Manufacturing device for sludge solidification test samples

A technology for manufacturing devices and test samples, which is applied in the field of environmental geotechnical engineering, can solve the problems of weakened fluidity, less material consumption, and more waste, and achieve the effects of reducing odor, saving materials, and rapid sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] see Attachment.

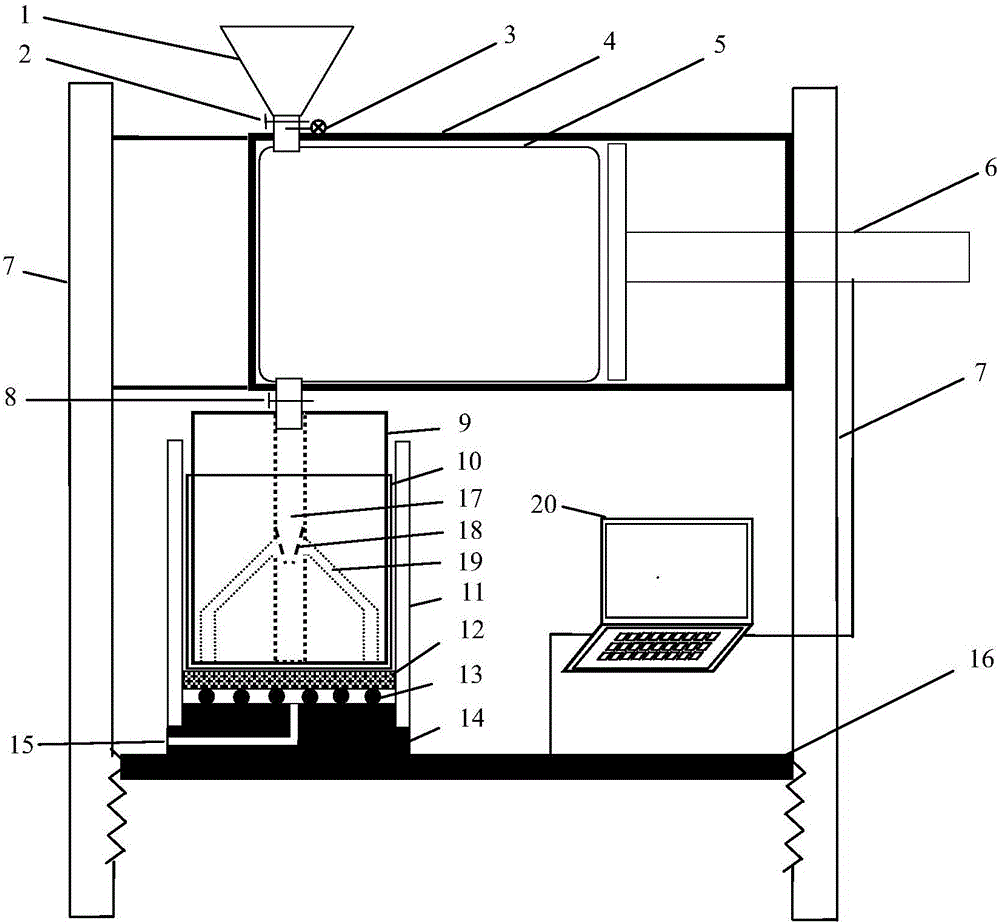

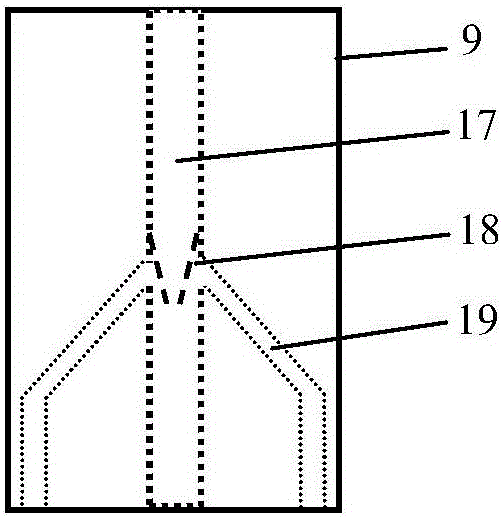

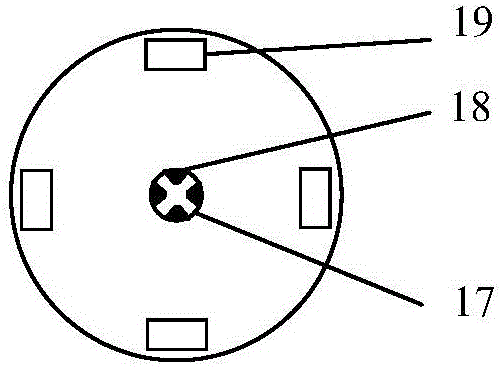

[0017] A sludge solidification test sample production device, the production device is composed of a storage system, a sample preparation system and an intelligent control rack system, wherein the storage system is composed of a piston chamber 4, a rubber bag 5 and a piston rod 6, and the sample preparation system It is composed of injection gun head 9, ring cutter mold 10, steel casing 11, permeable stone 12, glass beads 13 and base 14, and the intelligent console rack system is composed of bracket 7, carrying platform 16 and computer 20.

[0018] The piston cavity 4 is provided with a rubber bag 5, the rubber bag 5 is located at the front end of the piston rod 6, the upper end of the piston cavity 4 is provided with a feed bin 1, the lower end of the feed bin 1 is sealed with the rubber bag 5, and the feed bin 1 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com