Method for machining a material with high-power density electromagnetic radiation

A technology of electromagnetic radiation and processing materials, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as material disconnection and difficulty in thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

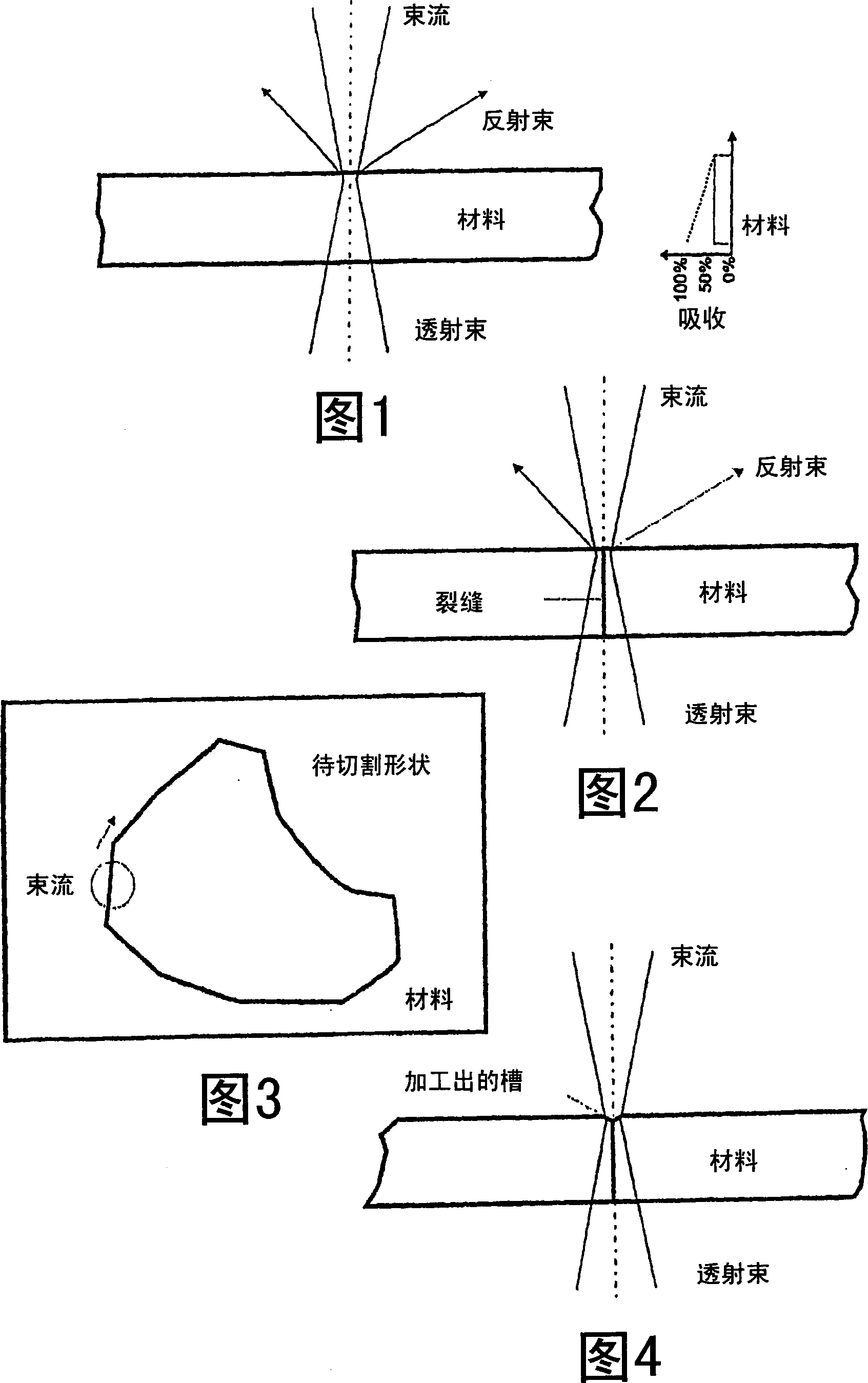

[0012] Processing is carried out with electromagnetic radiation, usually laser light. This radiation has a specific wavelength which is selected according to the material to be processed so that the radiation can penetrate the interior of the material without substantial surface absorption. Since the material-specifically selected beam is also focused inside the material, the result is stress conditions that cause the material to break apart in a controlled manner. This focusing process is carried out in the form of specific wavelengths by suitable methods. For example, laser beams can be focused by optics (lenses or mirrors). In some cases, focusing can also be performed by means of magnetic coils. It is important that the focal point of the radiation be located within the material and / or in the vicinity of a penetrating surface in order to generate radiation of sufficient power density within the material. In this way, high power densities are obtained by focusing the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com