Waste grease innocent treatment method and equipment for implementing same

A technology of harmless treatment and waste oil, which is applied to the recovery of fat oil/fatty acid from waste materials, the recovery/refining of fatty substances, and the production of fat, etc. It can solve problems such as endangering human health and achieve no pollution to the environment and low labor intensity. , automatic control of high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

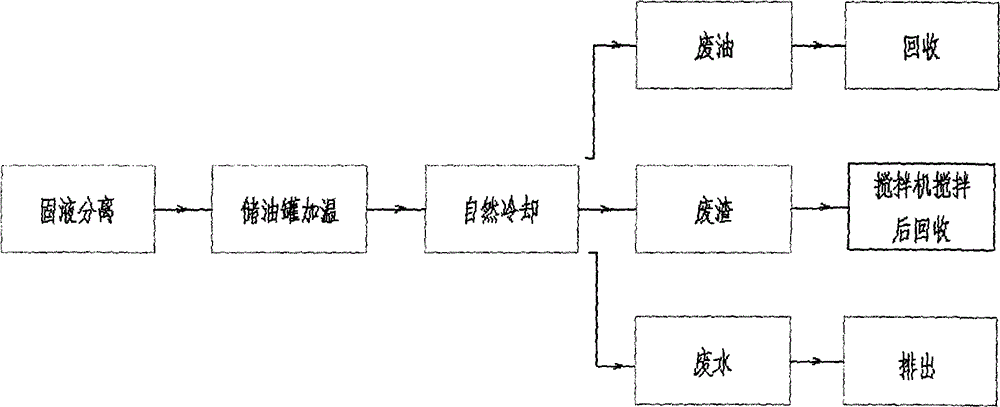

[0011] Such as figure 1 As shown, a method for harmless treatment of waste oil includes the following steps: the first step is to put the waste oil into a solid-liquid separator, and the impurities in the waste oil are extruded through solid-liquid separation; the second step is to The lifting pump lifts the waste grease treated by the solid-liquid separator to the heating oil storage tank for heating. When the liquid level of the heating oil storage tank reaches the preset position, the alarm system automatically sends out a beep signal to remind the valve to close; the third Step 1: When the waste oil is heated to 60 degrees Celsius in the heated oil storage tank, the alarm system will send out a buzzing signal to remin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com