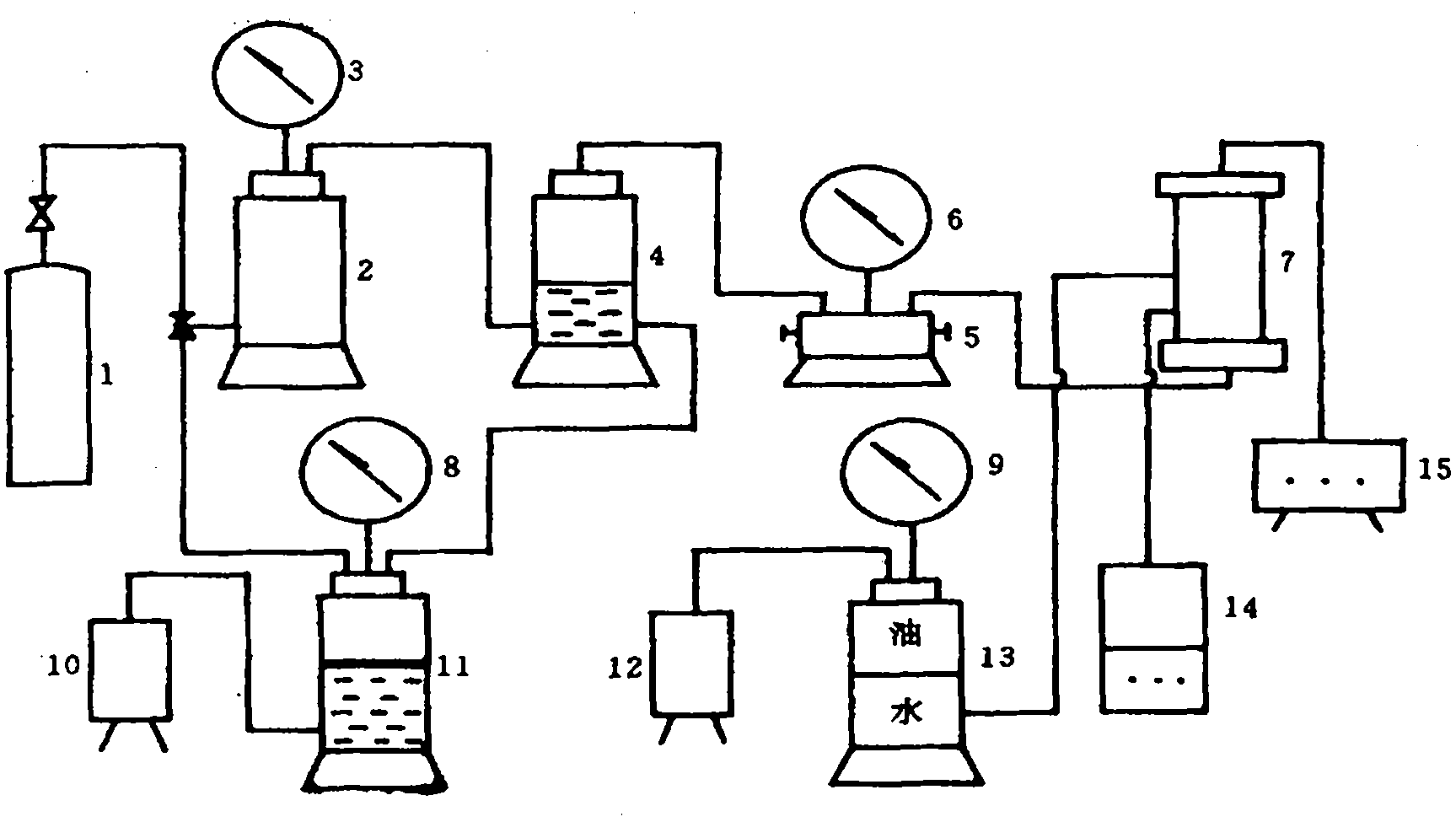

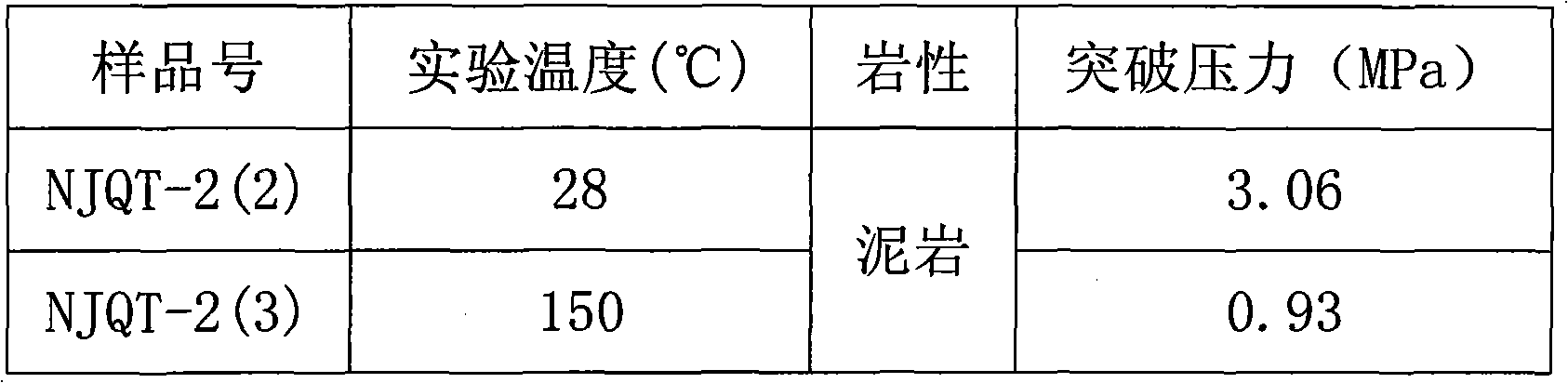

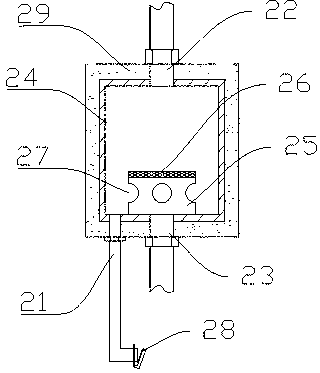

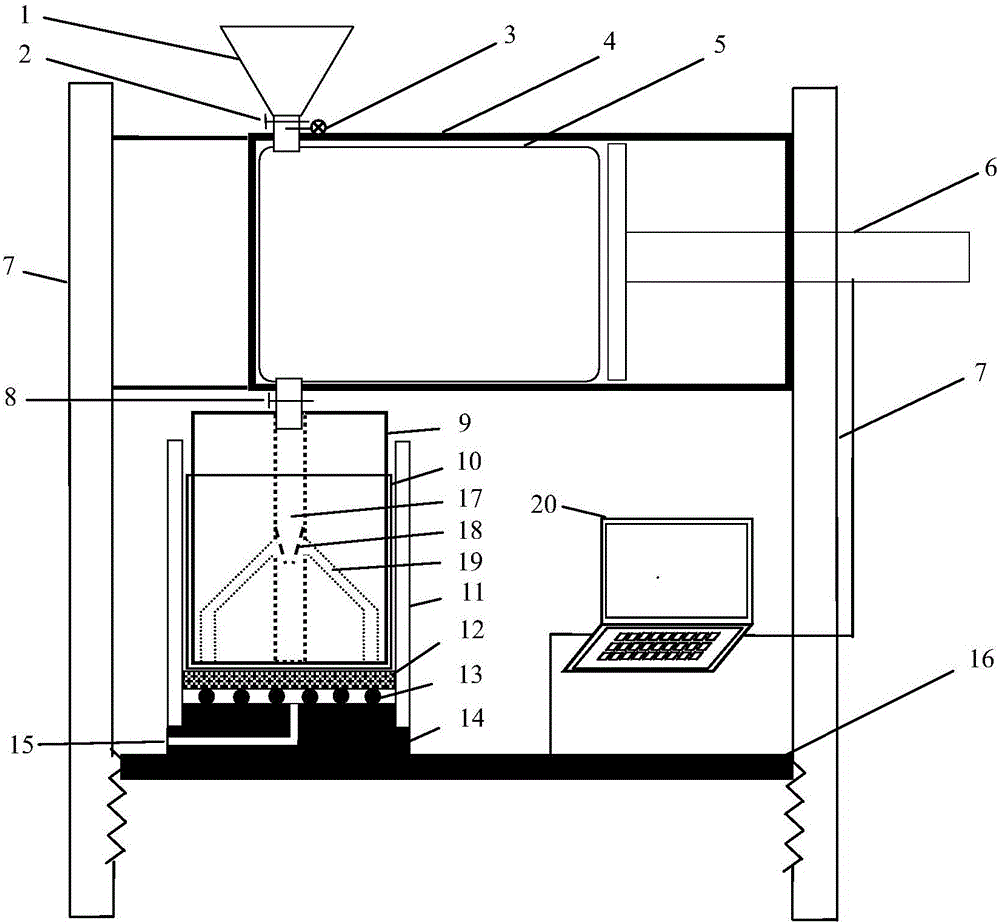

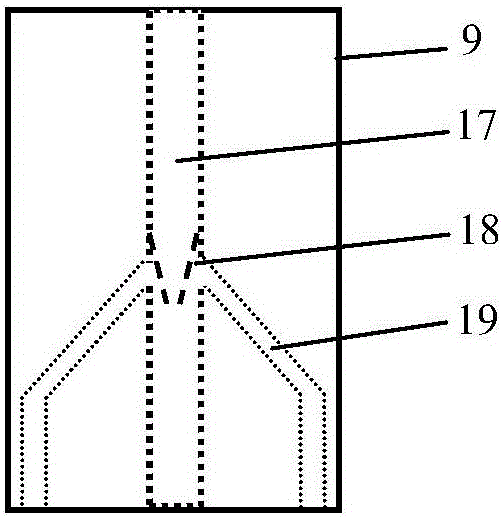

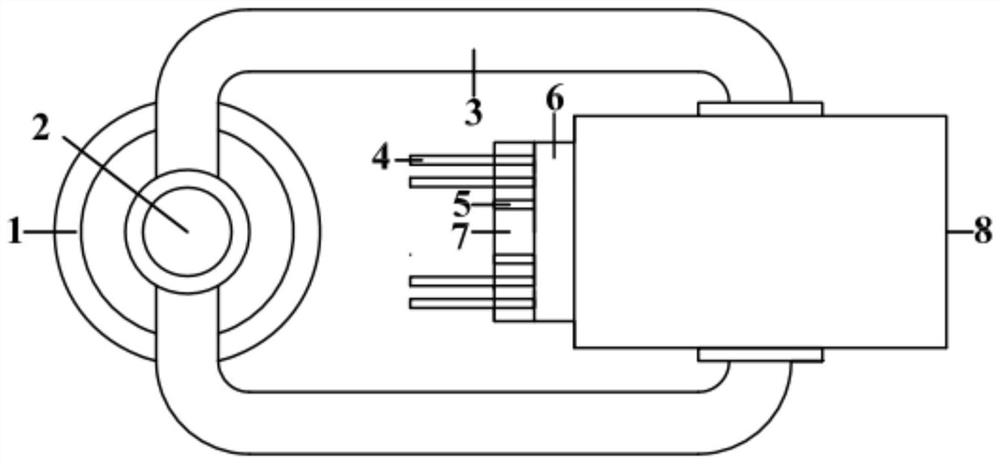

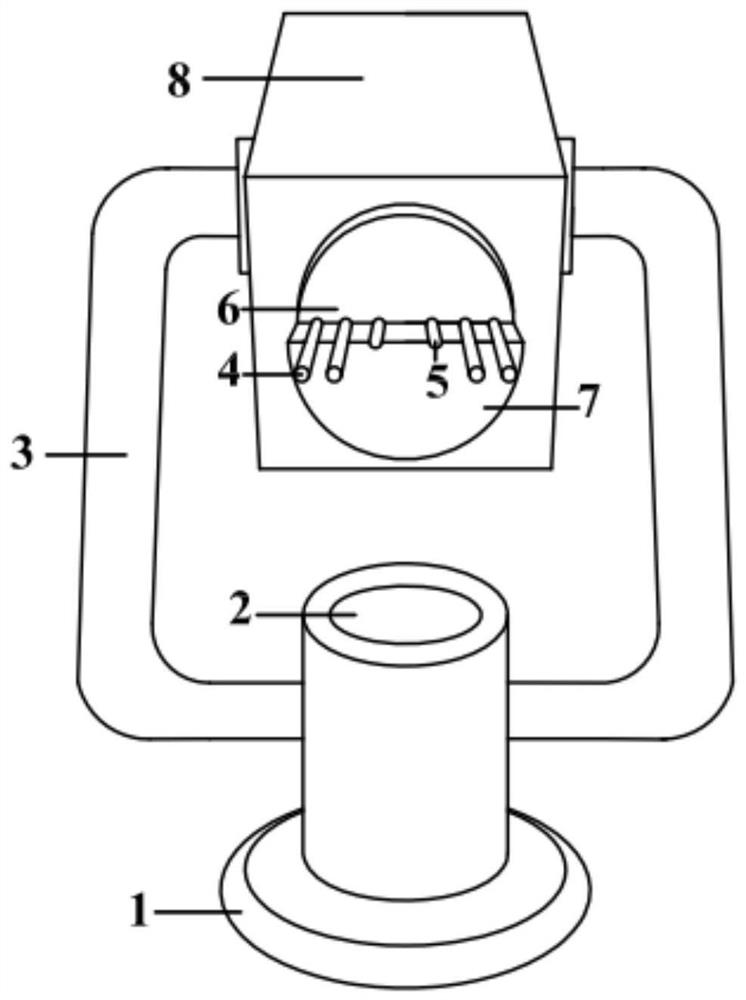

Device for measuring breakthrough pressure under rock sample simulated stratum conditions

ActiveCN102053038ANo evaporationGuaranteed reliabilityMaterial strength using tensile/compressive forcesPressure systemEngineering

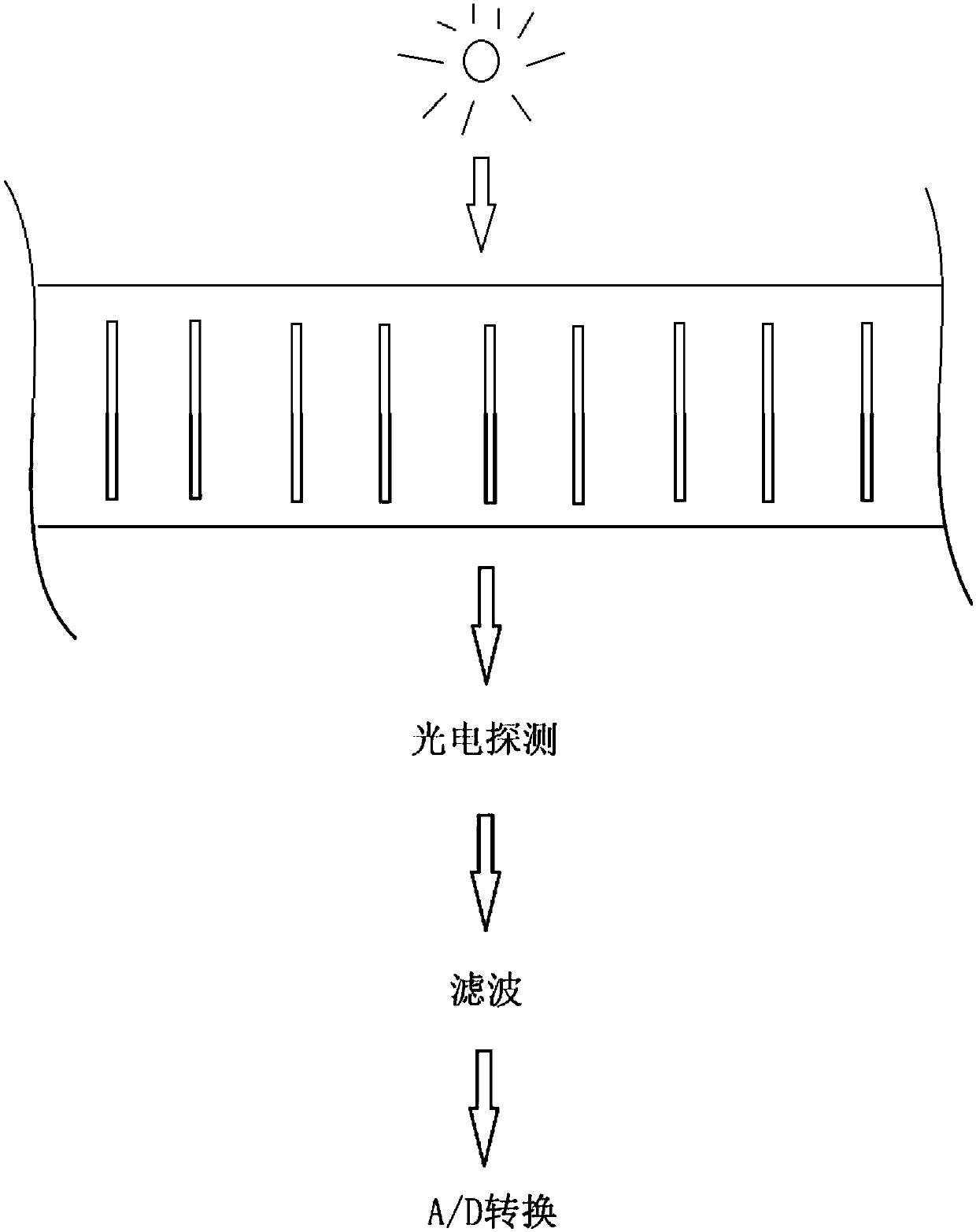

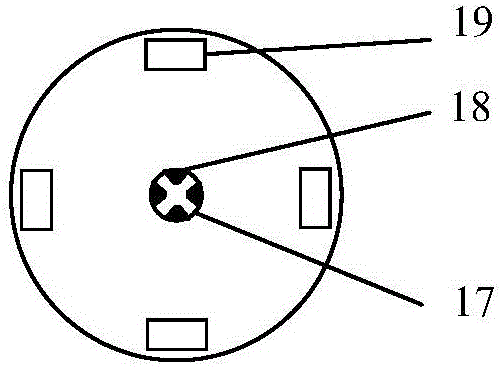

The invention relates to a device for measuring breakthrough pressure under rock sample simulated stratum conditions, which is mainly characterized in that a pressure system is additionally arranged at the outlet end of a core clamper to ensure that liquid behind the core can not be boiled and evaporated due to temperature rise. The pressure system comprises two parts, one is a preceding state cooling treatment device, one section of metal pipe is additionally arranged at the outlet end of the core and a heat radiating sheet is additionally arranged outside the metal pipe; and the other part is a backward state pressurizing and detecting system, a pressure source realizes constant pressure through a constant pressure pump, an air bubble detection part is characterized in that an optical fiber air bubble detector is sleeved outside a thick-walled quartz tube and connected with a computer for realizing automatic detection and ensuring that the experiment is used for measuring parametersof the breakthrough pressure under the stimulated stratum condition, wherein the parameters have important significance on the cap rock evaluation.

Owner:CHINA PETROLEUM & CHEM CORP +1

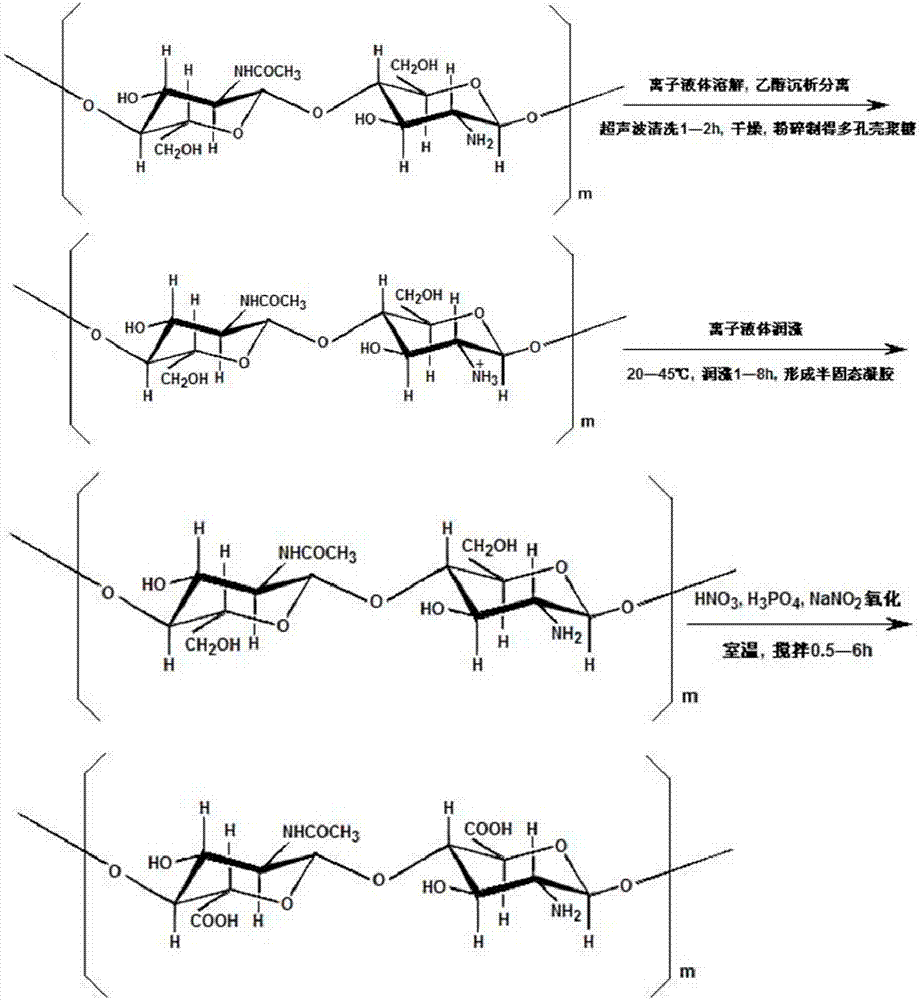

Selective-oxidized chitosan and heterogeneous preparation method thereof

The invention discloses a selective-oxidized chitosan and a heterogeneous preparation method thereof. The method is characterized in that according to preparation of the oxidized chitosan, macromolecular chitosan is dissolved in an ionic liquid, the chitosan is precipitated from the ionic liquid by adding absolute ethyl alcohol, and porous chitosan is obtained after the ionic liquid in a precipitation is fully replaced through absolute ethyl alcohol dipping and ultrasonic oscillation; the porous chitosan is moistened and expanded in the ionic liquid to form a semisolid gel with certain viscosity, and then partial or all hydroxyls at C6 position in pyranose rings of the chitosan are selectively oxidized into carboxyls in an ionic liquid medium to obtain the selective-oxidized chitosan with adoption of a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system. According to the method, operation is simple and convenient, the oxidation reaction rate is high, the oxidation degree of the chitosan is easily controlled, oxidation products are easy to separate, the yield of the products is high, the prepared carboxyl chitosan has good antibacterial activity and water solubility, and the ionic liquid can be recycled for cyclic utilization, which is environmentally friendly.

Owner:TAIHE KERUNGE GARMENT CO LTD

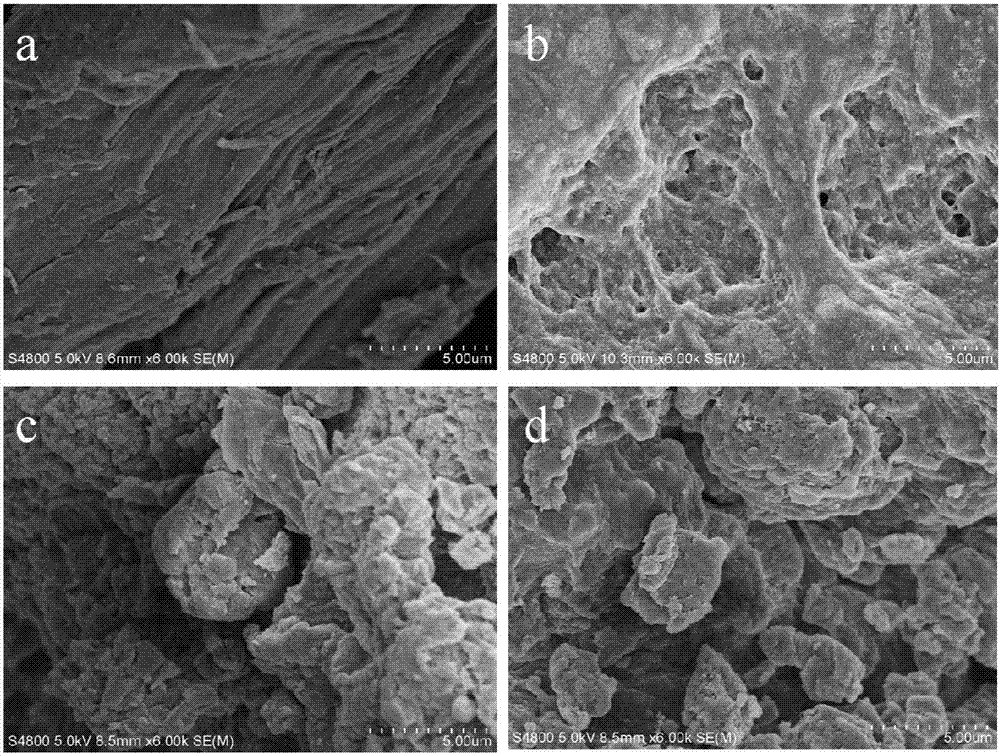

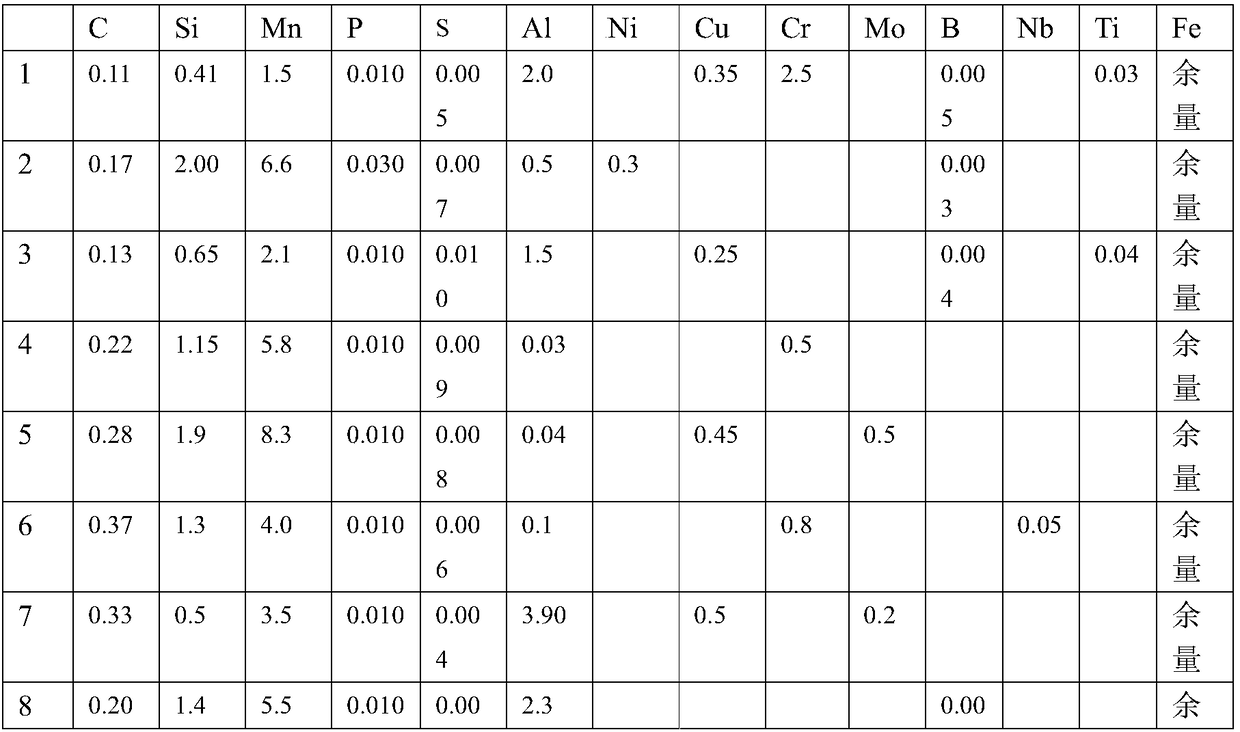

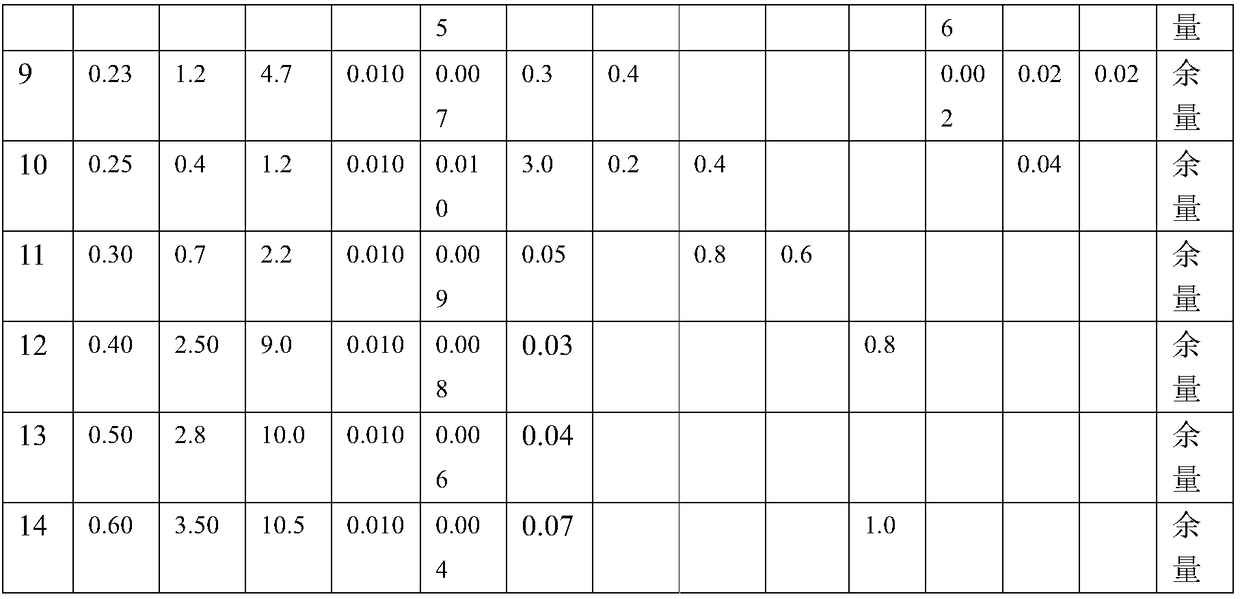

Zinc-aluminum-magnesium-plated steel plate, manufacturing method thereof, thermoforming method and component

PendingCN109112453AStrong corrosion resistanceNo evaporationHot-dipping/immersion processesMagnesiumIntermetallic

The invention discloses a zinc-aluminum-magnesium-plated steel plate, a manufacturing method thereof, a thermoforming method and a component. The zinc-aluminum-magnesium-plated steel plate has strongcorrosion resistance of coating. After hot stamping, a coating is completely transformed into an iron alloy layer, no evaporation of coating evaporation phenomenon and no liquid-phase erosion phenomenon is generated, no hard Fe-Al intermetallic compound is generated, the steel plate has high strength and good toughness, the strength of the steel plate is more than 1500 MPa, and the elongation is more than 5%.

Owner:ANGANG STEEL CO LTD

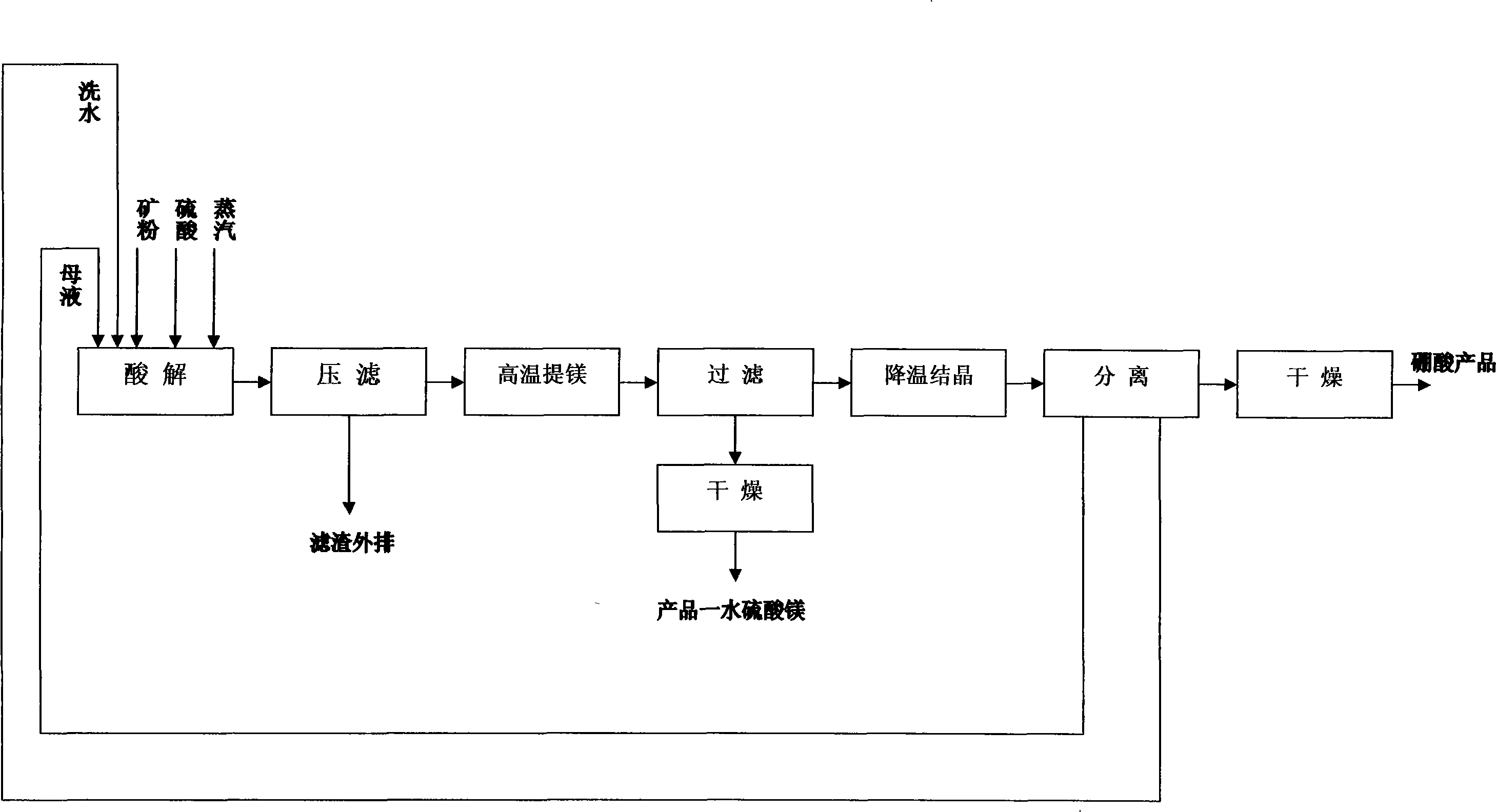

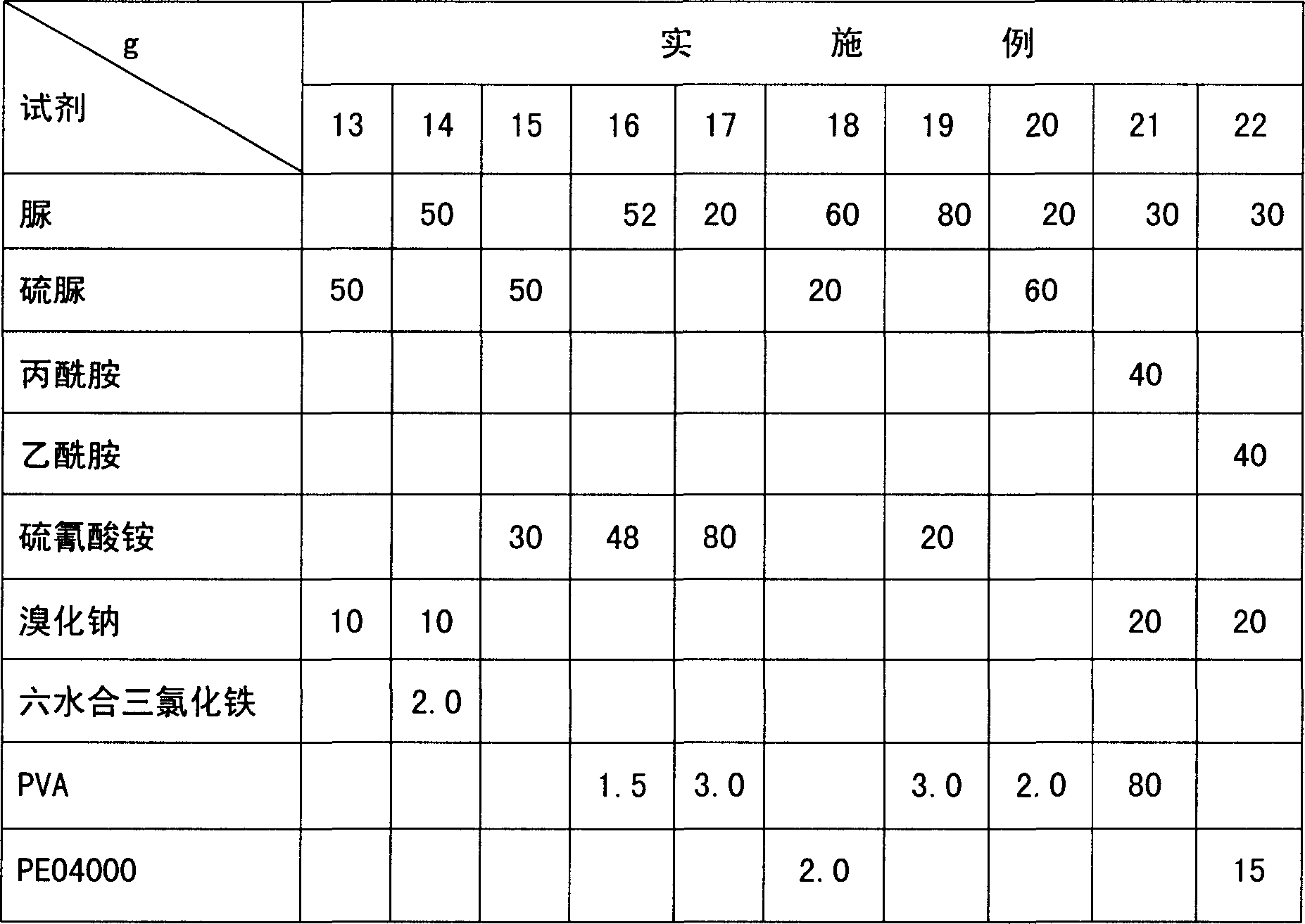

Technology for producing boracic acid and monohydrate magnesium sulfate by employing ascharite ore sulfuric acid process

InactiveCN101182003AReduce pollutionImprove economic efficiencyMagnesium sulfatesBoron-oxygen compoundsChemistryMother liquor

The invention relates to a technique for preparing boracic acid and magnesium sulfate monohydrate by utilizing ascharite sulfuric acid process. The method drives mother liquid and washing water to be heated to have acidolysis with ascharite powder and sulfuric acid when returned to an acidolysis tank; acid decomposing liquid is pumped into a magnesium extracting machine after filtering while hot; temperature in the magnesium extracting machine is raised and crystal magnesium sulfate monohydrate is separated out at a constant temperature while the boracic acid stays in liquid phase and magnesium sulfate monohydrate products are obtained after filtering and drying while hot. Filtrate is pumped into a boracic acid crystallizer and cooled to crystallize according to a well-known way and boracic acid products are obtained after centrifugal separation, washing with added water and drying. The mother liquid and washing water of the boracic acid return to acidolysis process for reusing. The invention solves the problem that a large discharge amount of mother liquid of the boracic acid is changed to be completely recycled. About a ton of magnesium sulfate monohydrate and 200 kilograms of boracic acid can be recycled from the mother liquid in production of each ton of boracic acid. The invention saves resources, reduces environmental pollution and promotes economic benefit of enterprises, thus being characterized by little investment, low energy consumption, low cost and high benefit.

Owner:李皛

Compsn. of releasing heat after contacting air

InactiveCN1834194AImprove conductivityNo vapor pressureHeat-exchange elementsThermal energyElectrochemical response

This invention relates to a composite that can release heat when contacting the air. The composite is composed of: metal powders that can release heat when reacting with the air, electronic conductive materials and ionic conductive materials at a volume ratio of 2~8:2~8:1~8. The composite can exist in the form of powder, particle or cream. The metal can be reduced Fe, Zn, or Mg alloy or Al alloy that can form metal-air battery in experimental conditions. This invention has such characteristics as easy usage, simple process, and controllable heat release. The composite can be widely used as mounting materials for heat-release rubber hard plaster or balck plaster, heat-release medical products for hot fomrntation, and other industrial products.

Owner:刘永录

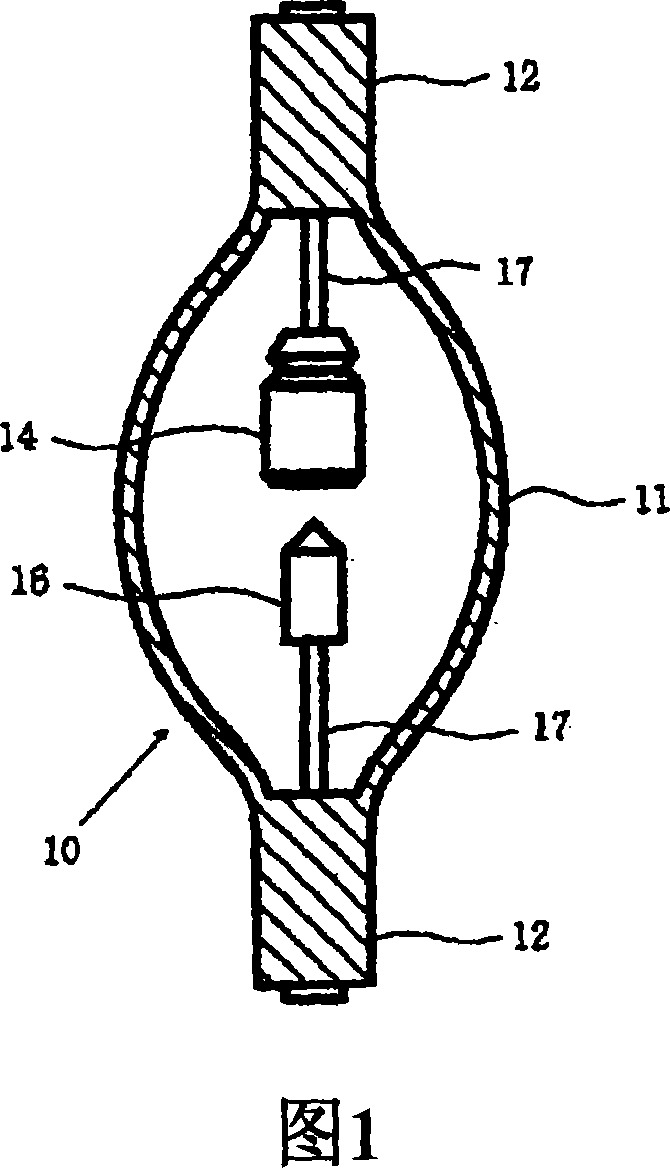

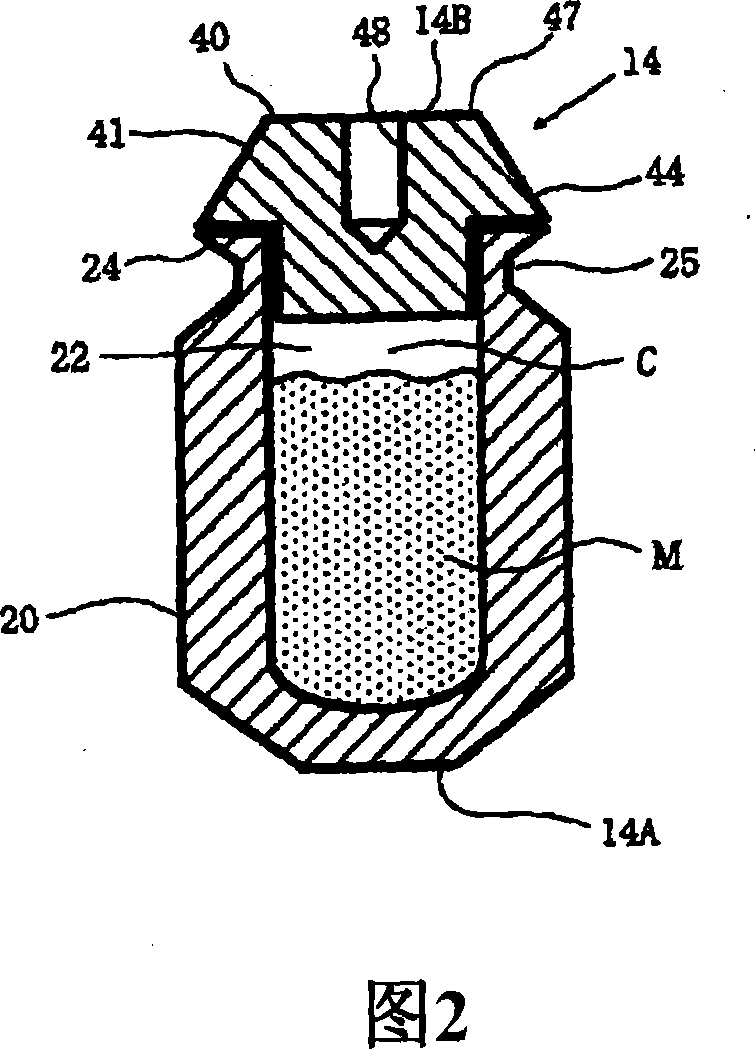

Discharge lamp

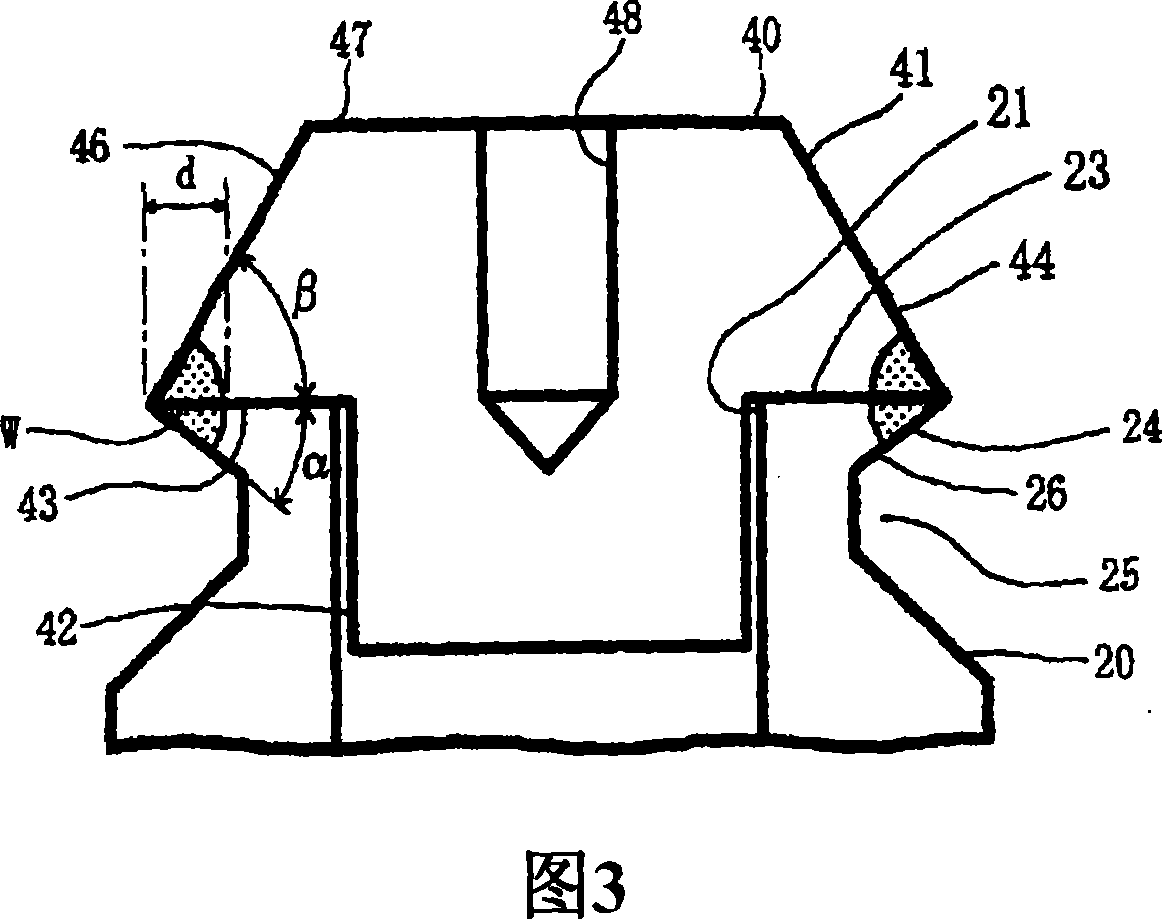

ActiveCN101055829AAvoid breakingNo evaporationHigh-pressure discharge lampsGas-discharge lampSharp angle

The invention provides a discharge lamp, which is provides with an electrode which is formed by that the electrode is composed of a cover part and a basic body part which is provided with a basic body part side flange part. The cover part is provided with an embedding part and a cover part mainbody which is provided with a cover part side flange part. A heat conductor is arranged in an enclosed space in the electrode; the electrode can not be damaged when the lamp is ignited and can work stably. In the electrode of the discharge lamp, the width in the radial direction of the cirque welding parts of the basic part slide flat surface and the cover side flat surface ranges from 0.8-3.0mm; furthermore, in an axial profile of the basic body part side flange part, the angle alpha of the basic body part side flange apex angle which is formed by the basic body part side flat surface and the basic body part side inclined surface is a sharp angle more than 30 DEG; in the axial profile of the cover part side flange part, the angle Beta of the cover part side flange apex angle which is formed by the cover part side flat surface and the cover part side inclined surface is a sharp angel more than 30 DEG; furthermore, the sum of the angle Alpha and the angle beta is less than 160 DEG.

Owner:USHIO DENKI KK

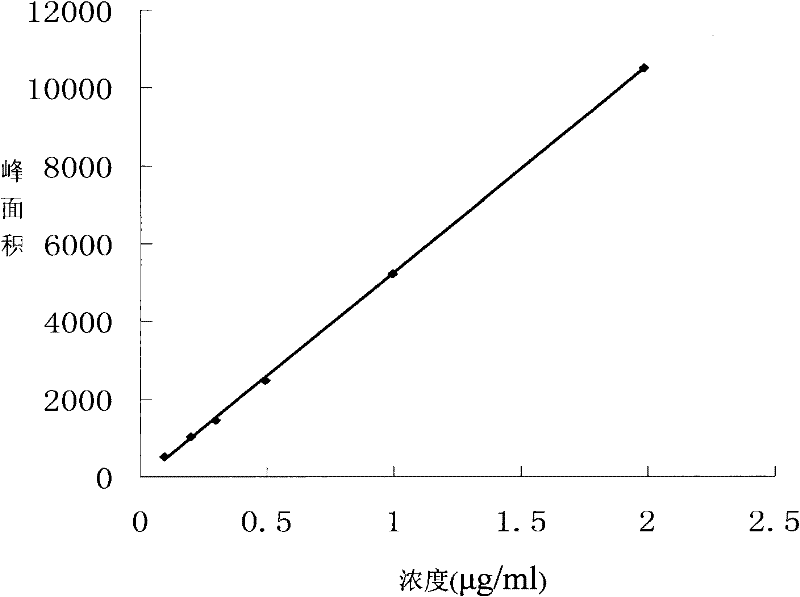

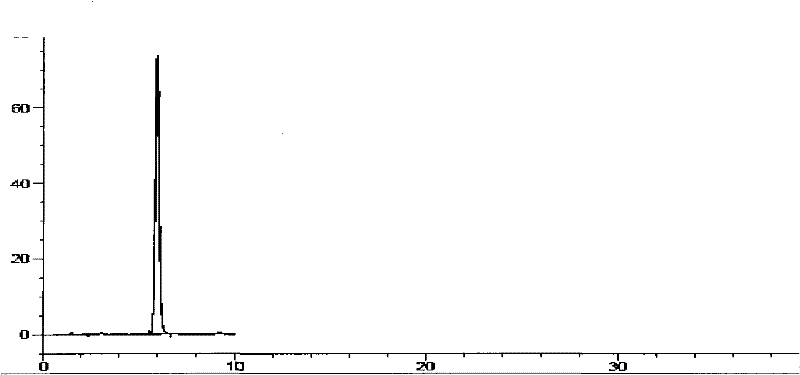

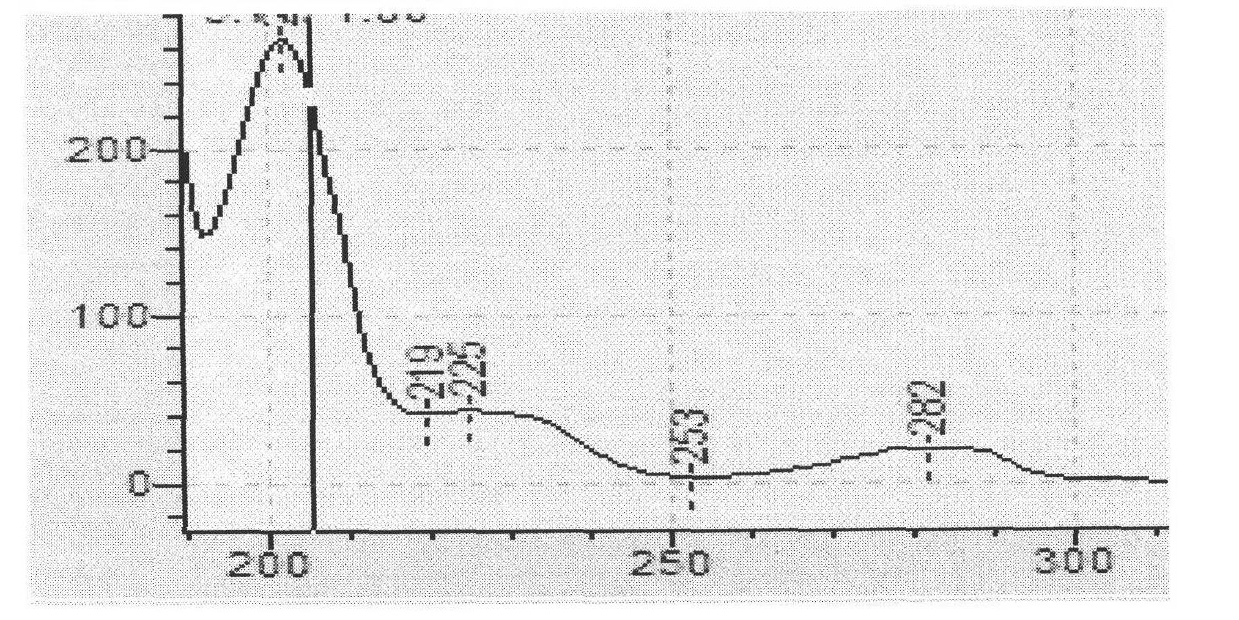

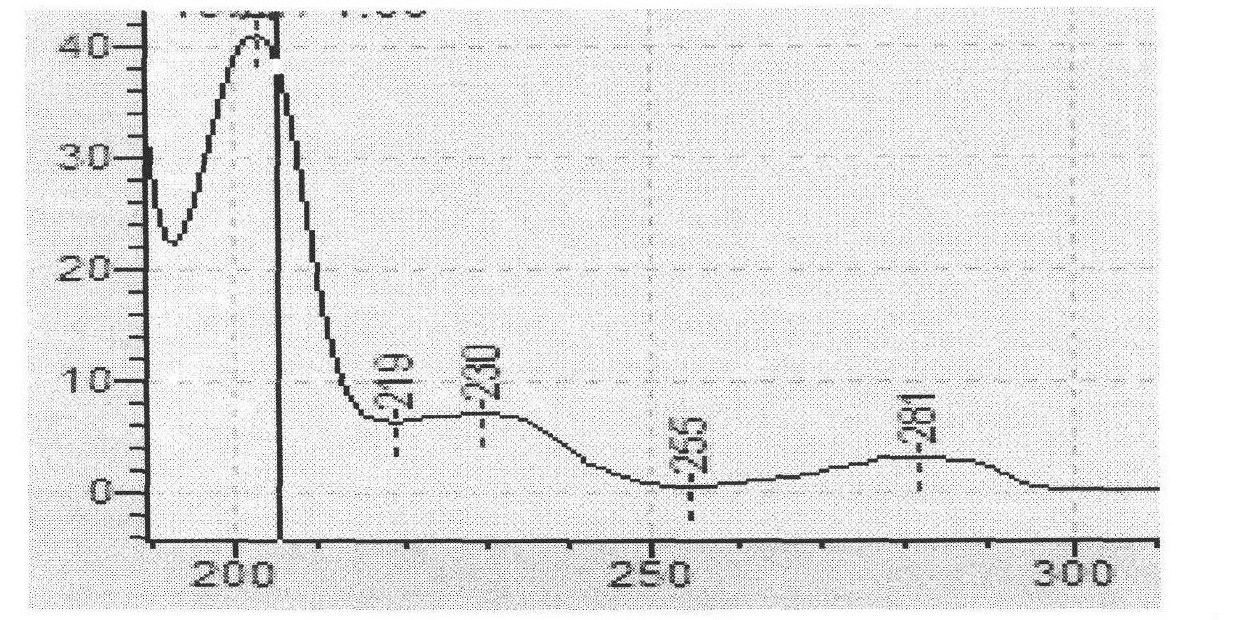

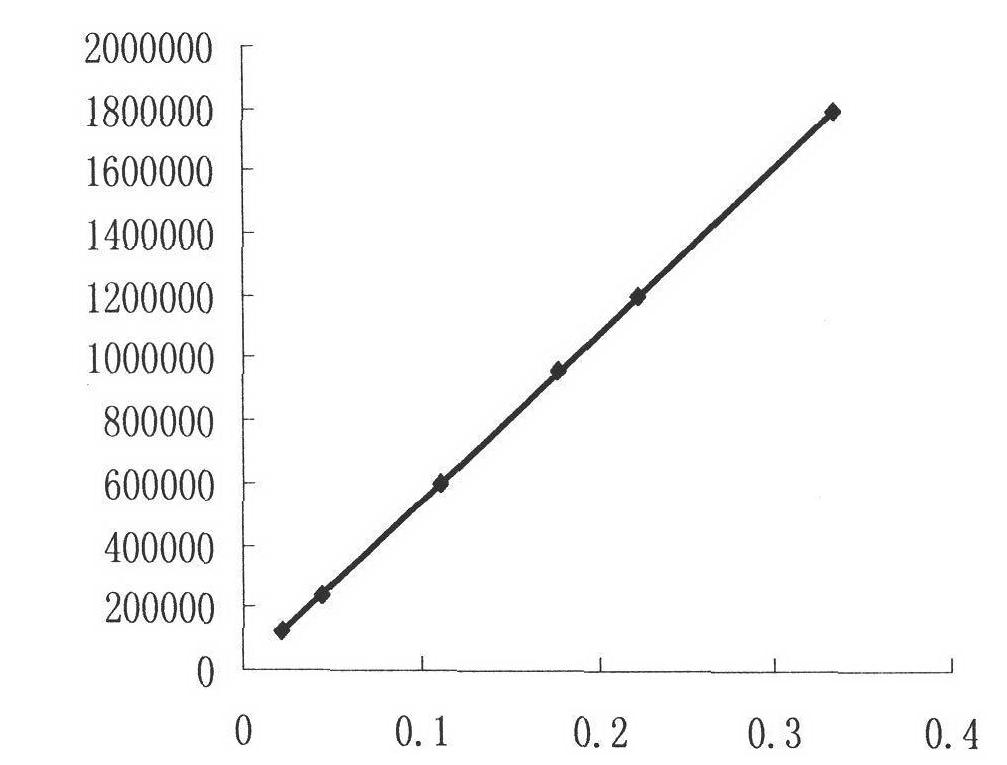

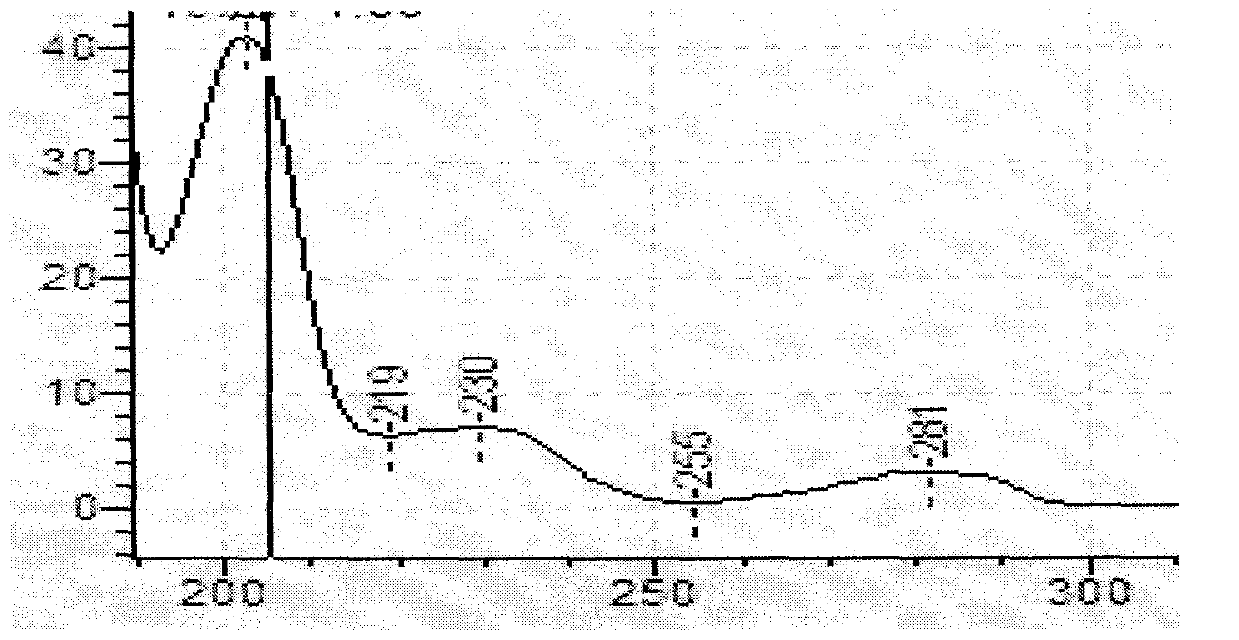

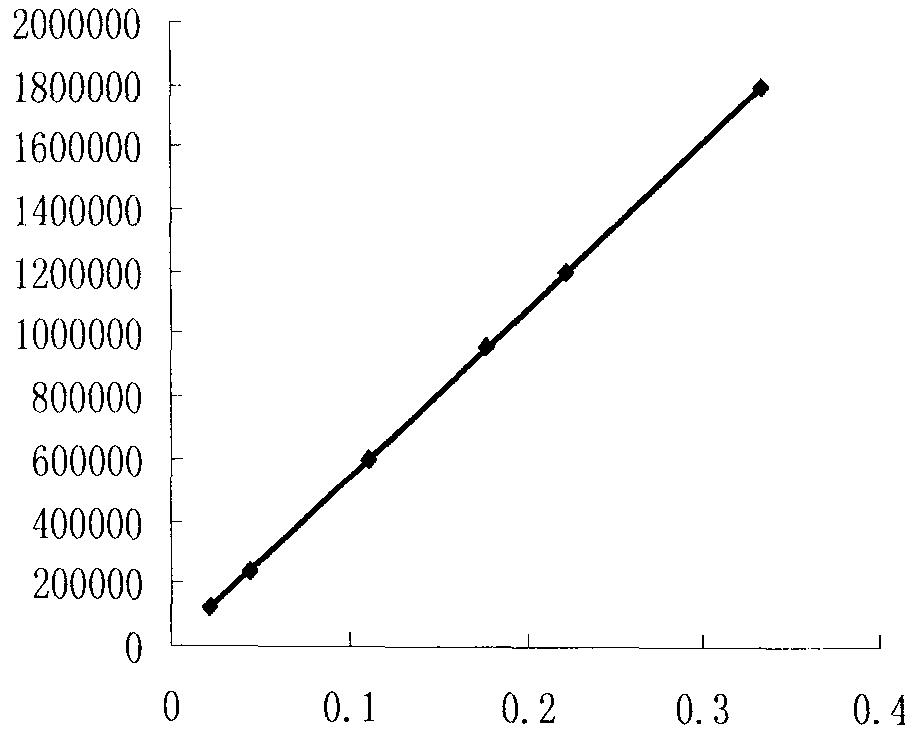

Method for quantitatively measuring baicalein and wogonin in scutellaria baicalensis simultaneously

InactiveCN102128889AThe method of proof is simpleQuick proof methodComponent separationPlant ingredientsPhosphoric acidLength wave

The invention discloses a self enzymolysis approach method of baicalein and wogonin in scutellaria baicalensis. The measurement method disclosed by the invention comprises the following steps of: carrying out enzymolysis on saponin compounds, such as baicalin, wogonoside, and the like in an aqueous solution by utilizing enzyme contained in scutellaria baicalensis at a proper temperature; after finishing enzymolysis, adding acid methanol; maintaining the stability of the baicalein when killing scutellaria baicalensis enzyme; fully dissolving emzymatically-decomposed baicalein; and filtering and adding filtered liquid as a sample solution. The baicalein and wogonin in the scutellaria baicalensis are simultaneously measured by an HPLC (High Performance Liquid Chromatography) by using a methanol-0.1 percent phosphoric acid solution with the volume ratio of (51-54):(49-46) as a mobile phase and 275nm as a detecting wavelength. The method has the advantages of simplicity, convenience, high speed, complete enzymolysis of components to be detected, and favorable wave crest separation. The self enzymolysis approach method of baicalein and wogonin in scutellaria baicalensis is reported for the first time and provides real basic content data for the full extraction and separation of the components. A content practical measured value of the baicalein is larger than a theoretical value calculated by molecular weights of baicalin and baicalein.

Owner:北京赛尔泰和生物医药科技有限公司

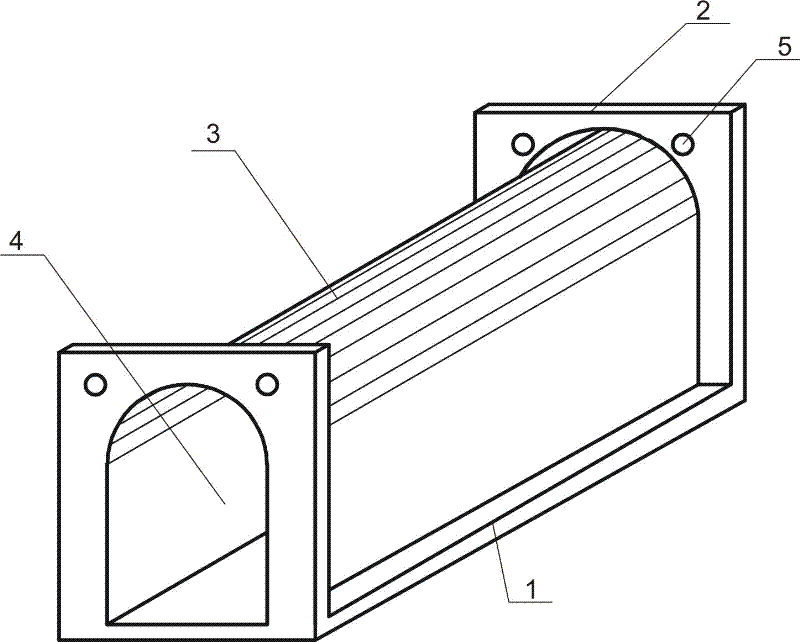

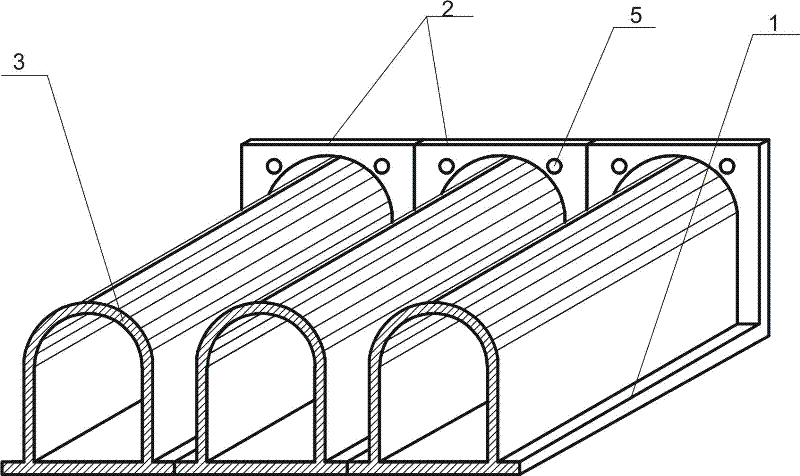

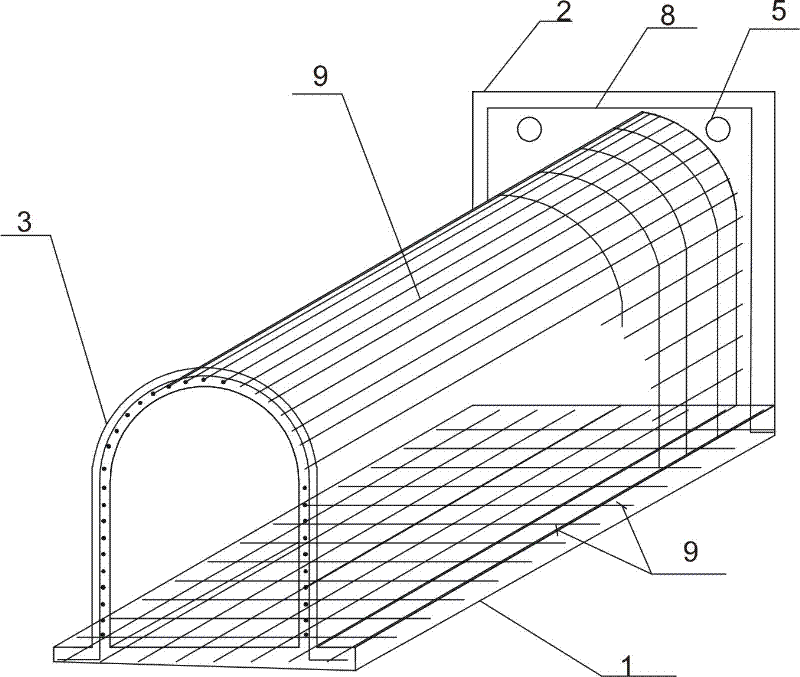

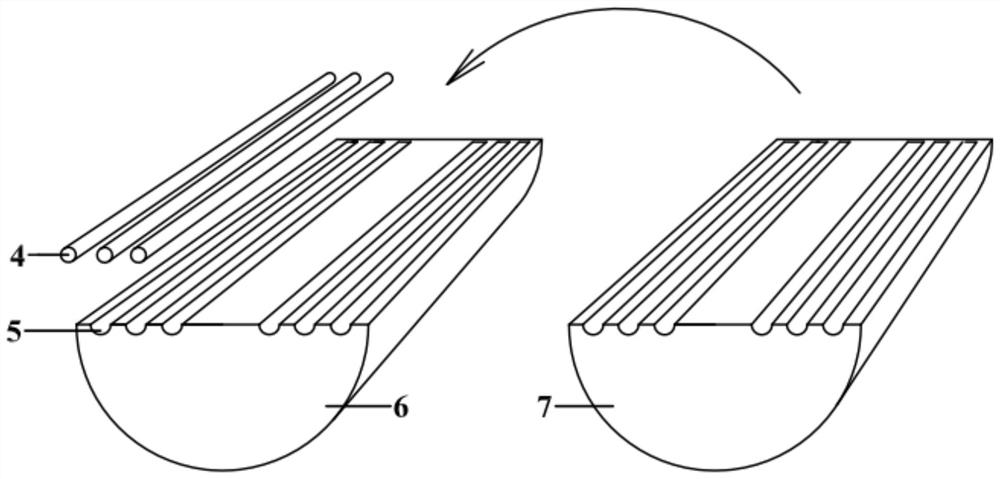

Fabricated culvert member and construction method thereof

ActiveCN102373675AImprove water delivery capacityReduce evaporationGround-workArchitectural engineeringMaterial resources

The invention relates to a fabricated culvert member and a construction method thereof. The fabricated culvert member comprises a base plate, a rib plate and an arc plate, wherein the rib plate is in a gantry shape and is fixed on both ends of the arc plate, the lower ends of the arc plate and the rib plate are fixed on the base plate, the three plates are integrated, and a space between the arc plate and the base plate is a drainage channel. The fabricated culvert member provided by the invention has the advantages of factory fabrication, field assembly, simple operation, guaranteed quality,quick construction speed, simple structure, reasonable force bearing, simple maintenance (installation, removal and replacement, good integrity, high strength, large adaptive deformation, no pollution, small environmental influence, practicability, economy and obvious effect, the maintenance of the culvert member saves 20-40% human resources, material resources and money less than that of common masonry pebble revetments, town bottom or buried circular pipe culverts, and the water utilization coefficient of the canal system can be greatly increased (evaporation and seepage are reduced).

Owner:余跃建 +1

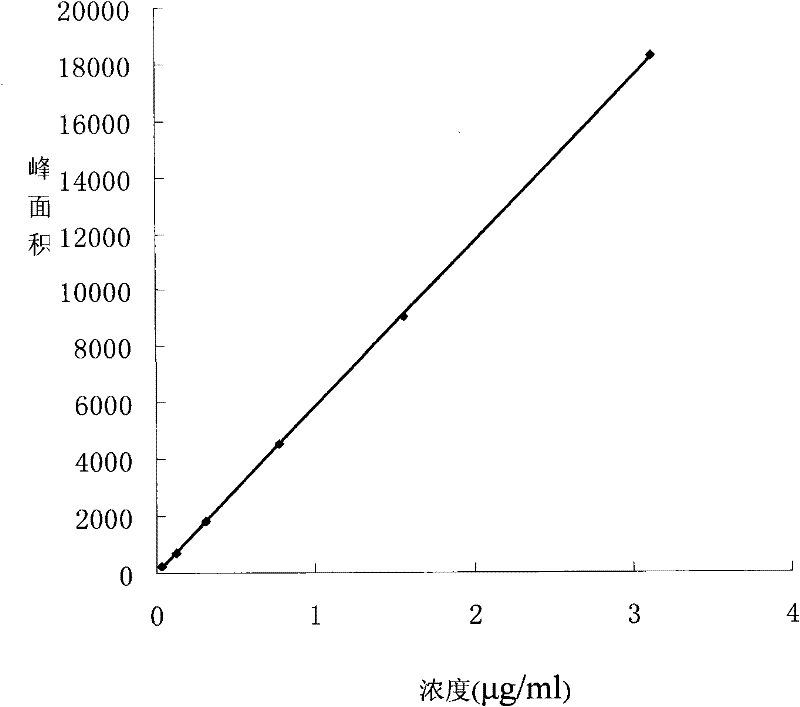

HPLC (High Performance Liquid Chromatography) quantitative method for cephaeline hydrochloride and ipecine hydrochloride in ipecacuanha medicinal material and preparation of ipecacuanha medicinal material

The invention relates to a HPLC (High Performance Liquid Chromatography) quantitative method for cephaeline hydrochloride and ipecine hydrochloride in an ipecacuanha medicinal material and a preparation of ipecacuanha medicinal material. The method is characterized by comprising the following steps: firstly, performing common isocratic elution according to PHLC method, and taking acetonitrile-carbinol-0.1% of phosphoric acid at a volume ratio of (8-9.5):(3-5):(86-88) as a flowing phase, wherein a detecting wavelength is 205nm; and simultaneously measuring the contents of the cephaeline hydrochloride and ipecine hydrochloride in the ipecacuanha medicinal material and a fluid extract, extract and tincture thereof so as to end the history of the measurement of total alkaloids of the ipecacuanha alkaloids in an acid base titration form according to the standard in multiple countries: after performing column chromatography separation for 4 times, respectively measuring the cephaeline hydrochloride and ipecine hydrochloride through delta A at 283nm and 350nm by adopting differential spectrophotometry. According to the method, only acidic aqueous carbinol or aqueous carbinol is used; after fine powder of the medicinal material is ultrasonically extracted or each preparation is diluted, a certain amount of subsequent filtrate is absorbed; and an alumina column is used for removing impurities so as to measure. The method is quick, convenient, accurate and capable of reappearing.

Owner:JING JING PHARMA

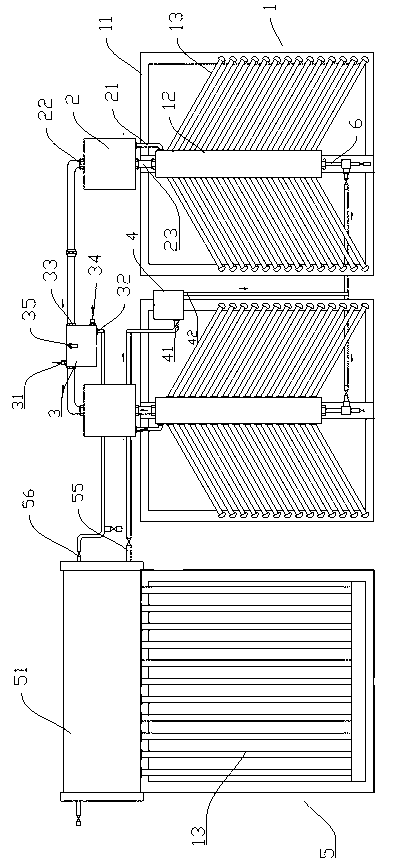

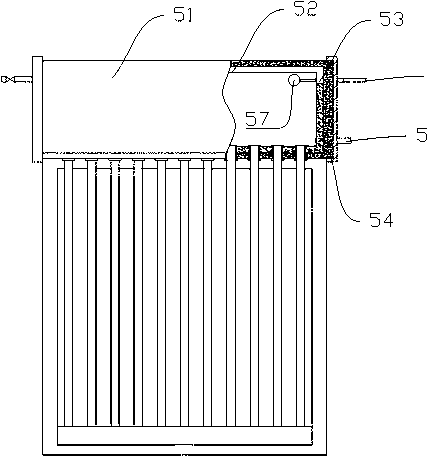

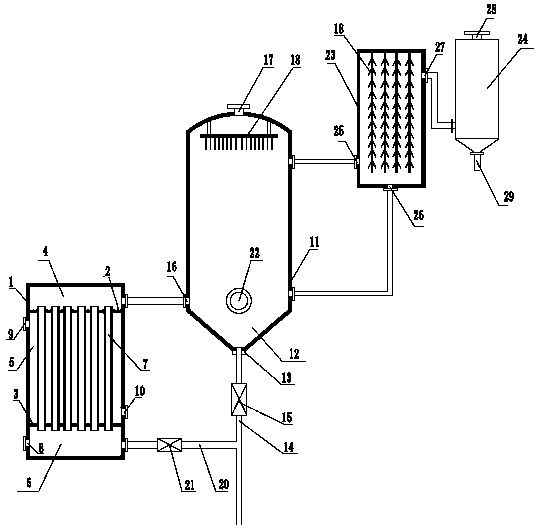

Solar seawater desalination system

ActiveCN103342400AFast deliveryQuick Pass PoolingGeneral water supply conservationSeawater treatmentWater circulationEngineering

The invention discloses a solar seawater desalination system, comprising a solar heating device, a steam-water separator, a condensation device, a water supplementing device and a warming and heat-storing device, wherein a header is vertically arranged, a water supplementing outlet of the water supplementing device is communicated with a water inlet of the header, the steam-water separator is arranged between and connected with an upper end opening of the header and the condensation device, a steam separating opening of the steam-water separator is communicated with a steam inlet of the condensation device, and a water supplementing inlet of the water supplementing device is connected with the warming and heat-storing device. The solar seawater desalination system provided by the invention is used for solar seawater desalination and has the characteristics of a fast water circulation speed, rapid heat transfer, long duration of continuous distillation, little influence by weather, good adaptability, etc. Moreover, in the operation process of the system, integral power consumption and energy dissipation are small, operation cost is low, latent heat of cooling of steam is effectively used, and a high utilization rate of solar energy is realized.

Owner:SHANDONG KAIYUAN ELECTRONICS

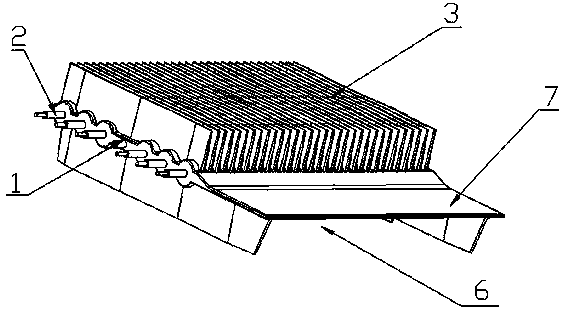

Electric heating plate with unbalanced fins shaped like Chinese character 'feng' and heating and humidification device

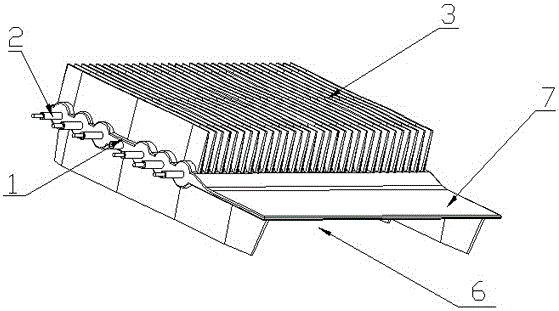

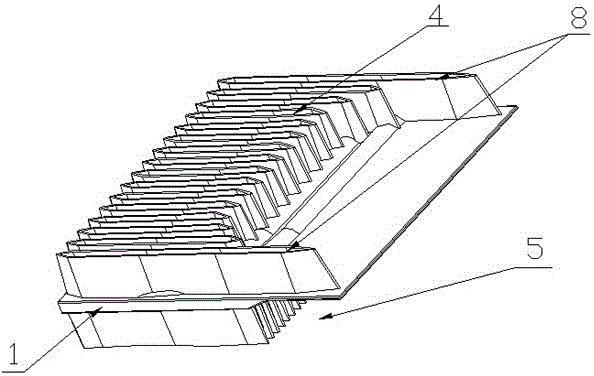

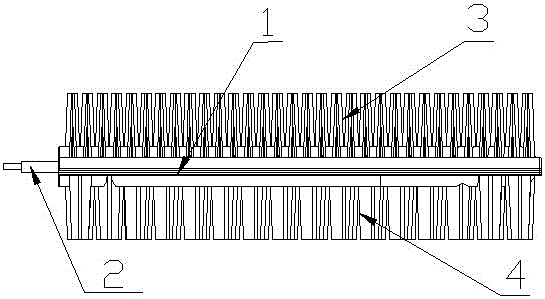

ActiveCN103791621AAvoid threadingOvercome or even eliminate thermal resistanceAir heatersHeating element materialsChinese charactersEvaporation

The invention provides an electric heating plate with unbalanced fins shaped like a Chinese character 'feng'. The electric heating plate with the unbalanced fins shaped like the Chinese character 'feng' comprises a substrate, wherein S-shaped electric heating tubes are cast in the substrate, air heating fins and evaporation fins are cast on the two sides of the substrate respectively, a separating plate is arranged at the front end of the substrate in an extension mode, and is used for isolation between a main ventilation area and a water mist evaporation area, evaporation baffles are arranged on the left side and the right side of the evaporation fins respectively, and the evaporation fins are thin and high. The invention further provides a heating and humidification device. The heating and humidification device comprises a heat-insulating shell, wherein an air suction inlet and an exhaust outlet are formed in the two ends of the heat-insulating shell respectively, and centrifugal fans, nozzles, the electric heating plate with the unbalanced fins shaped like the Chinese character 'feng' and a gas-and-steam mixing area are arranged in sequence from the air suction inlet. According to the electric heating plate with the unbalanced fins shaped like the Chinese character 'feng' and the heating and humidification device, the mode that operation of heating drying and operation of water supply vaporization humidification are independently carried out or are carried out in parallel is achieved, and the effects that the main ventilation area is free of water scale and the water mist evaporation area is descaled in a thermal shock mode are ensured.

Owner:浙江鼎美智装股份有限公司

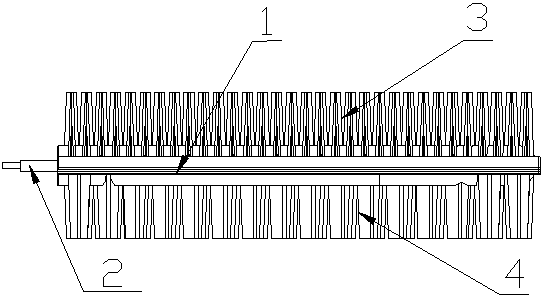

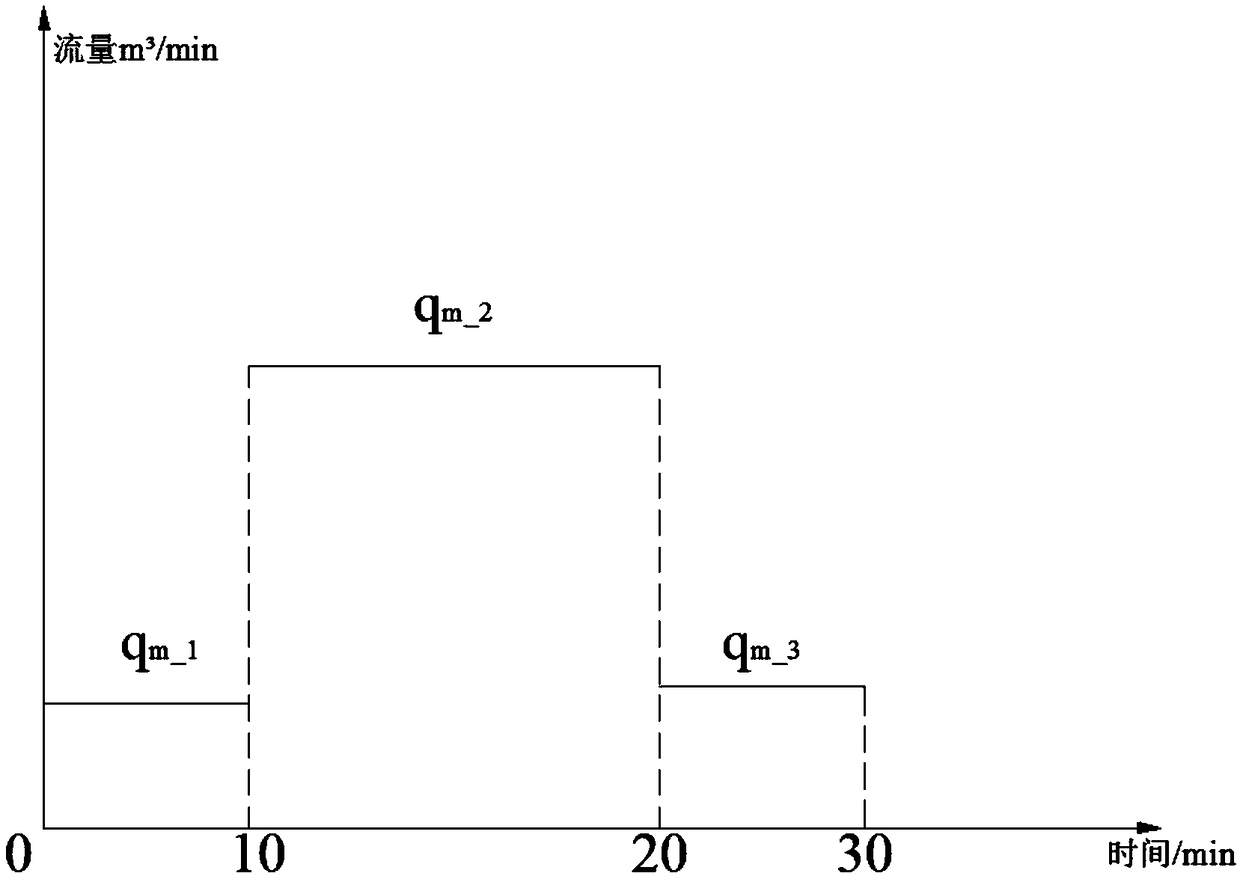

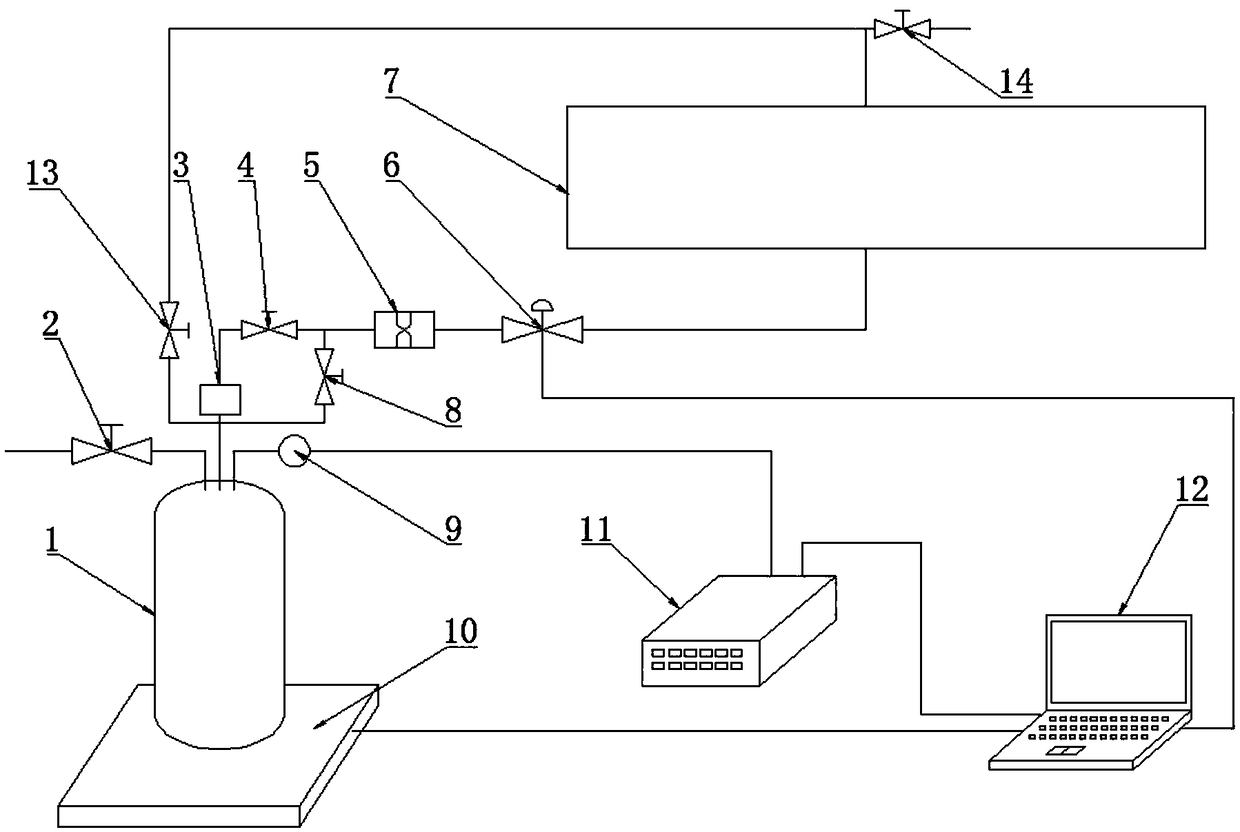

Low-temperature liquid filling method and system for detecting evaporation rate of low-temperature heat insulation gas bottle

ActiveCN109373178AThe interface state is stableNo evaporationFluid handledContainer discharging methodsGas cylinderBottle

The invention discloses a low-temperature liquid filling method and system for detecting the evaporation rate of a low-temperature heat insulation gas bottle. The method comprises the following stepsthat the low-temperature heat insulation gas bottle is preheated, an emptying valve and a bypass valve are opened, the bypass valve communicates with a low-temperature storage tank, a main valve is closed, the bypass valve conducts second-time pre-cooling on the low-temperature heat insulation gas bottle with the first preset filling mass rate, large-flow filling of the low-temperature heat insulation gas bottle is conducted, the aperture of an electric valve is increased, the main valve is opened, the bypass valve is closed, the low-temperature heat insulation gas bottle is filled with liquidfrom the low-temperature storage tank with the second preset filling mass rate through the main valve via a rotational flow generator, and the process is stopped when the liquid mass in the low-temperature heat insulation gas bottle reaches the 75% filling rate; and the aperture of the electric valve is reduced, the low-temperature heat insulation gas bottle is filled with the liquid from the low-temperature storage tank with the third preset filling mass rate through the main valve via the rotational flow generator, the main valve is closed after filling is conducted to the rated filling rate, standing is conducted for the preset time till the inner liquid surface stops rotating, and filling is finished.

Owner:XI AN JIAOTONG UNIV +1

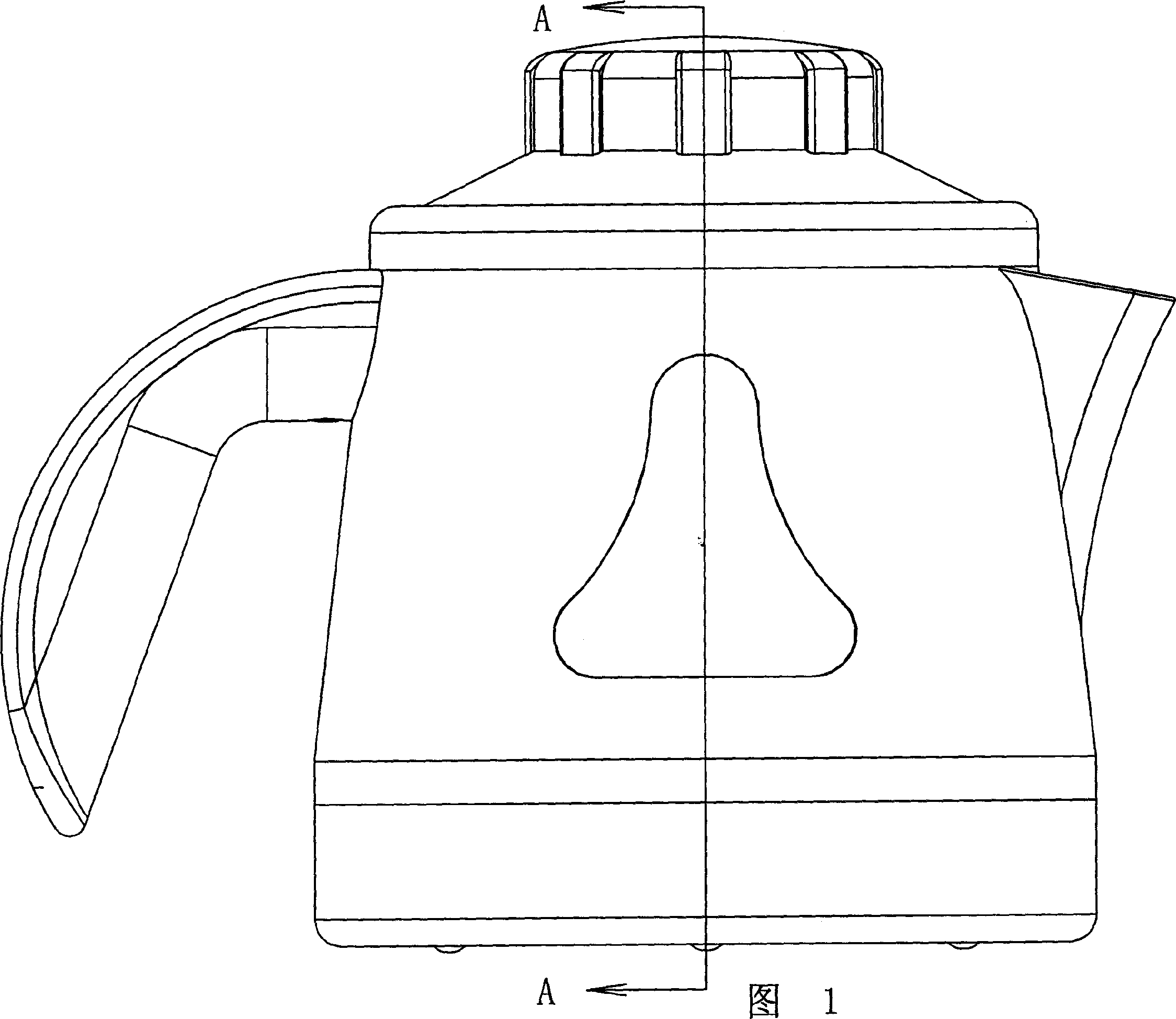

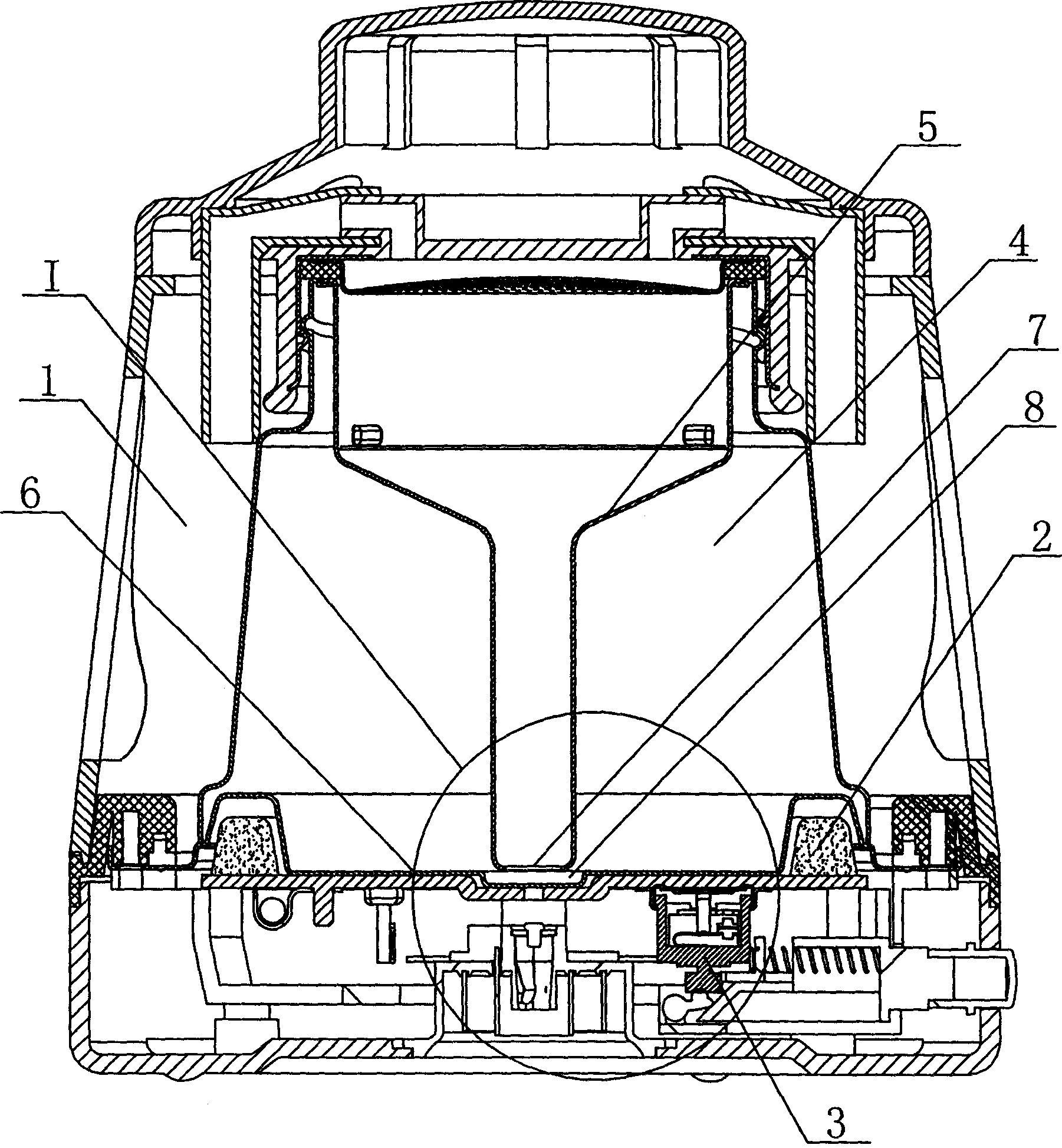

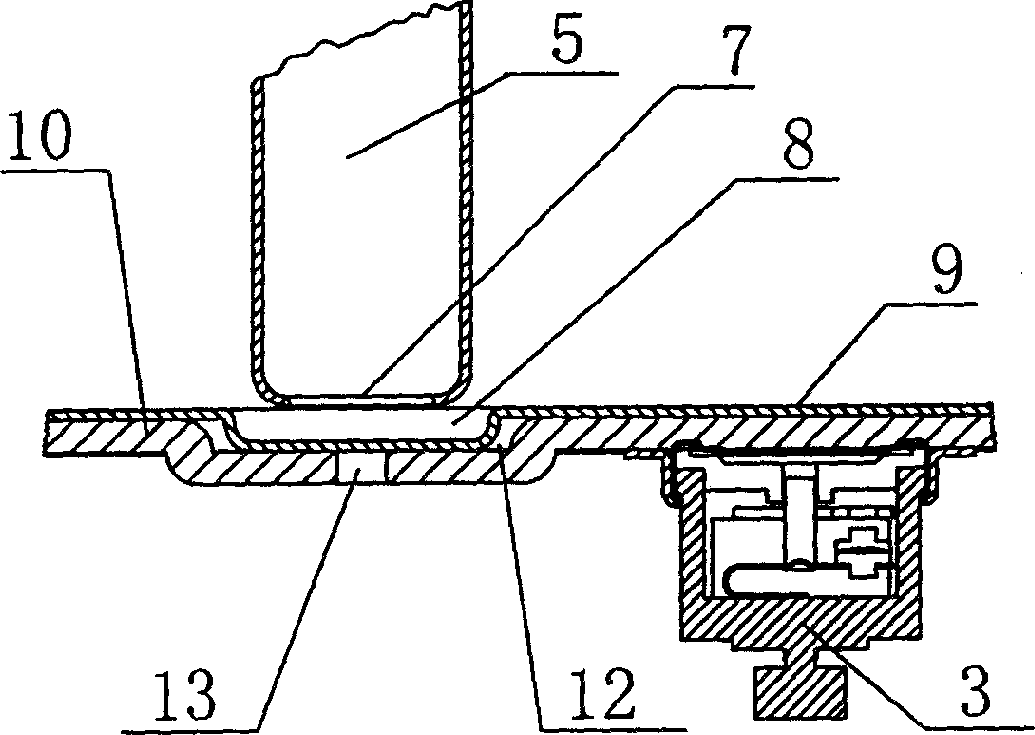

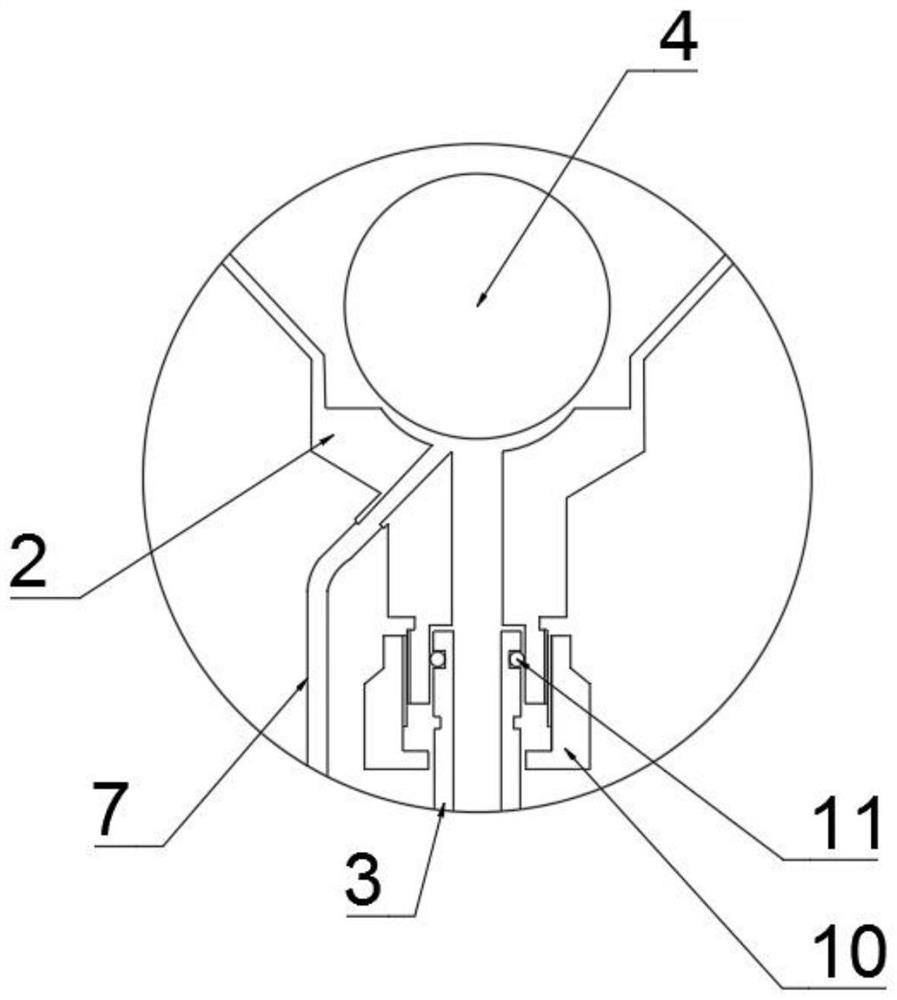

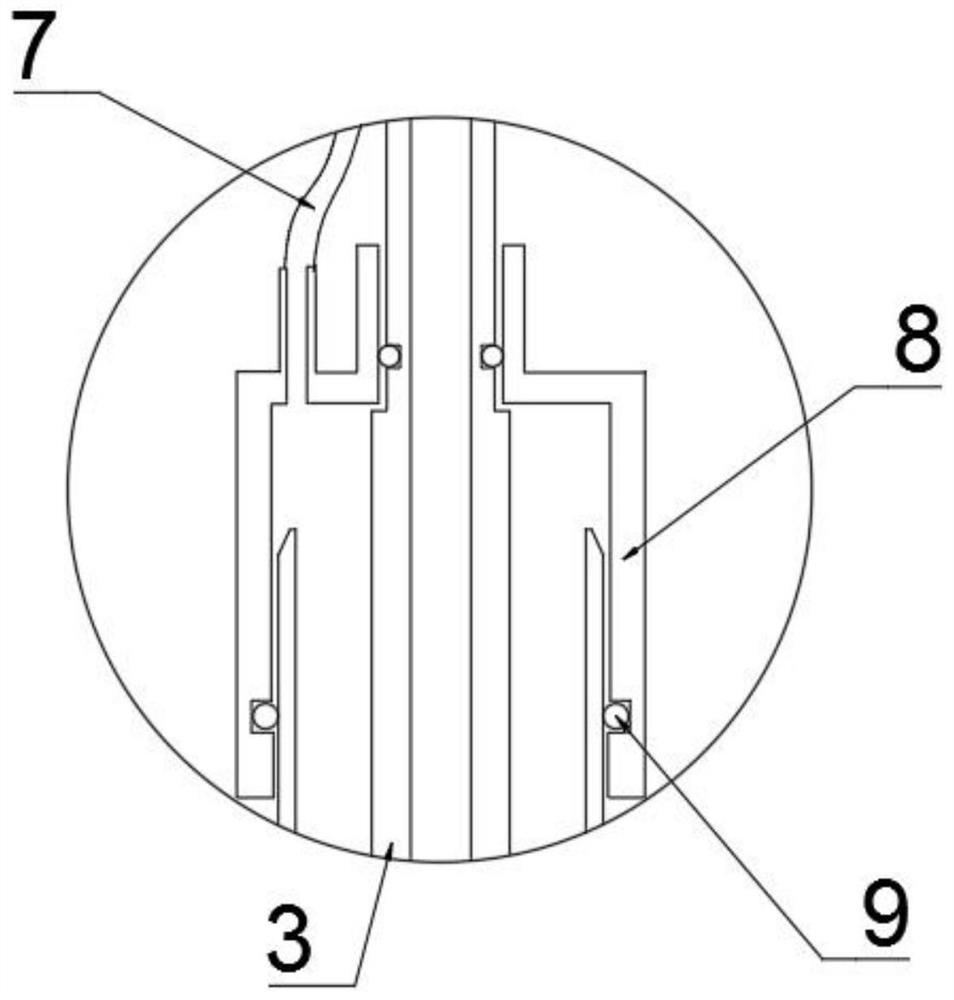

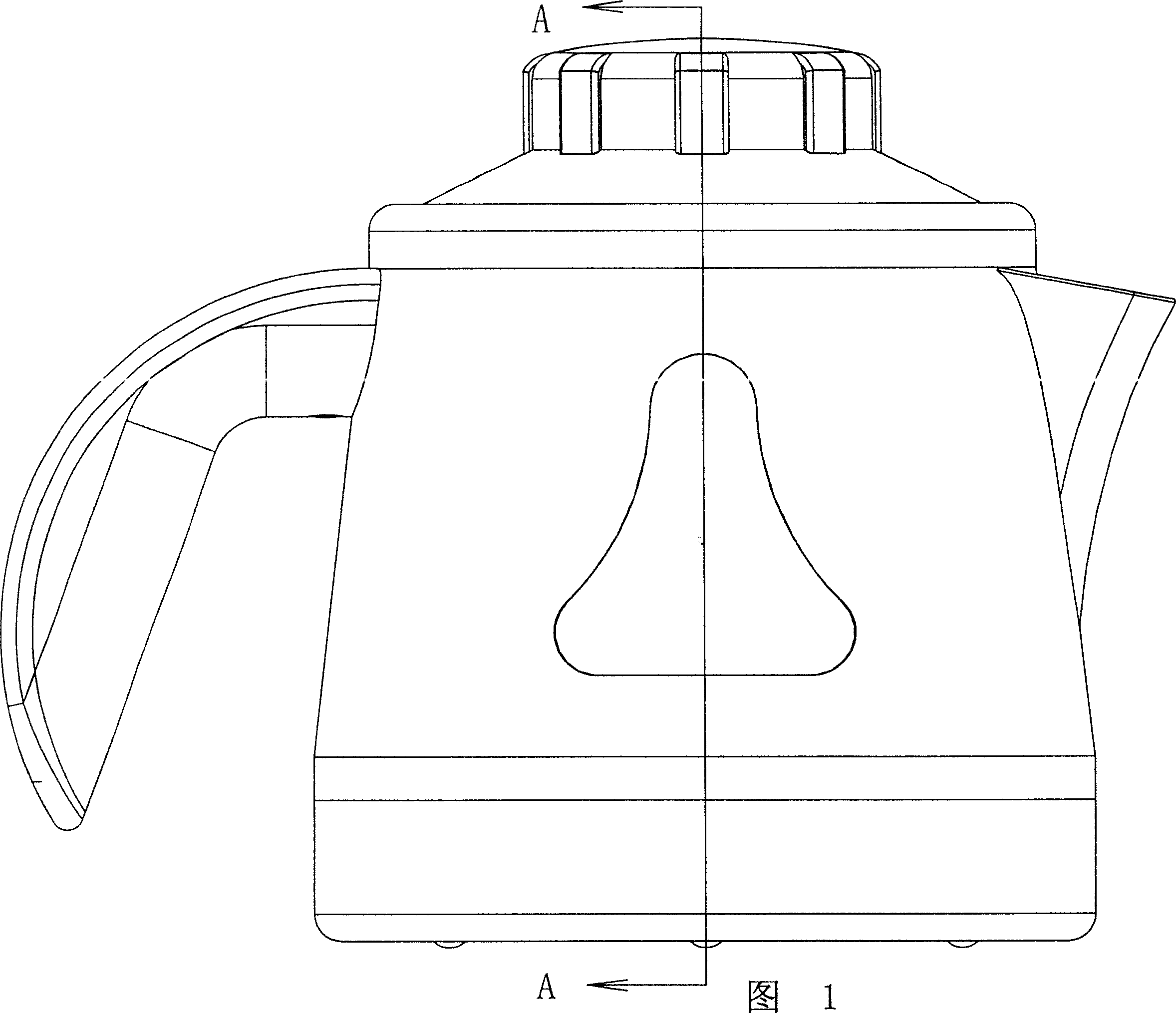

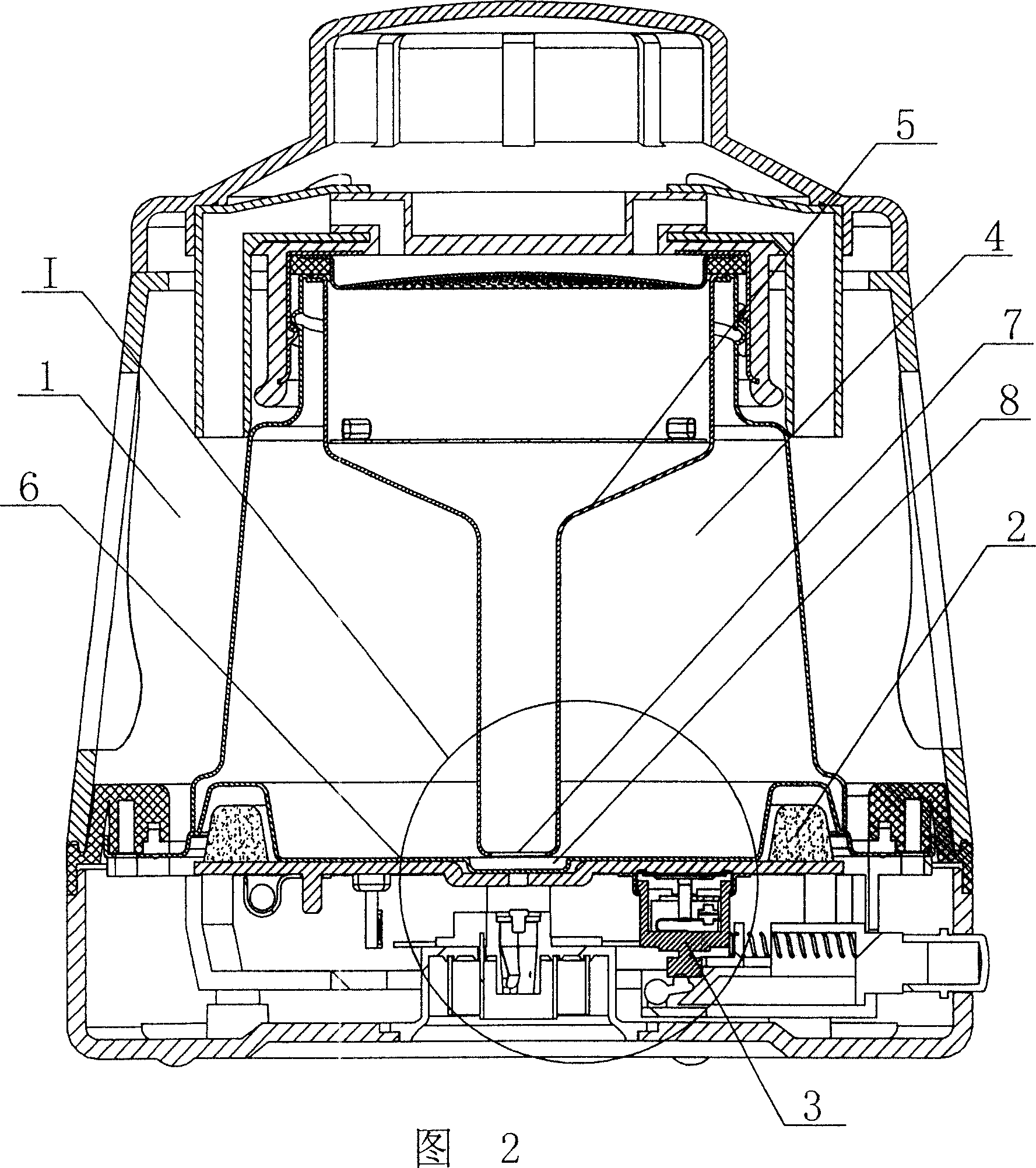

Electric kettle for boiling beverage

InactiveCN1701738AGuaranteed to burn dryNo evaporationWater-boiling vesselsBeverage vesselsElectric heatingPneumatic pressure

The invention discloses an electric kettle for boiling beverage, which comprises a kettle body for containing water, an electric heater arranged on the bottom of the kettle body, a thermoregulator for preventing heating when the water is boiling, a funnel arranged on the port of the kettle for guiding boiling water into a water container, a recessed portion is arranged on a water drainage position corresponding the funnel on the bottom surface, the boiling water on the bottom surface can be collected to the recessed portion and discharged from the water drainage. When the water on the bottom surface decreases, the remaining water will be centralized to the recessed portion at the action of atmospheric pressure, one part of the kettle surface will be exposed in the air, thus switching off the power supply for the electric heater, so as to guarantee the complete infusing for the coffee bean powder or tea.

Owner:邵志成

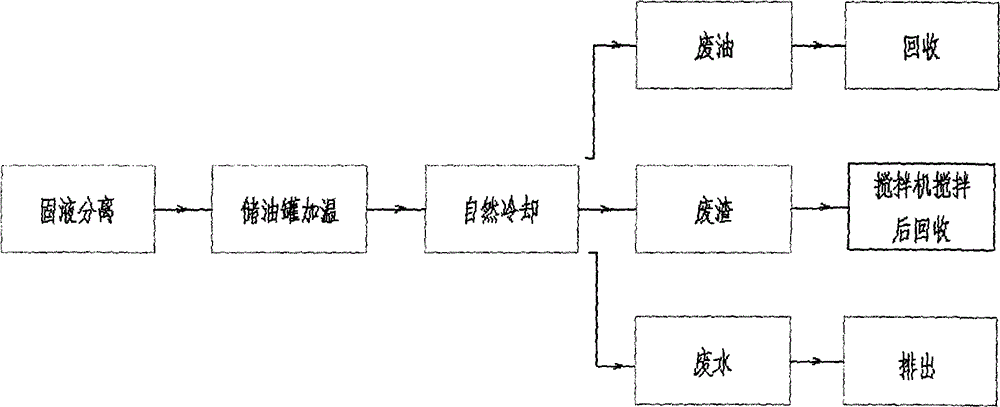

Waste grease innocent treatment method and equipment for implementing same

InactiveCN105886126ANo evaporationNo pollution in the processFatty oils/acids recovery from wasteFatty substance recovery/refiningOil and greaseHeating oil

The invention provides a waste grease innocent treatment method, comprising the steps of: firstly, putting waste grease into a solid-liquid separator to extrude out impurities in the waste grease by virtue of solid-liquid separation; then, lifting the treated waste grease into a heating oil storage tank to perform heating; next, heating the waste grease, and then naturally cooling the waste grease; then, discharging still waste oil into an outward transport package, discharging waste water by virtue of a pipe valve arranged at the lower end of the heating oil storage tank, and discharging waste residues into a stirring machine by virtue of the pipe valve; next, adding saw powder into the waste residues, performing stirring, and then discharging the waste residues into a second solid-liquid separator to perform solid-liquid separation; and finally, discharging solids, obtained after separation, by virtue of an outlet, and lifting liquid to the heating oil storage tank to perform cycle treatment. The invention also provides equipment used for the waste grease innocent treatment method to implement this type of treatment method.

Owner:安徽清溪环保科技有限公司

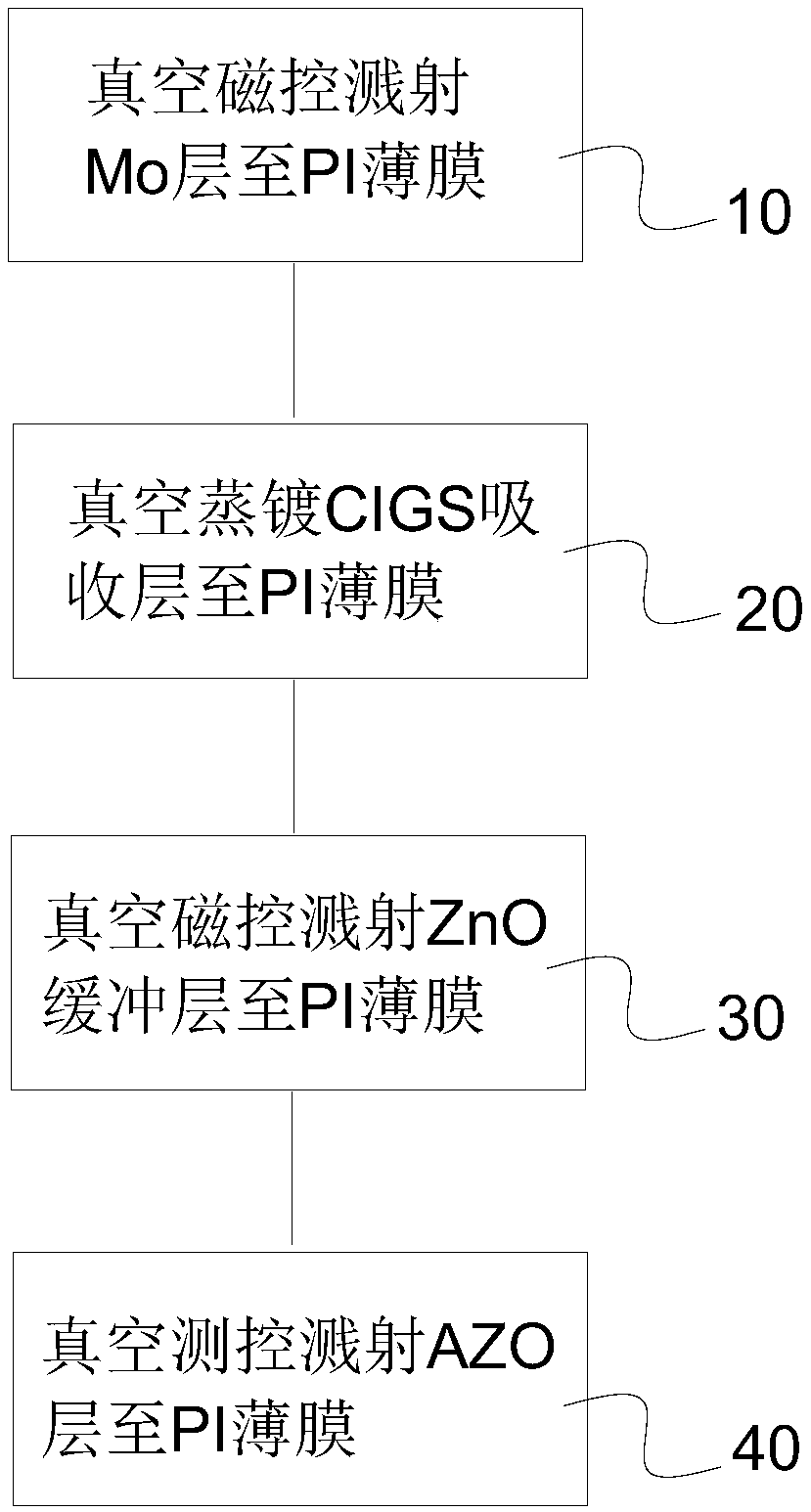

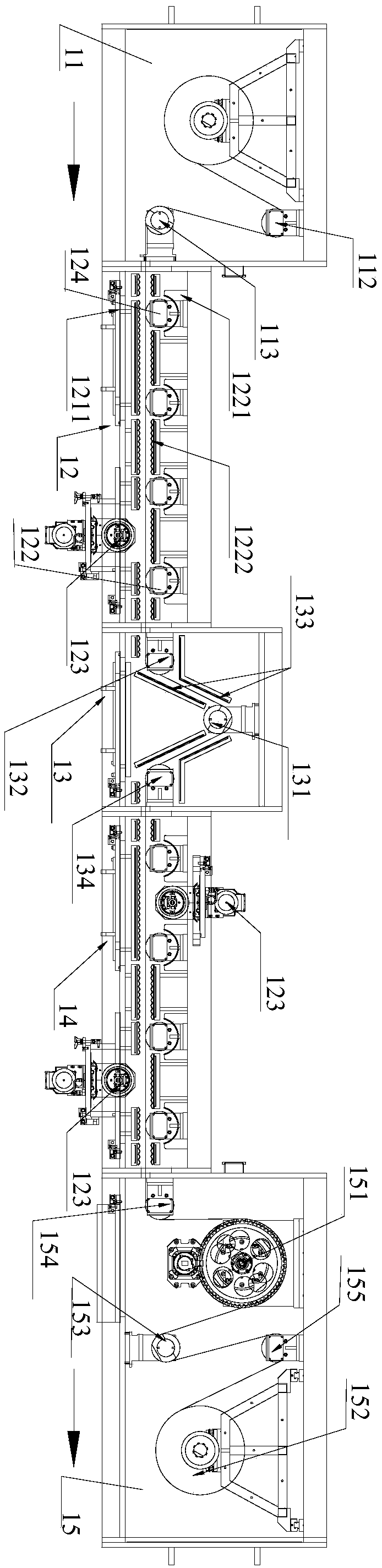

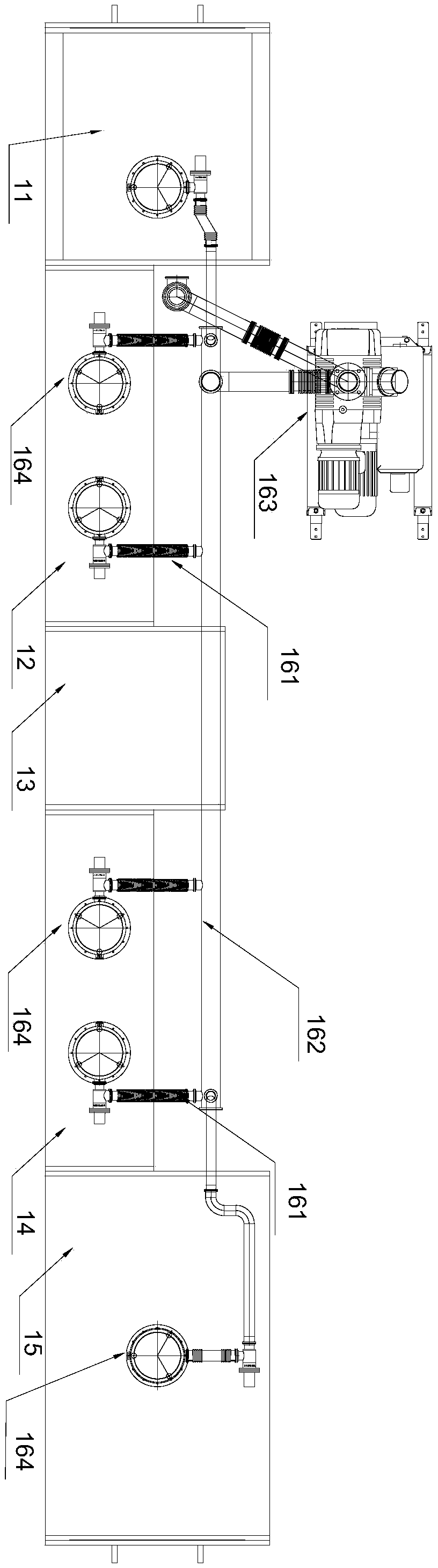

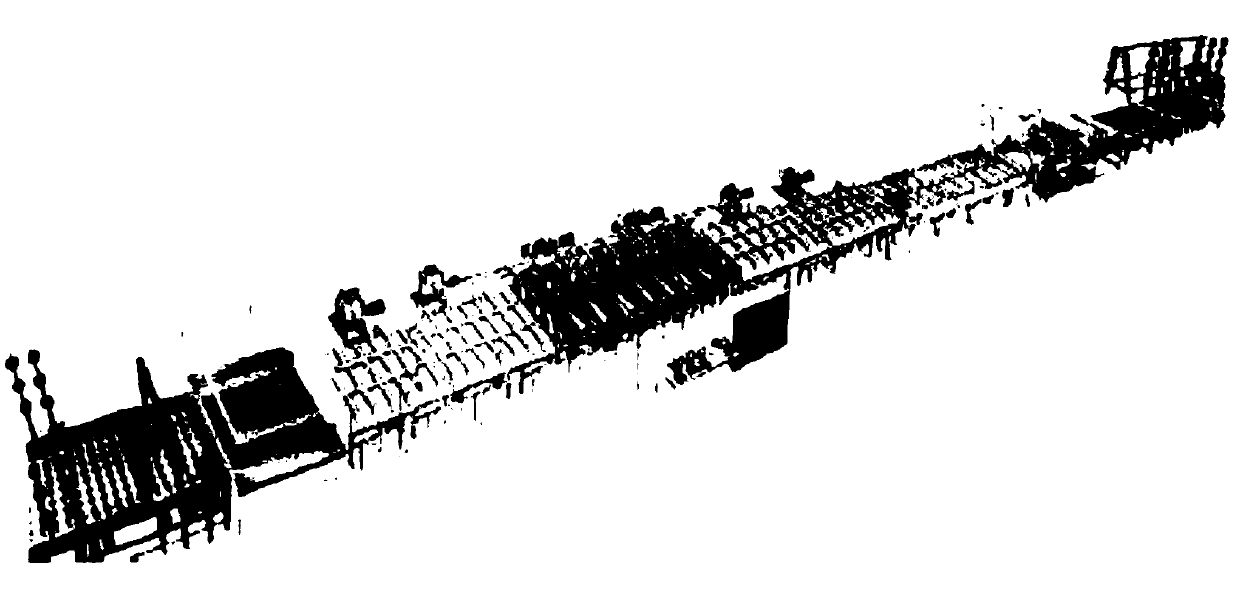

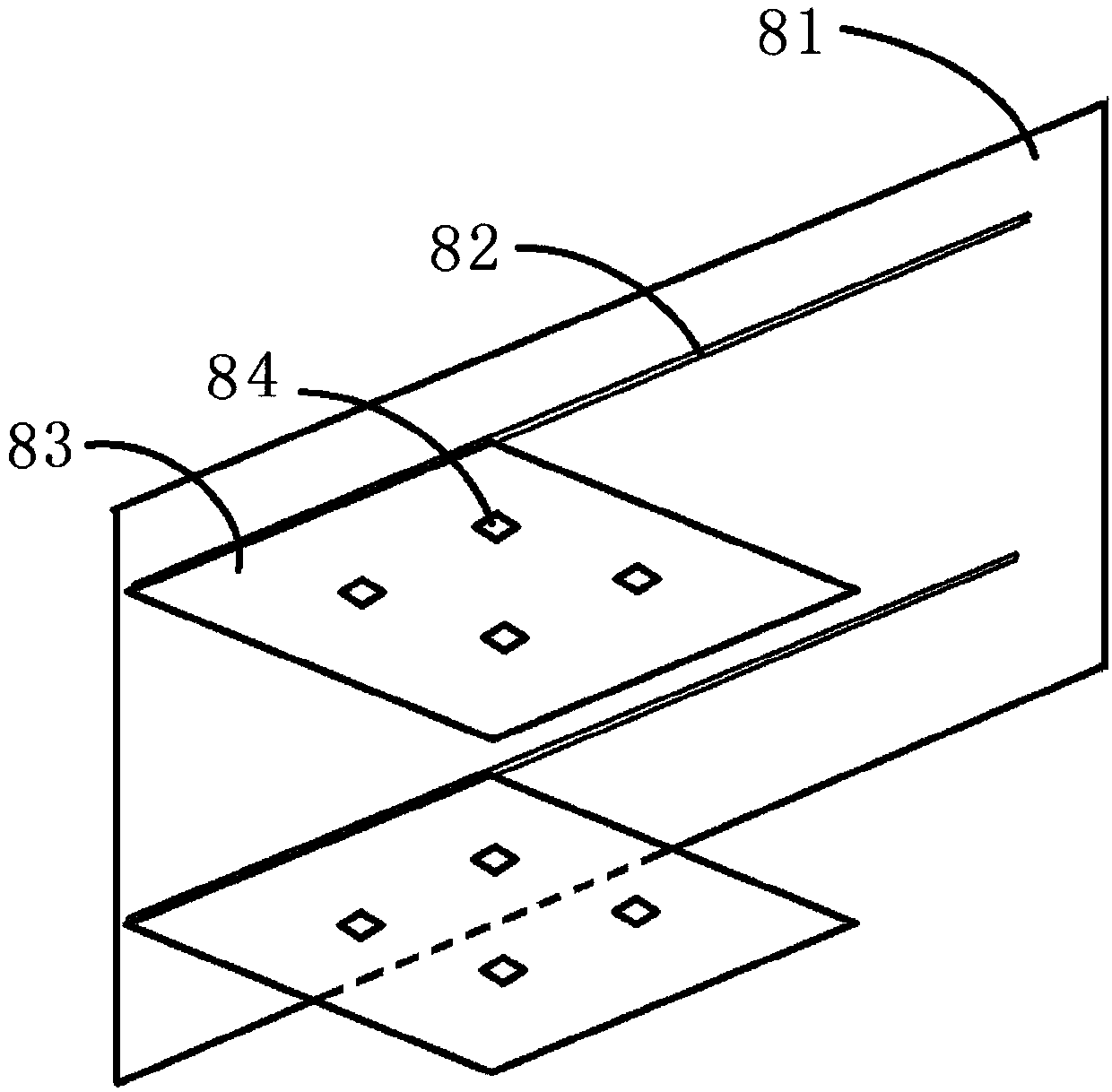

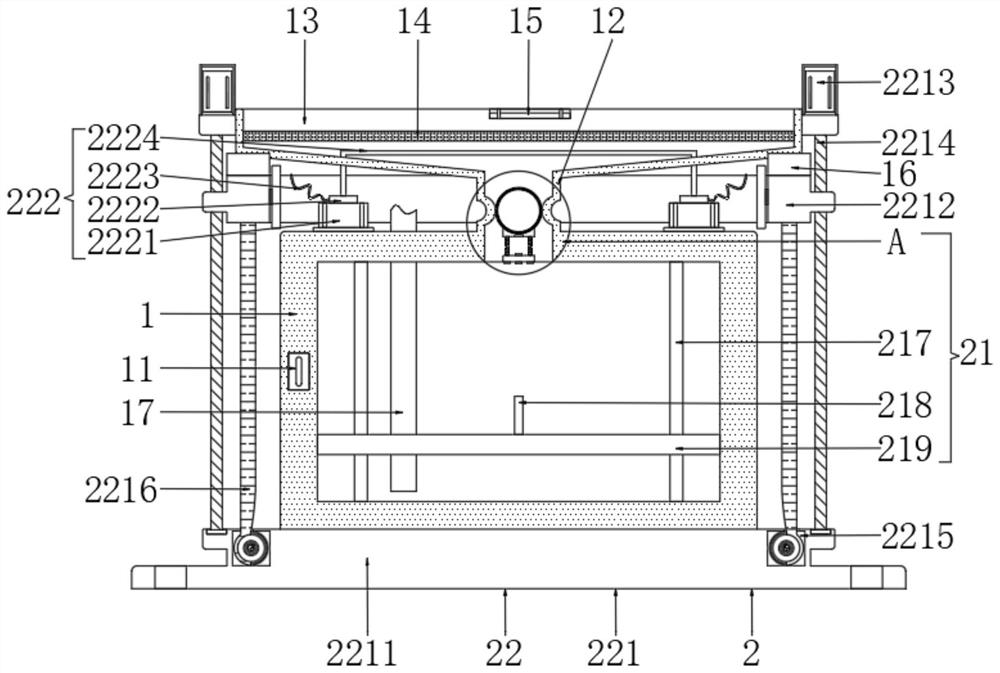

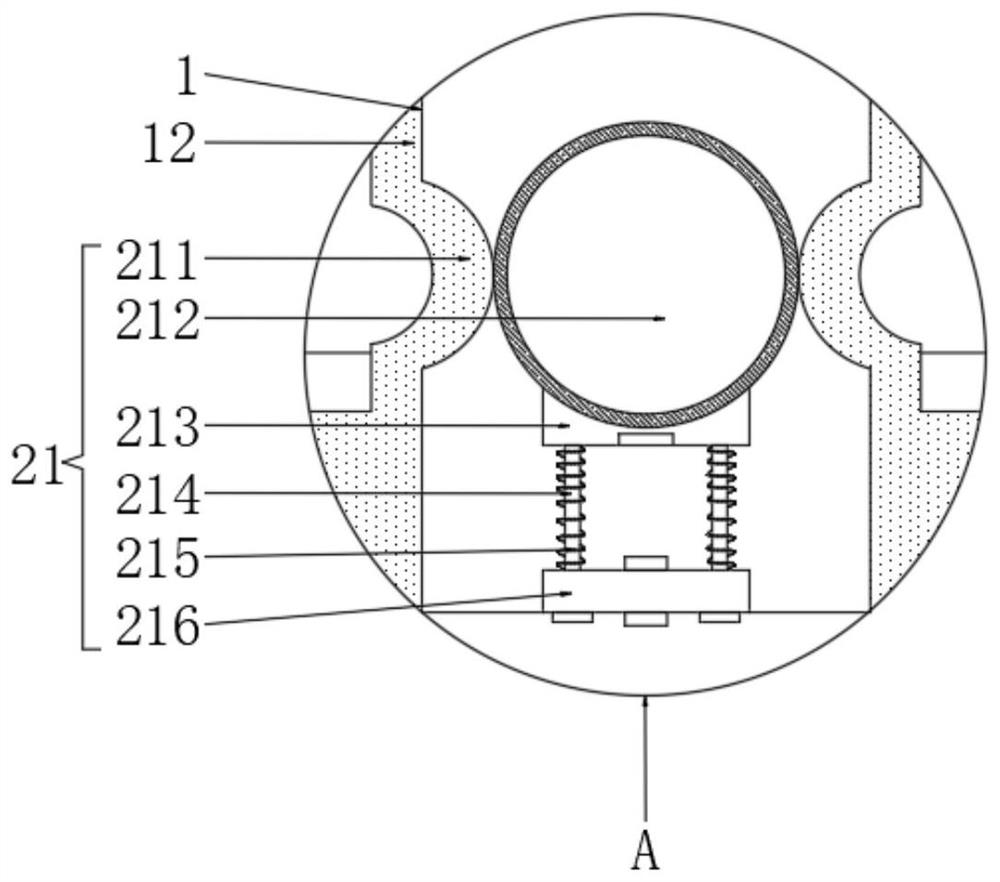

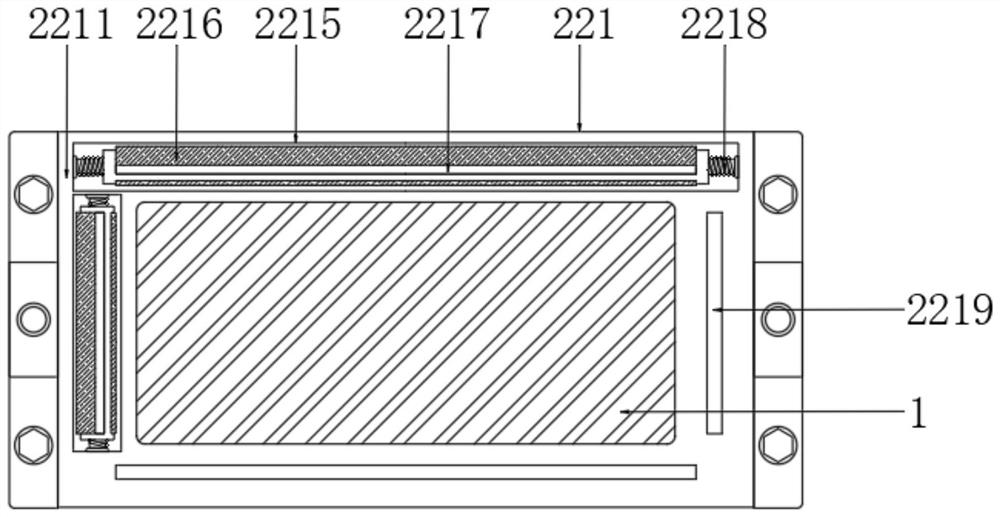

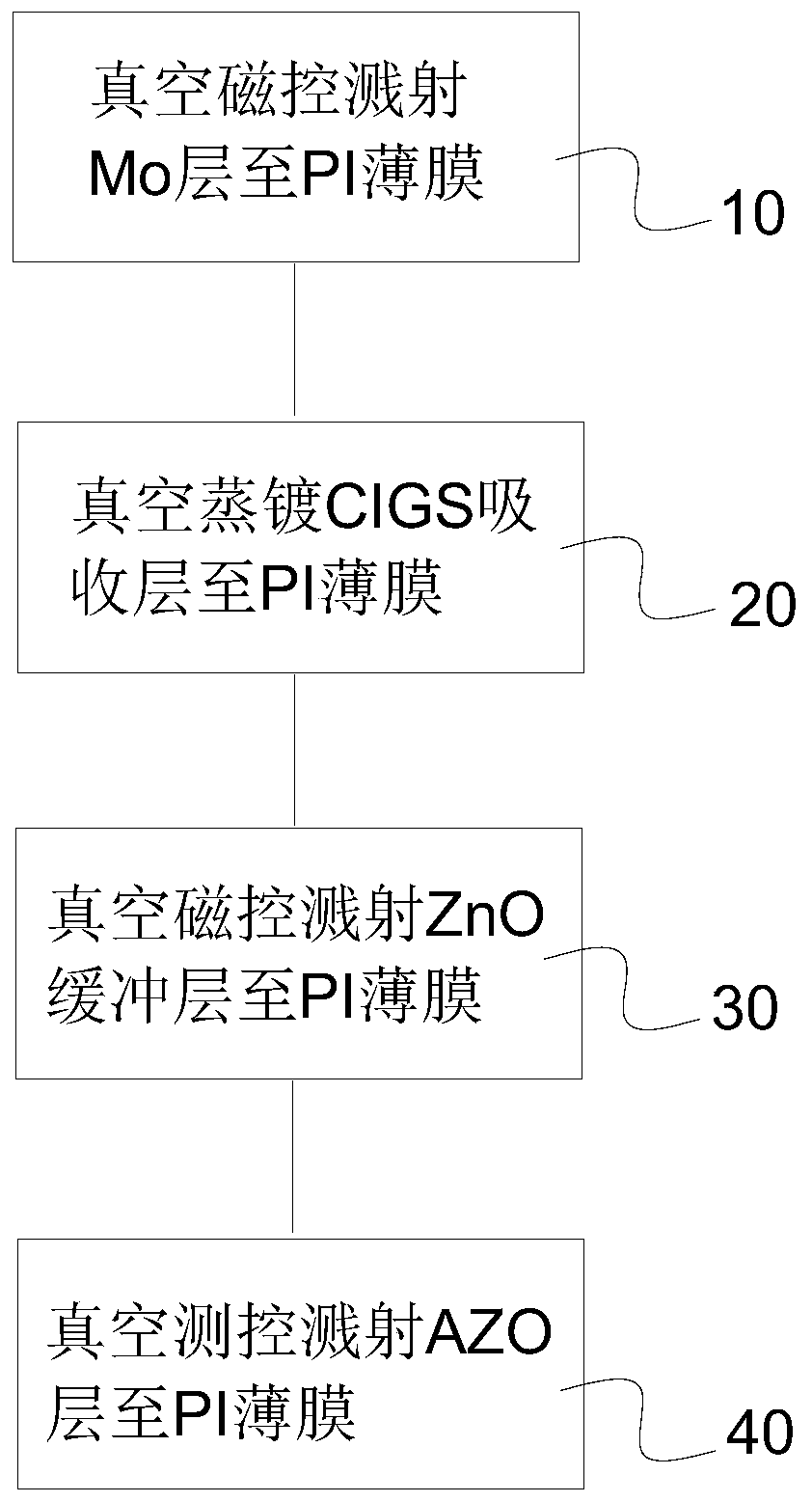

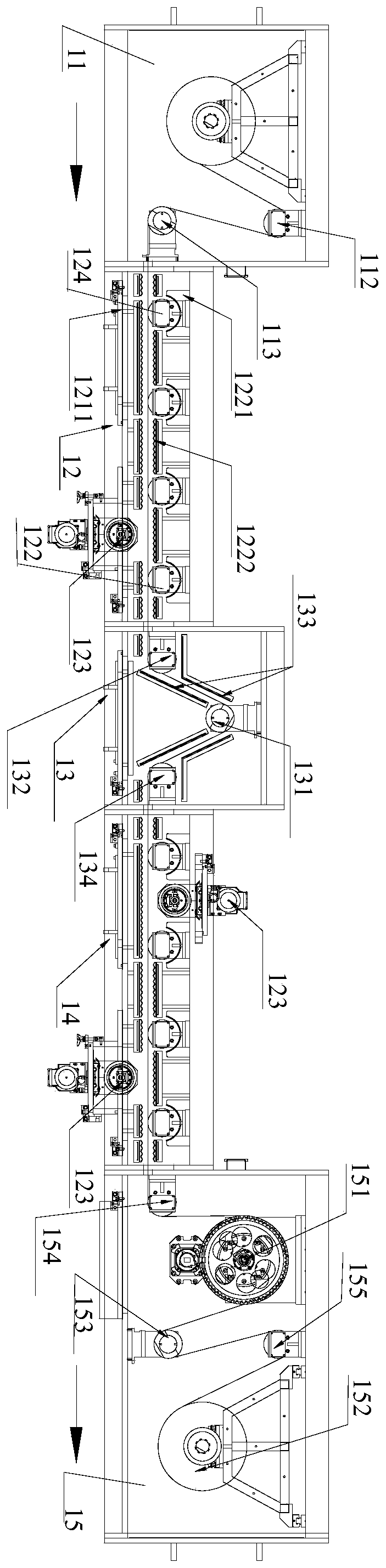

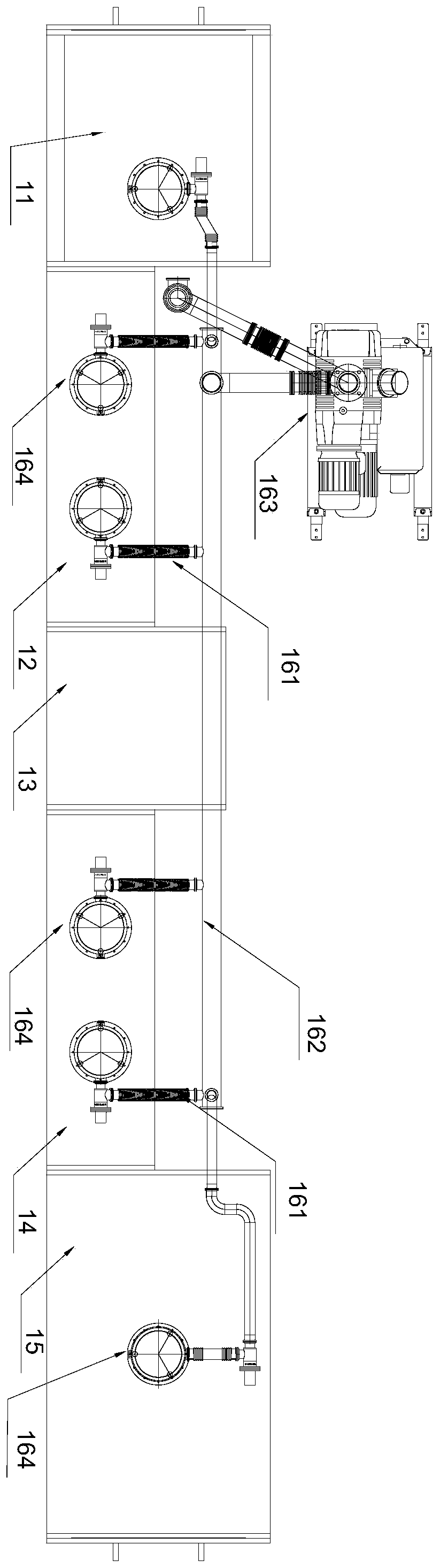

cigs solar cell film production line

ActiveCN106319473BReduce exposureAvoid destructionFinal product manufactureVacuum evaporation coatingProduction lineEvaporation

The invention discloses a CIGS solar cell film production line. The CIGS solar cell film production line comprises a plurality of coating sub-lines. The sub-lines sequentially and independently conduct vertical coating on a film. Each sub-line at least comprises an unreeling chamber, a coating chamber and a reeling chamber in the film unfolding direction, wherein a main drive roller is arranged in the unreeling chamber and the reeling chamber, a plurality of transmission rollers are arranged in cavities of the sub-line, and a tension detection roller and a tension adjusting roller are arranged in at least one cavity of the sub-line. The tension detection rollers are adjacent to the tension adjusting rollers, the tension detection rollers are used for monitoring the tension of the film in real time, and the tension adjusting rollers adjust the rotation speed of the tension adjusting rollers according to the feedback of the tension detection rollers so as to adjust the transmission speed of the film in the cavities; and the tension adjusting rollers are non-transmission rollers, and the unfolding track that the film passes the tension detection rollers and the tension adjusting rollers is the nonlinear track. According to the provided CIGS solar cell film production line, the element diffusion path is short, intermediate products are avoided, element evaporation is avoided, the film efficiency is high, and the CIGS solar cell film production line is particularly suitable for large-area scale industrial production.

Owner:旭科新能源股份有限公司 +1

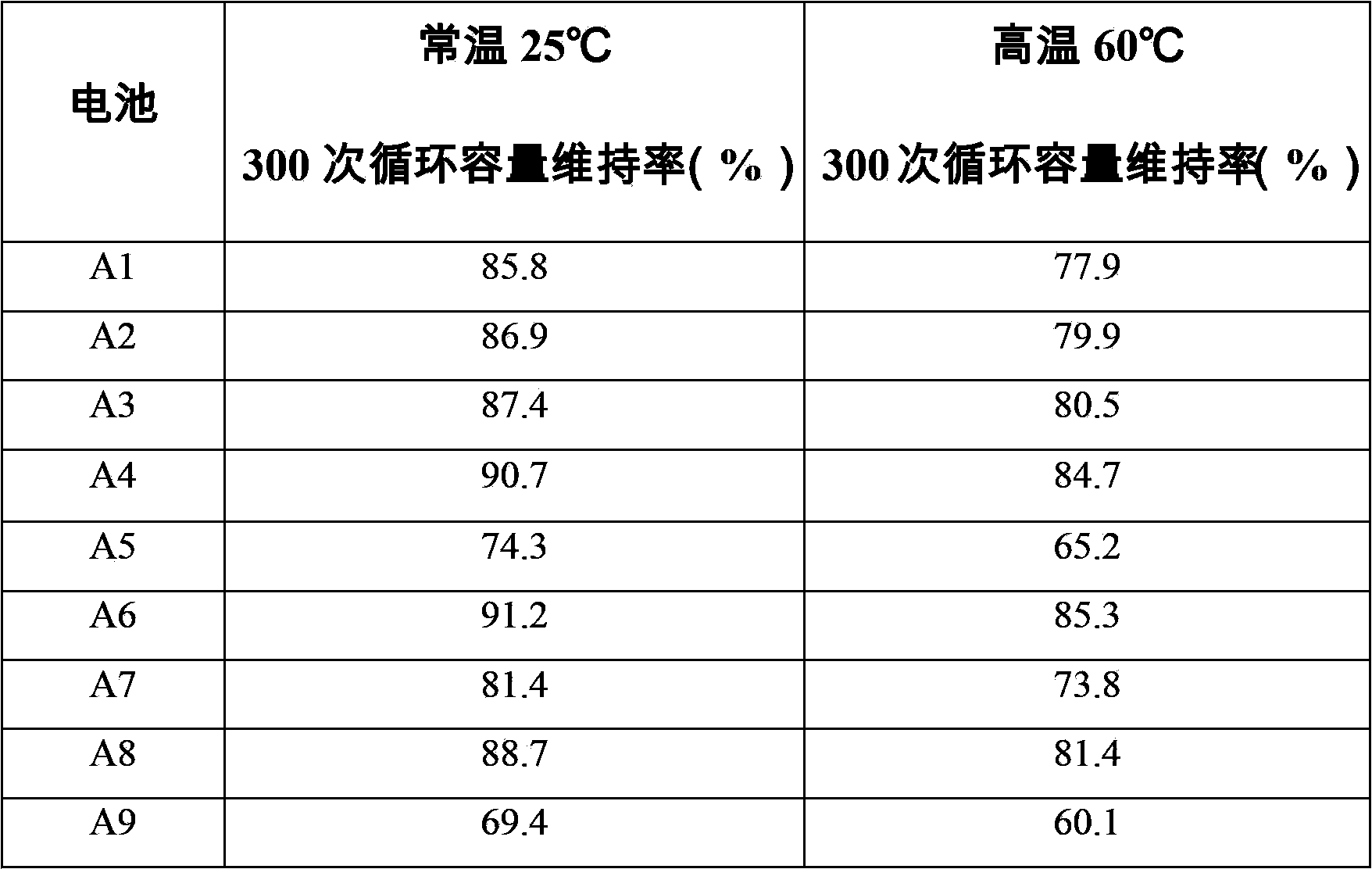

Lithium ion secondary battery negative active material and preparation method thereof, lithium ion secondary battery negative pole piece and lithium ion secondary battery

ActiveCN103794766AHigh specific capacityImprove conductivityCell electrodesSecondary cellsLithiumHigh energy

The embodiment of the invention provides a lithium ion secondary battery negative active material, which has a chemical formula of SiaGebAlcMd. Specifically, a, b, c and d respectively represent mole fractions, a is 20%-70%, b is 0.01%-10%, c is 1%-50%, d is 25%-75%, and M is one or more of Sn, Co, Ni, Ti, Fe, Cu, Mn, Mo, V and Cr. The lithium ion secondary battery negative active material has excellent cycling performance and initial efficiency. The embodiment of the invention also provides a preparation method of the lithium ion secondary battery negative active material, a lithium ion secondary battery negative pole piece containing the lithium ion secondary battery negative active material, and a lithium ion secondary battery containing the lithium ion secondary battery negative active material. The lithium ion secondary battery has high energy density and good cycle performance.

Owner:HUAWEI TECH CO LTD

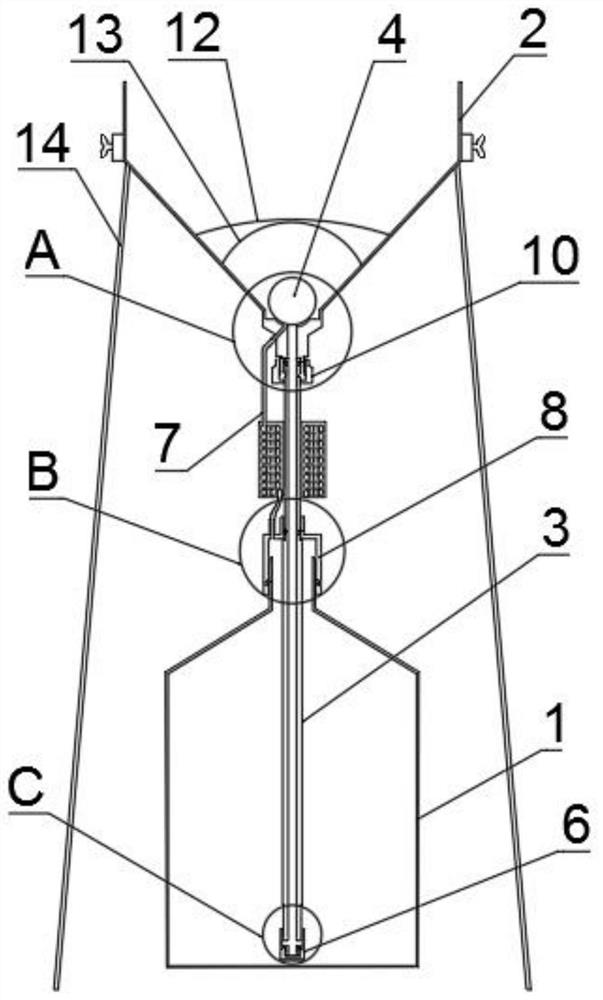

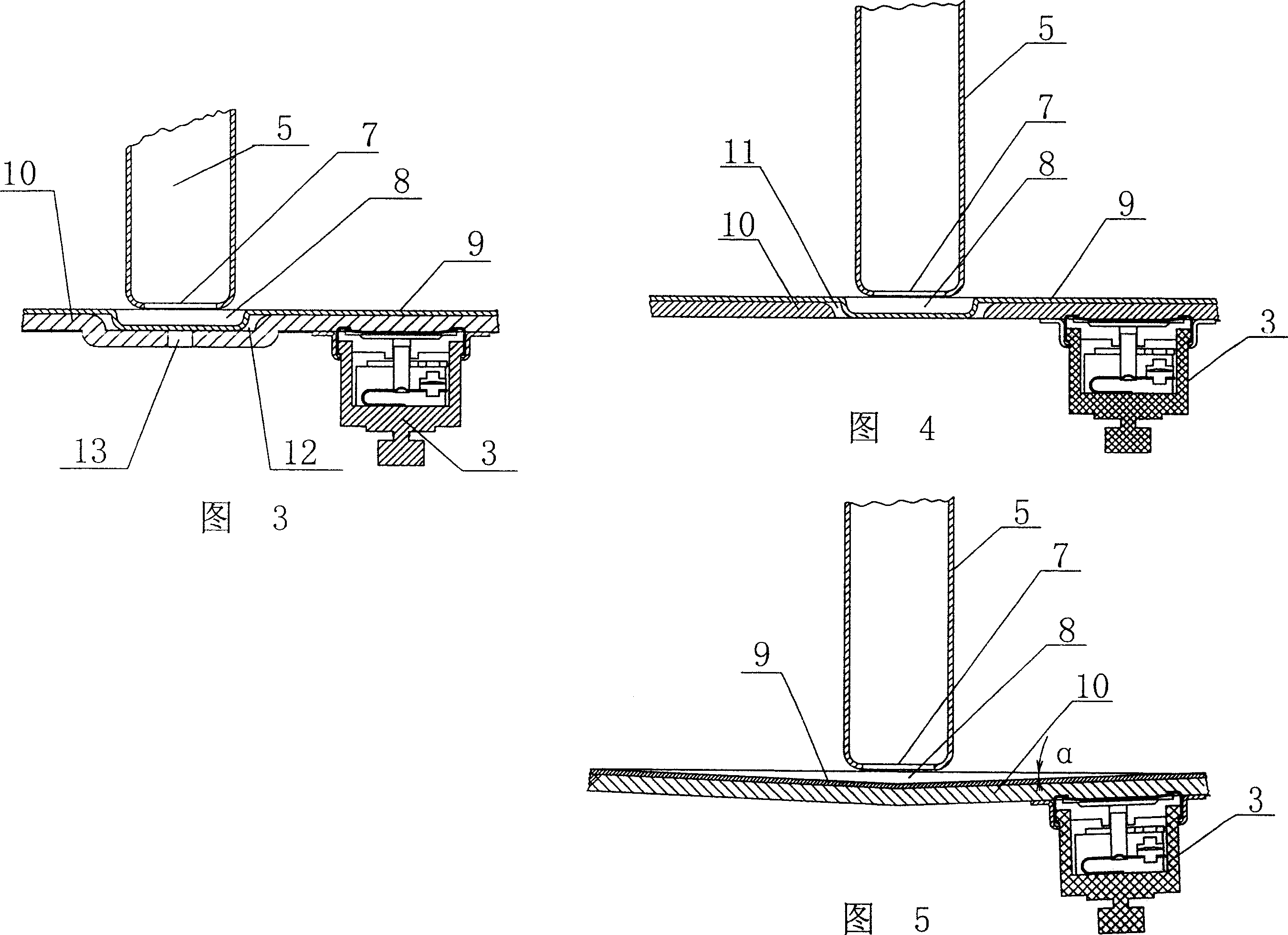

Isotope sample collection device for inhibiting evaporation and exchange of water sample

PendingCN113281098APrevent evaporationInhibit exchangeWithdrawing sample devicesEngineeringHydrology

The invention belongs to the technical field of isotope collection devices, and particularly relates to an isotope sample collection device for inhibiting evaporation and exchange of a water sample. The isotope sample collection device comprises a sample storage container, a funnel and a water guide pipe, wherein the sample storage container and the funnel are hermetically connected through the water guide pipe, the top end of the water guide pipe is hermetically communicated with a water leakage port at the bottom of the funnel, and a floating ball is placed at the bottom of the funnel; the bottom end of the water guide pipe extends into the bottom end of the sample storage container, a thread is arranged on the outer surface of the bottom end of the water guide pipe, a water outlet hole is formed above the thread, the bottom end of the water guide pipe is sleeved with a closed sleeve, and a thread is arranged at the bottom end in the closed sleeve and is matched and screwed with the thread at the bottom end of the water guide pipe; the bottom end of the funnel is further communicated with a pressure relief pipe which is arranged at the bottom of the floating ball, and the other end of the pressure relief pipe is communicated with the sample storage container. A small amount of rainfall is stored in the water guide pipe for the first time to form a small liquid level, and large-area water sample evaporation is avoided; the arrangement of the pressure relief pipe enables all rainfall in the funnel to flow into the sample storage container.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

Electric kettle for boiling beverage

InactiveCN100366204CGuaranteed to burn dryNo evaporationWater-boiling vesselsBeverage vesselsEnvironmental engineeringWater level

The invention discloses an electric kettle for boiling beverage, which comprises a kettle body for containing water, an electric heater arranged on the bottom of the kettle body, a thermoregulator for preventing heating when the water is boiling, a funnel arranged on the port of the kettle for guiding boiling water into a water container, a recessed portion is arranged on a water drainage position corresponding the funnel on the bottom surface, the boiling water on the bottom surface can be collected to the recessed portion and discharged from the water drainage. When the water on the bottom surface decreases, the remaining water will be centralized to the recessed portion at the action of atmospheric pressure, one part of the kettle surface will be exposed in the air, thus switching off the power supply for the electric heater, so as to guarantee the complete infusing for the coffee bean powder or tea.

Owner:邵志成

Method for preventing tube from scaling by using tubular heat exchanger for concentration of aqueous protein solution

InactiveCN108299544AAvoid drywallAvoid foulingPeptide preparation methodsProtein solutionPlate heat exchanger

The invention belongs to the technical field of bioengineering. In view of a technical problem that an existing tube is easy to scale, the invention provides a method for preventing a tube from scaling by using a tubular heat exchanger for concentration of an aqueous protein solution, wherein the method comprises a step of using the tubular heat exchanger for exchanging heat with the aqueous protein solution; the method is characterized in that an independent flash evaporation region is arranged above the interior of the tubular heat exchanger; a top end of the tube extends into the flash evaporation region; a tube cavity of the tube is always filled with a liquid material during heat exchanging operation; the heated liquid material is boiled in the flash evaporation region to form a gas-liquid mixture; an evaporation tank is also provided; the gas-liquid mixture in the flash evaporation region is injected into a material storage region at the bottom of the evaporation tank; gas-liquidseparation is performed by the evaporation tank; the concentrated aqueous protein solution is settled at the bottom of the evaporation tank; and an evaporated gas is discharged from an exhaust port in the top of the evaporation tank. The method provided by the invention has a beneficial effect of preventing the tube from drywall phenomenon to avoid occurrence of scaling in the tube.

Owner:荣成鸿德海洋生物科技有限公司

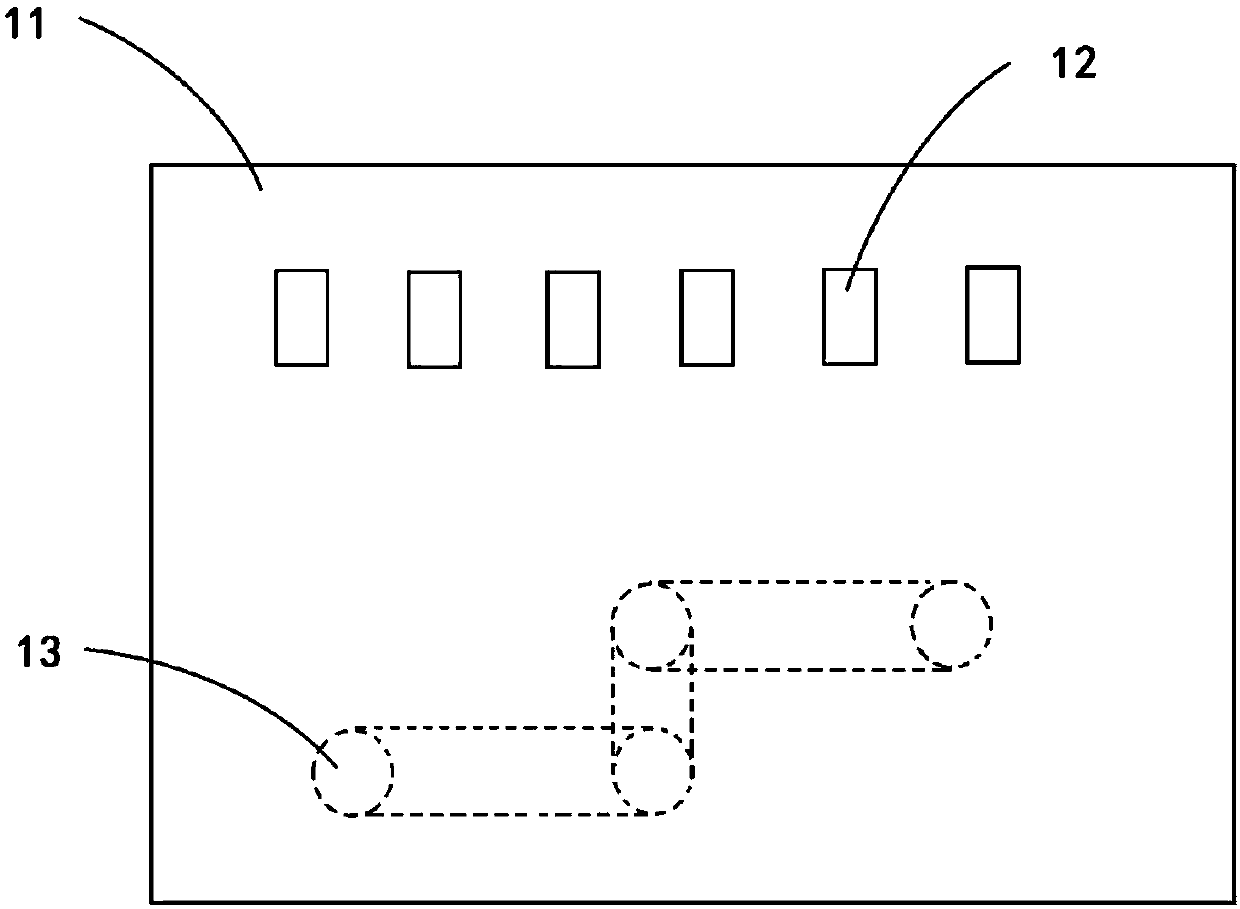

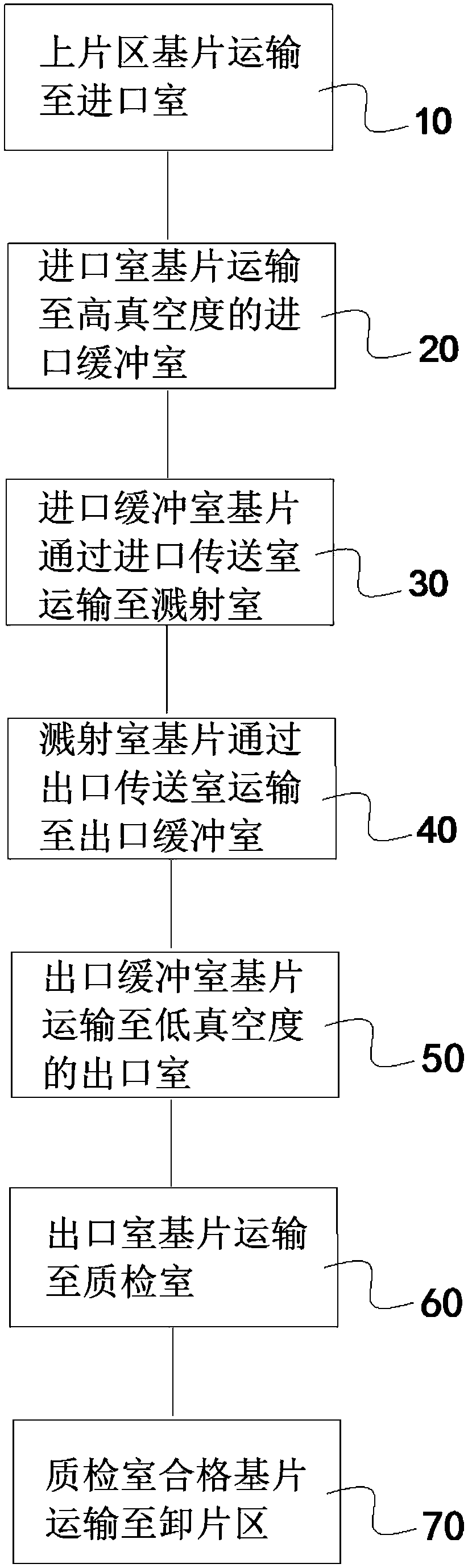

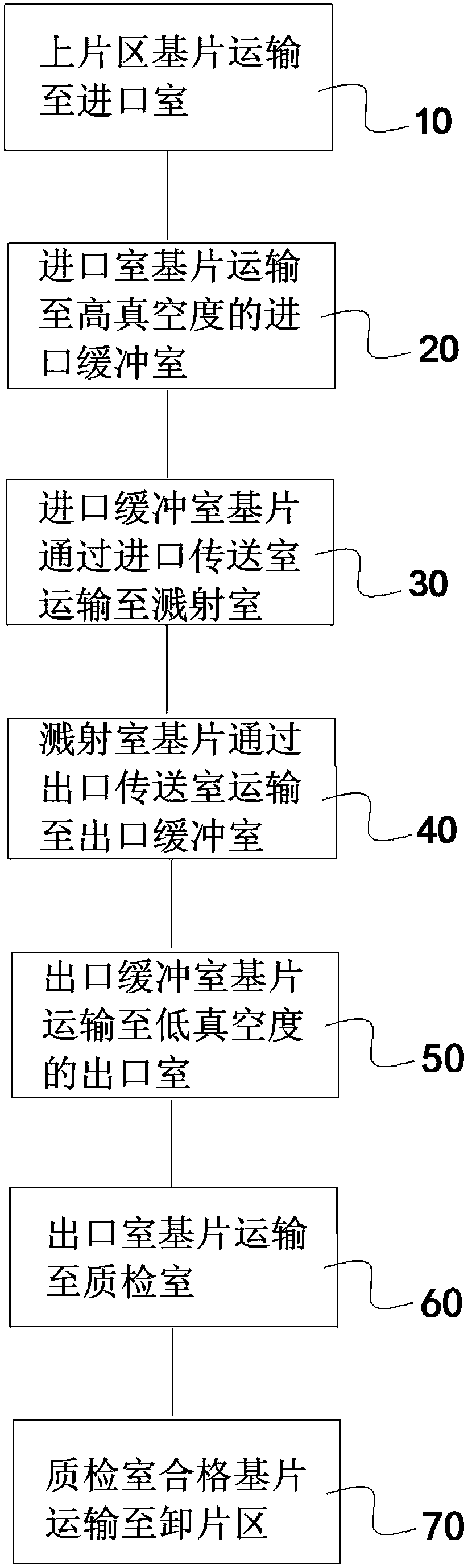

Vacuum magnetron sputtering coating production line for arc-shaped glass

InactiveCN109957769AIncrease profitAvoid formingVacuum evaporation coatingSputtering coatingProduction lineEngineering

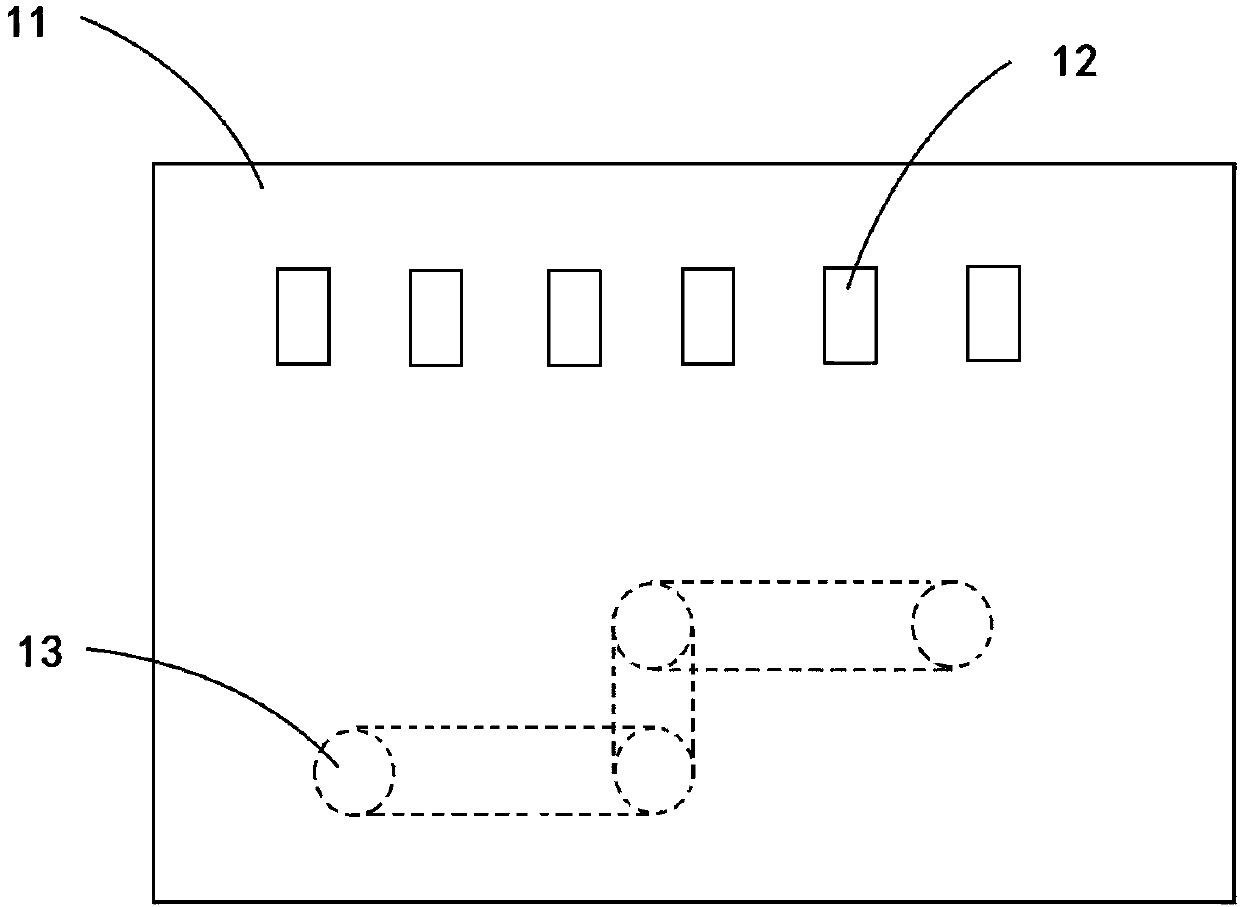

The invention discloses a vacuum magnetron sputtering coating production line for arc-shaped glass. The production line comprises a loading area, an inlet cavity, an inlet buffer cavity, an inlet conveying cavity, a sputtering cavity, an outlet conveying cavity, an outlet buffer cavity, an outlet cavity, a quality inspection cavity and an unloading area which are connected in sequence, transmission tables connected in sequence are arranged in the loading area, the inlet cavity, the inlet buffer cavity, the inlet conveying cavity, the sputtering cavity, the outlet conveying cavity, the outlet buffer cavity, the outlet cavity and the unloading area, a coating quality inspection table and a quality inspection system are arranged in the quality inspection cavity, and the transmission table inthe outlet cavity is connected with the coating quality inspection table. The vacuum magnetron sputtering coating production line for arc-shaped glass provided by the invention can realize large-batchand low-cost production of various coatings, and is high in sputtering deposition rate, high in process universality and particularly suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

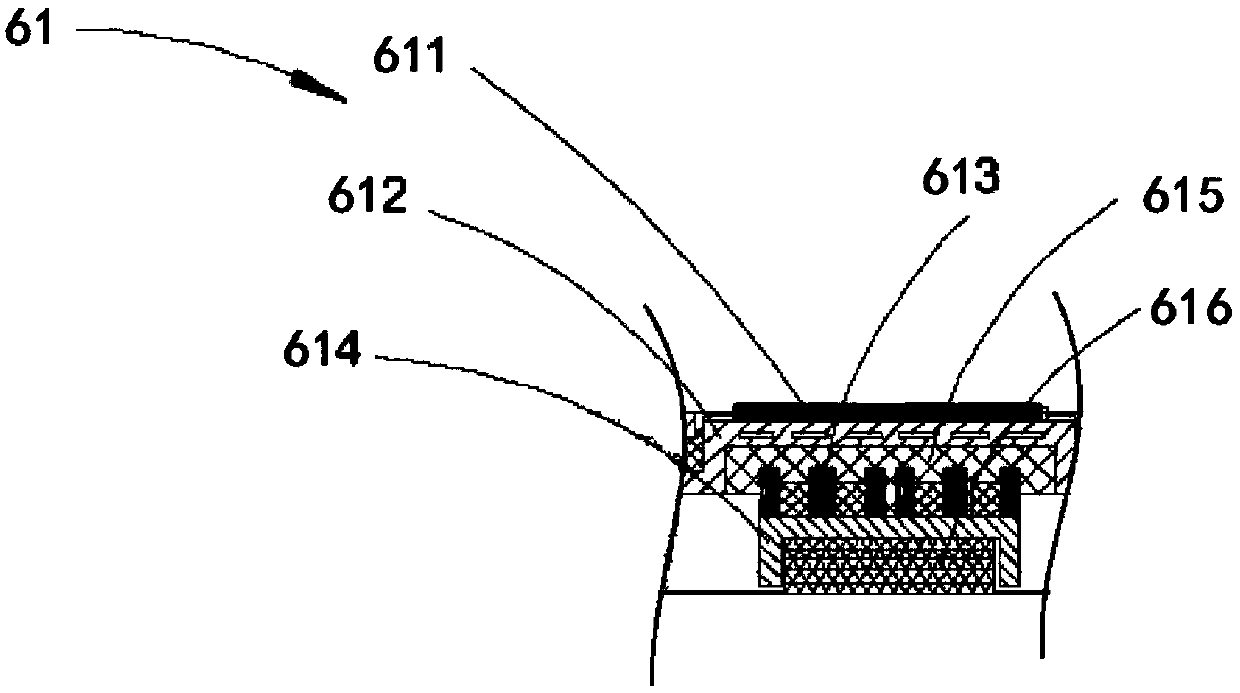

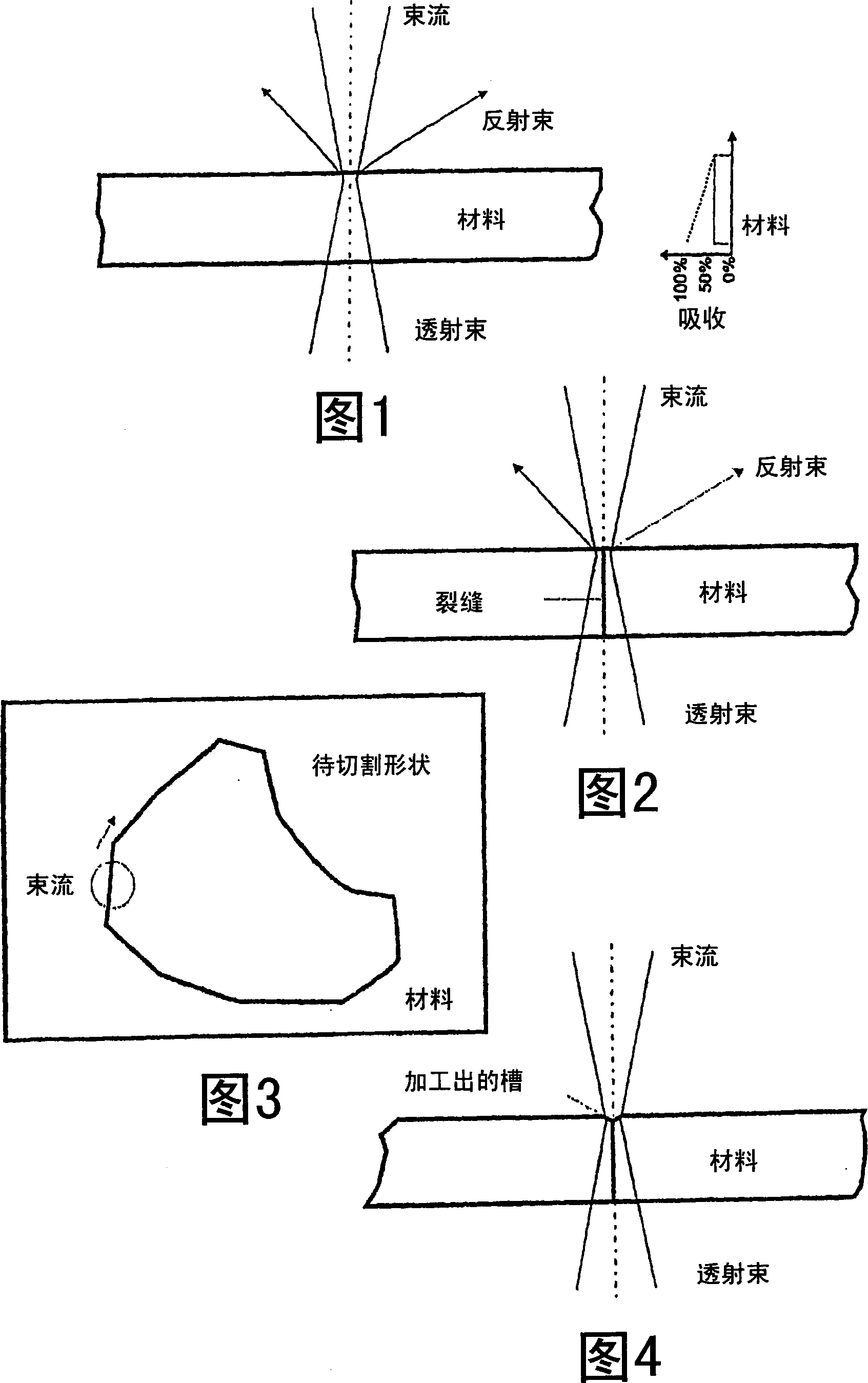

Method for machining a material with high-power density electromagnetic radiation

InactiveCN1946508ANo evaporationGlass severing apparatusWelding/soldering/cutting articlesCutting glassLaser light

The invention relates to a method for machining a material with high-power density electromagnetic radiation. The radiation has its wavelength selected material-specifically, such that the radiation penetrates inside the material without substantial surface absorption. The radiation is focused on a spot inside the material and / or in the proximity of a penetration surface and this spot is moved along a desired machining path. The electromagnetic radiation can be provided by laser light and the focusing can be effected by means of optics. The method is particularly useful in cutting glass and the method offers benefits, including only slight heating of the machined workpiece, smoothness of the fracture plane and no vaporization of harmful alloying elements.

Owner:萨米尔有限公司

Large-area AZO glass coating film production line

The invention discloses a large-area AZO glass coating film production line, which comprises a coating film line and a conveying line, wherein the coating film line comprises an inlet chamber, an inlet buffer chamber, an inlet conveying chamber, a sputtering chamber, an outlet conveying chamber, an outlet buffer chamber, an outlet chamber and a quality inspection chamber, the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber, the outlet chamber and the quality inspection chamber are sequentiallyconnected, at least a valve is arranged between the adjacent chambers, the conveying line comprises transmission rollers and a coating film quality inspection roller, the sequentially connected transmission rollers are respectively arranged in the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber, the coating film quality inspection roller is arranged in the quality inspection chamber, the transmission roller in the outlet chamber is connected to the coating film qualityinspection roller, and the transmission rollers and the coating film quality inspection roller are used for conveying a coating film substrate. According to the present invention, with the large-areaAZO glass coating film production line, the large-batch and low-cost production of various large-area coating films can be achieved, the sputter deposition rate is high, the process has strong versatility, the diffusion path is short, no intermediate product is generated, and no element is evaporated, such that the preparation is fast, the efficiency is high, the yield rate is over 95%, and the production line is especially suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Multipurpose metal film layer vacuum coating production line

InactiveCN109913846AReduce the impactIncrease profitVacuum evaporation coatingSputtering coatingProduction lineEvaporation

The invention discloses a multipurpose metal film layer vacuum coating production line. The production line comprises an inlet chamber, an inlet buffer chamber, an inlet conveying chamber, a sputtering chamber, an outlet conveying chamber, an outlet buffer chamber, an outlet chamber and a quality inspection chamber, wherein the inlet chamber, the inlet buffer chamber, the inlet conveying chamber,the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber are connected in sequence; transferring rollers connected with each other are arranged in the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber; a film coating quality inspection roller and a quality inspection system are arranged in the quality inspection chamber; the transferring roller in the outlet chamber is connected with the film coating quality inspection roller;and the transferring rollers and the film coating quality inspection roller are used for transferring a film coating substrate. According to the multipurpose metal film layer vacuum coating productionline, mass and low-cost production of various coatings are achieved with high sputtering deposition rate and strong process universality; an element diffusion path is short with no intermediate product and no element evaporation, so that the preparation speed and the efficiency are high, the yield is 95% or above, and the production line is particularly suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

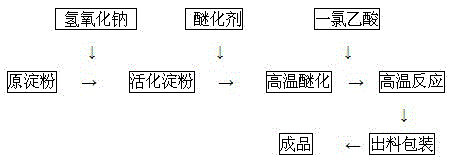

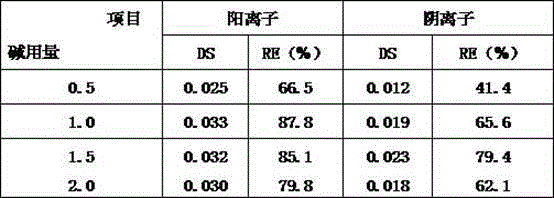

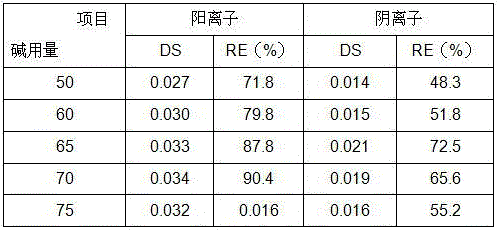

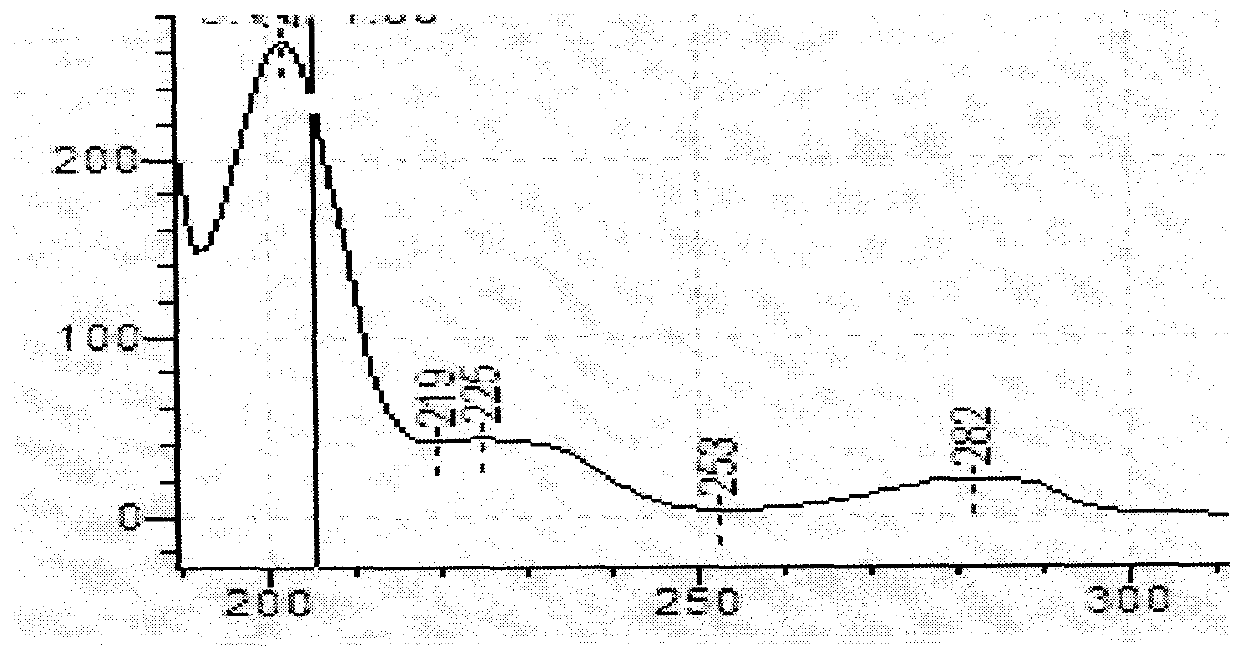

Method for preparing carboxy-type amphoteric starch in one step by semi-dry process

The invention discloses a method for preparing carboxyl-type amphoteric starch in one step by a semi-dry process, which is characterized in that: firstly adding a cationic reagent 3-chloro-2-hydroxypropyl-trimethylammonium chloride to carry out etherification reaction on the original starch, After the etherification reaction, directly add the anionizing reagent monochloroacetic acid to carry out the carboxymethylation reaction. Both anionization and cationization reactions are carried out in one kettle to prepare carboxy-type amphoteric starch in one step, and the production process is uninterrupted. The invention can effectively solve the shortcomings of wet process and dry process. Cationic and anionic groups are connected in the same starch chain, so that the product has the characteristics of cationic starch and anionic starch, and various performances are improved; the reaction time can be shortened from 8 hours to 6 hours; due to the shortened process, energy saving and consumption reduction, so that The product cost can be saved by about 12%.

Owner:抚州新天下知识产权咨询管理有限公司

HPLC (High Performance Liquid Chromatography) quantitative method for cephaeline hydrochloride and ipecine hydrochloride in ipecacuanha medicinal material and preparation of ipecacuanha medicinal material

The invention relates to a HPLC (High Performance Liquid Chromatography) quantitative method for cephaeline hydrochloride and ipecine hydrochloride in an ipecacuanha medicinal material and a preparation of ipecacuanha medicinal material. The method is characterized by comprising the following steps: firstly, performing common isocratic elution according to PHLC method, and taking acetonitrile-carbinol-0.1% of phosphoric acid at a volume ratio of (8-9.5):(3-5):(86-88) as a flowing phase, wherein a detecting wavelength is 205nm; and simultaneously measuring the contents of the cephaeline hydrochloride and ipecine hydrochloride in the ipecacuanha medicinal material and a fluid extract, extract and tincture thereof so as to end the history of the measurement of total alkaloids of the ipecacuanha alkaloids in an acid base titration form according to the standard in multiple countries: after performing column chromatography separation for 4 times, respectively measuring the cephaeline hydrochloride and ipecine hydrochloride through delta A at 283nm and 350nm by adopting differential spectrophotometry. According to the method, only acidic aqueous carbinol or aqueous carbinol is used; after fine powder of the medicinal material is ultrasonically extracted or each preparation is diluted, a certain amount of subsequent filtrate is absorbed; and an alumina column is used for removing impurities so as to measure. The method is quick, convenient, accurate and capable of reappearing.

Owner:JING JING PHARMA

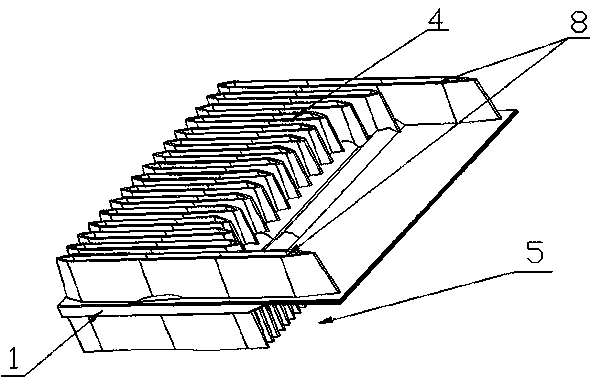

Manufacturing device for sludge solidification test samples

InactiveCN105784439ANo evaporationNo stinkPreparing sample for investigationVacuum pumpingGeotechnics

The invention relates to a manufacturing device for sludge solidification test samples and belongs to the technical field of environmental geotechnics.The manufacturing device for the sludge solidification test samples is composed of a storage system, a sample manufacturing system and an intelligent control rack system.A rubber bag is arranged in a piston cavity, a controllable feed port and a controllable discharge port are formed in the rubber bag, and it is guaranteed that no water evaporation or odor diffusion exists in the sample manufacturing process.By means of the mode of vacuum pumping and piston extrusion, it is guaranteed that initial raw materials are uniform and free of air, and sample manufacturing is rapid.A sample injection gun head is combined with a power compression piston controlled by a computer and a bearing table with an inductor, and it is guaranteed that a die cutting ring is tightly and fully filled with solidified sludge in the sample manufacturing process.The problems that more sample manufacturing materials are needed, consumed time is long, the samples are easily disturbed, holes are easily formed, the identity of the samples cannot be guaranteed, sample manufacturing is slow, the smell is heavy in the manufacturing process, and the reproduction of the samples is low are effectively solved through the manufacturing device.

Owner:LIAONING TECHNICAL UNIVERSITY

A Feng-shaped unbalanced fin electric heating plate and a heating and humidifying device

ActiveCN103791621BAvoid threadingOvercome or even eliminate thermal resistanceAir heatersHeating element materialsChinese charactersEvaporation

Owner:浙江鼎美智装股份有限公司

A water tank with high water retention for road construction vibratory rollers and its use method

ActiveCN112227150BNo evaporationImprove water retentionGeneral water supply conservationRoad cleaningWater collectionMechanical engineering

The invention discloses a water tank with high water retention for road construction vibratory rollers in the technical field of road construction vibratory rollers. A connected connecting pipe is plugged in, and a connected water collection bucket is fixedly arranged on the top of the connecting pipe; the water retention component includes an anti-evaporation component arranged in the connecting pipe, and an anti-corrosion and heat-proof component is arranged at the bottom of the water tank body. The present invention is equipped with an anti-evaporation component, so that the water in the water tank body will not evaporate. At the same time, it is also equipped with an anti-corrosion and heat-proof component. When the rectangular assembly frame is upward, the surrounding rain-proof cloth is pulled, and the surrounding rain-proof cloth surrounds the water tank body. Cooperate with heat insulation cloth, so that the water tank body will not be affected by high temperature, further reduce the situation of internal water evaporation and loss, and improve the water retention performance of the water tank body.

Owner:内蒙古华远路桥有限公司

Flexible film vertical vacuum coating production line

ActiveCN107794510BReduce exposureAvoid destructionFinal product manufactureVacuum evaporation coatingProduction lineThin membrane

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Reactor capable of controllably loading multiple catalytic materials, coating device and preparation method

ActiveCN113230992AImprove light energy utilization and catalytic efficiencyStrong combinationLiquid surface applicatorsChemical/physical/physico-chemical microreactorsPhysicsComposite material

The invention discloses a reactor capable of controllably loading various catalytic materials, a coating device and a preparation method. A rotor of the coating device is provided with a plurality of capillary tube positioning structures for fixing capillary tubes, and when the capillary tubes are fixed on the capillary tube positioning structures and centrifuged by a centrifugal machine, the axis of the capillary tube is in a plane perpendicular to the axis of the rotating shaft, and the axis of the capillary tube does not coincide with any diameter of the rotating shaft. A catalytic reactor is prepared by adopting the coating equipment, a reactor capable of controllably loading multiple catalytic materials is obtained, and during centrifugation, the total length of the same capillary tube is controlled to be located on the same side of the middle axial surface of a rotating shaft perpendicular to the axis of the capillary tube. According to the invention, PDMS liquid is coated on the set area of the capillary tube, so that catalytic materials can be fixed in the set area of the capillary tube, and various catalytic materials can be loaded on the same capillary tube by changing the mounting angle of the capillary tube during each centrifugal operation.

Owner:山东优检生物技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com