Lithium ion secondary battery negative active material and preparation method thereof, lithium ion secondary battery negative pole piece and lithium ion secondary battery

A negative electrode active material, secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problem that the alloy product is not uniform, limit the volume energy density of lithium ion secondary batteries, and affect the performance of lithium ion secondary batteries, etc. problem, to achieve the effect of excellent cycle performance and excellent first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

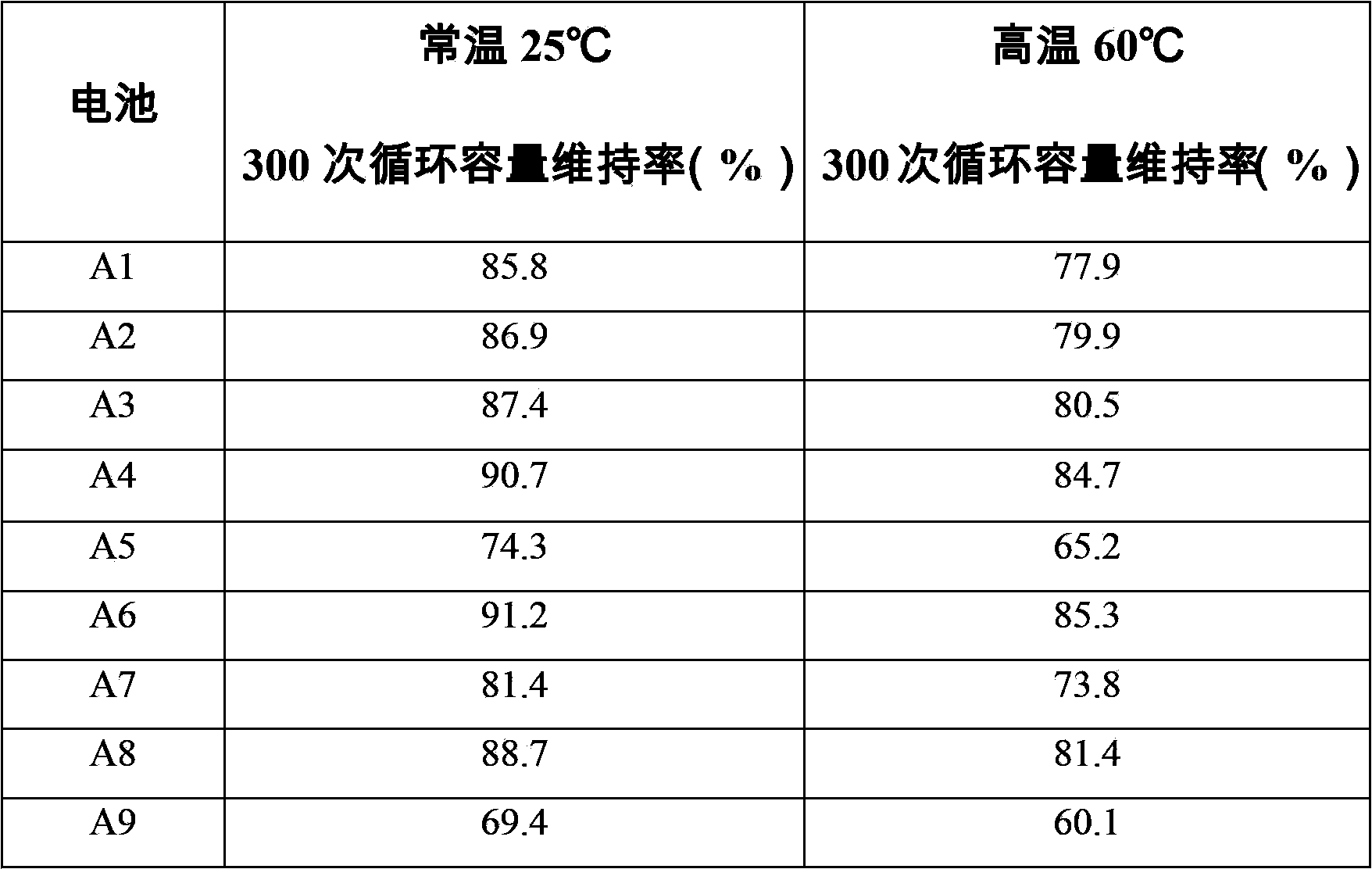

Examples

preparation example Construction

[0035] In a second aspect, an embodiment of the present invention provides a method for preparing a negative electrode active material for a lithium-ion secondary battery, comprising the following steps:

[0036] (1) Take the metals Si, Ge, Al and M, according to the chemical expression: Si a Ge b al c m d Proportioning and mixing to form a mixture, a, b, c and d represent mole fractions respectively, a is 20%~70%, b is 0.01%~10%, c is 1%~50%, d is 25%~75%, M is selected from one or more of Sn, Co, Ni, Ti, Fe, Cu, Mn, Mo, V and Cr;

[0037] (2) The mixture is placed in an arc induction furnace, melted at a temperature of 800~1000°C under vacuum or argon protection, and then cast into an ingot, and then the ingot is placed in a melt quenching furnace Inside, under the condition of vacuum or argon protection, it is smelted twice at a temperature of 800~1000°C, prepared into flakes or blocks by melt rapid quenching method, and then ball milled to obtain powdered negative elec...

Embodiment 1

[0056] A preparation method for a negative electrode active material of a lithium ion secondary battery, comprising the following steps:

[0057] (1) Take the metals Si, Ge, Al and Co, according to the chemical expression: Si 60 Ge 3 al 7 co 30 Proportioning and mixing to form a mixture;

[0058] (2) The mixture is placed in an arc induction furnace, melted at a temperature of 950°C under vacuum conditions, and then cast into an ingot, and then the ingot is placed in a melt quenching furnace, under vacuum conditions Secondary smelting at a temperature of 950° C., prepared into flakes by a melt quenching method, and then ball milled in anhydrous ethanol to obtain a powdery lithium-ion secondary battery negative electrode active material with a particle size of 25 μm.

[0059] Preparation of Negative Electrode for Lithium-ion Secondary Battery

[0060] The above-mentioned lithium ion secondary battery negative electrode active material, carbon fiber, lithium polyacrylate an...

Embodiment 2

[0067] A preparation method for a negative electrode active material of a lithium ion secondary battery, comprising the following steps:

[0068] (1) Take the metals Si, Ge, Al and Fe, according to the chemical expression: Si 40 Ge 5 al 25 Fe 30 Proportioning and mixing to form a mixture;

[0069](2) The mixture is placed in an arc induction furnace, melted at a temperature of 900°C under vacuum conditions, and then cast into an ingot, and then the ingot is placed in a melt quenching furnace, under vacuum conditions Secondary smelting at a temperature of 900° C., prepared into flakes by a melt quenching method, and then ball milled in anhydrous ethanol to obtain a powdery lithium-ion secondary battery negative electrode active material with a particle size of 10 μm.

[0070] Preparation of Negative Electrode for Lithium-ion Secondary Battery

[0071] The above-mentioned lithium ion secondary battery negative electrode active material, carbon fiber, lithium polyacrylate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com